Balancing and twisting – these two notions might seem to be at odds with each other, but today`s blog will help you explore how they come together in an engine`s gearbox. This post will surely resonate with mechanical engineers as well as automotive enthusiasts; however, even a general audience can enjoy the in-depth knowledge of these components of a transmission system.

The purpose of this blog is to introduce the mechanics behind the different kinds of bearings, the benefits they have, and their applications in the engineering industry. To start off, we have ball bearings and roller bearings – while the former is utilized to increase rotation, the latter ensures the transmission system can withstand heavy loads effortlessly. Features, uses and how different types of bearings can help improve a transmission system are sure to be covered in this blog, with some of the topics being lower torque requirements, friction Reduction, and Stability.

Challenges like noise and vibrations are something that can hinder the performance of automatic transmission bearings, but don’t worry! This piece is also going to help you grasp how to repair and service these automatic transmission bearings effortlessly. On the other hand, this guide will make sure you have the knowledge on how to replace an engine gearbox that’s faulty by pinpointing the signs of failure.

Ending off, this article will be a guide on why Torrington bearings are more desirable in some applications compared to other kinds of bearings while at the same time showcasing some of its target key features and advantages.

In this article, a clear understanding and appreciation of how bearings in transmission systems work will be unveiled, allowing us to smoothly operate intricate systems.

So, let’s jump in and go on this exhilarating exploration of gearbox bearings, shall we?

What Are the Different Types of Bearings Used in Transmissions?

In this case, let’s consider the bearings that aid in sound management and smooth transmission of high speeds. From ball bearings to roller and needle bearings, so many types of frames have their unique advantages over the other and are made to withstand certain loads and conditions. The moment you realize there is a variety of bearings, you will start paying attention to their intricacies and distinct purposes, which, in turn, will allow you to fully understand the importance of transmission systems and their distinct interconnected workings. As a result, let’s begin this voyage into the gearbox bearings and more!

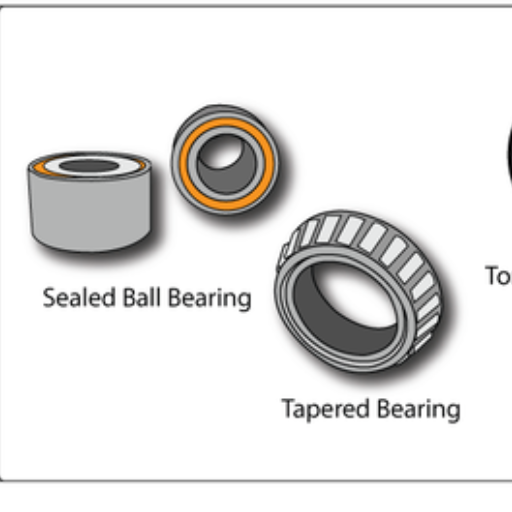

Exploring Ball Bearings in Transmission Systems

let’s delve into the world of ball bearings and their pivotal role in transmission systems. One can articulate a strong case for ball bearings as they are one of the most essential parts of gearboxes, and they aid in decreasing friction for rotation. These types of bearings consist of hardened steel balls fitted between an inner and outer race, which help with power transfer by decreasing contact area. With ball bearings, it is always the better option to have rolling elements rather than sliding surfaces; it changes the working towards greater efficiency, lesser wear and tear, and increased strength. Due to the volume, low friction, and other traits, these are best suited for many types of use in transfer systems, i.e., manual and automatic gearboxes. The instant detailed understanding of the complexities of ball bearings gives us the knowledge of their dynamic features and helps engineers as well as enthusiasts alike to have a comprehensive understanding with respect to making the gearbox perform optimally. Now, let’s continue and move along deeper into the creative world of ball bearings in transmission systems, as it is captivating.

