Bearings are key elements in many machines and mechanisms because they allow smooth movements and continuous efficient mechanics. No matter if you engage in engineering, manufacturing, or maintenance activities, it is important to have an understanding of ball-bearing specifications that fit the application. The aim of this blog is to explain in simple words the bearing sizes charts and nomenclature, which are usually viewed as complex, and that they serve both professionals and interested persons. The coverage of this guide includes standardized naming conventions, dimensions, and some performance characteristics of the bearings. As such, this guide prepares the readers to improve efficiency in their operations by allowing them to make sound decisions. As such, let us begin with some of the bearing specifications that would allow you to explore and make sense of such terminologies so you won’t feel lost ever again in such technical language.

What are the key elements of bearing specifications?

Bearing specifications encompass the bearing type as ball, roller, or thrust, dimensions such as inner and outer diameter as well as width, load capacity including both dynamic and static capabilities, speed rating in RPM, and material and lubrication requirements. Having these specifications guarantees that the bearing meets the requirements set by its applications and achieves the desired performance characteristics as well as durability and also efficiency in different working conditions.

Understanding basic bearing terminology

There are general bearing terms that warrant a brief explanation, and it is essential to bear them in mind while selecting the right bearing for applications. This elucidation is intended for:

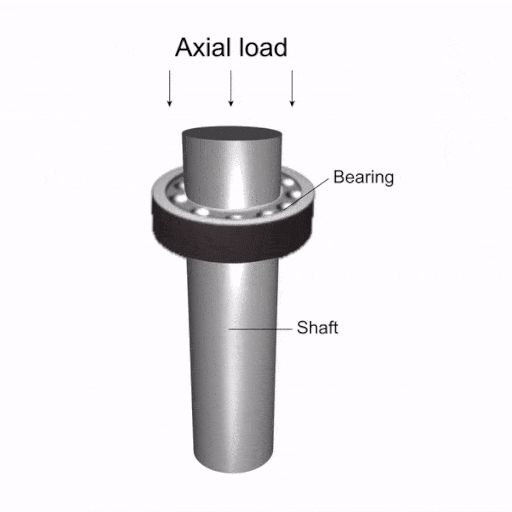

- Bearing Type – There are different types of bearings, such as ball bearings, roller bearings, or thrust bearings. Each type has its distinct purpose. For instance, ball bearings are more suited in applications where radial loads are present, while thrust bearings are suitable where there are axial loads.

- Dimensions – Generally, the sizing of the bearings is done on the basis of three parameters: inner radius, outer radius, and width. These are essential measurements because they ascertain whether or not the bearing is going to fit in your application properly. Always confirm these measurements with the necessary shaft and housing specifications.

- Load Capacity – Rotating elements like the bearings have two load capacities that need to be taken into account:

- Dynamic Load Capacity (usually measured in Newtons)reflects the bearing’s capability to bear loads while in motion.

- Static Load Capacity quantifies the amount of load the bearing can withstand when at rest without incurring damage.

- Speed Rating – This is the RPM that a bearing can use to work safely without any healing. If this rating is attained or surpassed, there will be overheating and lifespan degradation.

- Material Composition -An average bearing is made out of high-grade steel, although some special types will have ceramic or stainless steel as well. This affects wear resistance, corrosion resistance, and ability to withstand high temperatures or particular environmental settings.

- Lubrication Requirements – The aim of proper lubrication is the reduction of friction and wear. Bearings can either be sealed (pre-lubricated) or, during their usage, need to be periodically lubricated with grease or oil.

These parameters also delineate the functional specifications of the bearing. Understanding these concepts allows you to be well-informed regarding the adaption of the specific bearing into any equipment or system.

