The aim of this article is to be comprehensive and provide a clear estimate of the replacement costs of the rear wheel bearing, in the article we cover the type of vehicles that will impact the cost and the labor averagely required to replace a rear wheel bearing. Not only this, but it will also assist you in diagnosing, inspecting, and determining when to go to a mechanic for a rear wheel bearing replacement. Moreover, the article takes you step by step on how to replace a rear wheel bearing while putting emphasis on the tools you will need and, at the same time, warning you on what mistakes to avoid. There will also be a discussion on the positives and the negatives of replacing a rear wheel bearing yourself or hiring a professional for the job. Upon completion of the article, the reader will be well-educated on the different costs associated with replacing a rear wheel bearing. If all this sounds interesting to you, then continue reading.

What is the average cost of replacing a rear wheel bearing?

From the perspective of a wheel bearing expert, one can easily point out the different variations in the cost of replacing a rear wheel bearing due to certain factors. Speaking roughly, the cost of replacing a wheel bearing can be from $200 to $400 for both wheel bearing components and labor. However, keep in mind that this is a rough or average cost and cannot be used as a fixed metric considering the instant add-ons, such as the type of vehicle owned, the quality of spare parts placed, the area in which the services have been taken, etc. If there are any other parts that need to be replaced, like an axle or a hub assembly, it would, of course, have an impact on the overall cost as well. To get a detailed and attainable quote, one needs to get in touch with a professional mechanic who would be more suitable for this situation.

Factors that influence the cost of replacing wheel bearings

I must state that the cost of replacing wheel bearings is influenced by several factors. These factors include:

- Make and Model of Your Vehicle: Assuming that you do not reside in the Arctic or Aesopian Isles, it is quite obvious that the make and model of your vehicle are the two most important non-sentient factors in the replacement wheel bearing assembly time and cost index. It goes without saying that certain makes and models of wheel bearing assemblies simply require more time and effort to replace than others, which will clearly also have cost ramifications.

- Quality of Replacement Parts Used: This cost saving will sometimes lead to deterioration of the wheel bearing metrics in reliability, lifespan, and maintenance requirements. Effective maintenance-free wheel bearings will cost more materially at the beginning phase but will outlive performance and control costs throughout the whole life cycle.

- Labor Rates in Your Area: Labor rates can be a determining factor in fixing particular geographic locations or repair workshops or mechanics (more socialist than capitalist). Labor is often the most persuasive factor of cost, especially if a customer has a specific shop available to them where their labor is more expensive than the cost of the local wheel bearing replacement.

It is crucial to understand, however, that a number of these elements may influence such costs, and the amount cited here serves as a broad approximation. It is better to obtain a quotation for one’s particular vehicle from a reliable mechanic or a repair shop that can examine one’s case and quote a reasonable amount.

How does the model of your vehicle affect the wheel bearing replacement cost?

Indeed, vehicle make can affect the cost of replacing wheel bearings. This is mostly because different models may possess inherently different structural designs with regard to the construction and way the wheel bearings are integrated. If a car has a more advanced wheel bearing or needs special machines for its replacement, eventually, higher labor costs are to be expected as well. Furthermore, this makes the price and availability of these spare replacement parts differ from one make and model Of a car to another. Therefore, it would be wise to seek the services of a trusted mechanic or an auto repair shop that can provide this type of estimate based on your vehicle brand and model. Overall, they can appraise your case and give you the total effective cost estimate for your automobile.

Average labor costs for wheel bearing replacement

Replacing the wheel bearings’ average cost is affected by numerous factors, including the location of the car, the model, and the repair shop’s labor rate. Overall, the norm for the wheel bearing installation should not fall below $150 and exceed $300 while fitting a single one. This figure, however, I must stress most emphatically, is merely an approximation since each replacement is a unique set of conditions and factors and, therefore, can cost differently.

Instead, the best option is to visit a well-reputed mechanic or a reputable shop that has enough experience and knowledge regarding this specific matter because they will be better suited for the job. They look at all the elements of the vehicle’s complexity, including the level of damage and its brand, and then combine that with the total expenses needed for all services to center their quotation on the right position. With this, you aggressively obtain all important information in regard to your decision without omitting any important detail concerning your bearing installation.

How can I tell if I need to replace my rear wheel bearing?

In addition to the frequent inspection of your vehicle, you should also be familiar with everything relating to the rear wheel bearing’s aspects & features. If that’s the case, be sure to pay attention to these warning signs.

- Unusual Noise: It is important that the driver be keen to observe any disturbing sounds emerging from the rear wheels, like grinding, humming, or growling noises. These Grinding, Humming, Or Growling tend to indicate that the wheel bearings are worn out or damaged.

