The use of precision air bearings constitutes a major leap in motion systems, revising the boundaries of modern technology and engineering. Traditional bearings operate by having surfaces contact each other. However, air bearings consist of a thin film of pressurized air, creating almost zero friction surfaces. This thereby enhances both accuracy and efficiency as well as reliability to levels that have not been experienced before across a broader spectrum of businesses. The scope of operations has changed with the advent of advanced manufacturing, semiconductor production, high-precision metrology, and aerospace technology, which makes the role of precision air-bearing manufacturers crucial. The indication is that these manufacturers are not only making more and more sophisticated solutions but, indeed, are at the center of determining the direction that motion control will take by providing high-performing and wearing tools. This article describes precision air bearings and their distinct advantages, the markets that they transform, and the different companies that push such spectacular breakthroughs in technology.

What are air bearings, and how do they work?

Air bearings can be defined as high-technology devices manufactured without the need for bearing surfaces by utilizing air pressure. Consequently, such patented components “bear” most frictional forces through a constant supply of pre-stressed air, which is injected through specially engineered blades that are secured in a stationary structure. This infusion of air eliminates friction and has the ability to accurately and uniformly redistribute ai,r, resulting in perfect spherical motion while ensuring smooth and stable quality performance.

Understanding the principle of frictionless motion

I would like to point out that the basic principle of frictionless motion is that this is the foundation that drives high efficiency and high accuracy in applications requiring low operation. Air bearings are a perfect definition of this because they eliminate the contact between sliding surfaces completely, thus cutting down friction and improving performance. These bearings also facilitate controlled motion by maintaining quasi-static conditions and a thin, uniform air film around shafts, devices, and other parts, even in extreme conditions. This technology will revolutionize industries such as semiconductor fabrication, precision machining, and medical equipment, where small particles or defects can be catastrophic.

Comparing air bearings to traditional mechanical bearings

I can say that air bearings and mechanical bearings differ greatly from one another, which makes them suited for some tasks and not for others. So, for further understanding, I outline the most important aspects of these two types of bearings:

- Friction

One of the reasons for the differences between traditional mechanical bearings and air bearings is the level of friction. In traditional rolling element-bearings (which include, but are not limited to, ball or roller bearings), an element such as balls or rollers impact upon balls, which is known as bearing races or races. Over the course of time, such contact results in friction along the races, wear, and the requirement for lubrication. In contrast, however, air bearings do not come into contact with internal components but instead ride on a thin film of pressurized air. This greatly reduces friction with the result that bearing efficiency improves and its life span increases.

- Precision

Air bearings hold markers for high precision owing to their design, which lacks surface interface with their mating parts. Compared to air bearings, the mechanical components’ surface of contact allows for a much lower precision of interfaces, approximately rated micro to millimeters. Therefore, for critical systems applications, such as semiconductor manufacturing systems or high precision metrology equipment, air bearings are preferred over mechanical counterparts.

- Load Capacity

The general notion is that conventional mechanical aviation bearings have a larger load capacity due to the thick raw material structure. While aerodynamic bearings are reputed to be extremely smooth, their operating zone shall cover moderate loads. However, aerodynamic bearing design developments are slowly but surely advancing.

- Maintenance Requirements

Thanks to their simple mechanical configuration, Air bearings need virtually no maintenance, while Mechanical bearings have a rolling element/race that will require lubrication on a routine basis, and at some point, their elements will have to be replaced. In the end, air bearings provide good value, particularly in processes that have long duty cycles or where the capital outlay is justifiable.

- Environmental Suitability

Air bearings do not contribute to any contamination and, thus, are very clean and are suitable for applications on medical equipment or clean air environments. Mechanical bearings may occasionally be a source of contamination as lubricants break down with time and wear debris is generated, which is not acceptable for some of the applications.

- Cost

Although the initial investment in Air bearings is higher because of the intricate design and technology required to produce them, the returns from reduced maintenance and longer life span do compensate for this. On the other hand, the investment in mechanical bearings is minimal, but in the long run, maintenance and replacement costs will accumulate over the years.