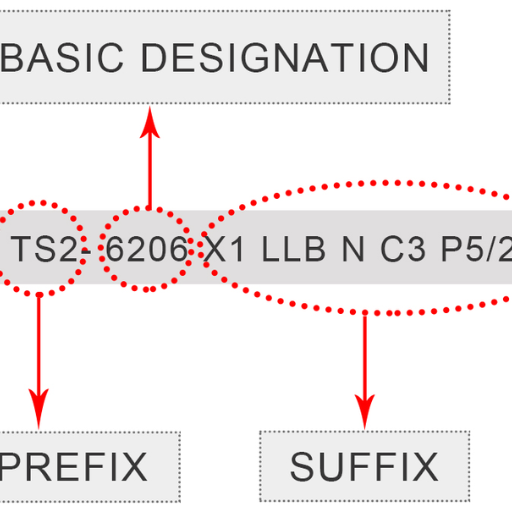

Deciphering bearing numbers and designations

Bearings are designated a universal metric system, and as such, their numbers are not random in any way, shape, or form. They assume systemic roles by providing vital information concerning the type of bear, its size, and operational abilities. Whether this was meant for or what the bearing series numbers suggest, I am able to escape risk this way as well as maximize factory effectiveness. This incremental or stepwise dissection & structuring of the designation not only guarantees that the selected bearing will suit the operational requirements but also reduces the intensity of danger faced. Such a systematic approach has been invaluable in the selection of the necessary sets of bearings for various systems. However, there are certain expectations I must maintain while applying this insight.

Exploring bearing types and their specific characteristics

There are various kinds of bearings, each having unique applications and functional requirements. A wide use of ball bearings is observed for light and moderate radial and axial loads, while roller bearings obtain high radial loads. Due to their slender form, needle bearings are suitable for space-constrained applications. Tapered roller bearings are particularly used where both axial and radial loads are present, such as in motor vehicles or heavy machinery. Caution is observed when using plain bearings as there are no rolling elements, which are useful for low-speed applications with high load stresses since they are efficacious in form and robust in construction. Knowing these types allows for enhanced efficiency and reliability of systems in different industries.

How do I read a ball-bearing size chart?

The process of comprehending a ball bearing size chart and ball bearing sizes becomes simple when the details are guided. First, I begin with the bearing series, which informs the type and scale of the bearing. Next comes the bore size, which is usually in millimeters and, in turn, the shaft diameter the bearing can fit after that comes the outer diameter and then width, which are basically the overall sizes. Finally, I always look for other details, such as the type of seal or bearing material, because they affect performance and fit. I ensure that I study the chart in a logical manner so that the most appropriate bearing for the application is chosen.

Interpreting diameter measurements in mm

To correctly understand the diameter measurements in millimeters, first consider the bore diameter; this is the internal hole of the bearing that is in line with the size of the shaft. Then comes the outer diameter, which indicates the total dimension of the bearing from one end to the other. The width measures the depth of the bearing. Every specification is very important for the proper fit and effect within the intended use.

Understanding inner and outer ring dimensions

Regarding my practice in the industry, it is evident that knowing the dimensions of the inner and outer ring is critical for the proper selection of any type of bearing. This is necessary for the inner ring to engage closely with the shaft, which gives it control and minimizes slippage in the course of rotation. The outer ring, on the other hand, dictates how the bearing is engaged with its housing. These dimensions must be accurate in order to preserve functionality, as even the smallest variation will result in a loss of performance, rapid deterioration, or failure of the system. Reliability and longevity in function are achieved by performing checks and ensuring that these values correspond to what is required by the application.

Analyzing clearance specifications

In relation to clearance specifications, I have always stressed their relevance to the performance of the bearings. Owing to the internal dimensions of the bearing, the working conditions of the parts of the bearing also change. This is what I normally do:

- Radial Clearance

The radial clearance, put simply, is the gap that exists between the rolling elements and either an inner ring or an outer ring. In the course of working, adequate radial clearance takes care of smooth relative rotation as well as accommodates thermal changes. Excessive radial clearance will lead to vibration, while too little will lead to overheating and excessive wear.

- Axial Clearance

Axial clearance defines the essentially acceptable clearance of a bearing in an axial direction along its axis. The value of the axial clearance should be left fixed, and no variations should be allowed for the application where axial loads are present. Lack of sufficient circumferential axial clearance would affect motion and induce excessive stress on the bearing components.