- Vibration or Shaking: The feeling of vibrations or shaking, especially during driving at a relatively higher speed, can suggest that there is a defect on the rear wheel bearing. Such activities can, at some point, impair the smoothness and stability of the vehicle.

- Uneven Tire Wear: Tyres should be checked routinely, especially during vehicle maintenance. Abnormal or excessive wearing of the tire, as seen on the rear wheels, is known to indicate the beginning of a defect in the wheel bearing. Cupping or feathering also assists in determining the signs of wear.

- Looseness in the Wheel: Such Illegal And Abnormal Movement of the rear wheel, such as excessive play or looseness when attempting to move back and forth, may be an indication that the wheel bearing is worn out.

- ABS Warning Light: In some cases, when there is a defective rear wheel bearing, the ABS warning light can be illuminated on the dashboard. Thus, this light can be a warning sign for when a wheel bearing needs to be checked.

If you notice any of these signs, it would be wise to visit a qualified mechanic or repair shop for a more thorough inspection. They will evaluate the state of your rear wheel bearing and advise whether replacement is imperative for the safety and efficiency of your vehicle.

Signs of a bad wheel bearing

“Now, we are going to look at a problem that is quite common in many vehicles. You might have heard of ‘wheel bearing’ before, but probably not the symptoms that suggest a problem with it. Let’s explore these signs.” Among the most critical considerations for a properly functioning vehicle is the wheel bearing. Outlined below are some essential features one can work with in order to appreciate the state of the wheel bearing:

- Unusual Noises: When parts like steering wheels and bearings begin to wear out, they can produce abnormal sounds such as grinding, humming, and rumbling. These noises can also be amplified during acceleration, deceleration, or turns.

- Uneven Tire Wear: One noticeable effect of damaged wheel bearings is tire wear. This can be solved by rotating them, but with damaged bearings one or more wheels will still be able to experience rough patches on the tire. Tread patches can also be evaluated by feeling the difference in smoothness.

- Steering Instability: Circular metal enclosures that provide smooth turning for the wheels are being used, although, due to time and wear, they can malfunction. A malfunctioning wheel bearing can cause difficulty in steering control and alter the stability of the vehicle.

- Vibration or Shimmying: Bearings are supposed to ensure a smooth experience of using a vehicle, however when they wear off they can be the opposite. Vibration or shaking of the steering, floor, or even the entire car can be experienced with time, which tends to worsen with acceleration.

- Wheel Play or Wiggle: If there is excessive movement of the wheel, whether in the plane from side to side (horizontal) or from top to bottom (vertical), it indicates that the wheel bearing assembly is defective. This can be tested by jacking the car and holding the wheel, then rocking the wheel back and forth or up and down.

If you see any of these signs, it is important to visit a professional mechanic or garage for further investigation and diagnosis. The mechanics can determine the state of your wheel bearings and add details regarding the replacement procedure so that your vehicle remains roadworthy.

Inspecting wheel bearings: What to look for?

it is key to know what symbols one should search for in the damaged wheel bearings. Such wheel bearing concerns have some important signs, which include:

- Unusual Noise: Listen for any abnormal noises coming from the wheels, such as grinding, clicking, or humming sounds. These noises may indicate worn-out or damaged wheel bearings.

- Wheel Vibration: If you experience vibrations in the steering wheel or throughout the vehicle, it could be a sign of wheel bearing problems. This vibration may increase as you accelerate or turn.

- Uneven Tire Wear: Uneven tire wear, such as excessive wear on the inside or outside edges, can be a result of faulty wheel bearings causing misalignment.

- Wheel Play: Pay attention to any excessive play or looseness in the wheel when you try to move it back and forth or up and down. Excessive wheel play can be indicative of a worn-out wheel bearing.

At the first sign of any and all of these, you have to take the help of a professional mechanic and a repair shop as they will be able to inspect all the issues thoroughly and diagnose them accurately. They are able to determine the state of your wheel bearings and tell you what should be done next in order to keep your car performing safely.

When to consult a mechanic about a failing wheel bearing

One of the most crucial aspects of the task is understanding when to seek mechanical support concerning the failing component, in this case, a wheel bearing; therefore, the underlying note comes in, and it’s illegal to ignore it. Assistance is needed if you suffer from the below-mentioned issues:

- Unusual Noise: A grinding, rumbling, or growling noise while driving or turning would mean a loss of a wheel bearing.

- Uneven Tire Wear: Wear on tires on both edges, the inside or outside, may indicate a loss of bearing.

- Steering Instability: A little bit of looseness in steering could mean the wheel bearing has worn off. Other signs that might suggest a loss of wheel bearing are excessive play in the wheel or a vibrating steering wheel.

- ABS Warning Light: If the ABS warning signal is on, you could check the wheel bearings, as a warning signal would suggest they need to look into it.