Overall, the selection and use of air bearings and mechanical bearings greatly depends on the particular task and its constraints. Therefore, if one wishes to achieve maximum precision, minimal maintenance and unobstructed movement then air bearings are the best option. However, for high-load applications where the price is a major concern, mechanical would be more suitable.

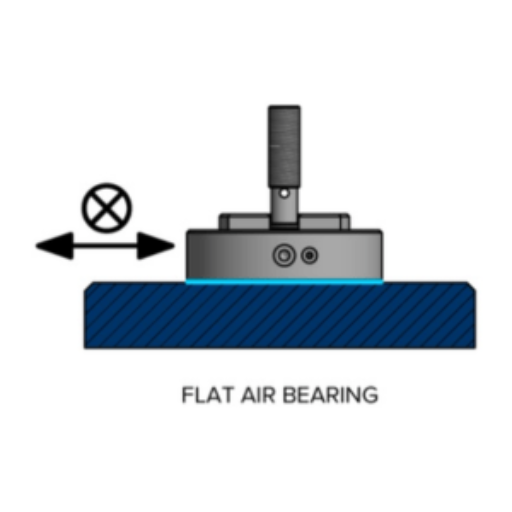

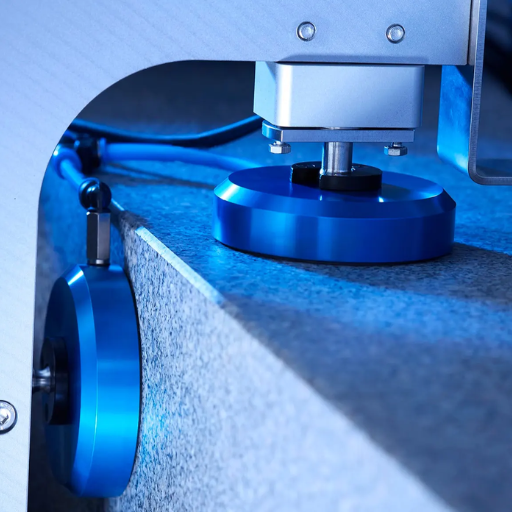

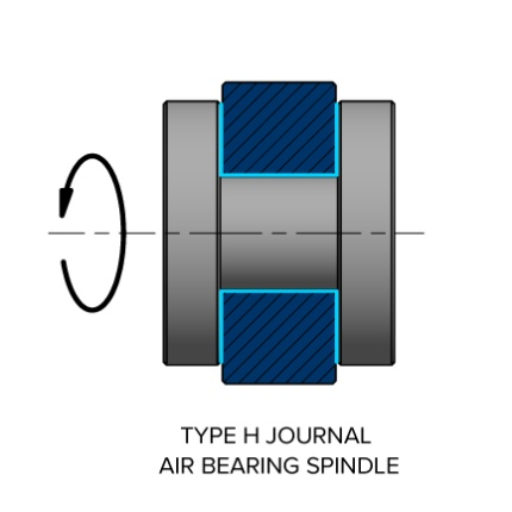

Types of air bearings: linear, rotary, and spherical

Linear air bearings, it’s fair to say, are unequivocally too efficient where friction is not a great hurdle to overcome and where every degree of it being eliminated makes the overall application an absolute precision work. Be it optical applications or metrology instruments, such bearings offer nearly unrestrained straight motion. Rotary air bearings, on the other hand, enable air support to rotational movement, which is effective in providing fast speeds or very precise movements, which is often required in turbines or even precision internal tools or machinery. Now, spherical air bearings, again, allow movement in many different directions, but they are most suited for parts where rotation in multiple axes is needed, such as in rotatable testing equipment or even certain screens/ parts in simulators. Every single type has its own unique characteristics that can be fitted for different industrial requirements.

How do air-bearing manufacturers ensure precision?

