Pillow block-bearing units are utilized throughout the industrial and commercial sectors. In this article, we will provide a description of pillow block bearing, its design, and the benefits it offers. Along with this, we will cover questions such as: what are the uses of pillow block bearings, and what factors should buyers have in mind before purchasing them? We will also discuss the methods of maintenance and installation of these units to keep them in optimal working condition. If you aspire to learn more about pillow block-bearing units or simply want to learn more about how to boost the efficiency of your machinery, this article will act as a one-stop solution. So, without any further ado, let’s embark on the journey to learn more about pillow block-bearing units.

What is a pillow block bearing?

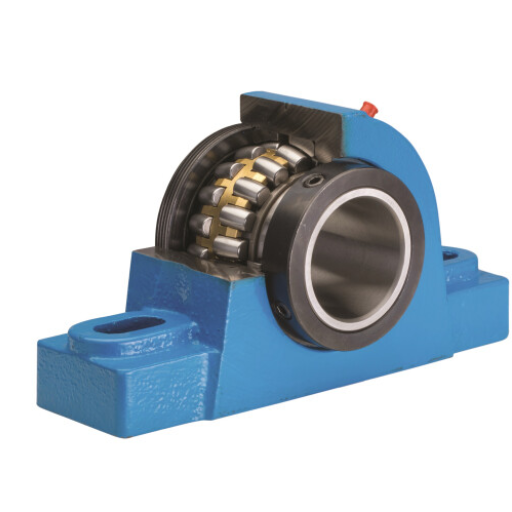

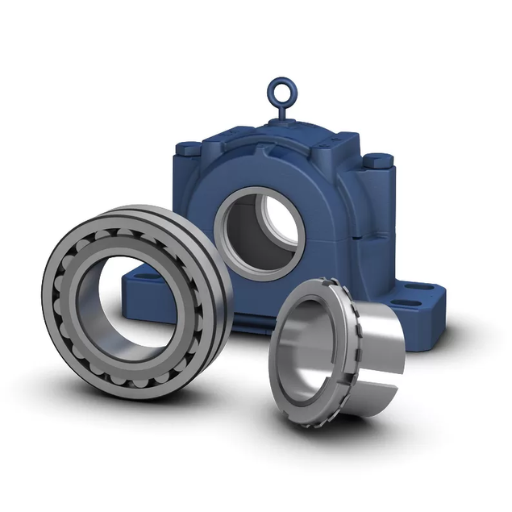

a pillow block bearing consists of an outer casing (‘pillow block’) and a rotating shaft bearing insert. It supports the rotating shaft and is a type of bearing used in many machines, etc. Please note that the casing is usually made of either plastic or metal p and is assembled with either a spherical or ball-bearing insert that is more durable than usual. The design itself permits it to be easily installed and maintained, and the bearing can be replaced. The application also bears a pillow block bearing in agriculture, mining, construction, and manufacturing, which makes sense since the efficiency and reliability of the machinery are paramount.

Definition and Overview of Pillow Block Bearing

Pillow blocks also known as plummer blocks are mechnimals inserts with spherical or ball bearings onto the mounting base. These are units used all across industries because they are easy to set up, replace and maintain. Pillow blocks are used extensively in upholding machinery’s performance for the agriculture, mining, and construction sectors.

Pillow blocks are highly durable and load bearing withstanding complex working conditions. Collaboratively they help with reducing the friction which results in better overall efficiency and productivity by ensuring maximum stability with intricate equipment. These Carolyn block bearings are highly versatile and dependable in applications working with complex machines or even heavy ones.

Components of a Pillow Block Bearing

Now, focusing on the building blocks of a pillow block bearing in detail to understand its industry use:

- Housing: The housing of a pillow block bearing is a case that incorporates the bearing insert and keeps it firmly in place. These are usually made from either cast iron, stainless steel, or thermoplastic materials which guarantee durability and protect the bearing.

- Bearing Insert: A bearing insert is also commonly referred to as an inner ring, or a rolling element. The purpose of such a component in a mechanical structure is to carry loads or allow them to rotate about a center. An average bearing insert has chrome steel or stainless steel base material, and has been specially designed to carry and endure high loads along with providing rotational motion with low friction surfaces.

