Welcome to our complete guide on the all-rounded technology of ball-bearing systems. In this guide, we will tackle features such as the range of different varieties, their applications, the advantages they possess, and even their range of loads they are able to handle. For those who have knowledge of these remarkable machines or are just beginning to understand the topic, this guide is meant to present a taste of how much ball-bearing systems are integrated into countless applications. Even so, from spectacles and machinery of all sorts to vehicles and equipment operating at notable speeds, we shall expose the myriad of industries to which ball bearings have attributed inventions. Without further ado, let us set sail on this thrilling expedition and uncover the domain of ball bearings.

What Are the Different Types of Ball Bearings?

Considering your knowledge on the subject, let us dive into the different types of ball bearings. Ball bearings are designed in different styles and structures for different applications and loads, with the most common ones as follows:

- Deep Groove Ball Bearing: Its design consists of relatively deep raceway grooves which allow it to absorb radial as well as axial loads. Its applications are electric motors, washing machines, automotive parts and so on.

- Angular Contact Bearing: In case of angular contact how ever there exists possibility that axial loads at some point be included along due to the nature of how they are designed specifically how many inner and outer ring raceways are used that are offset to each other giving away a contact angle enabling such load capacity to exist, this helping enabling high speed and high precision machines, for example, machine tool, automotive transmissions.

- Thrust Bearings: Without a doubt thrust bearings handle axial loads but are designed to withstand such loads, many heavy axial loads are to be supported in various applications for which thrust bearings withstand ability comes in hand. There are ball thrust bearing, roller thrust bearing etc., and are widely used in equipment such as automotive transmissions, construction machinery and others.

It is neither the correct point in calling the application for: But surely this misunderstanding that both Ball and Race were used in Ball-Race Rollers Себастиан set matters straight after he embraced all the alternative forms of the possible workings pointing out the inherent overcoming opportunity structure.

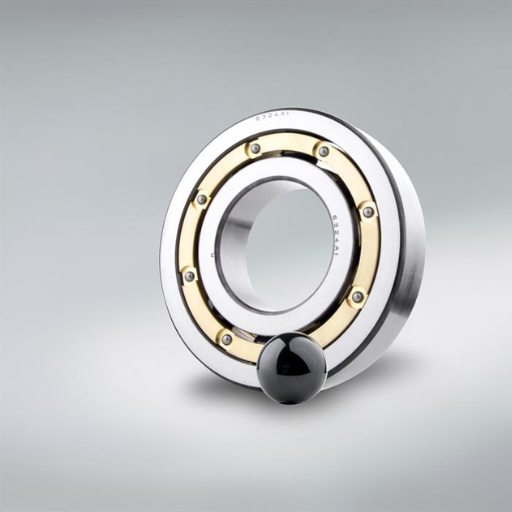

Understanding the Deep Groove Ball Bearing

I believe it is worthwhile to look at the Deep Groove Ball Bearing. The most common and the most versatile ball bearing type has to be this type of design. The type of bearing with deep raceways is capable of taking radial and axial loads. Deep groove ball bearings find their main field of application in the electric motor, fan, domestic appliances, etc, where low noise operation at high speed is essential. Their basic design requirement and the capacity to carry radial and axial loads have made them popular amongst the various industries. By knowing the nuances of selecting deep groove ball bearings, you will be able to apply them to your particular applications more reliably and efficiently.

Exploring the Angular Contact Bearing

You may have an idea about the Angular Contact Bearin,g but let me elaborate on it further and explain its importance in a mechanical assembly besides being an “Industry Insight.” Bearing in mind a high-speed performance or accuracy, angular contact bearings are suitable since they are able to take radial and axial loads at the same time. They are constructed in such a way that there is an inner ring and an outer ring that has a contact angle, allowing the bearings to accept axial and radial load. The benefit of using angular contact bearings is that they segment and allow for the easy formation of complex geometries, thereby enabling energy-efficient and reliable machinery in automobiles, aerospace, and manufacturers, respectively, within industries. The following paragraphs should discuss more about the characteristics, advantages, and application of the angular contact bearing within the realm of mechanical engineering.