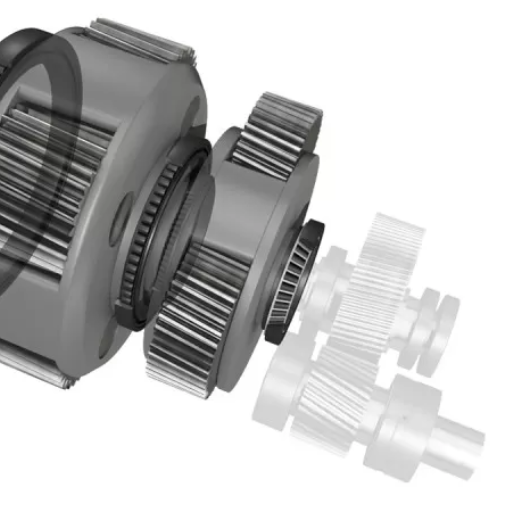

The Role of Roller Bearings in Gearboxes

In this piece, we shall look closely at one area in which the author possesses vast knowledge: the application of roller bearings in gearboxes. Roller bearings are the most delicate parts which interact with the gearboxes and are critical to the proper operation of the gearboxes. Roller bearings reduce friction between the gears and rotating shafts, allowing for smooth rotation of the gears at low resistance. The structural integrity and longevity of the gearbox are also augmented as roller bearings allow the loads to be transmitted over a larger coverage area. They are made in several forms like cylindrical, tapered, and needle bearings, which are suited for different types of gearboxes. With this knowledge, engineers and other enthusiasts can appreciate the importance of roller bearings in gearboxes and, as such, make requisite changes to better the performance, which, in the end, perfectly aligns with the goal of any seeking power sources. Therefore, without further ado, let us embark on this riveting and thrilling journey of exploring roller bearings in transmission systems.

Understanding Needle Bearings and Their Applications

Needle bearings are significant in transmission systems and serve specific uses by providing exceptional benefits. According to industry experts, These bearings are typified by slender, elongated cylindrical forms with a high aspect ratio. Due to their shape, needle bearings are perfect for situations where there are constraints on the radial dimensions, but a high load-carrying capacity is needed. This makes them particularly suitable for gearboxes, which have limited space but heavy loads. The factors base of needle roller bearings helps radial and axial loads, which results in smooth power transmission, decreased friction, and better gearbox efficiency. Moreover, in automotive, industrial, or other types of transmission systems, having needle bearings is essential for achieving a reasonable level of efficiency, durability, and smooth functioning, as it is very dependable.

How Do Transmission Bearings Enhance Performance?

Transmission ball bearings, enhance the performance of a multitude of systems. They provide efficiency, strength, and smooth functioning of gearboxes and transmission units. A short answer to the question, “How do transmission bearings bring in improved performance?” is as follows.

- Reducing Friction with Tapered Roller Bearings: This type of bearing allows for the Minimization of friction and maximizes energy transfer. Absent all of them, tapered roller bearings are designed to minimize friction and maximize energy transfer in gearboxes. Because of their step-like configuration, loads applied to the bearing are evenly distributed, and the frictional forces present in the contact are minimal, pooling to equilibrium the working efficiency of power transmission.

- Improving Torque Transfer in Automatic Transmissions: Usual transmission bearings, in the case of automatic transmission, perform multiple purposes, including those of torque transfer devices. They ease the adjusting forces acting in the automatic transmission caused by multiple functioning parameters by making the rotation smooth and reliable, which is reciprocated by accurate gear shifting.

- Maintaining Stability with Proper Preload: A properly set preload on transmission bearings is very essential for stability and reduced unwanted vibrations in the system. It promotes the smooth functioning of the system and, therefore, increases the working life of the gearbox components.

Achieving effective power transmission as well as less friction, increased lifespan, and improved operational efficiency can be realized in the gear and gearbox systems by the use of self-aligned transmission bearings of high quality and energy-efficient design.