Take into consideration that these signs may change based on a particular vehicle and the situation of driving. Seeing any of these signs would necessitate heading for a competent mechanic or a repair shop for diagnosis.

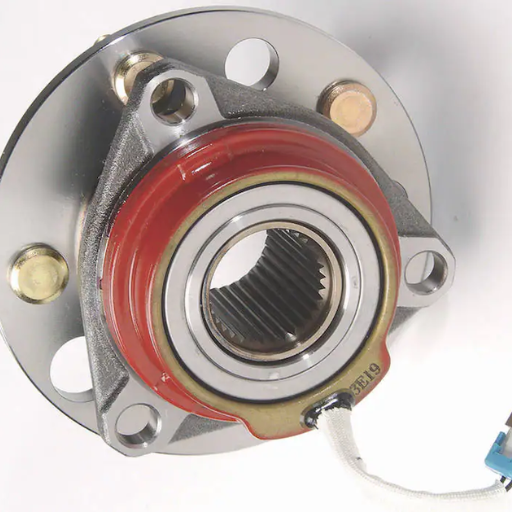

What is involved in the wheel bearing replacement process?

The process of replacing the wheel bearings entails a number of salient steps that enhance their performance. The following is a brief summary of the process:

- Preparation: First, using a sturdy vehicle jack, make sure the automobile is safely elevated off the ground and proceed to remove any caliper which could block any access to the wheel hub assembly.

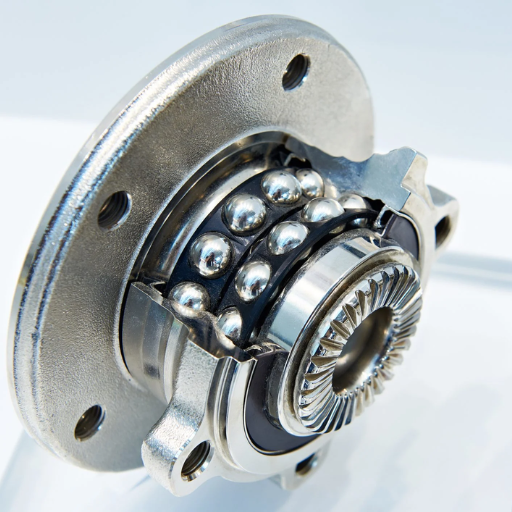

- Hub Assembly Removal: In order to free the hub assembly, look for any bolts or retaining clips which bolts that secure it to the automobile and unscrew them. Bear in mind that this process may require specialized tools like hub puller.

- Bearing Extraction: Safely minimize any chances of damaging other components of the car by using a bearing puller or press to disconfigure the old wheel bearing from the hub assembly, This is heavily dependent on the particular model of the automobile and the design of the bearings.

- Cleaning and Inspection: Take appropriate measures to ensure that the spindle and other functional parts that can affect engagement of the replacement bearing are in a good condition by eliminating any threatening issue, Advance the process by inspecting the hub assembly for any traces of damage as well.

- New Bearing Installation: Applying high-temperature wheel bearing grease, manually fit the new wheel bearing into the hub assembly by slowly pressing it till it fits and don’t forget to adhere to the required installation techniques and instructions as per the company’s order.

- Reassembly: Enough attention has been given to each bolt and retaining clip before reinstating the hub assembly making sure they have been sufficiently tight to avoid unnecessary problems. Continue the process by connecting the brake calipers and wheels whilst also taking care of the needed torque specifications.

- Testing: Once the replacement is complete, proceed to undertake a comprehensive road test to check the wheel bearing for any irregular sounds or vibrations during its operation.

There are basic guidelines and measures that one can follow but they may change from one vehicle to another. For precise and thorough guidance on your car, consider referring to the car’s repair manual or compounding an expert mechanic.

A step-by-step guide to replacing a wheel bearing

I will give you a concise guide on how to perform a wheel bearing replacement:

- Gather the Necessary Tools: Before you begin, please prepare the following tools:

- Jack and Jack stands

- Lug wrench

- Socket set

- Torque wrench

- Wheel bearing removal tool

- Wheel bearing installation tool

- Grease

- Secure the Vehicle: Confirm that the gear is in the neutral position. Proceed to Apply the pinch screw for the gear. Proceed by removing the lug nut for the wheel for which the bearing is required.

- Lift the Vehicle: Lift the vehicle with the use of a lifting mechanism. Once the moving part has been lifted, make use of the stand mechanism and place it comfortably on the vehicle.