Features of Thrust Bearings

Thrust bearings are quite interesting components, let’s take a closer look. In addition to being subjected to radial forces, thrust bearings are intended to take care of axial loading. These are a few important points that make thrust bearings crucial in a lot of applications:

- Contact Angle: The various thrust surfaces of thrust bearings have a designed contact angle which is the angle across the surfaces such that this contact angle is critical since it allows them to provide efficient use since both axial and radial loads are catered for efficiently.

- Load Capacity: As such, thrust bearings have a rated load carrying capacity since they can sustain a heavy axial load. The internal structure is designed so as to evenly distribute the load in that manner, it would not cause undue excessive stresses on the bearing parts and optimal functionality is achieved.

- Precision and Accuracy: In the manufacturing of thrust bearings high degree accuracy is put such that thrust bearings can rotate smoothly when forces are applied as loads and therefore motion is achieved. As such, precision in maintaining the rotation of machinery is enabled thereby frictional losses are reduced while maintaining machine efficiency.

- Durability: Since thrust bearings are made from high grade materials like steel or even ceramic which have a desirable strength and hardness, these bearings extend the ability of operators to run the bearings under very harsh operational conditions over a long period of time and still achieve excellent performance.

- Variety of Designs: For different applications, thrust bearings are designed in different ways. The most common types include ball thrust bearing, roller thrust bearing, and tapered roller thrust bearing. Each design has its own unique features that allow it to be able to withstand specific load requirements together with certain operating conditions.

With the addition of thrust bearings in mechanical systems, engineers are able to increase the reliability, efficiency, and performance of machines. The relevance of thrust bearings in machine performance is essential across all industries including automotive, aerospace, and manufacturing as they are designed to withstand axial loads.

What Are the Uses of Ball Bearings?

The use of ball bearings is extensive and multi-faceted, making them vital parts in many applications and throughout industries, even from the viewpoint of an industry expert. Some notable such applications where ball bearings are crucial include:

The use of ball bearings is common in various automotive modules such as engine, transmission systems and wheel assemblies, or among the modules incorporated in self-propelled vehicles. They allow smooth rotation, reduce friction and perform axial and radial loads, thus increasing vehicle performance and efficiency.

Within an industrial context, for example, ball bearings are used in machines and equipment such as: pumps and conveyors and power tools among others. They help ensure precise and smooth motion and energy loss, as well as heavy loading, capacities are incorporated to enhance operational dependability and efficiency.

Ball bearings are used in machines with high revolutions per minute (rpm) applications such as turbines, machine spindles or aircraft engines. Thanks to their low friction, and their capacity to take radial and axial load, they are suited for high demanding applications which require speed and accuracy.

These are some of the many examples of the numerous functions of ball bearings. Their reliability and flexibility render them essential for various operations in various industries to ensure the smooth running of machines and equipment.

Ball Bearings Used in Automotive Applications

let’s go deeper into the subject of ball bearings employed in automotive settings. The automotive industry greatly benefits from these, as an efficient operation of numerous components and systems is ensured. Ball bearings are employed in various automotive applications, including those that span from the engine to the wheels:

- Wheel Bearings: Wheel bearings can bear the weight of the automobile while allowing the wheels to rotate freely. It has a low friction loss which enables it to carry both radial and axial loads effectively, which enhances performance and lifespan.

- Engine Bearings:Most critical parts of the engine such as the crankshafts and camshafts are ball bearing supported. The bearing facilitates the motion encouraging the rotational speed of the engine components while minimizing the friction to the maximum usable output of the engine.

- Transmission Bearings: In the transmission system, ball bearings play an important role in enabling precise and quick gear changes. They are an important part of the mechanical system that uses transfer power with ease and resist axial force which strengthens the transmission as a whole.

- Electric Motor Bearings: Now with growing electric vehicles, ball bearings are coming up in electric motor applications too. They have bearings placed on the rotor of the electric motor which help in its free rotation, making sure that energy loss is minimal making the rotor as efficient as possible.

Ball bearings, when employed in the automotive applications, increase the performance, lifespan and safety of the vehicle. This is due to their capacity to transmit radial and axial loads while maintaining small friction which is essential in making several automotive elements function properly and without any effort.

Industrial Uses of Ball Bearings

let’s look at the industrial applications of ball bearings. There are many industries that make use of ball bearings as they possess special features and designs that help in better performance, longer service life, and efficient operations. Some of the notable industrial applications of ball bearings are:

- Automotive Industry: Ball bearings are essential in automotive applications for a smooth working of the wheels, transmissions, engines, suspension and other parts. Their enabling to withstand rotary and thrust loads at very low friction has increased the performance, reliability, and safety of the vehicles.