- Operating Conditions

One must take into account the speed, loads, and temperature fluctuations in relation to the clearance parameters. For example, applications with high rotational speeds may need clearance to be lower than ideal levels in an attempt to keep the system stable, while an increase in temperature may lead to an increase being needed for expansion reasons.

- Preloading and Fit

The design of the bearing’s seat also connects impact, whether fits are tight or loose, and how effective clearance would be. As an example, it is not uncommon that tight fits in such a case may lead to radial clearance being deleted due to the compression of the material, thus causing the need for alterations during fitting.

My adjustment of these parameters ensures that the clearance tolerances are tailored specifically to the expected application. This not only optimizes the efficiency and the performance of the machine but also cuts the chances of early and undesired breakdown.

What are the different types of bearings and their specifications?

Bearings can be classified into various categories since each type has a unique function and performance ability. Rolling element bearings, which include ball or roller bearings, are general-purpose bearings for applications where low friction and high speed are essential. For example, one type, ball bearings, is best suited for light to moderate loads, and roller bearings do well with heavy radial loads. There are also plane bearings, which use no rolling elements and are best suited for applications that require simplicity and high load, such as heavy machinery. There are also some specialized ones, such as needle bearings, which make them usable in narrow spaces, and thrust bearings, which are designed for axial loads. In my experience and practice, when there is a bearing to be selected, I stress the specifications of the load, the speed rating required, materials used, and lubrication needs so that they would best serve their purpose.

Deep groove ball bearings: Features and applications

Deep groove ball bearings are some of the most commonly utilized and multipurpose bearing types across the different sectors. Its characteristics include a simple design, reduced friction, and the ability to support radial and axial loads. These bearings are arguably the most effective in terms of speed and strength, which allows for their utilization in electric motors, automobile components, and some household items. When properly greased and cared for, deep groove ball bearings can guarantee performance in many operational conditions.

Tapered roller bearings: Understanding radial and axial loads

Tapered roller bearings are made to take up effective control of both radial and axial loads, and, from my experience, they fit quite well in the context of heavy-duty applications. In this way, these bearings load the conic surfaces equally during operations which reduces wear and extends life expectancy. I’ve seen them in autos quite a lot in parts such as wheel hubs and transmissions, which subject them to combined loading, which is a necessity for these parts. When fitted and aligned correctly, they work well, but slight misalignment makes them inefficient and increases wear. These bearings have unquestionable strength and bearing capacity and do well under pressure.

Angular contact ball bearings: Specifications for specific uses

Apparently angular contact ball bearings must conform to the specifications pertaining to the particular application in question. I have been making an effort to grasp the details of bearing parameters in quite a number of projects where I had to exercise a good measure of discretion in the selection of bearing, speed as well as load. For example, high-speed applications such as those of machine tool spindles generally need the use of rolling element bearings, which are designed of greater contact angle and better materials in order for the machine to be stable and strong enough. Furthermore, the preload conditions are also important because they influence the rigidity of the spindle and the operational accuracy. Also, I would mention a more forge-oriented practice such as active consultation of the manufacturers’ recommendations or using dynamic testing of the bearings – such methods would increase the possibility that these bearings could bear serious engineering applications.

How can I identify a bearing based on its specifications?

Identifying a bearing is no longer a complicated process once relevant criteria have been established. I always recommend commencing with the manufacturer databases or a product data-sheet, as it contains all the particulars they will need. I do this in an organized manner, and here is how it goes:

- Bearing Type and Designation – The first thing I check is the type of bearing, whether it is a ball bearing, roller bearing, or a specialized type, and the designation given by the manufacturer. This would, most of the time, include a number of letters or numbers which stand for the size, type, and features of the bearing.

- Dimensions – The inner diameter (ID) that I would want to cover is the inner surface of the bearing, the outer diameter (OD). T The width of the bearing The dimensions are critical because they determine whether the bearing will be physically located in the application. Always perform a heat test on them against the specifications of your equipment.

- Load Ratings -I take a look at the static and dynamic load ratings as they define the forces that a bearing can sustain during operation. Higher dynamic load ratings generally mean better-bearing performance under different operating conditions.