In order to maintain accuracy in the production process of air bearings, there is a need for advanced engineering combined with rigorous testing along with strict quality control supervision. For me, it begins with the choice of high-grade materials and components designed with tremendous accuracy. Our process incorporates state-of-the-art machining and finishing techniques so that we achieve the necessary tight tolerances for performance. Also, we put a lot of effort into verification processes, utilizing the means of inspecting cmm machines in measuring coordinates. Laboratory tests are also performed in the case that particular air bearings have been tested and approved for real-life use and have been shown to meet or exceed the required and set standards.

Precision engineering techniques in air bearing production

knowledge of engineering techniques is crucial, particularly when it comes to air-bearing manufacturing. Due to the advances in machining practices and the application of complex inspection procedures such as CMM, we are able to achieve maximum accuracy in all the parts manufactured. Every air bearing is then subjected to a series of performance tests under various operating conditions to ensure its reliability. Such a spirit of unwavering dedication to quality and precision is what differentiates us from others in the business.

The role of air pressure in maintaining accuracy

as you noted that air pressure is the precision-manufacturing force for air bearings. Everybody knows that air pressure is responsible for the extremely close clearance between the air-bearing surface and the counter surface. That clearance neutralizes a mechanical contact and, in turn, drastically diminishes friction and wear, which are indispensable in obtaining high accuracy and long life.

In order to comprehend air pressure’s contribution to precision, here are some relevant parameters that come into play:

- Air Film Thickness: The thickness of an air film is a function of air pressure. The amount of pressure to be applied has to be perfectly balanced – if there is more than enough pressure, the system would become unstable, and if there is not enough, there would be contact between atoms. This balance guarantees that everything operates as it should.

- Load Capacity: Air bearings make it possible for the load to be carried using air pressure. The only thing we do is adjust the pressure according to the weight and the working conditions so that the load capacity is proportionate to the performance requirement.

- Stiffness: Similarly, the stiffness of an air bearing, which quantifies the load-bearing ability of the bearing itself, would be dependent on the amount of air pressure supplied. Furthermore, sturdier bearings are more precise and reliable thanks to the significant degree of accuracy they require when moving.

- Flow Control: Airflow is a huge contributing factor to the amount of pressure that is scattered across the bearing surface. Lack of proper airflow regulation may lead to unknown changes in performance and accuracy.

We thus make it a point to manage and control these parameters so that air bearings can render the necessary accuracy and reliability expected in such stringent applications. This demonstrates the advanced engineering that goes into these components – the capacity to regulate air pressure.

What are the advantages of using air bearings in motion systems?

If we consider the benefits of incorporating air bearings in motion systems, I must say their performance remains unmatched when it comes to precision engineering. Since air bearings do not have mechanical contact, friction, wear, and maintenance issues are significantly reduced. The presence of no friction, in turn, ensures smoother movement as well as greater accuracy, which are essential in areas such as semiconductor manufacturing or precision measurement systems. Also, since they are able to work at high speeds with reduced vibration, high efficiency and extended life of the system are also achieved. I think air bearings are the most trustworthy components that provide high performance ratio, they should be used as a first priority in advanced motion systems.

Achieving frictionless and smooth motion

In order to accomplish free and non-contact movement, the incorporation of air bearings is crucial. These bearings form a thin film of high-pressure air around the moving surface, eliminating mechanical contact and subsequent friction. They have been implemented throughout industries such as semiconductors and aerospace as they spice up products with high durability while using modern manufacturing processes and airflow control, allowing bearings to be operated in an accurate, stable, and efficient manner.

Enhancing positioning accuracy in various applications

the invention of air bearings has brought a great change in the manner in which positioning accuracy is reached in many uses. Air bearings facilitate extremely high precision in tasks like semiconductor manufacturing, metrology, and even in aerospace by minimizing friction and blooming64 the problem of mechanical wear completely. I have experienced the reliability and performance enhancement of high-precision systems as a consequence of the ability of these air bearings to maintain constant motion irrespective of the surrounding conditions. This technology delivers continuous improvements in levels of accuracy and efficiency in evolving engineering applications.