- High-Speed Machinery: These bearings are widely used in high-speed subassemblies like turbines and electric motors. These are the devices which call for smooth rotation expect other routine operational demands. All these are satisfactorily accomplished with the help of ball bearings. Bearings capable of supporting both axial and radial loads also assist in reducing the risk of friction loss, which ultimately leads to lower maintenance costs for high-speed devices.

- Precision Instruments:Small ball bearings are commonly used in the manufacture of high precision devices such as watches, medical equipment, and laboratory devices. Because of their small size, low friction bearings having high rotational speeds are required to facilitate movements and provide steady functioning of the delicate instruments.

In conclusion, ball bearings are widely used in automotive, high speed machines and instrumentation applications where their specific advantages enhance performance, operational life and efficiency. Whether it is about enabling rotation, working at high speeds or making accurate movements, ball bearings are important in various industrial applications.

Applications in High-Speed Machinery

According to industry experts, ball bearings are widely used in many high-speed machines across different industries. These components serve quite an important role in fast-moving machinery and, as such, are manufactured to fairly high standards. Ball bearings have good construction and low friction properties, which make them reliable for applications that require high rotational speeds and accurate positioning or where extended working life is critical. Whether it is turbochargers, electric motors, machine tools, or aerospace apparatus, hitherto, the performance of the ball bearing was taken for granted as it was seldom subjected to high speeds without rotation. With ever-increasing demands, modern industry reliability and efficiency of operation were always destined to change.

What Are the Benefits of Ball Bearings?

With respect to the industry, the utility of the ball bearings is quite wide and indispensable. Mentioned below are several such benefits:

- Reduced Friction: The ball bearings are intended to have a minimum contact with the moving components, resulting in an easier and optimal working of the system. Due to the reduced contact, energy consumption is also low, effectiveness is improved, and the life of a machine is increased.

- High Speed Capability: The design peculiarities of ball bearings allow them to be used in high-speed operation because of their low friction and high rotation rate capacity. They make it possible to boost machinery operation speed without compromising stability and vice versa.

- Accuracy and Durability: The ball bearings have very high accuracy which is consistent and reliable even under adverse conditions. They have robust construction and high-quality material to endure wear and their application proves to be heavy-duty.

- Versatility: This type of bearing has become common in many industries and applications such as automotive, aerospace, and machinery among many others. Their versatility enables them to be used in a broad range of operating conditions as well as withstand varied environments.

- Improved Productivity: Being able to reduce contact, improve the effectiveness, and the performance of machinery, the ball bearings lead to better productivity. They aid in the reduction of downtimes, improvement of operational dependability and increase the efficiency of industrial processes.

To summarize, the disadvantages of ball bearings can be stated as low friction, speed, accuracy and life, versatility, and increased productivity. Such ball bearings’ advantages make them a basic element of maintaining slick and efficient functioning in various active industrial environments.

Advantages of Stainless Steel Bearings

let us take a closer look at stainless steel bearings and their advantages. Stainless steel bearings have many advantages which allow them to be used for different functions in various applications:

- Corrosion Resistance: The special feature of stainless steel bearings is that they have the ability to withstand corrosive conditions quite easily. When stainless steel which mostly contains chromium and other elements is used, it increases their resistance to rust and corrosion, even in extreme and corrosive environments.

- Durability: High quality of durability characteristics enable the use of stainless steel bearings in applications where a long working lifetime is required and resistance to wear is critical. These bearings can bear heavy loads, withstand high temperatures, and endure difficult working environments, guaranteeing the performance is maintained over a period.

- Hygienic and Clean: Since the stainless steel is a hygiene material and easy to clean, such bearings can be used in the industries dealing with food, pharmaceuticals and medical equipment. Stainless steel’s smooth surfaces help curb dirt, contaminations and bacterial growth thereby ensuring that sanitary conditions and product quality are maintained.

- Wide Temperature Range: Consequently, stainless steel bearings can be used in fairly low and high temperatures quite effectively. This morph allows the bearings to exhibit performance, and lubrication requirements under varying conditions.

