In ensuring that the wheels of the car rotate freely while being able to support the weight of the car itself, wheel bearings take on a crucial role within the vehicle’s suspension system. However, it comes at a time when the bearings start to wear out, forcing the driver to experience unusual noises and issues with steering, which, in extreme cases, can lead to dangerous conditions. This cannot be so bad if the issue is detected as early as possible. This article will help you to correctly pull out the wheel bearings from any car without causing damage to them. By the end of it, you should be able to easily explain the process of tire replacement and the subsequent bearing removal process.

What are the common symptoms of a bad wheel bearing?

Usually, a faulty wheel bearing can be diagnosed with certain signs. For instance, noise like grinding, humming, or roaring tends to be louder when the car is accelerated. Also, there may be an imbalance in the tires, wobbly or vibrating wheels, and a decrease in stability and control. Another sign is a lot of play in the wheel, which can easily be spotted during an inspection. In the case where these warning signs are not treated, the damage might be more complex in the future.

Unusual noises: grinding, humming, or clicking

strange sounds such as grinding, humming, and clicking are usually indicative of problems with the wheel bearings. As a rule of thumb, more damage is taken on the bearings of such parts whilst grinding due to lubricant insufficient or already damaged. A humming noise is usually caused when bearings begin to wear out but have not completely failed. A clicking sound can sometimes indicate that some dirt is stuck in the bearing or has an adjoining joint that is giving away. Such sounds have to be recognized in their early form as otherwise it would result in larger expenses being incurred, hence I always suggest that every car be taken for inspection at the first signs of adversity.

Steering wheel vibrations and pulling

People commonly ask me what could be the causes if they are facing steering wheel vibrations or if their car is pulling to one side. From my perspective, there are plenty of reasons that can result in these issues, and finding the exact cause most of the time involves checking certain parameters:

- Wheel Alignment – One of the primary reasons why the car pulls to one side is misaligned wheels. If your car seems to dominate or drift towards one direction much more than the other, then the likelihood of the car needing rear wheel alignment is very high. A combination of all these factors tends to alter the alignment most of the time. Sometimes, crossing a pothole or a curb may affect the wheels, but sometimes, it just happens through use.

- Tire Condition – In the event there is a difference in the left and right side tires, the uneven wearing of the tires or their pressure can cause a pull or vibration in the vehicle. Therefore, it’s best to check all four tires when assessing whether the tires are properly inflated or not.

- Balancing of Wheels –If you are sensing vibrations when turning the steering wheel at a given speed, then the reason might be an out-of-balance wheel. When this happens, there is an excessive force that causes shaking while driving, which is hardest to bear when steering the car.

- Brake System Issues – Vibrations may also be discernable as a result of the distortion of brake rotors or because of differential wear to some of them, emphasizing especially when brakes are applied as this shows other common phenomena like the rotors wearing out or needing resurfacing.

- Suspension and Steering Components – Among the most effective solutions to vibrations and a pulling sensation are replacing worn-out ball joints, tie rods, or control arms. All these components enable better stability of the car, and thus, it is best to have them checked if the problem persists.

- Road Surface – Lastly, don’t forget to consider whether the road itself is uneven or slanted, as this could cause minor pulling that disappears on smoother roads.

If you closely follow these parameters, you can identify the problem exactly. If there are such indications as constant vibrations or even pulling to one side, I advise you to have your car examined by a specialist sooner rather than later. Such problems might not appear serious at the first instance but, due to lack of remedy, can develop into larger complications and risks to safety.

How can I determine if it’s the front or rear wheel bearing?

I start by concentrating on the source of the noise or the vibration to establish whether the problem lies with the front or rear wheel bearing. For example, if the left side front bearing is worn out, the sound will be louder on the left front when turning towards the left side, indicating a problem with the opposite side front wheel bearing. Generally, however, in regard to rear bearings, the sound is more likely to be unchanged regardless of the steering angle applied to the vehicle, and thus, I use a change of sound when accelerating or decelerating the vehicle. Another test that is very useful in locating the affected bearing is simply taking a road test or elevating the car in order to feel for play and roughness while manually rotating each wheel.