Reducing Friction with Tapered Roller Bearings

a typology that proposes a technological solution for better performance of transmission systems for any machine is the adoption of tapered roller bearings. The tapered roller bearing is a bearing type that combines both radial and axial load applications, so it is efficient in areas or machines where friction should be reduced. Tapered roller bearings consist of an inner ring and an outer ring, which are frustums in shape. Tapered rollers are installed between the two rings. This type of design allows load to be well distributed between the two rings thereby reducing frictional forces hence a higher efficiency in power transmission. Tapered roller bearings, when applied in gearbox and transmission systems, say there is a better manner of transferring torque, less friction being generated, increased lifetime, and even efficiency of all the mentioned systems when looked at globally. The tapered roller bearing’s elegance and performance make it one of the most important features that enhance the performance of automatic transmissions, making them work seamlessly.

Improving Torque Transfer in Automatic Transmissions

let’s start by exploring how tapered roller bearings enhance torque transfer in automatic transmissions. These are high-performance bearings that are created to work in the harsh environments found within gearbox and transmission units. Manufacturers have introduced tapered roller bearings, which come with several significant benefits that enable enhanced torque transfer and transmission efficiency.

- Improved Torque Transfer: The bearing design employs tapered rollers, which are robust and possess good load strength, hence efficiently transferring torque within the transmission system. Additionally, the bearings possess dynamic features enhancing smooth power on and off while minimizing loss of energy while also maximizing system performance.

- Reduced Friction: A properly designed tapered roller bearing helps to end up with reduced friction, minimizing the power lost during torque transfer between components. This reduction in friction resistance leads to better transmission efficiency and wider performance and fuel economy ranges.

- Enhanced Durability: The construction of tapered roller bearings is such that they can withstand extreme conditions and high loads, which makes them ideal for automatic transmission environments. Their strength and durability would allow them to maintain consistent performance and longevity under heavy work conditions.

Installing tapered roller bearings into automatic transmission gives manufacturers better torque transfer, less friction, longer lifespan, and higher operational efficiency. These specially designed dynamic bearings are critical to the efficient functioning of automatic transmissions, ensuring optimal power transfer.

Maintaining Stability with Proper Preload

adequate preload is necessary to maintain the stiffness of automatic transmission bearings. Preload, labeled so, is the intentional application of an axial force to the bearings in order to achieve contact with the rolling elements and the raceways. Bearing in mind the right preload, a number of automatic transmission bearings-related problems can be solved quite well:

- Wear and Tear in High-Stress Environments: Preload assists in load dispersion around the bearings while avoiding its undue concentration that may cause stress, allowing them to have a longer lifespan whilst ensuring effective operation even under demanding situations.

- Noise and Vibration Issues: Over-vibration and noise in the transmission system can be attributed to insufficient or excessive preload. This can be avoided by means of the right amount of preload, which gives the bearings their optimal still operational position and restricts motions that would otherwise affect the smoothness and silence of the operations.

In order to find and replace damaged gearbox bearings, it must be to start to look for the signs of transmission bearing failure, these include One or two unusual noise, rough shifting or even leaks. When replacing input shaft bearings, it is necessary to follow a sequence that includes proper disassembly, inspection, and installation. Also, choosing appropriate repair items meant for the maintenance of the gears is fundamental.

In certain industry segments, Torrington bearings have also been preferred because of their reliability. In the case of caged needle bearings, which fall under the umbrella of Torrington bearings, they are accompanied by advantages such as High load bearing capability and robust, compact design, which provides for the efficient transfer of power.

By taking into consideration the scope and importance of the proper preload, wear and tear, bearing noise and vibration, detection and replacements of faulty gearbox bearings, and the importance of Torrington bearings, automatic transmission systems perform and last longer in the hands of industry professionals.

What Challenges Are Associated with Automatic Transmission Bearings?

If you are in the auto industry, you must understand the problems facing automatic transmission bearings. Indeed, there are some key issues to be aware of. Of investigative significance is the issue of wear and tear in high-stress environments. It is a known fact that Automatic transmission bearings are equipped with superimposed high forces as well as friction, and therefore, over a period of time, they are bound to wear out and get damaged. Action on this challenge is improved by regular service and supervision for proper lubrication management to prevent excessive wear out.

Noise and vibration are other challenges for automatic transmission systems. Defective or obsolete transmission bearings may produce noise and vibrations, which may interfere with the normal functioning and comfort of the vehicle. It is good practice to deal with noise or vibration problems immediately so as to avoid the transmission system destruction, which may cause abnormal, tedious operation.