- Compatibility: Many stainless steel bearings can be used together with lubricants of food, or of high-temperature types. This compatibility makes them more suitable for specific applications.

For all intents and purposes, bearings made of stainless steel can withhold corrosion, are long-lasting, have there hygienic properties, can withstand a quite broad temperature range, and can work excellently with lubricants of different sorts. With these features, stainless steel bearings can have many applications which demand high quality working, long term reliable use and relatively clean usage.

Benefits of Miniature Bearings in Precision Instruments

miniature bearings provide a number of advantages that make them very desirable in precision instruments. Let’s examine some of these key benefits:

- Reduced Friction and Increased Efficiency: Due to their design and construction characteristics, miniature bearings are intended for limitations of friction, which leads to smoother processes and increased efficiency in the functioning of precision instruments. This also makes the performance of movements and measurements with high precision possible.

- Space and Weight Savings: Miniature bearings are small in size and very light in weight and are, therefore, suited to applications with restricted space or with weight restrictions. Their small dimension facilitates the design of precision instruments that are more compact and portable.

- Enhanced Precision and Accuracy: Miniature bearings permit a combination of extreme precision with high speed of rotatory motion. This makes it possible for the precision instruments to output accurate results and be stable in function.

- Durability and Longevity: Miniature bearings are small in dimension but are designed to withstand harsh working conditions and possess good strength. They are made with high wear and corrosion resistance as well as fatigue resistance which makes the equipment an enduring one.

- Wide Range of Applications: Miniature bearings are used in medical instruments, laboratory apparatus, optical devices, robotic gimbals, and, in fact, all precision devices. This universality helps to use bearings reliably in diverse branches.

To conclude, miniature bearings are characterized by low frictional losses, compact design and weight, high accuracy and reliability, and a wide variety of applications. Thanks to these benefits, they become a core part of precision devices and enhance their functionality and reliability.

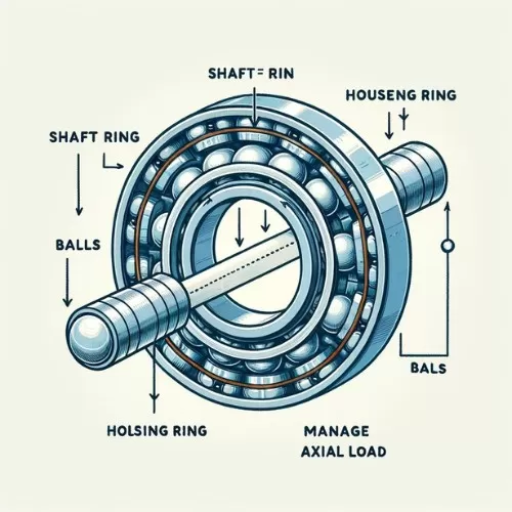

How Do Ball Bearings Handle Loads?

From an industrial point of view, let us examine how loads are inclined on ball bearings. Since they can take both axial and radial loads, ball bearings prove useful in various applications.

To begin with, the ball bearings and with a specific design, the bearing’s load is transmitted evenly over the balls allowing for rotation with minimal friction. The inner and outer tagline of the channels passes through the bearing balls rendering them mobile and reducing surface contact. While structurally sound, this specifics design reduces friction and heat, resulting to the increase on efficiency and the lifetime of the bearing.

If considering the load capacity of the ball bearings, it should be noted that yes, they are designed for radial and axial load application. Radial load is what acts so as to be perpendicular to the shaft and directs itself from the center of this shaft towards the outer ring of the bearing. Axial load is said to be the load parallel to the shaft axis along which its direction acts. In the internal design and construction of these bearings, both loads can be applied simultaneously.

As an example, various types of ball bearings are made to accommodate the different type of maximum load to be taken. These include deep groove, angular contact, thrust and quite a number of other together bearing types. Particular types are differentiated with respect to the shape features categorized within geometry so as to increase the capacity to bear the loads in distinct usage.

To sum up, load on the balls is transferred on several balls, rotating smoothly, which alleviates frictional contact. Apart from contact with the rotating parts, ball bearings are capable of radially as well as axially stable loads and therefore can be effectively employed in a number of different industries.

