When it comes to vehicle maintenance, every part is significant as far as safety and performance on the road are concerned. One of these vital parts that is often ignored by many people but plays a crucial role in the wheels functioning properly are wheel bearing seals. This article seeks to give an all-round guide on checking wheel bearing seals when doing a pre-trip inspection. In this piece, I will explain why this examination is necessary for both professional drivers and car owners who want to be proactive with their car care program, as well as what they should watch out for during the process and how it helps improve the safety and reliability of driving.

Why are wheel bearing seal inspections crucial for vehicle safety?

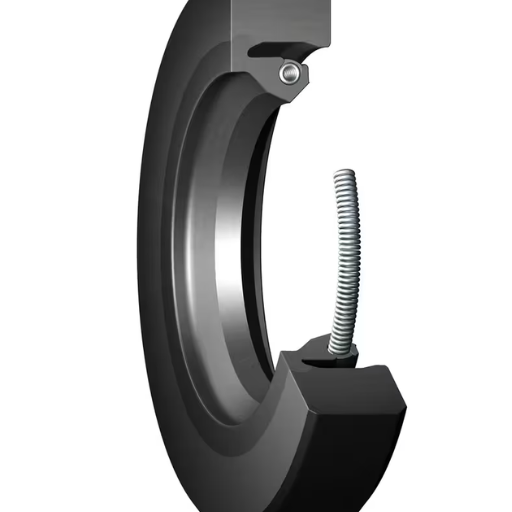

It is important to examine the wheel bearing seals in order to enhance the safety of a vehicle by preventing lubricant leakage and avoiding contamination of bearings. Seals that have been damaged or are malfunctioning can result in higher friction, overheating, and ultimately bearing breakdowns, jeopardizing the steadiness and manipulability of a car. Evaluations on a regular basis guarantee that the seal remains intact, thus reducing the chances of accidents and expensive repairs while offering better driving.

The role of wheel bearing seals in maintaining wheel integrity

My experience in the industry has taught me that wheel bearing seals are highly important to the wheel assembly. They prevent dirt, water, dust and other such impurities from affecting the bearings adversely. Besides, these seals keep lubricants in their place reducing friction and limiting wear with time. Through proper maintenance procedures and carefulness in these aspects of seal applications, I realized how long bearings could last; hence, they generally improved vehicle performance. Those who value safety must always appreciate this fact; otherwise, they compromise their safety as well as efficiency by not paying attention to them.

Potential consequences of seal failure

When seals fail, a number of serious problems result from this, and I have seen these issues myself in my years in the industry. Some outcomes of seal failure which I think are important for everyone to know are:

- Contamination of Bearings: When seal failures happen, dirt, water, and other debris get to the bearing housings. This contamination quickens wear and tear, thus significantly reducing the life span of bearings. Even minute particles may disrupt accuracy in precision machinery.

- Loss of Lubrication: A correctly functioning seal will ensure that lubricants remain inside the bearing house. In case this fails, lubrication starts leaking out, causing increased friction and overheating. Lack of enough lubrication can lead to bearings seizing,p resulting in catastrophic equipment failure.

- Increase in Friction and Wear: With failed seals, more unwanted particles and debris enter into the bearings while, at the same time, there is a loss of lubrication. As a result, excessive friction occurs, leading not only to damage to bearing surfaces but also possible warping or deformation during operations on other parts.

- Costly Downtime: Seal issues causing equipment breakdown often end up with an unexpected downtime. Taking care of broken parts or replacements takes time and may interfere with schedules, causing productivity losses and additional expenses.

- Safety Hazards: The overall system integrity could be compromised by failed seals. For example, when bearings overheat, they can ignite fires or create hazardous situations. This is especially important for industries where worker safety is directly tied to equipment reliability…

So as to evade such outcomes, I would propose routine checking and sealing. It is important to evaluate these parameters so that they match the system requirements; such factors include the type of seal material, operating temperature ranges, and pressure levels, amongst others. This way, you prevent problems before they escalate and ensure your machine runs smoothly throughout.

How seal inspections contribute to overall vehicle safety

For safety purposes, it is important to have proper seal inspection of the vehicle which most people often overlook in terms of maintenance. Fluid leaks, poor system functioning, and even mechanical failures can be caused by defective or damaged seals, thus posing a greater danger on the road. This will enable me to notice signs of wear or damage immediately, hence ensuring that brakes, transmissions, and steering systems work well. Besides extending component life, this approach also eliminates the chances of accidents caused by mechanical problems.

What are the key signs of wheel bearing seal issues?

