Ball bearings are very important parts of numerous mechanisms. They facilitate the reduction of friction, support the load, and provide smooth rotation. Machines and various household items all rely on these small but powerful devices. The article “Understanding Ball Bearings: Their Types and Functions” explains the concepts underlying ball bearing design, construction, and operation, describes its classification in more detail, and studies the areas where they can be used. This guide is useful for not only engineering aficionados but also other people who are interested in how things work. If you wish to understand the critical function that ball bearings have, this material will assist you.

What Are the Different Types of Bearings?

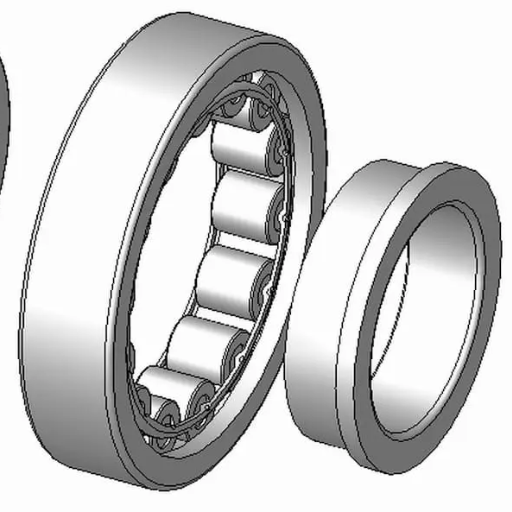

Bearings can be broadly classified into several categories based on their design and function. The most familiar kind of bearing is a ball bearing, which permits rotation with minimum friction and carries a radial and axial load; also, there are roller bearings which have to deal with heavyweight having cylindrical, tapered, or spherical rolls and, last but not least, needle bearings, which are like roller bearings but have long thin rolls better suited for confined spaces. Also, thrust bearings are structurally designed to withstand axial forces, and plain bearings do not have rolling parts and whose parts interact by sliding. That ensures optimal performance for all types of machines in various industries.

Understanding the Basics of Ball Bearings

it is important to understand how ball bearings work and their technicalities on a high level. Ball bearings are very useful and used in a lot of applications due to their outstanding design. As mentioned, each ball bearing has several parts, which comprise an inner ring, an outer ring, a ball set, and a cage that secures the balls. These rolling components ( the balls) minimize the friction of a surface in case of a rotating or linearly moving working element in order to facilitate the work. To begin with, here’s the deal:

- Load Types – Types of Loads – Ball Bearing is usually built to withstand two load types:

- Radial Loads – The resultant loads of the weight of a rotating wheel are perpendicular to the axis of rotation.

- Axial Loads – These loads are exerted parallel to the rotational shaft.

- Material Composition – The major component from which ball bearings are made is high-grade steel, like chrome steel. This alloy employs a strong, harsh, and wear-resistant steel. Materials such as ceramic or stainless steel may be utilized for specialized uses.

- Seals and Shields – A large number of ball -bearings are fitted with seals or shields to keep away involuntary entrance of dirt or moisture, which could result in a detriment to performance and operation over time.

- Precision Ratings – Each has been made with a different precision class, say, ABEC ratings, to meet certain conditions. If a medical or aerospace application is ever created that necessitates the use of higher precision bearings, then that’s highly fulfilling.

- Speed and Lubrication – Ball bearings have specific driven speeds. To help the bearings have large rotational speeds and low friction while in motion, proper lubrication, whether it’s oil or grease, is needed to create frictionless surfaces and reduce working temperatures, ensuring consistency and greater bearing life.

Ready to read more? I can explain to you specialty ball bearings or any system in which their use would be the most optimal. This would mean that one has an advanced understanding of the parameter, which is likely to help in selecting the most appropriate ball bearing for any application.

Exploring Roller Bearings and Their Applications

The text mentions the complexity that comes with the use of rotary systems, especially with the application of bearings. An even greater understanding comes from the practical side since it’s one thing to know how they work and yet a totally different thing to actually observe their proficiency in heavy load applications and friction reduction during rotation. Bearings are geometrically perfect as the load transfer is via cylindrical or tapered rolling elements, which makes them applicable to automotive, aerospace engineering, and industrial machinery. Consider the roller bearing application parameters such as the permissible load, speed of rotation, and site conditions. If you are facing a specific problem and would like to know how to solve it with the use of special applications, I can provide some useful hints.