- Grease Fitting: Some pillow block bearings have grease fittings. Grease fittings make it easy to lubricate the bearing. Lubrication is regularly performed to minimize wear and tear to the bearing, which improves the operating conditions and increases the working life of the bearing.

- Sealing Mechanism: Pillow block bearings are equipped with a sealing mechanism with an intention of saving the bearing from dust, dirt and moisture, which can cause damage to the motor. This is done to prevent the destruction of the bearings and other parts of the machine caused by exposure to foreign particles and to enlarge the service life.

A comprehensive understanding of these functionalities of a pillow block bearing is pivotal to picking the right type of bearing that is perfect for the intended purpose while ensuring satisfactory performance and long life.

How Pillow Block Bearings Are Designed

In the words of someone acquainted with the industry, a pillow block bearing is made to sustain and enable rotation in multiple use cases. It comprises key elements that allow it to function and enhance its life. A pillow block bearing is composed of the bearing, the housing, and the sealing.

- Bearing: The actual bearing is the centerpiece of a pillow block bearing. This is the component that bears the weight and allows rotation with the use of different types of bearing such as ball bearing, or spherical roller bearing depending on the need of the application for which it is used.

- Housing: This is the external case or cover which is used to enclose the bearing and provides support around it. Rigid materials like cast iron or stainless steel in that order of preference, are employed to manufacture the housing of the bearing. The housing of bearing has a surface for mounting the bearing.

- Sealing Mechanism: A pillow block bearing comes with a sealing mechanism, which can be a rubber seal or metal shield, which has a purpose of keeping the bearing free from dust, dirt, moisture etc. This allows the life span of the bearing to be increased by preventing a premature failure.

Knowledge of each of these components of a pillow block bearing is important so as to choose the correct type of bearing for a particular application and also to prolong the life of such bearings. If properly designed and selected, pillow block bearings can offer reliable support, permitting smooth bearing rotation and providing shielding against the external environment, hence making them important components of many industrial and mechanical systems.

How to Choose the Right Bearing Type for Your Needs?

As you may know, there are different types of bearings, and selecting the right type is quite an intricate task. Where deciding the appropriate bearing type is concerned, some factors are worth considering. Firstly, the load, speed, and environmental parameters of the application have to be analyzed. What makes this possible is a broad understanding of the various bearing types like plain bearings, ball bearings, roller bearings, and the list goes on in order to help place all factors in context. Besides the load capacity and speed of rotation of the shaft, it is usually crucial to evaluate the friction, cost, and maintenance requirements of the various bearing types. Also, by using the supplier’s or engineers’ knowledge, these considerations should assist in deciding which bearing type will give you reliable performance and long life for your industrial or mechanical system.

Factors to Consider When Choosing Pillow Block Bearings

I should take into account several fundamental factors when selecting pillow block bearings for a particular application. These factors are also crucial for the effectiveness, dependability, and lifespan of your mechanical or industrial system. Key considerations follow:

- Load Capacity: Analyze the load capacity requirements of your application to select the appropriate pillow block bearing that can support the expected loads without performance degradation.

- Environmental Conditions: Think about the environmental conditions that the pillow block bearing is going to work under which include but are not limited to temperature levels, fluids, dust or any corrosive elements. Choose a bearing which has provision for use under such conditions and still performs efficiently.

- Speed and Rotation: Find out the speed and rotation of your application to select a pillow block bearing which can work under such conditions without causing undue wear or generation of excess heat.

- Friction and Efficiency: Examine the degree of friction loss and energy consumption efficiency of the pillow block bearing expectation. Various classes of pillow block bearings will produce different results with friction that alters system efficiency and power needs.

- Cost and Maintenance: Consider the purchase price, the maintenance and service of the pillow block bearing and its forecasted life span. Evaluate the bearing from cost and long term benefits perspective concerning the needs of your application.

These considerations will provide you with enough details to make the right choice while identifying the most appropriate bearing based on the distinct requirements of your mechanical or industrial systems, thus assuring optimal effectiveness and durability.