By doing so, professionals in the field can complement such automatic transmissions, ensuring smooth power transfer devices that can function properly.

Addressing Wear and Tear in High-Stress Environments

When it comes to automatic transmission systems, dealing with wear and tear in difficult situations is extremely important. There is also a pressing need to quickly tackle any noise or vibration problems to mitigate the risk of further damage and maintain quiet and smooth functioning. In response to the above questions – here is a brief response:

- How to Identify and Replace Faulty Gearbox Bearings?

- Crafting phrases like noise, vibration, or trouble shifting gears are key indicators of a beginning bearing failure, and overly scrutinizing any of those aspects can even predict a bearing failure. Once it is certain that a bearing failure has occurred, the techniques associated with replacing the bearing also have to be courteously identified as they vary from the type of bearing to the location of the assembly.

- Why Are Torrington Bearings Preferred in Certain Applications?

- Başta torri ngton rulmanları ki olduğunun caged iğne rulmanları belli başlı konstruksyonlara axial ve radial yüksek yükleri kaldırabilmesinden ötürü mekanizmaya içine yerleştirilmektedir. Furthermore, the load capacity offered by them is extremely high so high stress levels in the transmission system are easily handled So in a short time, it becomes stress free for those bearings.

Through the use of bear2ngs such as the Torrington bearings in combination with taking suitable corrective actions like regular wear and tear assessments, drilling holes, and identifying malfunctioning gearbox bearings, professionals working in the industry will be best able to ensure the functionality and durability of automatic transmission systems in workstation environments with high levels of stress.

Solutions for Noise and Vibration Issues

Gearbox bearings experience noise and vibration issues, which, if not appropriately mitigated, can compromise the performance and reliability of automatic transmission systems. The long-term use and general functioning of the transmission system can be increased by industry professionals identifying and tackling these concerns in professional settings. In this article, we will analyze ways to resolve these issues.

There are a number of important steps one must follow while dealing with noise and vibration problems in the gearbox bearings of a gearbox:

- Identify and diagnose the issue: Inspect the noise or vibration source more closely by checking the input shaft bearings, output shaft bearings, or other elements together with the gearbox.

- Replace faulty bearings: In the case of a bearing failure, the damaged bearing should be replaced immediately since it is no longer serviceable. In the case of replacement of bearings, it is recommended to follow the manufacturer’s instructions and use adequate quality bearings for the application.

- Choose the right repair products: It is wise to use Torrington bearings as repair products since they are very strong, durable, and reliable. They are high radial and axial load bearings that exceed design limits and hence have exceptional applications.

Engineers are capable of achieving the best performance, reliability, and longevity of automatic transmission systems by addressing the noise and vibration challenges revolving around gearbox bearings through the right repair products.

As for now, let’s see how it’s done to diagnose and replace defective gearbox bearings and the unique properties that let Torrington bearings thrive in certain applications.

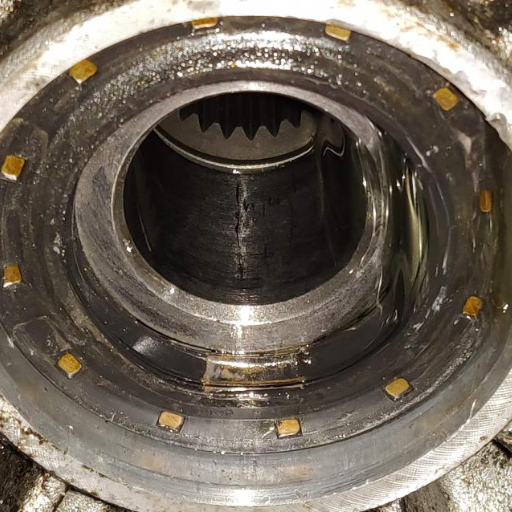

How to Identify and Replace Faulty Gearbox Bearings?