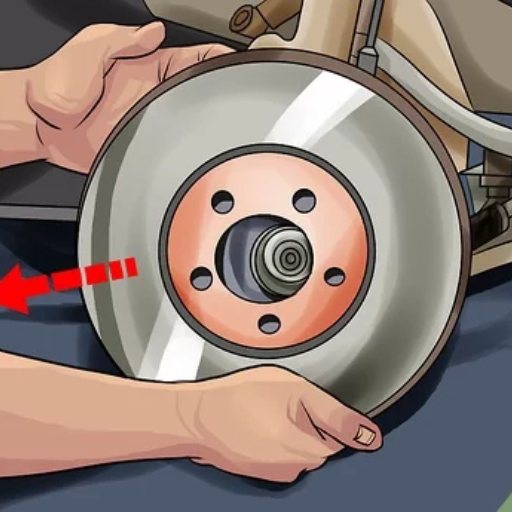

- Remove the Wheel: Proceed to take out the screws and remove the wheels from the vehicle.

- Access the Wheel Bearing: There might be other things in the way of reaching the wheel bearing, components such as brake calipers and brake discs. It is advised to have a look at the repair manual of the vehicle for more details on the removal process.

- Remove the Old Wheel Bearing: Using proper tools makes it easy to take out the exchange wheel bearing that is located in a closed hub. In some cases, there might be a retainer clip that needs to be removed or a tool pressed to remove the bearing.

- Install the New Wheel Bearing: For a more suitable fit for the bearing, grease it properly on the inside of the wheel. Then, grip the install tool and by using it, press the bearing into the part of the wheel hub. In the end, make sure the wedge is tightly placed.

- Reassemble the Components: Any extra components like brake calipers or discs that were detached earlier may be reattached.

- Install the Wheel: Place the wheel back on the wheel hub and hand-tighten the lug nuts.

- Lower the Vehicle: Jack the car and return it to the ground. After the car has touched the ground, use a torque wrench to ensure that the lug nuts are fastened according to the manufacturer’s recommendation.

- Testing: Finally, go on a test drive to check the new wheel bearing and make sure it has no unusual noise or vibrations while operating.

It is important to note that the specific steps and techniques may vary depending on the vehicle’s make and model. It is recommended to consult the vehicle’s repair manual or seek guidance from a qualified mechanic for detailed instructions specific to your vehicle.

Tools needed for wheel bearing replacement

this is the list of mandatory equipment that is required in order to be successful in a wheel bearing replacement:

- Jack and jack stands: These allow the vehicle to be raised safely and secured when in a vertical position.

- Socket set: A set of sockets in various sizes will be required to loosen the bolts holding the wheel hub assembly.

- Torque wrench: A torque wrench tightens bolts such that the set values are in respect to the manufacturer’s specifications.

- Bearing puller: A bearing puller is a tool that aids in the removal of the old wheel bearing from the hub.

- Bearing packer: This tool is used to pack a new wheel bearing with grease.

- Rubber mallet: It is also advisable to have a rubber mallet that can be used when knocking in or out the wheel hub assembly.

- Pliers: Pliers will be useful for removing and fitting retaining clips or snap rings.

- Wire brush and cleaning solvent: These are required in the cleaning of the wheel hub assembly and also for removing dirt and old grease.

- Grease and grease gun: It is important to use good quality grease with a grease gun when fitting the new wheel bearing.

- Safety equipment: It is essential to wear safety glasses and gloves while doing any repairs.

The wheel bearings are very easy to replace due to the ready market for bearing replacement machines and tools.

Common mistakes to avoid when replacing wheel bearings

Pour les professionnels de l’axe volontaire de l’industrie, il existe des erreurs comunes à éviter lors de la procédure de remplacement de roulements d’axes. Avoiding such interventions, you can be assured that the repair work will be executed correctly and will last. A few of these factors are addressed below.:

- Insufficient cleaning: Noncleaning the wheel hub and spindle properly before putting the new bearing could result in bearing failure or damage too soon. In order to provide a fresh contact surface to the new bearing, remove any dirt, rust, or old grease.

- Incorrect torque: A wheel bearing that is kept too loose or too tight can produce unnecessary friction or even wobbling of the wheel. Ensure that you don’t forget to check the torque which can aid in loosening the wheel properly.

- Lack of lubrication: For proper function, the new wheel bearing has to be coated with grease. Hence, ensuring the grease is applied properly without lumps being left behind is very important to avoid undesired bearing behavior.

- Neglecting safety precautions: Consider the size of car parts that are dealt with in the process of replacing the wheel bearings, goggles, and gloves that have to be worn to avoid injuries.

In order to always increase the effectiveness of your vehicle while providing its safety during the replacement of the wheel bearing, all you have to do is refrain from common mistakes and take the right steps.

Can I replace a wheel bearing myself, or should I hire a technician?