Comparison of Different Bearing Types

To assist you in making an informed decision, let us provide a brief comparison of various bearing types:

- Pillow Block Bearings: Known as the Plummer block bearing, pillow block bearings are extremely versatile and widely used across many industries. They comprise a bearing unit that is attached to a bearing housing (a pillow block) and a bearing that supports the rotation of a shaft. Numerous features make these bearings ideal for applications involving heavy loads; they are easy to mount and dismantle. They are popular in the application of conveyor systems, agricultural machinery, and manufacturing equipment.

- Spherical Roller Bearings: Spherical roller bearings are self-centring bearings, developed for use in circumstances with heavy loads in the radial direction and axial loads in both directions. The ability to move their center of gravity enables these bearings to correct shaft orientation that may not be centered. This type of bearing is predominantly used in heavy-duty equipment such as mining machines, steel mills and those of paper factories.

- Ball Bearings: Ball bearings are the most common form of bearing. These consist of two rings , one inner and the other outer, and a capsule in between the two which consists of small balls allowing for frictionless and low smooth rotation. Ball bearings are intended for a wide range of uses including electric motors, automotive parts, household, and industrial appliances and machinery.

- Roller Bearings: Roller bearings, which consist of cylindrical roller bearings, tapered roller bearings, and needle roller bearings, are made to withstand large radial loads and a small axial load. They tend to have high radial stiffness and, as a result, are used in many rotary applications like automotive, construction equipment, and printing presses.

- Thrust Bearings: Bearings that accommodate or are specifically designed for one direction of rotation are known as thrust bearings. In general, they are used in configurations like automotive transmissions, machine tools, and aircraft engines where rotational shafts need to be fixed in a particular axial position.

Each bearing type possesses distinct benefits and is optimized for different applications. The selection process of bearings should take into account their peculiar characteristics including load bearing capacity, velocity and working conditions such as dust, humidity and temperature in order to make sure that the bearings perform efficiently and last for a long period of time in your machine or industrial system.

Applications of Various Bearing Types

let us look into the applications of different types of bearings to understand their practical aspects in a better way:

- Deep Groove Ball Bearings: These bearings are primarily used in electric motors, automotive parts, and pottery appliances, where there are high speeds and radial loads.

- Angular Contact Ball Bearings: These bearings have significant torque and can take radial and thrust load as well, it is used in machine tools, pumps, and gearboxes.

- Cylindrical Roller Bearings: Cylindrical roller bearings have greater radial load capacity and usually finds its applicability in construction machinery like construction equipment, rolling mills, and crushers.

- Tapered Roller Bearings: Tapered roller bearings fit the needs of applications where radial and axial loads need to be carried, these are a common feature in automotive wheels and in transmissions.

- Spherical Roller Bearings: These bearings are suitable for use in heavy loads and where there is misalignment of the shaft, such as, in mining equipment, vibrating screens, and conveyor systems.

- Needle Roller Bearings: Considering their small size, they fit well in the automobile transmission systems, industrialer gearboxes, and even in agriculture machinery.

Identifying the usage of each bearing type ensures that one gets the right decision when choosing the optimal bearing for their mechanical or industrial system. It is therefore critical to take into consideration the operating parameters of the equipment such as load capacity, speed then environmentally related aspects to ensure optimum reliability and service life of the equipment.

What are the Advantages of Pillow Block Bearings?

I believe the merits of pillow block bearings are striking and abundant. Let’s consider some of the key benefits that make these bearings quite popular across many applications:

- Easy Installation: Installing pillow block bearings requires less skill than most average do-it-yourself tasks as they come completely encased in a hosing ready to bolt onto other components.

- Enhanced Load Capacity: Yet another strength of these types of double row bearings comes from their remarkably high load carrying capabilities while being constantly subjected to high stresses.

- Shaft Protection: Pillow block bearings come in a well-protected hosing which minimizes possibilities for external damage, dirt, or non-suitable alignment.

- Versatile Performance: In addition, they easily accept other different styles or sizes of shafts improving versatility within a designated use or task.