Understanding Radial and Axial Loads

There are two loads that are experienced by ball bearings in applications, axial loads and radial loads. It is important to first differentiate between the two in order to appreciate the manner in which the ball bearings bear the bearings:

- Radial Load: A radial load can be described as a load which is directed towards a radius and perpendicular to the axis of rotation. It acts either perpendicular to or in a direction toward the center of the bearing. Radial loads may include the load created by a shaft rotating about an axis or the load created due to a belt or gear.

- Axial Load: An axial load, also referred to in some industries as a thrust load, is a load which is ever directed parallel to an axis of rotation. It acts in a direction that is inline along the axis. Examples of axial loads include the force transmission through mechanisms able to push or pull, such as a motor or a hydraulic moving cylinder.

The engineering of ball bearings is such that they are capable of bearing radial and axial loads with great effectiveness. Their structure incorporates a multitude of balls, distributing the load evenly and minimizing friction during rotation. Such a load distribution enables ball bearings to accommodate both types of loads effectively and accurately.

Additional different kinds of ball bearings are available in order to increase the load capacity even further. These modifications, deep groove, angular contact and thrust ball bearings, are created for certain load characteristics. Each kind is designed with certain factors and geometry aimed at the improvement of load-carrying capacities in different applications.

In conclusion, ball bearings are critical to the workings of industrial machines as their primary purpose is to bear loads on the balls which facilitates friction reduction and the engagement of smooth rotation. They are able to bear radial and axial loads equally, thus making them significant and dependable parts in many sectors of industry.

Ball Bearings Designed for Load Capacity

I am able to provide further details concerning load capacity and its significance with regard to ball bearings. It is critical to make sure that the structure of ball bearings is such that they possess adequate load capacity. This is important for ball bearings since a wider load capacity ensures that ball bearings do not lose their functions even when subjected to heavy loads and shocks. When the load is more or less evenly distributed over the balls, a ball bearing can support both radial and axial loads which in turn reduces friction and enhances smooth rotation.

In terms of load capacity, mechanisms that include the types of ball bearings in question also vary according to their intended use. For instance, deep groove ball bearings can be used in situations where a high radial load is present. Angular contact ball bearing are also effective because they are capable of withstanding both radial and axial bearing forces. Thrust ball bearings are designed to fit situations where axial loads apply.

In conclusion, it can be said that ball bearings, which are designed for maximum load capacity, are key assets in many industrial applications. These devices provide a much more uniform load distribution and allow for the reduction of friction and smooth rotation, thus making them multidimensional and dependable in an array of industries. The selection of the kind of ball bearing with the required loading level allows industries to improve the work, dependability, and effective life of machines and equipment.

What Are Self-Aligning Ball Bearings?

self-aligning ball bearings are best fitted in applications where shaft misalignment is likely between the housing and the shaft. Self-aligning ball bearings, unlike most other kinds, are able to adjust to even the smallest angular misalignments, which is useful in circumstances of shaft deflection or mounting inaccuracies. A pair of rows of balls and a spherical outer ring encase these ball bearings, allowing self-adjustment and alignment, hence reducing stress and increasing bearing life. This allows them to operate smoothly in rather difficult circumstances, such as vibration or deflection of the shaft. This self-aligning capacity makes it suitable for many engineering applications.

Features of Self-Aligning Ball Bearings

self-aligning ball bearings are endowed with many features that make them suitable for several applications. Below are the critical characteristics of self-aligning ball bearings:

- Misalignment Tolerance: The sustained relationship between the housing and the shaft is accommodated in such a way that the interfaces between the two components are fitted together. The operation can still be smooth with minimal angular misalignment across the two ends of the shaft, even when it is subjected to deflection, or the joint surfaces have mounting errors.

- Automatic Alignment: Each bearing has two rows of balls encased within a spherical outer ring. This arrangement allows the bearing to self center, which is beneficial to the restoration process while facilitating a smooth operation through reducing the internal stresses on the bearing.

- Versatility: Such tools are helpful for various types of applications owing to the fact that they have been engineered to handle both concentric and eccentric applications of stress. Their use you can find in auto industries, building sites, mines and manufacturing in general where deflection, shift vibrations and errors or abnormal placements might be present.

- High Load Capacity: Even with such abilities, self aligning ball bearings can sustain high levels of applicated stress due to structural changes that enhance the vertical carrying capacity of his tool. Such aspects enable them to resist an immensely comparable or greater amount of weight in use allowing for them to be relied upon during demanding environmental conditions.