Based on my knowledge of the industry, replacing a wheel bearing on your own or employing a technician is determined by a few factors such as your know-how, tools available to you, and ease in performing car repairs. Though some do-it-yourself enthusiasts, that is, individuals who have the necessary mechanical skills and experience,e replace wheel bearings, we should still take into account the following aspects:

In summary, one must evaluate one’s skills, comfort level, and available resources prior to making a choice. However, if the proper resources and knowledge are at hand, and the do-it-yourself way is appealing, then a DIY mode can be advantageous. On the contrary, if one is inexperienced or if the task appears too sophisticated, it would be wise to let a qualified technician replace the wheel bearings so that the task is performed safely and correctly.

Pros and cons of DIY wheel bearing replacement

let’s attempt to answer briefly the question of the advantages and disadvantages of undertaking the replacement of the wheel bearings oneself:

Pros of DIY Wheel Bearing Replacement:

- Cost Savings: Replacing the part on your own can be very cost-effective because you do not incur any labor costs.

- Learning Opportunity: You can attempt new tasks and prove to yourself that you are capable of doing something else.

- Convenience: You can tackle the job whenever you think it is most convenient for you.

Cons of DIY Wheel Bearing Replacement:

- Complexity: The task of Wheel bearing replacement is demanding as it involves specialized tools and technical intervention.

- Time and Effort: Repairs carried out through DIY are more time-consuming and strenuous particularly if one is inexperienced or faces unforeseen circumstances.

- Risk of Error: A damaged part also results from the unfastening of the upper or lower post, which is also a case of improper torque or improper installation.

Given the above, it is important to first examine how skilled, comfortable, and well-equipped one is in order to determine whether a DIY wheel bearing replacement is worth the effort. If someone is self-assured and possesses the right equipment and expertise, landing on DIY might be a great benefit. But if you do not have the required skill sets or the repair seems quite intricate, you might as well pass the wheel bearing replacement to an expert so that the replacement has been performed correctly and securely.

When is it best to hire a professional for wheel bearing replacement?

What we can say is that they have specialist training, so it is best to leave the wheel bearing replacement in the following scenarios to a professional:

- Lack of Experience: If you know little about the auto repair field, then hiring an expert is preferred. For professionals, replacing wheel bearings is easy because it requires some skills and experience, and the job can be done perfectly.

- Complex Repair: Finally, if you suspect the wheel bearing replacement to be a tad too complicated or if it requires specialized equipment, you should hand over the task to a professional. In this way, you minimize the possibility of errors or create further damage.

- Time Constraints: In the event that time is not on your side, or you cannot afford the luxury of time, engaging a professional will be of great value to you. They are professional technicians who have experience in replacing the wheel bearing, thus helping the client get back on the road in no time.

- Safety Concerns: If you envisage having problems with the repair such as whether you can perform the repair perfectly, the best solution is to hire a professional since they will be more than able to replace your wheel bearings correctly, therefore ensuring that their aftermath does not result in the possibility of crashes from bad installations.

Handing your wheel bearing housing replacement to a qualified technician ensures one of the repair tacts, for it will be performed with all the paraphernalia of professionalism.

Cost comparisons: DIY vs. hiring a technician

let’s compare the cost of a Do It Yourself (DIY) wheel bearing replacement with that of hiring a technician. Although Do It Yourself work (DIY) may appear cost-effective at first sight, there are other aspects that need to be taken into account.

DIY:

- Lower Initial Cost: Replacing the wheel hub bearing on your own means that you won’t have to pay the labor costs.

- Time and Effort: The practice of replacing bearings requires time, strength, and some clamps for holding.

- Skill and Knowledge: Accurate replacement means that you need to possess the necessary mechanical skills and knowledge to carry out that task.

Hiring a Technician:

- Professional Expertise: Technicians possess the knowledge and the skills necessary to perform wheel bearing replacement in an appropriate way and with great precision.

- Time and Convenience: In case this is the case, then you do not need to look for someone or beg your friends, hiring a technician will help you want to have done the job.

- Quality and Accuracy: As a rule, professionals practice the correct use of parts and the installation and perfection of a given procedure, thus ensuring few complications in the future.

It is vital to consider the risks and challenges posed by Do it Yourself tasks against possible cost savings. Making a simple blunder while working on a DIY project can translate into an expensive repair or, worse still, put your personal safety at risk. As a general rule of thumb, it is better to seek guidance from an experienced professional to ensure that the task in question is performed in a safe and precise manner,r which will ultimately give you a sense of assurance for a long time.

What happens if I ignore a failing rear wheel bearing?

To begin with the repercussions of this with all the seriousness it demands, neglecting a malfunctioning rear wheel bearing puts at great risk not only the condition of the vehicle but also the driver and others on the road as well. Leaving the problem can end in a number of ways, including:

- Unsafe Driving Conditions: A malfunctioning rear wheel bearing detrimentally affects the management of a vehicle’s stability, thus making a vehicle difficult to steer. The risk of unforeseen loss of control and wrecks, among other accidents, can easily arise as a consequence.