Identifying noise changes when turning left or right

alteration of sounds, when turning left or right is a great diagnostic sound of a wheel bearing issue. There is some load transfer from one vehicle bearing to the other when the vehicle is turned about the steering pin. For example, if there is a sound increment should i transverse a left turn then i realize that the right bearing is most likely to be loaded and probably faulty. However, it is to be noted a sound increment during a right turn usually signifies a lapse at the left bearing. These directional indicators are not absolutely accurate, but they are good, considering that they can help focus the investigation toward more promising leads even before the careful inspection.

Differentiating front and rear wheel bearing symptoms

there is a quite simple yet effective way of determining whether the front wheel bearing or the rear wheel bearing is affected, primarily based on where the noise comes from and how the noise behaves. The familiar grinding noise noticed when making a turn could indicate problems with the front wheel bearing. This is, in most cases, the noise and vibrations which are transferred into the steering system admittance being the reason it is easier to detect. Rear wheel bearing problems, however, are usually more difficult to localize because they do not interfere directly with steering operations. Rather, one will hear a distinct hum, grind, or rumble coming from behind at the higher end of the speed range. I have always preferred to do the testing on a quiet road in order to minimize interference from outside noises. Over the years, the standard or rather prominent symptoms have always proved to be the most helpful in ascertaining the origin of the problem.

What techniques can I use to pinpoint which specific wheel bearing is bad?

The procedure that I more commonly use is the “load shift”- which is a test. I always try it out when I’m driving across a not-so-busy, safe road and at a moderate speed. All I have to do is to gently turn the steering wheel to the left and to the right. Now, if one of the two seems to be louder while the other is softer, it means that the bad wheel bearing is located on the side of turning the steering wheel- meaning it experiences more pressure. For instance, when I’m turning left, it means that the right-side bearing is probably the problem. Another effective step is to safely remove the vehicle and hand spin each wheel while listening for a grinding noise or excessive play as rotation takes place. These methods, in conjunction with the owner’s ability to listen for changes in noise or vibration, are vital instruments I apply in a bid to help me ascertain the problem.

The “cornering method” for isolating bearing noise

one of the most effective ways to localize bearing noise is the ‘cornering method.’ In light of experience, to identify which side is problematic, A simpler way to diagnose a bearing problem is to notice how the sound changes as a car turns. For instance, if the noise increases while turning left it most likely indicates that there is a problem with the right side bearing as mostly it is the one that takes the most load towards the left. Not only is this effective in saving time, but it also helps in preventing unnecessary disassemblies, thus making it a great first stage in the process of diagnosing bearing problems.

Using a stethoscope or mechanics’ listening tool

Using a stethoscope or mechanics’ listening tool can sometimes be a more accurate way of locating problems. This time, I used the tool to contact different parts of the wheel assembly while rotating it so as to determine the exact source of the strange sound. The enhanced noise enables me to check whether it is really the bearing that has gone bad or if the sound could be coming from some other part, like the CV joint or brakes. This strategy, however, increases the accuracy of the technique and prevents misdiagnosis, which, in the end, saves time and the need for replacement expenditure.

Jacking up the car and manually spinning the wheels

It’s a simple step, yet an important one to diagnose a fault inside the wheel which is i jacking up the car, then manually turning the wheels one by one. I do this while the car is jacked up, gently turning each of the wheels and listening for grinding noises to check if a wheel bearing is damaged. This procedure also aids in hearing problems and allows me to examine the movement to check if vibrations are present or if the movement is jerky. This solves the issue of having to assess each wheel’s condition and allows me to precisely determine the fault’s origin, which allows me to make a more confident diagnosis.

Are there any visual signs that indicate a wheel bearing is going bad?