Reducing wear and extending system lifespan

wear has to be reduced even in the smallest of its dimensions for the long-term functioning of any mechanical system to be reliable. Air bearings do this greatly, and their frictionless function prevents slow and steady wearing due to surface contact. This not only increases the operational life of the machines but also proves to be beneficial in terms of maintenance and unanticipated downtime. I have witnessed state-of-the-art systems greatly benefit from this technology, whereby the systems still retained their designed functionality after operating for years uninterruptedly. This is done by air bearings whereby minimization of wear is achieved, and to me, this offers a low-cost engineering solution while conforming to the principles of sustainable engineering, thus making air bearings to be a revolution in engineering.

Which industries benefit most from air-bearing technology?

air-bearing technology has shaped several sectors. However, what appears to be of particular note is precision manufacturing, as the technology allows for near frictionless motion, which is an integral requirement of high-accuracy machines like semiconductor fabrication equipment and CNC machines. Another zone where air bearings are deployed is in aerospace, where they are claimed to complement flight simulators and testing platforms with sufficient stability and precision. The medical sector also stands to gain a lot, especially for imaging systems like the MRI that require a vibration-free environment. There are a limited number of examples, but it seems that the effective use of air bearings now extends throughout a wide variety of industries.

Aerospace applications for air bearings

Air bearings have a special importance in the aerospace industry as they enable frictionless motion of those tasks where extreme accuracy and dependability is a requirement. They eliminate mechanical contact between themselves and other surfaces which translates into low wear, high stability, and low maintenance – all these aspects are very important for flight simulators, testing of satellite components, and also for high precision manufacturing of aerospace components.

Semiconductor manufacturing and air-bearing stages

I can unequivocally assure everyone that air-bearing stages are very crucial components in the fabrication of semiconductors. The tasks undertaken when manufacturing semiconductors are very intricate and delicate in nature and, therefore, require an accurate and stable supply of energy that mechanical systems are generally incapable of providing. Air-bearing systems meet this need with their ability to provide motion without friction.

Here’s a breakdown of why and how air-bearing stages are so important in this industry:

- Precision and Accuracy: In the semiconductor production arena, one is often required to set positioning tolerances in the range of nanometers. Air bearings, by not having any contact, eliminate errors due to friction or even wear, which results in unparalleled positional accuracy.

- Repeatability: In the course of a wafer being processed, inspected or in lithography, consistency becomes paramount once again. Due to the absence of contact, air bearings recover better repeatability since there are no mechanical inconsistencies that develop over time.

- Vibration Isolation: During sensitive operations with semiconductors, vibrations can cause the quality of the product to suffer. As air bearings have a damped motion by nature, they help reduce vibrations and offer stability to the process.

- High-Speed Performance: There are some types of processes in the semiconductor industry, such as wafer scanning, where there is a clear requirement for both high travel speeds and high accuracy. The air-bearing stages, in this case, facilitate both high speed and ease of movement throughout the processes.

- Cleanroom Compatibility: Semiconductor fabrication is carried out in environments with very high cleanliness levels. Air bearings suit such applications well since they do not contribute any particles from mechanical wear to the environment, thereby enhancing contamination-free operations.

These properties certainly position air-bearing stages as an outstanding solution within photolithography, wafer inspection, and die bonding situated at the intersection of rotary stage and linear stage designs. They also help manufacturers keep up with the requirement for frictionless interaction and precision control of motion, which are driving the development of more compact and efficient semiconductor components.

Precision engineering in medical and scientific instruments

The Form of Precision Engineering is the core element for the design and fabrication of sensitive scientific and medical devices with the proper degree of accuracy, reliability, and practicability. Such instruments are frequently deployed in critical tasks, and even slight errors can have serious repercussions. Below, we will address the precise parameter that emphasizes the necessity of precision engineering in this specific regard:

- Accuracy and Repeatability

Great care must be taken in the use of robotic surgery instruments or even imaging systems, as these instruments must have minimal movement while performing a task. The parts have been constructed such that they always work and repeatfully function, benefitting safety risks during important phases of surgeries.