- Material Composition -The material of the bearing is important information regarding the same’s applications as well as its longevity or durability. For instance, stainless steel wringing bearings are suitable and recommended for damp environments as they resist corrosion. However, ceramic bearings work well in most situations involving rapid motion or heat during operation.

- Speed Ratings – Each type of bearing has its own set maximum speed. I ensure that this maximum speed is bigger than the working speeds of the application in order that the bearing does not overheat or wear off prematurely. This maximum speed value is known as RPM or Revolutions per minute.

- Seals and Lubrication – Finally, I examine the sealed status of the bearing, i.e., if uncompromised seals have open spaces for relocation of lubricants or if the bearers are available for relocation due to shields or must remain blocked throughout the application. Expectations about relocation or exposure can assist or even completely remove the interference from maintenance.

I’ll make sure to take all of these factors into consideration in order to accurately make the determination of the particular bearing and to determine that the bearing is indeed perfect for that order. If there’s still any confusion, I’ll look up the part number or reach out to the producer.

Decoding bearing series and prefixes

Though understanding the bearing series and its prefixes can be a tedious task initially, it gets easier as one gains experience. Every prefix and series code has a specific purpose: to communicate the structural configuration and size of the bearing as well as its intended operational capabilities. To illustrate, prefixes generally portray the presence of structural features, such as unique seals or types of materials, while series code describes the axial and radial dimensions, such as the length and the width, respectively. With these standardized codes that are developed, a bearing’s functionality can be roughly understood even without completely taking it apart or examining it in detail. It is the comprehension of these details that enables me to make a wise selection of the component in question in a reasonable time, thus cutting down unnecessary time wastage and costly errors in the application of the components.

Understanding suffix meanings in bearing nomenclature

The last part of any bearing designation would say more about the bearing’s applications and functionality, so I have learned over the years how important this knowledge is to any profession in the industry. These suffixes would routinely represent such functional aspects as seals, cages, or even a clearance level, which would affect the performance of the bearing in more or less defined operational conditions. For example, if there was a need to use bearings in an open dusty atmosphere, one can specify a type that says “2RS,” which means two rubber seals, the same way it is appropriate to say “C3” when referring to bearings with internal clearance for high-temperature operations. Getting acquainted with such details, I cannot waste time more than necessary because I can determine very quickly what individual construction will be of bearing needed for that particular job and thus ensure almost uninterrupted service in the most critical conditions.

Using ISO standards for bearing identification

ISO norms for bearing marking offer a global standard to sort and comprehend bearings according to their class, size, basic tolerances and features. By applying such standards, professionals are able to easily interpret the values marked on the bearing in relation to its bore size, series, and precision class, enabling interchangeability and functionality over a broad spectrum of applications.

What do the numbers in a bearing designation mean?

In regard to bearing designations, I mention them to people as a spoken language in a shallow sense that gives all information about the bearing. Each digit or letter in the description has its significance. For example, the first one or two digits normally show the kind of bearing and the general use, and the subsequent numbers often describe the bearing’s dimensions, including, for instance, its bore diameter. More letters and numbers might specify bearing series and width and any special features that involve seals and lubrication. These numbers assist in the selection of correct replacements as they inform us of the kinds of bearings that are suitable for specific functions, thus saving time and cost altogether.

Breaking down the first and fourth digits

Bearing types are classified in accordance with primary functionality and are generally indicated by the first digit of a bearing designation. In the case of good radial and axial loadings where the requirements are still not too severe, a deep-groove ball bearing having a radial type of internal clearance classified as “6” is used. On the other hand, the width series of bearings is designated by the fourth digit of the sequence. The presence of a “0,” “1,” or “2” in this position indicates standard, narrow, and extra-narrow width series, respectively. Hence, these digits act as indicators as well, which eliminates a lot of time consumed in the selection of bearings for a particular usage.

Interpreting bore size and outer diameter information

In regard to the interpretation of the bore size and the outer diameter information, I solely depend on the numbering system to obtain the correct measurements’ that would make my decisions. Inch-power will be the bore size represented by the last two digits of the bearing designation, which is usually the case in most circumstances. If for instance, the last two digits are “20”, the operating bore size will be a hundred mm. The outer diameter of the ring is obtained with the aid of standardized tables that relate to the bearing series and the inner diameter. This orderly method makes it easier and more pleasing to select bearings that conform to the requirements of the work.