It is your responsibility to locate the defective components, replace the gearbox bearings, and ensure the gearbox design ratio is optimum for the performance and long life span of the automatic transmission systems. Here are several technical procedures to consider as follows:

- Inspect for Unusual Noise and Vibration: Inspect the prompt gearbox and gearbox housing for any unusual noise or vibrations. These may be signs of bearing failure.

- Check for Excessive Play: Apply some force and try to move the input shaft and then the output shaft lightly back and forth. Play or looseness may indicate worn-out bearings.

- Look for Leaks and Contamination: Check the area around the gearbox for leaks or any indication of fluid contamination. Deteriorated seals or contaminated fluid can contribute to bearing failure.

- Remove and Replace Faulty Bearings: To do the replacement of the gearbox bearings, disassemble the gearbox as instructed by the manufacturer. Take care to remove the bearings that are worn down or damaged and replace them with others that are of the appropriate size and type.

Important to keep in mind gearbox bearing replacement involves a fair amount of technical skill and the use of specialized tools. If one is not confident in their skill set, it would be best to hire a certified expert.

It is through these steps that one is able to locate and replace the damaged gearbox bearings so as to guarantee the seamless use of the transmission system.

Signs of Transmission Bearing Failure

I will provide a brief answer to the question, “What are the signs of transmission bearing failure?” in terms of transmission bearing failure.

Recognizing the symptoms of transmission-bearing failure is essential in keeping your gearbox working properly. Watch for the following signs that may indicate a problem with the bearings:

- Unusual Noises: You will have to check the bearing if you hear unusual and abnormal grinding, whining, and rumbling sounds coming from the gearbox. Those sounds may be tales of worn or faulty bearings.

- Vibrations: Unusual movements experienced while driving or shifting, e.g., gears, may also be a sign of bearing failure. The movements may be due to misaligned or worn bearings in the gearbox.

- Difficulty in Shifting Gears: Grinding and shifting gears for smooth transitions but failing to do so may be an indication of worn-out or damaged transmission bearings.

- Leaking Fluid: The presence of fluid leakage from the gearbox is cause for concern. Leaks may be caused by damaged seals as well as fluid contamination, which causes interference with the bearings.

One must not delay in seeking out a professional in the event that one observes any of the aforementioned signs so as to avoid severe gearbox and transmission damage. A professional is needed in this instance, due to the fact that replacing a gearbox bearing is an intricate endeavor.

Steps for Replacing Input Shaft Bearings

If an individual is considering the possibility of replacing input shaft bearings in a gearbox, what are the steps? Let me suggest some:

- Gearbox Disassembly: Start by taking the gearbox off the automobile and gently take the assembly apart to gain access to the input shaft bearings.

- Bearing Removal: Apply consideration and specialized tools to get rid of the old input shaft bearing for the first time. This could require putting pressure or using a bearing puller according to the design utilized.

- Cleaning and Inspection: All the components that are to be re-used should be cleaned thoroughly to the original specifications and mating surfaces, in addition to the original combinatory surface of the gearbox housing that has to be redeposited for any traces of wear or damage.

- Bearing Installation: This also comprises the change of the input shaft bearings that are to be fitted on the bushes assembly using the gearbox housing. Add suitable grease to ensure easier rotation than before.

- Gearbox Reassembly: This covers the reassembling of the gearbox where the settings, components, and torque that the manufacturers recommend are observed. Ensure that all the gears utilized and their components are enacted and set in the right orientation relative to each other.

- Testing and Quality Assurance: After the gearbox has been built again, it should be thoroughly tested to check on the issues related to whether the brace has the desirable functions and look into any potential problems it notices in detail. Check if the gear changes, if they make undesired sounds, and if they leak in a feeling.

If you focus on precision and attention to detail while following these processes, you can easily replace input shaft bearings in your gearbox and restore its functionality. But of course, for intricate gearbox repairs like this one, it is advisable to go to a professional or a gearbox specialist.