When to Use Plain Bearings Over Others

plain bearings are most suitable for applications with a focus on simplicity, low cost, and acceptable durability. Such applications would be within a load and speed range that can accommodate the use of such bearings, or space limitations prevent the installation of more sophisticated bearing systems. Furthermore, their robust and low-maintenance construction enables plain bearings to perform well in dirty or corrosive environments. For heavy industrial use of plain bearings where there is a perpetual oscillating action or exposure to shock loads, their inherent resistance to galling or seizing will work well. I usually recommend plain bearings when quick operation or accurate control feature less prominently than ease of use and long life.

How to Choose the Right Type of Bearing for Your Needs

Various bearing types can be selected based on the kind of load they will be subjected to, system features, and operation conditions. Due to their higher load capacity, roller bearings are excellent for heavy asphalt radial loads. Ball bearings are usually the ideal option for applications that require limited operating speed with maximum accuracy. Depending on the design and application of the entire system, a plain bearing is ideal when space, component count, and simplicity are requirements. Take into account the bearing surroundings such as **temperature, the level of contamination, lubrication**… to select appropriate materials and design of the bearing. Selecting a bearing appropriate for the application will help obtain the expected performance and endurance.

Evaluating Load Capacities: Radial vs. Axial

Bearings load capacities are a subject matter that raises many questions, but let’s start with load types that your application will be subjected to – radial, axial, or combined radial and axial. In my experience, here’s how I break it down to make the best selection:

- Radial Load –This pertains to the right angle forces acting on the shaft. The use of ball bearings or cylindrical roller bearings is recommended in applications that involve predominantly radial loads, such as rotational shafts or conveyor rollers, since they have the capability to take such perpendicular forces, allowing rotative movement.

- Axial Load – These are forces that are emplaced along the axis or the length of the shaft. Join’s bearings are appropriate for thrust washers or when vertical loads in screw jacks require handles, axial thrust ball bearings or radial thrust roller bearings where bearing handles allowing them better withstand axial forces, their design is meant for that.

- Combination of Loads – A lot of applications also carry both the radial load and the axial load at the same time. For such cases, the angular contact ball bearings or the spherical roller bearings are suitable since they are specially designed to resist loads applied in several planes.

In order to select the right bearing, I always suggest considering the expected load capacities of your system. Determine both radial and axial forces, rotational speed, misalignment, and lubrication. By looking into these factors systematically, the information provided will not be at variance with your requirements.

Determining Rotational Speed Requirements

Determining the rotary shall be done after determining the maximum operational speed of your application and demonstrating the bearing selected has some additional ability to spin faster without damage from heat or friction. In this case, pay attention to the bearing type, cage material, and lubrication method, as they have a notable impact on the performance at elevated speeds. Always refer to manufacturer speed rating specifications so as to realistically use the bearing with consideration to the requirements posed by the application.

Factors Influencing Bearing Selection

According to how I operate, the process of bearing selection appears to be a trade-off between a number of critical requirements. The very first is the load capacity: it is important to define if the bearings have to support radial, axial, or mixed loads. Then, I consider a place of use because temperature contamination or moisture may have a direct impact on the bearing’s life span and operating reliability. Maintenance and Lubrication are equally important; it is essential to use the most suitable type or method for optimal operation, more so for difficult and high-speed applications. Last but not least in order of the other factors that I take into consideration are the precision requirements, where the tolerances and fit of the bearings affect the efficiency and degree of alignment. In this way, all these factors will enable me to be sure that the bearing design is optimum for the application.

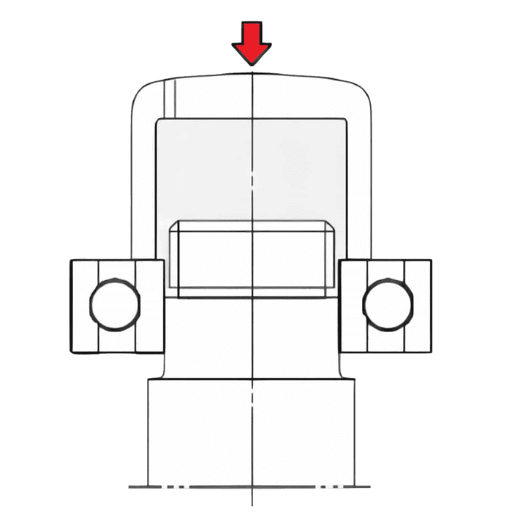

What Is the Proper Bearing Mounting Technique?