- Reduced Maintenance: Furthermore, due to their heavy-duty built quality, these types of block bearings do not require heavy maintenance, thus avoiding prolonged downtimes and reducing costs.

- Wide Range of Applications: Pillar block bearings are also applicable in various other industries and machinery, such as cars, agricultural related devices, and equipment used in mining.

These benefits enable pillow block bearings to be a consistent and effective option for pillow block bearings industrial and mechanical assemblies since they are stable, durable, and designed for long-term use.

Benefits of Using Pillow Block Bearings

let me share the major advantages associated with the use of pillow block bearings. They exhibit several benefits that explain their popularity across a number of sectors:

- Stability and Durability: Mounting blocks1886 are original heavy-duty machine units with a warranty of 10,000-40,000 hr. —7-10 years of use. These units were designed for high stability, reliability, and low maintenance demand. Due to their construction and loading capacity, they can work under heavy load applications.

- Reduced Maintenance: Mounted blocks are constructed to be low in maintenance demands. The units are of high reliability therefore contributing to decrease in downtime and unit costs. This makes the operation more productive.

- Versatility: Mounted block bearings are used in automotive, agricultural, mining and manufacturing applications. These can be used in almost any machinery and equipment therefore very usable in many scenarios.

- Easy Installation: The best advantage of mounted blocks is that there is minimal downtime during replacement or maintenance due to ease in pillow block replacement. It is made easy due to the mechanical construction and a typical type of mounting system.

- Longevity: People like them because they are easy to fit and considering the needs also in some cases the block often prefer places that are not easily accessible, wearing or excessive friction.

To conclude, pillow block bearings have an edge in radial and axial load support, stability and strength, reduced maintenance, versatility, ease of installation, and durability as well as longer lifespan. These attributes make them the best components for optimization in the operational efficiency and dependability in most systems in many industries.

Why Spherical Roller and Ball Bearings are Preferred

spherical roller and ball bearings are the most commonly bearings used in the machinery design, and let’s not forget the fact that these bearings do have advantages. Bearing in mind the use of these types of bearings, one can easily appreciate the reason for such a choice. Some are mentioned below and provide a useful basis for selection.

- High Load-Carrying Capacity: Spherical roller and ball bearings can bear high radial and axial loads which makes them well suited for applications where there is a lot of mass or force is applied.

- Durability and Reliability: These bearings are specifically designed for severe environments such as high temperatures, shocks, and vibration. Because of their superior build and material, these can be used for a longer period of time during harsh conditions.

- Versatility: Spherical roller and ball bearings can be designed in multiple designs and shapes, which can fit different types of applications across all sectors, such as medical, military, robotics, etc. This modularity makes it easier for users to pick the ideal bearing according to their needs. Suitable bearing for specific requirements.

- Wide Speed Range: These bearings have been designed to work over a large spectrum of speeds from low to high. They provide great rotational characteristics that optimize performance consistency and help facilitate reliable operating parameters under margin conditions.

Industries can take advantage of the remarkable load carrying capacity of spherical roller as well as ball bearings which has also the versatility to be used on a variety of operational speeds. These bearings are extensively used in a variety of industrial machines in which their efficient and reliable performance ensures their effectiveness for most experts in the industry.

How to Install and Maintain Pillow Block Bearings?

the assembly and service of the pillow block bearings is certainly an important thing that needs to be observed in order to guarantee their performance and the life span of the bearing units. Below are some guidelines you have to adhere to:

- Pre-Installation Inspection: No evidence of damage, any defect, or cracks is to be found in the bearing, housing, and shaft. Also, the surfaces are to be clean and free of any dirt.

- Correct Alignment: It is essential that there is a correct orientation of the bearing nose. A bearing nose is connected to a bearing housing and to a shaft so as to minimize high intensity forces or incorrect direction of the parts during use. Appropriate alignment methods and tools are used for this purpose.

- Appropriate Lubrication: Make sure to apply the recommended oil on the bearing and check the oil level constantly to ensure that there are smooth operations. Proper lubrication can help prolong the life of the bearing components.