Choosing the Right Repair Products for Gearbox Maintenance

It is important as an industry expert to select the appropriate repair products that will enhance the performance and increase the lifespan of the gearbox. In some specific applications, Torrington Bearings are regarded as the best for their unique features and functionalities. The following are the reasons:

Advantages of Caged Needle Bearings:

- High Load Capacity: Caged needle bearings find their application in areas where there is a combination of heavy load along with moderate levels of vibration. These bearings are designed in such a way that they can endure not only high radial loads but also high axial loads.

- Compact Design: Due to their compact design, these bearings are particularly useful in areas with limited space, for example within gearboxes where performance would otherwise be impaired.

- Precise Operation: With caged needle bearings, accurate and smooth motion is maintained, which helps improve the efficiency and overall reliability of a gearbox.

Applications Requiring High Radial and Axial Loads:

- Automotive Transmissions: In Automotive Torrington Bearings A Broad Spectrum Of Applications Embracing Ferrite Applied ResearchAndDevelopmentGovernance promotion in transmission systems. They are now applied to Torrington Bearings that support a Pulley Bearing Along the Shaft’s peculiar functional purpose where substantial radial and axial load needs to be generated by the transmission system.

- Industrial Gearboxes: The entire changing apparatus, i.e., CTs showing Telescopic Torrington Bearings, of heavy machinery and industrial geared ones comprise Cromec Tolzier K Michalon and Torrington. If unaltered, the current trend would suggest that Torrington Bearings will outperform the competition in handling high loads combined with demanding operating conditions.

Letting gearbox maintenance professionals employ Torrington Bearings or caged needle bearings, assuring that any repairs and replacements made will stand up under heavy loads, vibrations, and harsh operating conditions.

Why Are Torrington Bearings Preferred in Certain Applications?

Torrington Bearings are recommended in certain applications as they have certain special attributes and performance qualities that are preferred. As an expert in the field, here’s what I believe helps Torrington Bearings stand out:

- High Load Capacity: Torrington Bearings are constructed for applications where exceptionally greater radial and axial loads need to be carried.

- Durability and Reliability: Due to their structure and materials, Torrington Bearings provide tremendous reliability and durability and can work with minimal failures even at extreme working environment conditions.

- Precise and Smooth Operation: Caged needle bearings, a sub-type of Torrington Bearings, ensure smooth and precise operation which boosts the efficiency and reliability of the gearboxes of the motors greatly.

- Wide Range of Applications: Torrington Bearings are widely used in numerous applications, including automotive transmissions and industrial gearboxes. The wide variety of capabilities to withstand extreme working conditions makes TORRINGTON bearings more economical.

Selecting Torrington Bearings for these applications offers gearbox maintenance, which means a significant performance boost owing to their excellent load capacity, durability, precision, and versatility – all crucial for use in robust settings.

Advantages of Caged Needle Bearings

caged needle bearings have an abundance of benefits that permit their use in a multitude of applications. Here are a number of the major benefits of caged needle bearings:

- High Load Capacity: Thanks to their capacity to take up radial and axial loads, caged needle bearings are suitable for many applications where high load-carrying capacity is paramount.

- Precise and Smooth Operation: Caged bearings reduce friction between moving parts, making operation precise and smooth; hence, maximum performance is achieved. This aids in increasing the performance and dependability of gearboxes and other machines.

- Durability and Reliability: Caged needle bearings possess great durability and reliability. They are designed to endure harsh working environments while still performing consistently as per the demand.

- Versatility: Due to their versatility, caged needle bearings are common in a lot of industries and applications. They are widely used in automotive and industrial gearboxes for their performance in extreme working environments.

Due to their remarkable load capacity, robustness, accuracy, and broad applicability, caged needle bearings are suitable for all industries that have to cope with difficult radial and axial loads and seek reliable and efficient performance.

Applications Requiring High Radial and Axial Loads

Having a strong understanding of this field, one can certainly say that machinery requirements such as high radial and axial loads are not rare since heavy-duty machinery tends to work in harsh environments, and industries like automotive, construction, agriculture, and manufacturing rely on these forces. Some interesting examples of applications which require high radial and axial loads are:

- Automotive Transmissions: The transformation of power in an automobile transmission system is accompanied by its radial and axial loads due to its constituent units. Such loads are effectively managed by caged needle bearings.