- Further Damage to the Vehicle: As I said, due to force, different elements, such as suspension systems, are prone to breakage or wear in the long run if a luminous bearing goes unfixed for as long as one wishes. This can quickly escalate to bigger problems and pose a greater cost, however the bigger problem is that it leaves the vehicle unable to move.

- Increased Repair Costs: Choosing to drive with a luminous bearing holding axle and hub casters unfixed lends itself to multiple stresses being placed on the axle over time. Making repair costs more expensive in the future once other parts, such as the stern of the vehicle, begin to break as well.

- Excessive Tire Wear: A broken bearing also means the force on the shaft applying equal force on the wash is gone, shifting the contact center of the tire, hence making a bearing faulty when excessive force is placed, but broken bearings do break, thus end up loosening themselves over time resulting in greater contact when excessive force is applied making tires need to be replaced often due to significant wear over time.

To conclude, neglect of a worsening rear wheel bearing will ultimately lead to dire consequences in regard to vehicle performance, safety, and finances. Always make it a point to fix the problem sooner rather than later by speaking to an expert so that the mistake doesn’t happen again, allowing you to have peace of mind with a very well-maintained vehicle.

Consequences of driving with a bad wheel bearing

Let’s talk about the repercussions of operating a vehicle with a faulty wheel bearing. According to ‘Cat’s Garage’ and a lot of other blogs, the moment when a rear wheel bearing fails and is neglected has great repercussions on motor functions, vehicle safety, and expenses. Now, here three of them are to consider:

- Handling and Control Issues: The stability and turn control of your vehicle are poor when there is damage to your wheel bearings, which leads to a compromised ability to perform the best maneuvers over time. This can be quite hazardous during critical situations that arise because one has to respond quickly or forcefully change direction.

- Increased Risk of Accidents: This impaired handling with some cornering movement, plus the fact that the wheel could be moving in an uncontrolled manner, means that it is much easier for an accident to occur. A wheel bearing can contribute to the mass of the vehicle, and once this mass gets out of hand, keeping control of the vehicle becomes hard, and it is particularly a big problem in heavy rain.

- Excessive Tire Wear: The failure of your rear wheel bearing could leave you with unevenly worn-out tires, which can cause your tires to wear out quicker than they should, and that would then mean having to replace the tires with newer ones. This increases expenses in the long run and also puts the overall performance and safety of the automobile into jeopardy.

- Costly Repairs: Allowing for a bearing to destroy itself only permits damage to be donated to other parts, for example, the axle or even the hub assembly. This becomes a route for getting more expensive and larger repairs down the road in the picture. Dealing with the cause of all problems the right way should prevent acquiring more expenses and repairing an automobile in a more effective manner.

Undoubtedly, one must grasp the ramifications of driving with a faulty wheel bearing and remedy the situation so as to not compromise the performance and safety of the vehicle or pose any risk to personal finances. Engaging a qualified professional and obtaining necessary repairs on time is critical in order to have peace of mind as well as a smoothly operating vehicle.

How a damaged wheel bearing can affect your vehicle’s performance

Gaining an understanding of how a broken wheel bearing can affect your vehicle’s performance as an industry expert will help you ensure its maximum functionality and safety. A compromised wheel bearing will lead to the following issues which interfere with the performance of your automobile:

- Noise and Vibration: If you have an impaired or aged wheel bearing, then you might hear a scooping sound when you are turning the steering wheel or when the vehicle is at high speeds. You might also feel a vibration in the steering wheel or in the whole car. These signs may alter your driving experience as well as inform you that some wheel bearing has failed.

- Uneven Tire Wear: A worn-out wheel bearing can induce off-centered tires, which means that one side of the tire is more overwhelmed than the other. This not only shortens the lifespan of the tires, it also puts a negative impact on the traction and control your vehicle has meaning it would be harder to maintain stability while driving on the road.

- Alignment and Suspension Issues: Wheel maintenance is essential because if a wheel bearing starts to weaken, then the alignment of the car will be affected, as well as the suspension. If the tires of your car are not properly aligned, then there will be steering issues, which means you would have to steer harder, which would put increased pressure on the fuel, which would, in turn, consume it at a higher rate than usual while also causing more tires to wear down faster.

- Safety Concerns: One of the greatest concerns regarding wheel bearings is how they might heighten the chances of an accident. This might happen because as a wheel becomes looser, the bearing starts to become weaker, and that wheel might eventually get stuck while driving, which will make the car uncontrollable. This can be very dangerous especially if the car is speeding or is in a precarious situation.

Timely attention is required towards wheel bearing concerns so as to maintain the functionality, safety of the vehicle, and peace of mind while driving. It is imperative to consult with an accomplished technician and then either repair or replace the damaged wheel bearing, as it will save the driver from any further damage, expensive repairs, and threats to safety.