Understanding additional numeric codes for special features

Auxiliary codes are made use of in new designs, signifying clearance, seal protection, material, or other characteristics that are different from the basic requirements of normal operation. These include perhaps C3 for internal clearance, J for steel cage, M for brass cage, or Z and ZZ for one or two shields, respectively. As such I know which bearings are designed for say high speeds or low and high temperatures or have been designed for a particular oil so that they can be used in such instances.

How do bearing specifications affect performance and selection?

Yes! Bearing specifications are critical in both the performance and the selection process because every single detail of the design incorporates operational requirements. This is my way of doing so:

- Load Capacity: For most projects, I tend to first consider the load capacity of the bearing, whether it be radial or axial. For larger applications, I prefer to source bearings that have more dynamic and static load rating bearings. This prevents the bearing from taking on forces that it will not be able to endure and experiencing excessive wear or even shearing.

- Speed Rating: The speed rating for the bearings is crucial, which in turn decides the suitability of the bearing for higher velocity applications. Whether it be operating machinery, turbines, or spindles I ensure that the maximum speed of rotation of the bearing does not surpass the specifications of the system. A mismatch here can lead to overheating or failure.

- Material Construction: The material of the bearing offers a considerable contribution towards its stability, durability, temperature range, and even the type of lubricant that can be used with the type of bearing, whether it be a steel, ceramic, or hybrid bearing. For instance, ceramic bearings can be utilized at high rpm and high temperatures due to their small size and great thermal resistance.

- Lubrication Requirements: The type and frequency of lubrications are also rather important. If ZZ or 2RS bearings have a seal or shield, they are usually already lubricated, so little maintenance is required. In contrast, open bearings may need to be lubricated frequently, however they provide flexibility in terms of which lubricant to use.

- Operating Environment: In most cases, what determines the selection of bearings are the environmental factors where the bearings would be used, including temperature and weather, moisture, and the chemical substances surrounding it. Usually, bearings that have a coating or specific clearance are more suitable for use in areas where there are chances of corrosion or heat expansion.

- Precision Levels (ABEC/ISO grades): More often, I opt for a tight tolerance section for aerospace or even robotic applications. I always try to select higher grades as these provide reduced vibration bearings, which facilitates smooth operations and gives efficiency.

I study these parameters in such a way that, when choosing a bearing, it not only satisfies the present application but also warrants the increased life and efficiency of the system. This methodical approach minimizes the chances of system failure in addition to guaranteeing maximum productivity in the harshest of conditions.

Evaluating load capacity based on specifications

In performance evaluation of load capacity in relation to specifications, I concentrate on dynamic and static loads provided by the manufacturer. As given in the dynamic load ratings the general endurance of the bearing during continuous operation under standard conditions may be assessed, static load ratings reveals the level of the applied load, which can be sustained by the bearing without permanent deformation. On the other hand, I take into consideration shock loads and moment loads, which may occur in practice, verifying the fact that the bearing is able to withstand these phenomena. So, in a manner of speaking, after reviewing these specifications, if they agree with the demands of the application, the rules are decisive in bearing selection, which can be guaranteed to perform satisfactorily and for a long period of time.

Choosing the right clearance for your application

Choosing the appropriate clearance should be seen as a trade-off between functional aspects and application needs. In high-temperature conditions or where thermal expansion of the shaft is significant, it is advisable to have a greater clearance to avoid possible seizure. On the other hand, for applications where pa recise location or reduced vibration is of importance, the requirement is usually for tighter clearances to improve stability. Always review the operating instructions provided by the manufacturers, and do not forget any operational variations to maintain the efficiency of the bearings and prolong their functioning.