- Minimized Tolerances

Instruments such as spectrometers or more advanced electron microscopes will need parts to be built with minimal or no tolerances. This is crucial when measuring or even observing groundbreaking particles that need precision from such materials.

- Enhanced Stability

Inadequate vibration or motion error can cause environment-sensitive instruments to fail; therefore, enabling precision makes the system more stable, allowing it to be more robust, particularly in a lab or a clinic.

- Durability and Reliability

Like any other tool, medical or scientific instruments will experience wear over time; however, tools made from high-quality density would withstand the test of time, thus making maintenance rare.

- Scalability for Miniaturization

There is a rise in need for devices that are non evasive, light and portable, precision engineering allows such devices to be built while also keeping effective components.

Medical and scientific instruments must meet industry and efficiency standards that are relevant to humanity, which is why precision engineering has evolved as a focus parameter, thereby ensuring reliability and innovation amongst instruments.

How do manufacturers customize air bearings for specific needs?

For custom air bearings, the first step is to know all the demands of the application. My experience in such work involves close cooperation with clients in a bid to define core parameters like load capacity, stiffness, and operating conditions. There are also other considerations, such as the materials used; for instance, we often get advanced alloys or ceramics to achieve some equilibrium between durability and performance. Precision machining and unique shapes also help create the bearings so that they integrate well into the required system. In addition, we work together on performance testing for simulations and the construction of prototypes to finalize the design before mass production. Such precision enables us to provide air-bearing solutions catering to specific operational requirements very reliably.

Designing custom air bearings for unique applications

Air bearings, as a rule, are an application’s special-purpose devices tailored to satisfy its functional requirements. This involves selective material choice, e.g., advanced alloys and ceramics, special geometrical forms generated by machining processes, and rigorous testing of prototypes. Each solution is tailored to the appropriate performance parameters of the system and ease of introduction into that system.

Integrating air bearings into existing motion systems

I believe that a critical approach needs to be taken to employ air bearings technology in an already existing system. In my case, the first task is to establish how air bearing could fit with some of your system requirements, for instance, load-bearing ability, control accuracy, and environmental considerations. I always start with a detailed inspection of the existing infrastructure – this includes adequate air supply systems, alignment tolerances, and thermal expansion effects. Correct offset is yet another important step because this results in all of the capabilities necessary for this particular application’s performance without damaging the coherent operation of the system. If all relevant elements are put into appropriate positions and factors are taken into consideration during the integration process, the smooth installation of air bearings into the motion system will improve its performance.

Balancing performance and cost in custom solutions

It is crucial to devise a plan when it comes to mergers the factors of achieving desirable performance and lowering expenditures of custom solutions. One ought to start by defining the key aspects of the application and then design a custom solution that meets those requirements without being too complex. Modular components with due consideration of physical properties and sufficient strength can also be cost-effective. Stakeholders’ involvement in discussions on the design aspects of the solution enables target performance to be achieved on the solution at the required cost. Thus, the intelligent application of common sense combined with creative ideas helps build cheap and effective custom solutions.

What are the latest innovations in air-bearing technology?

I’ve witnessed first hand how the latest reforms in air bearings technology have transformed precision engineering as we know it. One of the monumental changes is the use of advanced materials like carbon composites and ceramics, which enhance performance by improving structural integrity and thermal resistance. Furthermore, the alteration of air bearings in combination with smart sensors allows for instantaneous recording of essential parameters, thus enhancing predictive maintenance and overall efficiency. Another significant advancement has been the use of 3D printing,g which permits intricate and customized forms of construction that were virtually impossible at one time. These achievements increase the versatility and efficiency of air bearings, thus extending their applications in many more sectors, including aerospace, electrical systems, and microelectromechanical systems design and development н.