- Regular Maintenance: In the course of routine maintenance examinations, people might check for audible noise, vibration, etc and even inspect for physical damage to the component. Any component which is found faulty and worn out must be repaired to ensure proper functioning of the systems.

- Protection from Contaminants: Considerable risks or chances of transferring dust particles, dirt and moisture should be avoided to maintain integrity of the pillow block bearings. Efficient sealing or covers might required to be fitted to the components to avoid penetration of foreign materials.

Keep in mind that adherence to the manufacturer’s directions during installation and maintenance of the equipment is highly necessary. In addition to this, it is prudent to seek appropriate assistance from qualified professionals or observe such manuals intended for this particular case.

Steps for Proper Installation and Maintenance

proper installation and maintenance of pillow block bearings is fundamental for ensuring that they function correctly as well as have longevity. The following are the main processes that must be observed:

- Thorough Inspection: Before fitting, inspect the bearings for any signs of damage or defects. Check that clean and smooth surfaces of the shaft and the housing are to properly fit together.

- Correct Alignment: Slide the pillow block bearing into the housing and the shaft. It may be noticed that the bearing is not perfectly fitted to the shaft and the housing which would cause it to rotate smoothly. When this happens, it is said to be misaligned. A misalignment will result in decreased lifetime of the device and greater usage costs. Precise alignment is strongly recommended with proper tools such as dials indicators or any other laser alignment tools.

- Proper Lubrication: The Right Amount of Enough- To apply greater bearing life, applying lubrication is vital as it decreases friction. So, it is essential to apply the recommended lubricant before and during placement on the bearing. But being wary, manufacturers will advise you on how much and what type of lubricant you are to utilize.

- Secure Mounting: Travel – When installing a pillow block bearing, it should be done in a proper manner. For this to occur, the block bearing should not mount loosely on the housing or the surface. To achieve the proper setting, the appropriate fasteners should be used as well as adhering to certain specifications such as torque that is relative to the manufacturer.

- Regular Maintenance: Axis Motor Replace noise, vibration, or other physical signs of damage that can be replaced and check every once in a while. Regular maintenance should detect this early and so should the checking of parts that have undergone wear.

Be mindful, that for correct installation and maintenance, it is necessary to follow the guidelines as well as recommendations of the manufacturer. It is equally good to seek assistance from specialists or check comprehensive operation manuals that relate to your application. By following these guides, you will be able to safeguard the effective functioning and durability of your pillow block bearings.

Common Issues and Troubleshooting Tips

As someone with specialist knowledge of the industry, you should be mindful of some of the problems that may arise, specifically with pillow block bearings, and how to rectify those issues adequately. For this, the following points are important:

- Lubrication Problems: A lubricant is a vital resource in prolonging the lifespan of pillow block bearings. Failing to apply the correct type, amount, or periodic lubricant can result in the premature failure of the bearings leading to wear. Be sure to follow the instructions of the manufacturer as closely as possible.

- Misalignment: Premature failure can result from excessive loading and buildup of stress on the bearings due to misalignment. It is advisable to inspect and align the structure on a regular basis as a necessary precaution.

- Contamination: The utilization of pillow block bearings can be inhibited by the dirt, dust, and moisture which are contaminants. Make sure that the sealing procedures are in place in order to mitigate pollution. As a best practice, ensure to routinely clean and examine the bearings to get rid of the debris.

- Overloading: Stress and premature failure can result from the overuse of the load capacity. Make sure to choose the required bearing type and size while calculating the load requirements.

- Vibration and Noise: The excessive noise and vibration can be traced to the pillow block bearings as they are indicators. It is a good idea to monitor unusual vibrations and noise frequently so that the cause can be resolved timely and complex problems can be avoided.

Taking proactive steps to solve such prevalent problems and putting in place suitable corrective actions will guarantee the best performance as well as the service life of your pillow block bearings in several industrial processes.

Where are Pillow Block Bearings Used?

pillow block bearings are good at performance and consume less energy, due to which they are great for industrial applications. Their flexibility in usage translates into them being frequently used in tools and other equipment that need strong support and efficient motion. Below are some common applications of pillow block bearings:

- Agriculture and Farming: For various outdoor activities, agriculture uses tractors, harvesters, and irrigation equipment – to name a few. Pillow block bearings are integrated into this machinery as they ensure the rotational motion of the parts by providing support that also allows for smooth operation even in outdoor conditions.