In order to guarantee that the bearing is mounted correctly, the task is completed in the following sequence. The first step that I take is to check whether the surrounding environment is clean or not, for any small debris may impact the overall performance of the bearing. Then, I use only the appropriate tools for the task, which are specialty types of presses or heaters, so that the application of too much pressure or body weight does not occur, which could potentially harm the bearing. Concerning interference fits, I do use thermal expansion or mechanical pressing methods by evenly applying pressure to the designated ring depending on the type of bearing. At this point, I have to stress- how, on every occasion, when such actions take place, I check an alignment to make sure it stays within an operational range, hence smooth functioning. By the end, proper seating is confirmed, and a particular lubricant is selected to enhance the performance and prolong the lifetime of the bearing. Accomplishing these tasks in a structured approach allows one to gain desired results in a reliable manner without compromising efficiency.

Step-by-Step Guide on Press Fitting

- Prepare the Components

Before starting any work, I make sure that all the components are properly maintained, decontaminated, and free of any debris. Furthermore, an examination of the bearing and housing should be carried out in order to detect any possible areas that can affect the fitting and durability of the substance.

- Determine the Correct Fit Type

As part of the design evaluation, I analyze the need for the assembly, whether it be a standard fit or the parts that need an interference fit to join the assembly together. This is determined based on the operational loads, speed, and temperature the components have to withstand.

- Choose the Right Tools

In relation to fit type, I use hydraulic or arbor presses or thermal tools for expansion, which are all precision fitting tools. Additionally, using the ideal equipment also ensures that the housing and/or bearing is not damaged and that all the components fit seamlessly.

- Apply Consistent Force

First, evenly disperse some force while doing so, ensuring that the bearing is positioned correctly. For cases where an interference fit is required, other than force, heat application can be utilized to expand the housing (or bearing) and make fitting simpler.

- Check Alignment Constantly

Last but not least, force location is one of the most important things in a press fit. In order to accomplish this, the position of the component or components being pressed is monitored to avoid excessive wear and thus eradicate the chances of premature failure.

- Final Inspection and Lubrication

After the insertion of the bearing, it is my duty to take a closer look to ascertain if the bearing is in its correct position. To complete the assembly, I then apply the prescribed lubricant in order to enhance the performance and the life span of the assembly.

In this manner and with attention to detail, I complete an assembly that is both safe and effective, working even in the more exacting environments.

Ensuring Correct Alignment of Inner and Outer Rings

There’s no doubt that ensuring the inner and outer ring planes are well aligned is crucial for the functioning of the bearing as well as its durability. To ensure this, I make use of accurate measurement devices and handle the parts very gently while mounting. The use of appropriate jigs, even force application, and compliance with the specified tolerances can considerably reduce the occurrence of misalignments. It is evident that monitoring this operation at each stage guarantees that both components are positioned hose well and are able to work efficiently under the operational forces.

Common Mistakes in Bearing Mounting and How to Avoid Them

Bearings are often subjected to overheating or excessive friction due to improper usage, installation, or lubrication. One of the most notable earmarks for such distress is improper lubrication. Bearing lubricants are insufficient in the required amount or type, which is essential for them to function optimally. Over and under-lubrication can be a major concern, and as a rule of thumb, manufacturers should always be referred to. It is prudent to state that lubrication should be approached through a meticulous lens, as starting out with the wrong lubricant or using too much/little can cause a cascade of failures right from bearing distress to being rendered inoperative.

Apart from this, in my line of work, I have also noted that using improper lubricants or hammers also poses a risk during installation and bears a hint of negligence, while loosening tools can render the bearings unusable. On various occasions, I have personally advised that I find it feasible to use induction heaters, hydraulics, or bearing pullers on mounts. This ensures that the practical aspect of the installation procedure is intact and nurtures a glass-like mentality as a bearing should never be affected, which can render it useless.