- Low Friction: The self alignment any components deformation cause minimizes the contact between the bearing and housing which helps reduce friction. The very reduction of friction cut fuel consumption and energy losses enabling the tools to better reliability and durability in a wider circumference of use.

Self-aligning ball bearings present mechanical solutions with their excellent features to many industries by providing consistent operational reliability, extended service life, and improved operational efficiency.

Applications Where Self-Aligning Bearings Are Ideal

self-alignment sockets are strongly recommended for use in locations where misalignment, shaft or bearing(pivot) deflection, vibrations, and/or mounting errors may occur. Their design provides vast flexibility,y allowing diverse applications because of their ability to accommodate misalignment:

- Automotive: The bearing type most widely used in the automotive steering, suspension and powertrain systems is the self aligning type which possesses the capability to withstand angular misalignment due to road and vehicle dynamics and is fairly efficient.

- Construction: Self aligning ball bearings are used in construction cranes, hoists, concrete mixers etc., where heavy loads and working conditions create vibration and misalignment.

- Mining: Misalignment and vibrations is usually the case with mining crushers, conveyors, and vibrating screens among other equipment. The demands in these areas require the use of self-aligning bearings which are durable and provide performance under the extreme mining environments.

- Manufacturing: Scrims or Khadi textile and textile processing machinery, printing machinery, and devices in the food industry use self-aligning ball bearings for many applications. They operate efficiently and smoothly even with high-speed induced misalignment.

The self aligning ball bearings in this case are recommended for use since they have a high load, low friction and self aligning features which increase equipment reliability, increase service life and increase operational efficiency.

Reference

- Ball Bearing Types & Applications – EZO USA

- What are Ball Bearings Used For? – Lily Bearing

- Types, Design, Applications and Benefits of Ball Bearings – IQS Directory

Frequently Asked Questions (FAQs)

Q: What are ball bearings, and how are they constructed?

A: Ball bearings are a type of rolling-element bearing that feature balls to maintain the separation between the bearing races. They consist of an inner and outer race, and the balls themselves, which allow for smooth motion and reduced friction in applications requiring rotational movement.

Q: How are ball bearings used in various applications?

A: Ball bearings are used in many applications to support radial and axial loads, enabling smooth and efficient rotational movements. They are commonly found in machinery, automotive components, and even household appliances, allowing these devices to operate with reduced friction and wear.

Q: What is the difference between ball bearings and roller bearings?

A: Ball bearings use balls as the rolling element, which is ideal for applications requiring lower friction and noise. Roller bearings, on the other hand, use cylindrical rollers and are suitable for carrying heavier loads. Each type of bearing has its advantages depending on the specific application requirements.

Q: Why are precision ball bearings important?

A: Precision ball bearings are crucial in applications where high accuracy and minimal friction are required. They are designed to provide superior performance in terms of speed, load capacity, and noise reduction, making them essential for precision machinery and instruments.

Q: What are hybrid ball bearings, and when are they used?

A: Hybrid ball bearings are made with steel races and ceramic balls. These bearings are also known for their high-speed capabilities, reduced weight, and longer lifespan. They are often used in high-performance applications where reduced friction and increased efficiency are critical.

Q: What are double-row deep groove ball bearings?

A: Double row deep groove ball bearings are similar to single row designs but feature two rows of balls, allowing for a higher radial load capacity. They are used in applications where the width of the bearing is limited, but higher load support is needed.

Q: How can you prevent damage to the bearing?

A: To prevent damage to the bearing, ensure proper installation, regular maintenance, and appropriate lubrication. Bearings must be protected from contamination, excessive loads, and misalignment to prolong their lifespan and maintain optimal performance.

Q: What are the common designs of ball bearings?

A: Common designs of ball bearings include deep groove, angular contact, and thrust ball bearings. Each design is suited for different types of loads and applications, providing versatility in the use of ball bearings across various industries.

Q: How long have ball bearings been around, and why are they still used today?

A: Ball bearings have been around for centuries, with their basic principle dating back to ancient times. They are still used today because they provide efficient and reliable means of reducing friction and wear in countless applications, contributing to the longevity and effectiveness of mechanical systems.