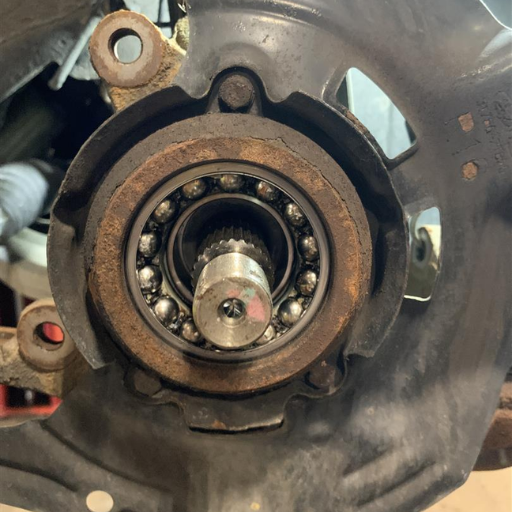

Sure, while diagnosing a damaged wheel bearing, I explicitly look for some physical signs useful for substantiating my diagnosis. One of the signs, quite often, is wear and tear on the tires caused by misalignment of the wheels owing to a bad bearing. The rusted area I examine for leaks and over grease or grease stains around the hub also warrants attention. Too much grease or grease deposits around the wheel assembly indicate that the bearing seals were already worn out. Besides, rust formation or discoloration around the bearing housing can indicate overheating and, hence, excessive wear or even failure. All these visible signs of damage and proper testing enable me to determine the state of the wheel bearing.

Inspecting for grease leaks around the hub

The first thing I note when inspecting a wheel for grease seepage or leakage is whether there are signs of grease accumulation on the wheel assembly or any part of the hub. This implies that the grease was not provided enough protection by the bearing retainer or that the seals are damaged and grease has started to seep out, and hence, the part is not properly lubricated. It has also been my practice to remove all residues and watch out for any seepages that might be new after the vehicle is operated. After repeated spills exist, chances are that the seals would require replacement, and this needs to be done quickly; otherwise, the wheel bearing and its parts would sustain too much damage, which would be hard to undo.

Checking for excessive wheel wobble or play

Before examining for excessive wheel wobble or play, it is essential to first secure the vehicle in either a lifted position on a vehicle lift or ablaze jack stands. I proceed to, however, firmly get hold of the tire at the 12 and 6 o’clock positions and and rocking it gently back and forth. If there is some excessive movement of the wheel or some looseness noticed during movement of the wheel, this also signifies the presence of worn wheel bearings or some issues with the suspension system as well. In case I sense looseness or play, I would check the bearing hub assembly and other adjoining parts to focus on the problem area and establish the cause of the issue. This stage of examination cannot be skipped because excessive wobble causes uneven tire wear, worsened handling, and even more serious complications and problems in the future.

How quickly does a wheel bearing deteriorate once it starts to go bad?

А wheel’s hub bearing, just like the wheel itself, fails to function properly. The pressure on it and the particular circumstances undeniably affect the rate at which it disintegrates. Hub bearings wear out and become dry and rusted unless one takes care that they do not end up in hot high vibrations or are driving under incredibly strenuous conditions. For all practical purposes, a wheel can get damaged in rough conditions or speeds within a few hundred miles of driving. As such, the degrading nature of the wheel bearing can be alarming and a cause for concern. There is a level of immediacy in that situation where one would want to change the wheel bearing and/or the wheel itself to prevent the problem from worsening. If they had to endure such vibrations, the mounts would rather not last long, and neither would the wheel or wheels or bearings. A vibration would only be the start; sounds would soon follow suit. There is an overarching theme where time is of the essence, with late detection eventually leading to more serious problems.

Understanding the progression of wheel bearing failure

Ilgu shaj ovimdan mercha yani bu avval shundoq uchragandir deya ehtimol qilaman yuitish bering. Only one aspect mentioned by the author points out the secret to improving bearings: “figuring up an oil bearing with proper viscosity”. One may note the idiosyncrasy of the high-pitched voice emanating from the bearings. On the contrary, the bending allows for the production of high-pitched bearings. However, this, in turn, implies that the shaft is subjected to increased stress, thus leading to concentricity deviation and excessive contact with the shaft.