When operating and installing the bearings, it’s also advisable to maintain cleanliness as dirt and other particles can easily make their way into a non-clean environment, which in turn contaminates the bearings and makes them irreparable. Practically speaking, when I sense that the components and the environment are clean enough, I make sure to seal the bearings and place them back into the packaging they arrived in.

Finally, it happens when some installers do not pay attention to the dimensions of the shaft and the housing. If such surfaces are out of tolerances, this can result in fits that are too loose, some components being asymmetrically located with respect to each other, or even excessive radial load acting on the bearing. When installing the bearing, I perform measurements of some parameters, such as the diameter of the shaft, hinting that the housing bore shaft is maintained, and tolerance classes with appropriate instruments to safety check if the bearing can be put to use.

Beneath the surface of these factors in the present context, failures in bearing mounting can be largely minimized, and acceptable performance of bearings in operating conditions can be ensured by adopting a systematic approach while assembling or installing them.

How Do Bearings Affect Machine Performance?

Bearings are essential parts of machines in that they reduce friction and allow smooth movement, which, therefore, have a direct impact on machine performance. Their function helps in operational effectiveness, improves the accuracy of machines, and increases the durability of mechanical systems. Taking into account the fact that poorly performing or incorrectly fitted bearings result in energy waste, unreliability, rapid wear, and excessive costs accruing from downtime losses, it is essential to select and maintain the bearings properly.

The Role of Bearings in Reducing Friction

it is correct that none of the components in any machinery is more significant than bearings. Bearings provide geared surfaces for sliding contact, thereby decreasing resistance and widening up heat. Such frictional activity is enabled by interacting components formed of thin fair coatings due to their surface and lubricant properties. Their contribution to the economy is considerable: increasing the parameters of the machine’s effectiveness, decreasing energy consumption, increasing the life of components, and even reducing maintenance expenditures. It is well known that excessive friction causes wear and tear to the components of a system, rendering it inefficient or on the verge of failure if not for perfectly working bearings.

Impact of Lubrication on Bearing Efficiency

Correct lubrication is essential in improving bearing performance. It lessens the friction of surfaces that are in contact, cuts down wear and tear, and also aids in removing heat generated during use. Maintaining a constant lubricating film allows the bearing to work under less load, meaning an increase in service life and dependability of the bearing. Moreover, suitable lubricants can protect against pollution and rust and provide the desired functionality under a wide range of operating conditions.

Signs of Wear and Tear in Bearings

it is necessary to highlight the early detection of possible damage to bearing parts. Typical signals consist of odd sounds such as grinding or clicking, excessive vibration during operation, and noticeable increases in operating temperature. Visual changes such as pitting, discoloration, or cracks on bearing surfaces can also serve as important indicators. Regular inspections and monitoring are key in detecting the rise of such issues beforehand so that proper measures are taken to replace or repair the damaged components, enabling the smooth functioning of the systems.

How Often Should Bearings Be Replaced?

How often a bearing is replaced is closely related to the working conditions, load, and maintenance performed. Under perfect operating conditions with adequate lubrication and protection, it seems that bearings could last several years. On the other hand, if they are subjected to heavy loads or become damaged, it may be wise to check and change them before any problems arise. The rule of thumb is to adhere to the manufacturer’s advice and inspection and determine the replacement frequency of bearings in a way that guarantees the reliability and safety of the system.

Can Bearings Be Repaired?

Certainly, we have the possibility of bearing repair, but that depends largely on the type and extent of damage suffered by the bearings. Based on my experience, this practice is quite cost-effective as well as environmentally friendly when only small and isolated damage has occurred. Here are the relevant parameters I assess in order to figure out if repair is feasible:

- Type of Damage: The surface of the bearing has small scratches or minor pits. These scratches are easily polishable. Only under extreme cases, such as having deep dead cracks, deformities, or other physical harm rendered on the bearing, may one consider switching to an entirely new bearing.

- Size and Application: While the smaller standard bearings are easier to purchase, it is the larger custom made bearings which are harder to replace that are used in unique specialized machines due to the different cost rates, thus are more worth repairing as opposed to replacing.

- Machinery Downtime: The time factor is also very important. On older machines where parts are hard to find, sourcing new bearings can carve out more time than repairing the existing ones.