Key Signs of Wheel Bearing Seal Issues

What are the main symptoms of a wheel bearing seal failure, and what can be done to prevent it? Examples of that include grease leakages around the wheel hub that can be easily seen, grinding or humming noise when driving, irregular tire wear, and excessive play or vibration on the wheels. Such signs frequently indicate a problem with seals, which ultimately results in contamination of bearing assembly and diminished function.

Visible leakage around the wheel assembly

Sometimes, you will notice leaking around the wheel assembly. This is usually caused by the deterioration of the wheel bearing seal or, in some cases, its damage, which allows grease to escape. Reduced lubrication occurs as a result of this leakage, and there is also an increased risk of debris intrusion that could lead to faster wear-off and compromised performance of the bearing system. The best way to address this is through quick action and replacement of seals.

Unusual noises or vibrations from the wheel area

In my own experience, strange sounds or vibrations emanating from the wheel area are usually a sign of a failing wheel bearing. This may come as a humming, growling, or grinding noise that gets louder with speed or when going around corners. Vibration, however, can result from excessive bearing wear or misalignment in the wheel assembly. Preventing more damage to the suspension system and road safety is important by addressing these signs early enough. Whenever I see these signs, I always recommend having it looked at by a professional.

How do you properly inspect wheel bearing seals during a pre-trip check?

For me to ascertain the condition of wheel bearing lubricants in a pre-trip check, it is advised that I first visually check for signs of leakage around the hub. If any grease or oil has been discharged by the seal, this would indicate that there is some damage or wear. Then, I will confirm that the area around the seal is clean and without any unwanted substances that might spoil it. Afterward, using my hands, I can try rocking tires to identify whether there is a cause for concern or not, like when a seal is damaged or a bearing needs replacement. Should anything seem out of place—whether a leak, an unusual movement, or any damages—I deal with it promptly before I hit the road to avoid much bigger problems later on.

Visual inspection techniques for identifying seal problems

How I typically approach it step by step and make sure that nothing is missed when determining seal issues through visual inspection.

- Check for visible leaks – A common sign of a seal problem is often fluid leakage. I do a thorough search within the sealing area to check for any oil, grease, or other fluids that shouldn’t be there. Even an insignificant oozing may indicate the beginning of seal failure.

- Inspect the seal material – I examine the actual seal for fractures, rips, or noticeable abnormal shapes. Over time, seals can degrade because of heat, pressure and wear, therefore physical damages indicate that it might be time to replace your seal.

- Evaluate the surrounding area – Don’t focus on the gasket alone. I also look around at my components to identify if there’s any dirt, corrosion, or strange residue that may compromise its performance. This results in wearing out of the seal if not well taken care of.

- Look for alignment issues –A wrongly positioned seal will cause uneven wearing or gaps, which may lead to leakages. While doing this inspection, I am very keen when taking note of where my gasket has been installed so as to ensure it is sitting flush and properly aligned with adjacent parts.

- Check for wear patterns – Uneven wear around the seal or adjacent components could mean that there isa constant contact problem or wrong installation. These patterns speak volumes about how the system works.

These parameters make evaluating the well-being of seals possible. Early detection can help address problems, thus saving time and averting future drastic issues. Never rush, and do not be committed to a comprehensive examination of every item; indeed, this is the main secret of ensuring public safety and equipment reliability.

Checking for proper lubrication and grease levels

Lubrication is an important aspect of any mechanical system that keeps it running smoothly over a long period. This means checking the oil level, greases applied, their application pattern, and the signs of contamination. I want to be sure there is enough oil in it as the manufacturer recommends and that this oil has not degraded or been combined with dust or moisture. If one forgets this step, it will lead to more friction, thereby overheating and later breaking down of equipment. These levels need to be monitored regularly to prevent premature wear and tear so that the machines keep on performing effectively.

Assessing seal integrity and potential contaminant intrusion

To assess seal integrity, you need to go through the sealing process meticulously and check if there are any signs of leaks on these seals. The seals must be seated correctly with no leakage. The presence of unusual residues, dirt buildup, or a change in lubricant quality may suggest possible intrusion by contaminants. Timely replacement of worn out seals is necessary in order to maintain good performance of equipment and avoid costly downtime.

What causes wheel bearing seal failure?