Factors that influence the rate of deterioration

a few factors strongly influence the rate of wheel bearing wear. To begin with, the conditions of the vehicle’s operating environment matter a lot, such as being driven on bad or bumpy roads, which increases the rate of degradation. Furthermore, road debris, wet conditions, mud, or salt can promote rust and corrosion over time which negatively influences the bearings. The second concern is the bearing quality, which is already compromised by the use of cheap materials. The other aspect is not following directions during fitting and occasional checks during use, which include pouring grease periodically, which also leads to quicker wearing out. If these factors are taken into account and dealt with, the wheel bearings stand to last much longer and not fail out of the blue.

Can I continue driving with a bad wheel bearing, and if so, for how long?

My recommendation for you is to never drive when the wheel bearings are bad. To my knowledge, if someone continues to drive under such conditions, they would pose safety risks such as loss of control of the vehicle or increased damage. While you may be able to drive for a short distance, the timeline is not known and depends on how bad the issue is. Signs, such as an unsteady ride, abnormal vibrations, or grinding, should be considered an indication that you need to pull over and fix the problem. Fixing these problems leads to the safety of the driver while preventing damage to other components, such as the hub assembly or axle, which is considerably expensive.

Risks associated with driving on a failing wheel bearing

The dangers of driving with a worn-out wheel bearing are not to be taken lightly. one of the first concerns is the possibility of a wheel coming off, and this can lead to terrible accidents at any speed. Furthermore, a damaged wheel bearing creates excessive force on the hub and surrounding parts, aggravating wear and necessitating more costly repairs. Have everyone forget about that. It also impedes the handling of the car, whose wheel may become imbalanced, making it less stable. I have also witnessed some instances where, due to bearing problems, the yawing of the steering wheel causes decreased efficiency of the braking system, thereby increasing the distance needed in order to come to a stop. For your safety and that of your vehicle, it’s self-evident what you should do—let’s put it mildly—be proactive.

Estimating safe driving distance before replacement

The preservation of a failing wheel bearing may last a few hundred miles and vary based on the damage incurred. Still, it is not advisable. A thumb rule or an expert order is to not take risks and immediately opt for replacing it instead of driving. This is because a risk of enhanced structural damage or more repairs taking place is a possibility, and moreover, it is dangerous. So, presumably, no one should ever have to engage in driving with a damaged hook bearing. Otherwise, replacing such degraded components is grossly expensive.

How can I prevent wheel bearings from going bad prematurely?

Avoiding wheel bearing failure can be done by practicing good driving habits daily as well as servicing them regularly. Based on my experience, the most critical aspect is ensuring bearings are properly lubricated as there are cases of heavy grease or oil contamination that can make them wear out faster. Another practice that I suggest is checking the seals before installation to ensure there are no damages and that the seals are properly positioned to prevent moisture and debris from getting into them. Additionally, don’t cross deep or flooded water and don’t traverse muddy areas too often, as such conditions will subject the bearings to hostile environments, which will degrade them with time. Lastly, a balanced and well-inflated set of tires eliminates unnecessary pressure on the bearings, which will consequently lead to longer usable time. By applying all these methods, you will greatly minimize bearing failures.

Proper maintenance and inspection routines

Wheel bearings can last longer if they undergo regular maintenance and inspection programs. First, if there are any signs of abnormal noise or vibration while operating the bearings, it is wise to check these as they are signs of wear. Follow the manufacturer’s specifications regarding the grease and its application, and remember to change it whenever it is due. Routine checks should be done on the seals to check for cracks or any signs of wear and ensure that they are intact in order to avoid contamination. Tire alignment and balance should also be checked to ensure that they do not exert extra stress on the bearings. If such procedures are followed on a routine basis, it will benefit you and minimize repair costs.