- Conveyor Systems: Manufacturing firms, logistic companies, and even the mining industry relies on conveyor systems and with the use of conveyor belts in these systems, pillow block bearings are a necessity as they relieve the conveyor’s weight allowing effective relocation and transportation of goods.

- Food and Beverage Industry: Mixers, bottling machines, packing lines – all these equipment are used in the food and the beverage industry, but to ensure proper functioning, sanitization is key. This is why dolly block bearings are crucial as they can tolerate harsh washing regimes while still maintaining the required strict hygiene protocols.

- Mining and Construction: For the construction and mining industries, heavy-duty machinery is crucial and conducting a reliable operation in such extreme environments often becomes an issue. But with the use of a pillow block bearing, even the shock, impact, and harsh environment can be tolerated.

- Printing and Packaging: In order to carry out printing and packaging activities in an accurate manner, the use of printing press, gears, packaging, and labelling machines is of utmost need, but without stable support of pillow block bearings, even smooth and precise movement would not be possible.

Pillow block bearings are crucial parts of many other machines, such as material handling equipment, textile machinery, air-conditioning systems, etc. Because they are economical, durable and easy to install, they are widely used in many sectors.

Industrial Applications of Pillow Block Bearings

I would like to address the subject of industrial applications of pillow block bearings. These versatile components bear a significant load in general machines in almost all industry sectors. Here are some key industries where pillow block bearings are extensively used:

- Food and Beverage: Accurate position and unwavering stability are essential for any machinery functioning in food processing and packaging applications. Pillow block bearings are designed to withstand frequent washdown as well as frightening standards of hygiene and thus dominate these essential areas with a lack of ay distrain constraints. Such attributes enable the tools to perform all their critical operations of bearing weight without the slightest worry of malfunctioning.

- Material Handling: The fork lifts, cranes and hoists all employ pillow block bearings and in such instances are able to work in conveyor belt systems as well. Conveyors are instrumental when it comes to the smooth and efficient movement of large masses of goods supporting facilitates, immune from the risks of carrying enormous excesses in warehouses, invention structures, and centers located in distributed places.

- Textile Machinery: Apart from spinning , weaving and dyeing machines pillow block bearings are used in the textile industry as well. Such machinery cannot function effectively without the pillow block bearing since intricate processes such as accurate wash and direction are involved in the operation and blanket blocks tend to malfunction.

- Mining and Construction: When using heavy duty machines in construction or mining, pillow block bearings are ideal securing maximum releability. With a number of constructions being started in this day and age around the world, the demand for pillow blocks tend to never run dry as the tools are subjected to a multitude of harsh conditions and require immense shock and load resistance.

- Printing and Packaging:Using pillow blocks in printing and packaging machinery as well as other devices that utilize the products ensures eyepopping precision while also minimizing the risk of instability due to unsupported movements.

A mere handful of case studies illustrate the scope of industries where pillow block bearings find standard application. Such bearing components are used in HVAC equipment as well as in textile machines and are characterized as being multi-purpose With their capability to endure significantly high loads and unfriendly conditions, pillow block bearings are active in promoting effective and trouble-free functionality of equipment in various industries.

Role of Pillow Block Bearings in Machinery

I know you may be curious about how these units function in machinery. In supporting the work and making it easier to carry out, these components are indeed quite critical in many processes and efforts. These bearings are made to handle heavy loads, bumps, and extreme temperatures, all of which are essential for the smooth functioning of the equipment in more strenuous situations. It will be all the more precise in defining the role of bearings in practically guaranteeing the effective functioning of machinery. For even the most demanding activities like mining, construction, printing, and even some packaging, the use of such pneumatic bearings helps to anchor movement in a manner that optimizes the entire process. As a final thought, I would like to say that pillow block bearings and clamps are very important components of almost any machinery and can be relied upon as they are robust, dependable, and provide ease of installation and adjustment in most cases.