- Maintenance History: Repairing techniques and ways are revamped nowadays; therefore, bearings that have been well-maintained over time are said to be more fixed for repairs.

- Cost-Benefit Analysis: A detailed examination of advantages and disadvantages is necessary while factoring in the alternate replacement procedures and the bearing’s possibility to fail. In cases where over half of the cost of repair reaches 60% of the cost factor for switching to a new bearing, I would suggest an option favoring the simpler of the two.

It is equally important to avoid working with untrained personnel or general facilities for bearing repairs because precision is involved. Once I am finished with the repairs, I make it a point to check the bearings for proper lubrication and subject them to tests, which will ascertain that they are working as required. Always remember, if everything around civil concerns about assets, fire an individual a replacement part instead. Safety and effectiveness should never come into question; if there is a concern, then always worry about the outcome of replacing it.

What Are the Best Practices for Maintaining Bearings?

In order to take proper care of bearings that include effective lubrication, following periodic maintenance, and operating within the recommended criteria, use the right type and amount of lubricant in the right way in order to reduce friction and wear. Organize regular inspections to check for any overheating, abnormal noise, or dirt accumulations, and maintain the environment free of debris to avoid erosion. Likewise, ensure correct mounting procedures and do not overload the bearing to enhance its life. Periodic check-ups and pre-emptive servicing are important for optimum performance and to evade unforeseen breakdowns.

Reference

- Mastering the Art of Bearing Installation and Removal – This article discusses the intricacies of bearing installation and removal.

- Mastering the Art of Selecting Agricultural Machinery Bearings – A guide focused on selecting the right bearings for agricultural machinery.

- The Complete Guide To Bearings – This comprehensive guide covers various types of bearings, their design features, and operational modes.

Frequently Asked Questions (FAQs)

Q: What is a bearing, and why is it important in machinery?

A: Bearings are mechanical components that facilitate motion by reducing friction between moving parts in types of machinery. They are crucial for ensuring smooth operation and longevity of equipment.

Q: What are the different types of bearings used in machinery?

A: Common types of bearings include deep groove ball bearings, angular contact bearings, needle roller bearings, self-aligning ball bearings, and tapered roller bearings. Each type serves specific functions and applications depending on their design and load capacities.

Q: How do deep groove ball bearings function?

A: Deep groove ball bearings consist of an inner race, an outer race, and a set of balls. They are designed to support radial and axial loads, offering smooth and efficient operation. Their deep raceways allow for higher speeds and better load distribution.

Q: What is the role of the inner race and outer race in a bearing?

A: The inner race and outer race are crucial components of a bearing. The inner race is mounted on the rotating shaft, while the outer race is fixed to the housing. These races contain the rolling elements, enabling smooth rotation and load transfer.

Q: Can you explain the concept of self-aligning ball bearings?

A: Self-aligning ball bearings are designed to accommodate misalignment between the shaft and housing. They have two rows of balls and a common concave spherical raceway in the outer ring, allowing the bearing to self-align and reduce stress on components.

Q: What are the advantages of needle roller bearings?

A: Needle roller bearings have a smaller cross-section compared to other types, allowing for compact design solutions. They are suitable for applications with limited radial space and can handle high radial loads.

Q: How do angular contact bearings differ from other types?

A: Angular contact bearings are designed to handle both radial and axial loads simultaneously. They have raceways in the inner and outer rings that are displaced relative to each other, allowing for high-speed applications and increased load capacity.

Q: What factors should be considered when selecting bearings for machinery?

A: When selecting bearings, consider factors such as load type, speed, operating conditions, lubrication, and space constraints. Understanding the specific requirements of the application will help you choose the most appropriate bearing type.

Q: How can I learn more about bearing maintenance and installation?

A: To learn more about bearing maintenance and installation, you can refer to instructional guides, attend workshops, or watch detailed tutorials available on platforms like YouTube. This will help ensure proper handling and longevity of your bearings.

Q: Where can I find a comprehensive FAQ on bearings?

A: You can find a comprehensive FAQ on bearings in specialized technical manuals, industry websites, and forums dedicated to mechanical engineering and types of machinery. They provide valuable insights and answers to common questions about bearings.