Repeatedly, I have observed that wheel bearing seal failure is often a result of multiple factors. Inappropriate setup is one of the most common causes of incorrectly placed seals being affected when there is pressure on them. Conversely, dirt, moisture, and dust cause contamination, which can quicken deterioration by entering the seal. Further, seal material may be destroyed over time due to overheating from overloading or insufficient lubrication. Thus, the passage of time makes these seals non-flexible. Hence, they develop creaks, which lead to leaks . Always undertake regular maintenance and install properly, as well as monitor operating conditions to prevent such failures.

Improper installation and maintenance practices

My experience constantly shows how seals are affected by improper installation and maintenance practices that can greatly impact their lifespan and overall performance. These are some of the key factors to consider when dealing with this problem.

- Alignment during Installation

One of the most common mistakes I come across is a misalignment of the seal at the time of installation. If not aligned properly with the shaft or housing, it can cause uneven wear and excessive friction. Hence, you should use the correct tools and make sure that the seal fits perfectly in its intended place.

- Force Applied During Installation

Seals are fragile parts and can easily be destroyed by too much force. For instance, pounding a seal into place or using inappropriate tools could deform it. Usually, this involves applying even pressure through a press or specialized installation tool as recommended for mounting seals.

- Surface Condition of the Mating Parts

The surfaces where the seal contacts must be clean, smooth, and have an appropriate finish. A scratch, burr, or any other debris on these surfaces will cause breaking of the seal resulting in early failure. To avoid such problems, I usually advise my clients to check and prepare these areas before the installation process begins.

- Lubrication during Installation

Another key aspect of installation is lubrication. Failure to properly lubricate the seal while installing can result in high friction and heat at startup that could damage the seal material. Proper use of the right lubricant facilitates not only an easy installation but also offers immediate protection once the system starts running.

- Maintenance Frequency

Even if a seal is perfectly installed, it will fail if it is not monitored and maintained adequately. Regular checks for pollution, wear, and appropriate lubrication are crucial to tackling small problems before they become big issues. I always recommend setting up a maintenance program and following it through to ensure that every item has been taken care of properly.

By addressing these parameters systematically, most problems resulting from incorrect installation and servicing can be avoided. It’s about dedicating ample time to ensure rightness in the process and checking the surroundings as the seal gets old.

Normal wear and tear over time

What I have found is that normal wear and tear is something one cannot avoid when it comes to the lifecycle of any sealing system. With time, the materials are naturally degraded by factors such as temperature changes, friction, and exposure to the environment, which they can hardly control. However, diligent monitoring and preemptive maintenance programs could help slow this process down. The life of the seal can be extended greatly if it is kept clean, well-lubricated, and free from contamination. Although wear and tear are inevitable, proper strategies can maximize the utility of the sealing system before it requires replacement.

Environmental Factors Affecting Seal Performance

Factors such as temperature variation, exposure to ultraviolet radiation, chemical compatibility, humidity levels, and abrasive contaminants can have a great impact on the performance of seals. Material expansion or contraction can be caused by extreme temperatures, while UV degradation may affect some polymers for many years. Additionally, excessive moisture and/or incompatible chemicals that are in contact with the seal can also weaken its integrity. To keep seals functioning at their best, it is important to know and control these environmental factors.

How often should wheel bearing seals be checked and replaced?

Based on my own experience in the industry, wheel bearing seals should be inspected during routine maintenance or at least once every 12,000 to 15,000 miles, depending on vehicle usage and operating conditions. Regular checks are vital because seals can break down as a result of wear and tear over time, heat exposure and also contamination. In the case of replacement, it is commonly suggested wherever you see any signs of leakage, damage or excessive wearing out. Proactive inspections guarantee smooth operation and avoid expensive repairs later on in life.

Recommended inspection intervals for different vehicle types

As an industry expert, I highly advise that you should always adjust your inspection schedules to suit your particular kind of vehicle and driving habits. In most cases, it is enough to check seals as well as vital fluids in a passenger car after every 12000 to 15000 miles so as to maintain its performance at peak level. On the other hand, heavy-duty trucks and those frequently used under harsh conditions should be inspected every 6000-10000 miles. Motorcycles are different because of their wear patterns; therefore, checks should be made every 4000-6000 miles. In conclusion, any unexpected breakdown can be avoided if one follows his/her owner’s manual about regular maintenance, which helps in elongating the life span of the vehicle.

Signs that indicate the need for immediate seal replacement

Some obvious indicators that call for an immediate replacement of the seal. The most common, according to my experience, is when you see fluid leaking around the seals because it can indicate damage or wear. Also, strange sounds may come from there, such as whining or grinding—it happens mostly if a seal breaks, resulting in inadequate lubrication. Additionally, more shaking upon moving or accelerating and inconsistency while maintaining pressure in hydraulic systems are other signs that might be considered dangerous, especially when ignored. In case you discover any of these problems, I strongly suggest that you should fix them without delay so as to prevent further severe damage to the vehicle components. Prioritize regular check-ups and quick repairs at all times for proper vehicle functioning, safety, and efficiency purposes.