Avoiding driving habits that stress wheel bearings

In order to prevent undue stress on wheel bearings, some smooth and restrained methods of driving should be adopted. Such practices minimize wear and tear on your bearings, such as avoiding aggressive starts, slamming brakes, or sharply turning. Irregular driving habits like hitting potholes and curbs can, over time, also affect the bearings. Avoid exceeding vehicle load capacity, as exceeding it increases the stress on the wheel assemblies. Realistically, with safe driving methods, one can avoid putting undue stress on their wheel bearings and thus improve their lifespan.

Reference

- CarParts Blog: How Can I Tell Which Wheel Bearing Is Bad? – This source provides insights on identifying bad wheel bearings by listening for specific noises.

- Free ASE Study Guides: Wheel Bearing Diagnosis – A guide that helps distinguish between wheel bearing and brake noise.

- The Group Training Academy: Wheel Hub Damage Analysis Guide – Offers detailed instructions on inspecting wheel hubs and bearings for damage.

Frequently Asked Questions (FAQs)

Q: How can I tell which wheel bearing is bad while driving down the road?

A: When you’re driving down the road, a bad wheel bearing will often make a humming, growling, or grinding noise. The noise typically changes as you accelerate, decelerate, or turn. To determine which wheel bearing is affected, try gently turning the steering wheel left and right while maintaining a steady speed. If the noise gets louder when turning right, it’s likely the left wheel bearing, and vice versa.

Q: What are the signs of a front wheel bearing going bad?

A: Signs of a bad front wheel bearing include a humming noise coming from the front of the vehicle, steering wheel vibrations, and uneven tire wear. If you notice these symptoms, it’s important to have your vehicle inspected promptly, as a faulty wheel bearing can lead to serious safety issues.

Q: How do I determine which wheel bearing is making noise?

A: To determine which wheel bearing is making noise, drive at a moderate speed on a quiet road. Shift your car slightly to the left or right within your lane. If the noise increases when you move right, the left wheel bearing is likely the culprit, and vice versa. Additionally, you can have a mechanic use a stethoscope to pinpoint the exact location of the noise.

Q: Can a bad wheel bearing affect steering?

A: Yes, a bad wheel bearing can affect steering. You may notice increased play in the steering wheel, a pulling sensation to one side, or vibrations through the steering wheel. These symptoms are especially noticeable when turning or at higher speeds. If you experience any of these issues, it’s crucial to have your wheel bearings checked promptly.

Q: How long can I drive with a bad wheel bearing?

A: It’s not recommended to drive with a bad wheel bearing for an extended period. While a wheel bearing can go for some time before completely failing, continuing to drive with a faulty bearing increases the risk of the wheel seizing or even detaching from the vehicle. It’s best to address the issue as soon as you notice symptoms to ensure your safety and prevent more extensive damage.

Q: Are symptoms different for front wheel bearings versus rear wheel bearings?

A: While the symptoms are generally similar, there can be some differences. Front-wheel bearings often cause more noticeable steering issues and vibrations in the steering wheel. Rear wheel bearings may cause more pronounced vibrations felt through the seat or floorboard. In a front-wheel-drive vehicle, front-bearing issues may be more noticeable during acceleration, while in a rear-wheel-drive vehicle, rear-bearing problems may be more apparent when coasting.

Q: How can I check for a bad wheel bearing when the vehicle is stationary?

A: To check for a bad wheel bearing when the vehicle is stationary, jack up the suspected wheel and support the vehicle safely. Grab the tire at the 12 and 6 o’clock positions and try to rock it. If there’s noticeable play, the bearing may be worn. Next, spin the wheel. A grinding noise or roughness as the wheel spins can indicate a bad bearing. However, a professional inspection is recommended for a definitive diagnosis.

Q: Can weather or road conditions affect wheel bearing noise?

A: Yes, weather and road conditions can affect wheel bearing noise. Cold weather can sometimes make bearing noise more pronounced as the grease in the bearing thickens. Wet roads may temporarily reduce bearing noise, making it harder to diagnose. It’s best to assess bearing noise under various conditions to get a complete picture of the issue.