Potential costs of neglecting a wheel bearing issue

A wheel bearing issue is a problem that, cannot be ignored as it leads to several expenditures that are in addition to the basic cost of repairing or replacing the part. Here are some potential costs of neglecting a wheel bearing issue:

- Safety Hazards: Allowing a failing wheel bearing to go unchecked certainly puts your safety at risk. If a bearing is to fail, it may cause the wheel to seize or lock up whilst in motion, which will then make it impossible for the operator to maintain control. This is very worrying, especially at high speeds during critical moments of driving.

- Increased Repair Costs: A failing wheel bearing can be the cause of considerable aggression, which may, with time, damage other components of the suspension system, hence the need for repair work to be done on the damaged components, such as the loss of the carrier or spindle. These repairs may tend to be more severe and cost-consuming than early treatment of wheel bearing failure.

- Tire Wear and Alignment Problems: Worn-out wheel bearings can modify the positioning of wheels due to their equal positioning, hence enhancing the rate of wear on the tires. The rate of tire wear is detrimental not only to the quality and durability of the tire but also to the cost of having to replace worn-out tires earlier than expected.

- Reduced Fuel Efficiency: A defective wheel bearing will eventually cause a more tedious effort due to increased resistance on the wheel. Due to the extra workload placed, it will only be expected that over time, the fuel efficiency will decrease, which will eventually result in a larger expense at the fuel gauge.

Taking care of wheel bearing problems immediately can save you these kinds of costs and also be sure that the performance, safety, and lifespan of your vehicle is well catered for. Consulting a certified repairer and having the affected wheel bearing either mended or replaced is wise for the reliability and safety of your vehicle as well as your mind while driving.

Are there any warranties or guarantees on wheel bearing replacement?

Please keep in mind that the limitations stated above about seam welding are founded on what is known as the shortage of standard testing and analysis in the automotive manufacturing industry. This was rather well explained in the presentation provided above. There is no single agreement in the industry or external associations that states how performance testing should be done or which parameters should be measured. Warranties and guarantees on the replacement of wheel bearings are therefore subject to the particular auto repair service or manufacturer, among other factors, such as auto shops. Some auto repair shops do, in fact, cover all of their services under warranty. It is important for the auto owner to ask the auto shop about the warranty before replacing the wheel bearing. Limitations of coverage, exclusion of parts, and warranty period must all be stated and understood. Moreover, the brands and the specific products determine whether wheel bearings are warranted or not. The auto repair service provider and the auto repair shop serve as channels through which the car owner can make an informed decision after reviewing the warranty information. Automatically, I know, purchasing a car that comes with a warranty is rational, however, the thought process involved in replacing the car’s wheel-bearing assembly remains disregarded.

What to Look for in a Warranty for Wheel Bearing Replacement

In this instance, there are several important considerations that should be kept in mind so as to attain the broadest coverage possible when deciding on a warranty for replacing the wheel bearing. Take care of the following aspects:

- Length of Warranty: Does the warranty cover a specific time? The longer the warranty period, the more coverage and satisfaction it guarantees.

- Coverage for Parts and Labor: Make sure that the warranty includes both the replacement of the wheel bearing and the necessary repair work.

- Limitations and Exclusions: Examine the warranty provisions in detail for any limitations or exclusions that may impact the coverage. This could include things like mileage restrictions or certain circumstances which can void the warranty.

- Manufacturer’s Warranty: Do not forget to ask about the warranty offered by the wheel bearing manufacturer as well. The manufacturers of particular products have different warranty conditions; hence, it is necessary to know what is covered.

Taking these elements into account and conversations with your auto repair service provider, you have the opportunity to make an educated selection and obtain a guarantee for your wheel bearing replacement that offers complete and satisfactory coverage for your investment.

Understanding your rights as a consumer regarding auto repair services

Being knowledgeable about your rights when it comes to auto repair services is critical for you. Such knowledge can also guarantee effective repair when problems arise with your wheel bearings. There are a few things worth noting:

- The Right to Transparency: It is the prerogative of every customer to understand how an auto repair service works. This means being provided information such as how the wheel bearing would be replaced, costs involved, and all the guarantees that come with the service.

- The Right to Quality Workmanship: Customers have the right to demand good service after giving away their cars in an auto repair service center. This means the job should be done properly and without being careless as the repair must be done as per industrial standards.

- The Right to a Written Estimate: All customers should be able to comprehend a written estimate of the wheel bearings before replacing them. All estimates should include how much the parts would be as well as how much labor would be so that the customer knows how much the repair will cost in total.