Exploring High-Load Applications

In your skill as an expert in the industry, you might be wondering about the particular applications in which the use of pillow block bearings is useful under high load. These bearings are highly adaptable and are employed in various industries and applications that require considerable support and dependable operations. And here, only a few examples of high-load applications are presented where pillow block bearings are indispensable:

- Heavy Machinery and Equipment: Sectors such as metallurgy, construction, or agriculture, which are characterized by the frequent use of heavy equipment and high operational vibrations, rely on pillow block bearings to support machinery like conveyors, crushers, and centrifugal pumps. This allows the silencing of communication and controlled and balanced motion even when the machines work under huge loads.

- Printing and Packaging Machinery: During the operation of printing presses and machinery used for packaging, there is a need for precise rotation of shafts, rollers, and other needs. Known as pillow block bearings, these devices assist in consistent rotation, reduction of idle time, and overall performance improvement.

- Material Handling Systems: The material handling systems which include conveyor systems and lift systems, need bearing assemblies for proper operation and stability with low friction while rotating. These applications utilize pillow block bearings effectively providing needed support and working efficiency under tough conditions.

- Industrial Fans and Blowers: Industrial fans and blowers usually require pillow block bearings since they work under low rotational friction. They essentially help to support the shaft which rotates the blades on the fan from one side which directs the airflow towards the blades increasing the air pressure. This contributes to ventilation and temperature control systems in different industrial buildings.

- Power Transmission Systems: In the industry dealing with power transmission systems, pillow block bearings are crucial elements for transferring rotation. It is quite common for them to be fitted in gearboxes, pulleys and other parts involved in power transmission.

To conclude in short, pillow block bearings by their nature are critical components in several application domains where heavy loads are encountered. Because they are able to bear heavy loads, shocks and severe conditions to provide stable support and rotation, these components are essential in preserving the integrity, accuracy, and efficiency of machinery in high demanding conditions.

Reference

- The Complete Guide to Pillow Block Bearings – Monroe Engineering

- Understanding Pillow Block Bearings Nomenclature – PGN Bearings Blog

- Pillow Block Bearing Installation Guide – FHD Bearings

Frequently Asked Questions (FAQs)

Q: What are pillow block-bearing units?

A: Pillow block bearing units consist of a housing and an insert bearing. They are used in machinery to support rotating shafts and are designed for easy installation and maintenance.

Q: What materials are typically used for pillow block bearings?

A: The material for pillow block bearings is usually cast iron or steel. These materials provide durability and strength, although other materials like stainless steel or thermoplastics may be used depending on the application.

Q: How do I choose the right pillow block bearing?

A: Choosing the right pillow block bearing depends on factors such as load capacity, shaft size, speed, and environmental conditions. It’s crucial to ensure that the bearing will support the intended load and fit within the application’s specifications.

Q: What are the types of pillow block bearings available?

A: Common types of pillow block bearings include SAF pillow block bearings, split pillow block bearings, and flange bearing units. Each type is designed for specific applications and load requirements.

Q: What is the difference between a pillow block unit and a flange bearing?

A: A pillow block unit supports a shaft that is parallel to the mounting surface, while a flange bearing mounts perpendicular to the shaft axis. Flange bearings are often used in applications requiring precise alignment.

Q: What applications require pillow block bearings?

A: Pillow block bearings are used in various applications requiring support for rotating shafts, such as conveyor systems, agricultural machinery, and industrial equipment. They are versatile and can be found in many sectors.

Q: How do pillow block housings aid in bearing installation?

A: Pillow block housings simplify the installation process by providing a ready-to-mount unit that aligns and supports the bearing, reducing setup time and ensuring proper alignment with the shaft.

Q: Why are safe pillow block bearings commonly used in heavy-duty applications?

A: SAF pillow block bearings are robust and designed to handle heavy loads, making them ideal for heavy-duty applications. They provide excellent support and longevity under demanding conditions.

Q: What should be considered during pillow block-bearing replacement?

A: During pillow block bearing replacement, it’s important to assess the compatibility with the existing shaft and housing, ensure proper alignment, and select a bearing that matches the load and speed requirements of the application.