Advancements in porous media air bearings

Las superficies de fricción que se encuentran en la mayoría de los dispositivos rotatorios que permiten un movimiento libre son conocidas como elementos antifricción. Las tecnologías de las que se habla son cada vez más utilizadas en industrias como la robótica y la fabricación de componentes en semiconductores. Tales industrias requieren un alto grado de precisión debido a la naturaleza de los componentes fabricados. La unión de sistemas de diseño por ordenadores, técnicas de fabricacion aditivas, junto con la disponibilidad de una gran cantidad de nuevos materiales, ha resultado en la creación de medios porosos que aumentan la capacidad de estas cargas, y las cargas pueden ser muchas veces más que la capacidad normal de estas componentes gracias a la optimizacion de su diseño en tres dimensiones. Las importantes innovaciones que se han producido en las áreas de ciencia de materiales.

Developing smart air-bearing systems with integrated sensors

Constructing smart air-bearing systems that are equipped with sensors is an interesting problem that demands a level of engineering skill and craftsmanship. I think the challenge here lies with the need to fit the sensors without hampering the bearing ability. These sensors can help in interpreting useful information by measuring the pressure, temperature, and vibration of an entity in real-time. The engagement of this data enables maintenance within boundaries, preventing wear and tear that affects operations. Our efforts have, therefore, been mainly directed towards aiding the design of these sensors without complicating the workings of the bearing or the overall system. This approach makes room for air-bearing systems that are not only smarter but also more responsive to the complex requirements of modern technologically driven industries.

Exploring new materials for enhanced air-bearing performance

The strengthening of air-bearing systems is determined by the enhancement of materials, starting with novel ceramics-reinforced polymers. Such materials are of structural composites class, enabling greater performance, stability, and more fatigue-resistant structures at reduced weights. Also, there is a possibility of testing some coating layers, like DLC or molybdenum disulfide, which can be used to enhance aerodynamic effectiveness. With such innovative materials, it is possible to fabricate devices which have better precision and endurance as well as performance, fully satisfying the criteria of contemporary industrial or scientific tasks.

How do you choose the right air-bearing manufacturer for your project?

While selecting the appropriate propulsion air bearing system manufacturer I usually advise making compromises on certain factors, however there are a few defenders I recommend focusing on. First and foremost, their experience and history should be reviewed, and those who specialize in manufacturing top-quality air-bearing units for various industries should be sought. Second, focus on customization; a competent manufacturer would offer to collaborate with you on the most appropriate design. Moreover, check their level of commitment towards the fulfillment of their assigned tasks in terms of technologies and materials. Finally, customer support is imperative – work with a company that promises and delivers effective and timely support and service throughout your engagement. Keeping these factors in mind, you can make an informed decision that fits your project-related needs.

Evaluating manufacturers’ expertise and track record

The track record and industry presence of the manufacturer – their past projects and experience – need a comprehensive assessment. Here, my journey begins with seeking their history – duration in the market and breadth of industries served. A strong portfolio, such as case studies or client testimonials, is valuable because it reflects the capacity of that manufacturer to offer acceptable and dependable solutions. In addition to that, I consider certifications and technical qualifications as proof of seriousness with regard to quality and compliance issues. As a result, it is more probable that the manufacturer, who is already reputed for quality and versatility, will be able to handle the peculiarities of such a project.

Considering factors like customer support and lead times

In terms of customer support and lead times, these aspects are critical for aiding in the execution of projects. Strong customer support can always be relied on to eliminate uncertainties, whether it is addressing issues or seeking guidance, which in turn helps in avoiding unnecessary cost overruns. With regard to a manufacturer, take time to assess the lead time performance of the manufacturer in order to gauge the efficiency of the manufacturer in meeting project time frames. Firms that promote candor, adaptability, and willingness to react are more likely to provide reasonably acceptable standards for the quality and time of delivery of their products.