- The Right to Warranty Coverage: Always confirm whether the auto repair service backs the wheel bearing replacement by any warranty. Knowing what the warranty supports you for will save you from critical failures after a repair which includes breakdowns or defaults from the auto repair service.

I recommend knowing your rights prior to visiting wheel bearing auto repair services so as to assist you in making wise decisions as to the care and repairs of your car. Always feel free to ask your service provider if something is not well understood.

How to choose a reliable auto repair service for wheel bearing issues

An industry expert would be the person who needs to choose a reliable auto repair service for wheel bearing problems after great scrutiny and research. Here are some guidelines that one needs to look into when choosing an auto repair service:

- Reputation and Experience: Bearing repairs are sometimes undertaken by general auto service rather than specialist facilities. This, however, is not the best practice and should be shunned at all costs. It is vitally important to ask for past experience and reputation affecting the service lock. The best way is contacting a few previous clients as they seek superior quality goods or headings.

- Certifications and Credentials: Not every wheel bearing repair shop can serve you with exactly what you need. It is essential to check if the technicians or mechanics working there have relevant training and certification. Such credentials can be easily issued by honorable organizations like Automotive Service Excellence.

- Quality of Equipment and Parts: When coming to serviced PTY LTD head office as well as repair facilities it is important to raise some clear questions about the quality of parts and equipment the workshop is planning on using. For example, it would be reasonable to ask whether they are going to use OEM parts since they are specifically made for use in a certain product or vehicle line.

- Transparent Pricing and Estimates: On other occasions, for the first time visiting a garage, wheels recur to fully ine lavishing with a lever in one hand and an auto repair manual in the other. Thus, these experts have firsthand experience dealing with alarming customers. Thus, Lynn Henry, being a master of such business, stresses auto repair services, quoting publications and assistance practices between broken modulated prices.

- Warranty and Guarantees: Another equally important aspect is whether or not the company provides clients with sufficient guarantees regarding axle shaft repairs. It definitely is not pleasant to work with this kind of people since this practice shows that the company has no generous tendency, which leads to savings.

- Customer Service and Communication: Focus on the level of customer service and communication the repair service offers. Reputable service staff will answer equally to the customer’s service, elaborate on the scope of the work, and respond to every question posed to them.

After considering all these details, you can now make an informed selection on which car restoration service to consult for your wheel-bearing problems. Remember that quality, reputation, as well as reading material, and discussing care protocols are critical to keeping the vehicle in the best possible condition always.

Reference

- Kelley Blue Book – Wheel Bearing Replacement Prices & Cost Estimates

- J.D. Power – How Much Does It Cost To Replace Wheel Bearings?

- AutoZone – How Much Does a Wheel Bearing Replacement Cost?

Frequently Asked Questions (FAQs)

Q: How much does it cost to replace a rear wheel bearing?

A: The cost to replace a wheel bearing can vary widely depending on the make and model of your vehicle, with prices typically ranging from $300 to $800, including parts and labor.

Q: Do I need to replace the front wheel bearing at the same time?

A: While it’s not necessary to replace the front wheel bearing simultaneously if one is worn out, it’s a good idea to inspect the other bearings, as they may also need replacing soon.

Q: What factors affect the cost of replacing a wheel bearing?

A: Factors that affect the cost include the type of vehicle, whether the bearings are sealed or require additional work to access, labor costs in your area, and if any additional components like brake pads or rotors need to be serviced.

Q: How can I tell if my wheel bearing needs to be replaced?

A: Signs that your wheel bearing is going include a grinding noise when driving, uneven tire wear, vibrations in the steering wheel, or a loose wheel. If you suspect an issue, it’s best to have it checked by a professional.

Q: Is it safe to drive with a worn wheel bearing?

A: Driving with a worn wheel bearing can be dangerous as it can lead to wheel failure. If you notice symptoms of a failing bearing, it’s crucial to address the issue promptly.

Q: Can I replace just one wheel bearing, or should I replace them all?

A: While you can replace one wheel bearing if one is worn out, it’s often recommended to replace the other bearings on that axle to maintain balance and performance.

Q: What is included in the labor to replace a wheel bearing?

A: Labor to replace a wheel bearing typically includes the removal of the wheel, brake components, and hub assembly, as well as the installation of the new bearing and reassembly of the wheel assembly.

Q: How long does it take to replace a wheel bearing?

A: The process of replacing a wheel bearing usually takes around 1 to 2 hours, depending on the vehicle and the technician’s experience.

Q: Will replacing my wheel bearings affect my new car warranty?

A: Replacing wheel bearings on a new car should not void your warranty, provided the work is done by a certified technician and follows the manufacturer’s guidelines.

Q: How can I get a free detailed estimate for wheel bearing replacement?

A: Many auto repair shops in your area offer free estimates for services like bearing replacement. You can call local shops or check their websites for online estimate tools.