What are the best practices for preventing wheel bearing seal issues?

To me, the only way to avoid wheel bearing seal problems is by regular maintenance. It is crucial that seals are frequently checked for signs of weariness, harm, or leakage since this can save a lot of time and money if detected earlier. Make sure you use good quality grease that is right for your vehicle and its application so as to prevent friction and overheating. Take note of your driving conditions, as too much dirt, water, or road salt might degrade seals more quickly; hence, one should be extra careful in cleaning and maintaining his/her wheel assembly in such environments. Lastly, always follow the manufacturer’s recommendations for service intervals and use compatible parts to ensure long-lasting performance. A proactive attitude is what will help you win the battle against such issues in the future.

Proper installation techniques for new seals

Proper fitting of new gaskets is essential for efficiency and durability. Consider the installation process with regard to the following key aspects:

- Clean the Surrounding Area

Make sure to clean the housing and shaft properly before installing the seals. Any dirt, debris, or old grease can affect the functionality of the seal resulting into early wearing out or leaks.

- Inspect the Components

Scratches, dents, or uneven surfaces on a shaft should be identified prior to installation. There must be no roughness in order for it to have a good seal that is free from leakages. If any problems have been noticed with them, you need to fix them initially before proceeding further.

- Use the Recommended Seal Type

Always use seals that meet the manufacturer’s requirements in terms of their suitability to your specific application. This entails checking compatibility in terms of materials used in manufacture, sizes, and designs, among others. Usingthe wrong seals may lead to poor performance or failure.

- Apply Lubrication

Lightly lubricate the inner lip of the seal with high-quality grease or oil to reduce friction during installation. This helps avoid damage to the seal lip as it interacts with rotating components.

- Use the Proper Installation Tools

Use seal drivers or other specialized tools that are designed for installing seals. Never use common tools like hammers because they can exert uneven pressure that will damage the seal or cause it to be misaligned. When pressing the seal, ensure its fit is tight and the entire surface in contact with the housing is even.

- Align the Seal Correctly

Before starting installation, make sure you align the seal perpendicular to the shaft. Misalignment could result in the fast wearing of the unit and a subsequent failure of this sealing device. For dynamic applications in which there is constant motion on the shaft, this step must never be skipped at all.

- Follow Torque Specifications

If additional fasteners such as bolts or flanges are being used in your application, follow torque values provided by the manufacturer. An incorrect tightening procedure can put undue strain on both the seal and the surrounding area.

- Test for Proper Seating

When installed, check that it’s evenly seated against the housing; visually inspect it. Run a trial test before full operation to identify any leaks or poor sealing prior to putting everything together.

If you wish to have the best installation and prolong the durability and efficiency of your seals, then these steps need to be closely followed while respecting every detail. Ensuring that the right technique is used saves you from failure and further maintains the lifespan of surrounding components which reduces maintenance costs in the future.

Regular maintenance checks and lubrication

It has been my experience that taking care of your seals and associated parts requires periodic services and lubrication. I always advise seal inspections to be done at regular intervals, looking for signs of wear, deformation, cracks, or leaks. By detecting these problems early, I can avoid expensive breakages. Furthermore, the addition of the right lubricant decreases frictional forces, reduces wear,and enhances efficiency. However, it’s hardly necessary to summarize that using the proper lubricant is vital for an application in order to avoid any issues with the seal’s compatibility. Consistency in maintenance practice is the key to prolonged equipment life and optimal operation.

Protecting seals from external contaminants

It is important to safeguard seals against foreign elements, as this relies on proper sealing designs, installations, and maintenance. Using dust lips or reinforced edges on the seal can help keep debris and fragments from entering the seal. Moreover, making sure that the installation and maintenance areas are clean significantly improves the chances of there not being any contaminants in the system. These contaminants include but are not limited to environmental factors such as extreme temperatures or chemicals. Following these steps will improve not only the performance of a seal but also the equipment’s lifespan.

How do wheel bearing seal problems impact overall vehicle maintenance costs?