Assessing the manufacturer’s ability to provide custom solutions

One of the core attributes of a manufacturer is his ability to deliver tailored solutions, and this speaks volumes about his skills, flexibility, and his orientation towards the end user. Seek out past works done by them which demonstrate that tailored solutions were put into practice and that they are eager to work with the customers to meet their specific needs. Look into engineering aspects, their skills in design and how well they are able to meet specific features without compromise on quality and other required standards. Specialization in customizing the product, more often than not, indicates a potential business associate who is able to tailor his product range to suit the requirements of projects such as yours.

Reference

- OAV Air Bearings – A leading manufacturer of air bearings and motion systems.

- New Way Air Bearings – Known for their porous media air-bearing solutions.

- Nelson Air – Specializes in precision air-bearing components and systems.

Frequently Asked Questions (FAQs)

Q: What are OAV air bearings and how do they work?

A: OAV air bearings are precision motion components that use a thin film of pressurized air to provide near-frictionless movement. These bearings work by creating a cushion of air between two surfaces, allowing for smooth and precise motion in linear, rotary, and planar applications. OAV air bearings eliminate physical contact between moving parts, resulting in superior performance compared to traditional ball bearings or bushings.

Q: What are the advantages of air bearings in precision motion systems?

A: Air bearings offer several advantages in precision motion systems, including 1. Near-zero friction, resulting in smooth and precise movement 2. Reduced wear and longer lifespan 3. Improved positioning accuracy and repeatability 4. Elimination of stick-slip effects 5. Low vibration and noise 6. Ability to operate in clean environments 7. Suitability for high-speed applications: These benefits make air bearings ideal for ultra-precision applications in industries such as semiconductor manufacturing, metrology, and medical equipment.

Q: How do air bushings compare to traditional bushings in motion control applications?

A: Air bushings offer significant advantages over traditional bushings in motion control applications. Unlike conventional bushings that rely on physical contact and lubrication, air bushings use a thin film of air to eliminate friction. This results in smoother motion, higher accuracy, and reduced wear. Air bushings are particularly beneficial in precision positioning systems where even minor friction can impact performance.

Q: What types of air bearings are available for different motion requirements?

A: Precision air bearing manufacturers offer a wide range of air bearings to suit various motion requirements: 1. Linear air bearings for straight-line motion 2. Rotary air bearings for precise angular movement 3. Planar air bearings for multi-axis motion in a plane 4. Air bearing slides for guided linear motion 5. Air bearing spindles for high-speed rotation 6. Flat round air bearings for planar XY motion 7. Vacuum preloaded air bearings for enhanced stiffness. These specialty components can be combined to create complex, multi-axis positioning systems.

Q: How do rotary air bearings improve performance in precision motion applications?

A: Rotary air bearings significantly enhance performance in precision motion applications by providing frictionless rotary motion. They offer several advantages over traditional rotary stages, including: 1. Higher rotational speeds 2. Improved angular accuracy and repeatability 3. Reduced runout and wobble 4. Lower heat generation 5. Smoother operation, especially at low speeds These benefits make rotary air bearings ideal for applications such as optical scanning, precision machining, and semiconductor inspection equipment.

Q: What are planar XY air bearings, and how are they used in precision motion systems?

A: Planar XY air bearings are specialty components that provide frictionless motion in two dimensions (X and Y) within a single plane. They are commonly used in precision motion systems that require smooth, accurate movement over a flat surface. Planar XY air bearings are often employed in applications such as: 1. Wafer inspection and lithography equipment 2. Precision coordinate measuring machines 3. A flat panel display manufacturing 4. High-precision assembly systems These bearings enable ultra-precise positioning and scanning operations in industries requiring nanometer-level accuracy.

Q: How do air bearings eliminate friction in linear and rotary motion applications?

A: Air bearings eliminate friction in linear and rotary motion applications by creating a thin film of pressurized air between the moving surfaces. This air film acts as a lubricant, preventing direct contact between the bearing and the guide surface. As a result, there is no static or kinetic friction, allowing for smooth and precise movement. The absence of friction leads to improved motion quality, reduced wear, and enhanced positioning accuracy in both linear slides and rotary stages.