- Construction Equipment: Bulldozers, excavators, cranes, and other large-scale construction machines work in difficult harsh conditions and bear large loads. Caged needle bearings support and provide stability and reliability of such machines and many of their components.

- Industrial Gearboxes: Gearboxes are essential in most industrial operations, and they often receive high radial and axial loads while performing their power transmission function between different elements of their machinery. Caged needle bearings assist in better lubrication and less wear, thus improving the efficiency of operations.

- Agricultural Machinery: Tractors, combines, and harvesters are a few farm machinery that work in rough terrains and tough working conditions. These machines employ caged needle bearings in a number of its elements to resist the radial and axial loads produced when the machine operates.

In all such applications requiring high radial and axial loads as well as in caged needle, other bearings are critical for ensuring operational as well as structural aspects. This industry’s tool workers place a lot of trust in these bearings because of their remarkable ability to withstand many forces.

Reference

- An Overview of Engineering Bearings, Types, and Applications – This document provides a comprehensive overview of various types of bearings and their applications, including those in transmission systems.

- Research and applications of active bearings: A state-of-the-art review – This article reviews the latest research and applications of active bearings, which are relevant to transmission systems.

- A comprehensive review on self-powered smart bearings – This review discusses the advancements in smart bearings, including their role in data processing and wireless transmission.

Frequently Asked Questions (FAQs)

Q: What are the different types of bearings found in transmission systems?

A: Transmission systems commonly use roller and ball bearings, needle bearings, and plain bearings. Needle bearings consist of small needle-like rollers, while plain bearings offer low-friction support for rotary or sliding shafts. Each type serves a specific function to ensure the efficient operation of the transmission.

Q: How do bearings function in a manual transmission system?

A: In manual transmission systems, bearings play a crucial role by supporting transmission shafts and reducing friction as gears shift. Manual transmission bearings help in the smooth transfer of power from the engine to the output shaft, allowing for seamless gear changes.

Q: What is the significance of the output shaft bearing in a transmission system?

A: The output shaft bearing is vital for supporting the output shaft as it transfers torque from the transmission to the differential or driveshaft. It helps maintain alignment and reduces wear by minimizing friction and vibration.

Q: How are clutch bearings related to transmission systems?

A: Clutch bearings are integral to the operation of the clutch system within a transmission. They allow smooth engagement and disengagement of the clutch, facilitating the transfer of power between the engine and the transmission, especially in vehicles with manual transmissions.

Q: Why is it important to lubricate bearings in transmission systems?

A: Lubrication is critical for reducing friction and preventing wear in transmission bearings. Bearing grease or transmission fluid is used to maintain optimal performance and longevity of the bearings, ensuring smooth operation and preventing overheating.

Q: What role does a thrust washer play in a transmission system?

A: A thrust washer is used to absorb axial loads within a transmission system. It provides a smooth surface for rotation and helps maintain the alignment of components, preventing metal-to-metal contact that could lead to wear and damage.

Q: How do needle bearings differ from other types of bearings in transmission systems?

A: Needle bearings consist of small needle-like rollers that provide a large surface area for supporting radial loads in limited spaces. They offer high-speed capability and low-friction performance, making them suitable for specific areas within transmission systems where space is constrained.

Q: What should be considered when selecting bearings for transmission systems?

A: When selecting bearings, it’s crucial to check the vehicle manufacturer’s specifications to ensure compatibility with the system. Factors such as load capacity, speed rating, and environmental conditions should also be considered to choose the appropriate type of bearing.

Q: Are plain bearings suitable for high-speed applications in transmission systems?

A: Plain bearings can be suitable for high-speed applications, provided they are designed to handle such conditions. They offer low-friction support and can be engineered to meet specific performance requirements, although roller and ball bearings are more commonly used for high-speed applications.

Q: How does the differential relate to transmission bearings?

A: The differential is connected to the transmission output and requires bearings to support its operation. Bearings in the differential help manage the torque distribution to the wheels, ensuring smooth and efficient vehicle movement, especially during turns.