From my perspective as an industry insider, I have seen that if the seal fails, it may let in contaminants into the bearing and allow vital lubricants to escape. This means that wear and tear could increase, perhaps leading to the premature destruction of the bearing. When compared to fixing a damaged bearing, fixing seal problems earlier is more expensive and time-consuming. Additionally, this neglect can cause other damages to adjacent parts like hubs or axles, which increases repair costs. For effective management of maintenance costs, always be proactive by monitoring the condition of seals and rectifying any issues immediately.

The relationship between seal failure and costly repairs

The connection between seal failure and costly repairs is apparent based on my experience. In most instances, it is a worn-out sealing unit that is the weakest link in the chain. When this is not identified in time, the damage caused increases fast. I have seen cases where a damaged seal allowed for dirt, water, and moisture to enter into the bearing assembly, causing rusting and eventual mechanical failure of parts under load stresses. Instead of simply replacing a seal as we would have expected, some major repair work on bearings, axles, and other components had to be done. The main lesson here is taking care of seal-related issues promptly safeguards an automobile from expensive repairs while maintaining it safe as well as dependable on the highways. It’s crucial to always maintain proactive maintenance strategies because they are really rewarding in the long term.

Long-term benefits of regular seal inspections

As an expert in the field, I can say that the importance of regular checks on seals cannot be stressed enough. In my case, routinely inspecting seals for damage and wear has provided better performance and longer life of critical parts. Inspections minimize the chances of untamed positive unnoticed issues that are often resource drenching ordering that more often saves resources in the long run. Other than the cost savings, the practice maximizes reliability and safety, which upholds customer satisfaction and goodwill. An easy measure, but one that pays off in the longer term.

Reference

- Fleet Maintenance: Wheel-End Maintenance Checklist for Pre-Trip and Post-Trip Driver Inspections

- The Truckers Report: What Do You Actually Check on a Pre-Trip Inspection?

- AMSOIL Blog: Tech Tips for Maintaining Wheel Bearings

Frequently Asked Questions (FAQs)

Q: Why are wheel bearing seals critical components in a vehicle?

A: Wheel bearing seals are critical components because they are designed to keep lubricant within the wheel assembly and prevent contaminants from entering the wheel bearings. They play a crucial role in maintaining the integrity of the wheel bearings, preventing premature wear and potential bearing failure.

Q: What are the main signs of a leak in wheel bearing seals?

A: The main signs of a leak in wheel bearing seals include visible oil leaking around the wheel area, grease or lubricant on the inside of the tire or wheel rim, and a wet or oily appearance on the outer surface of the hub. These indicators suggest that the seals aren’t functioning properly and require immediate attention.

Q: How often should wheel seals be checked during pre-trip inspections?

A: Wheel seals should be checked during every pre-trip inspection. Regular inspection helps identify potential issues early, preventing more serious problems and ensuring the vehicle’s safety. It’s essential to make this check a routine part of your pre-trip procedure.

Q: What is a common cause of wheel seal failure?

A: A common cause of wheel seal failure is improper installation. If a seal is installed incorrectly, it may not seat properly, leading to leaks and premature failure. Other causes include wear and tear, contamination, and exposure to extreme temperatures or harsh environments.

Q: How can drivers prevent seal failure and extend the life of wheel bearings?

A: To prevent seal failure and extend the life of wheel bearings, drivers should regularly inspect seals for signs of wear or damage, ensure proper installation of wheel components, avoid overloading the vehicle, maintain correct tire pressure, and follow recommended maintenance schedules. Additionally, promptly addressing any unusual noises or vibrations can help prevent more serious issues.

Q: What should drivers check for when inspecting wheel bearing seals?

A: When inspecting wheel bearing seals, drivers should check for any signs of leakage, damage, or wear. Look for oil or grease around the seal area, check for any visible cracks or deterioration in the seal material, and ensure the seal is properly seated. Also, be aware of any unusual sounds or vibrations coming from the wheel area, as these may indicate compromised wheel bearings or seals.

Q: Can damaged seals lead to other vehicle issues?

A: Yes, damaged seals can lead to various vehicle issues. When seals fail, lubricant can leak out, and contaminants can enter the wheel assembly. This can result in increased friction, overheating, and premature wear of the wheel bearings. In severe cases, it may lead to bearing failure, which can cause wheel lockup or separation, posing significant safety risks.

Q: Are there any new questions or concerns regarding wheel bearing seals that drivers should be aware of?

A: While the fundamental importance of wheel bearing seals remains unchanged, drivers should stay informed about new seal technologies and materials that may offer improved performance or longevity. Additionally, with the increasing use of electric and hybrid vehicles, some manufacturers may have specific guidelines for seal inspection and maintenance in these newer drivetrains.