Considering radial and axial load requirements

In order to understand how to select the right bearings for a given application, one must analyze the radial and axial load requirements, as they have a direct impact on the size, type, and shape of the bearing that will be most appropriate. Where a radial load is delivered perpendicular to the shaft, an axial load equals a force delivered parallel to the shaft, and the bearing has to withstand the two resultant forces reliably. Carry out an evaluation of the magnitude and direction of these loads and make use of bearings that limit the concentration of these loads in any one particular region in order to increase service life. Also, the maximum loads during peak periods and dynamic factors must be taken into consideration in order to ensure maximum endurance and efficiency.

Reference

- Introduction to Bearing Specifications – This source provides insights into common dimensions and bearing capacity.

- Technical Information on Ball Bearings – Offers technical details on ball bearing types, selection factors, and load data.

- Ball Bearing Size Chart – A comprehensive size chart for ball bearings.

Frequently Asked Questions (FAQs)

Q: How can I identify bearing size using a bearing size chart?

A: To identify bearing size using a bearing size chart, you’ll need to measure the bearing bore (inner diameter), outer diameter, and width. These measurements correspond to specific numbers in the bearing nomenclature. For example, in a single-row deep groove ball bearing with the code 6205, “62” represents the bearing type, “05” indicates a 25mm bore size. Use these measurements to cross-reference with the chart to find the correct bearing specification.

Q: What is internal clearance in bearings, and why is it important?

A: Internal clearance refers to the total distance through which one bearing ring can be moved relative to the other in the radial or axial direction. It’s crucial for proper bearing function, especially in high-speed applications. The right amount of clearance ensures optimal performance, reduces friction, and prevents overheating. Bearing clearance is particularly important in radial bearings and can affect the overall efficiency of mechanical systems.

Q: How do I interpret the nomenclature for metric and inch bearings?

A: Metric bearings typically use a number-letter-number format. For example, in “6205 ZZ,” “62” indicates the bearing type, “05” represents the bore size (25mm), and “ZZ” denotes shields on both sides. Inch bearings often use a letter-number format, like “R8,” where “R” represents the bearing series and “8” indicates an inch fraction bore size. Understanding these codes is essential to accurately identifying bearing specifications.

Q: What are the key components of a bearing?

A: The main components of a rolling bearing include the inner ring, outer ring, rolling elements (such as balls or rollers), and cage or separator. The bearing bore is the inner diameter of the inner ring, while the outer ring’s outside surface forms the outer diameter. These components work together to reduce friction and support loads in various mechanical applications, from standard bearings to specialized types like needle roller bearings or thin section bearings.

Q: How can I determine the bearing bore size without a size chart?

A: To determine the bearing bore size without a chart, you can measure the inner diameter of the bearing using a caliper or micrometer. For metric bearings, multiply the last two digits of the bearing number by 5 to get the bore size in millimeters. For example, a 6205 bearing has a 25mm bore (05 x 5 = 25). For inch bearings, the bore size is often directly stated in the nomenclature or can be derived from the series letter and number combination.

Q: What’s the difference between radial and axial bearings?

A: Radial bearings, such as deep groove ball bearings, are designed to support loads perpendicular to the shaft axis. They’re commonly used in applications where the primary load is radial. Axial bearings, also known as thrust bearings, support loads parallel to the shaft axis. They’re used when the main load is in the axial direction. Some bearings, like angular contact ball bearings, can support both radial and axial loads simultaneously.

Q: How do I identify a bearing when the markings are worn off?

A: To identify a bearing with worn markings, start by measuring its dimensions: bore size, outer diameter, and width. Compare these measurements to a bearing size chart. Look for any remaining visible features like seals or shields. If it’s a ball bearing, count the number of balls. For roller bearings, note the type and size of rollers. With this information, consult a bearing supplier or manufacturer to help identify the bearing type and specifications.

Q: What do the third and fourth digits in a bearing number represent?

A: In many bearing numbering systems, the third and fourth digits often represent the bearing’s width series. For example, in a 6205 bearing, “05” indicates the width series. This information, combined with the bearing type (represented by the first two digits), helps determine the bearing’s overall dimensions. However, interpretation can vary between manufacturers, so it’s always best to consult the specific manufacturer’s guidelines or a comprehensive bearing size chart to understand the full meaning of these digits.