Both angular contact ball bearings and radial bearings are used in most equipment. However, their unique configuration and particular performance features make them suitable for different applications. It is necessary to understand the differences between the two types of bearings in order to choose the right one so as to maximize functionality, efficiency, and durability within a particular setup. This article discusses the main advantages of using angular contact ball bearings in place of radial bearings, emphasizing how the structural configurations of the angular contact bearings enable them to perform better in terms of load, speed, and other performance characteristics. This guide will thoroughly cover all of the critical factors of each type of bearing so that you can choose the right one for your application, whether it is high-speed machinery, strong axial loads, or accurate engineering.

What are angular contact bearings, and how do they work?

Angular contact bearings are uniquely constructed in such a way that they are able to hold both the radial and the axial components of the load operating simultaneously, which provides for their adoption in high precision and high-speed applications. In addition to this, their construction encompasses inner and outer raceways, which are eccentrically arranged to each other, thus making an angle of contact. This angular configuration permits them to bear axial thrust in one direction or both directions depending on their design, thus allowing their use in machines with strict requirements of uniformity in the stability as well as the load.

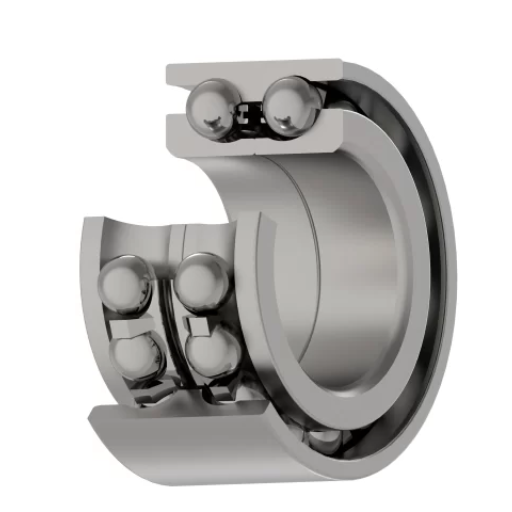

Understanding the design of angular contact ball bearings

It is the greatest achievement in engineering, angular contact ball bearings. These bearings are made to support both radial and thrust loads equally well. This is achieved through the angular contact bearings that allow for precision load transfer and are required in high-speed and reliable applications. Considering such requirements, the bearings can be configured as single-row, double-row, or matched pairs, which increases versatility. Their robust design considerations simplify friction and ruggedize the overall design, which makes them critical machine parts in the ever-increasing complexity of machinery and mechanical systems.

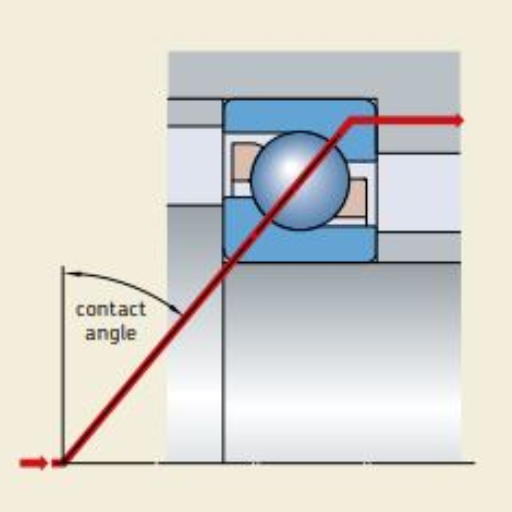

Exploring the contact angle and its importance

I do not intend to waste your time; however, I would like to explain why understanding the contact angle in bearings is critical. To better understand the contact angle, it is the angle with a bearing axis, which involves the angle between the load line (along which the load is carried through contact between the ball and race) and the plane perpendicular to the axis of the bearing. This angle is used to influence the way a bearing operates under various types of loading conditions.

- Axial Load Handling: Bearings that have a higher contact angle are more suitable for the axial load, which is the force that is applied parallel to the axis of rotation. Due to this, They find applications in the automotive hubs or machine spindles where there are significant axial forces.

- Radial Load Balance: A contact angle that is smaller in size moves the focus to radial load as one acting on the perpendicular to the axis. This balance is important in cases for instance electric motors or a basic conveyor mechanism where radial forces need to be countered.

- Load Distribution: The angle of contact has a load of bearing on a number of loading bearing parts. An incorrect angle would result in load uneven distribution, causing enhanced wear and tear of the bearing, decreased effective life of the bearing, and system inefficiencies.

- Operating Speed: In the case of bearings where a smaller contact angle is present, it is easier for them to achieve greater operating speeds due to the reduction in internal friction. In contrast, a greater contact angle weakens the speed capacity but enhances the bearing, which supports the axial load.

In order to optimize the performance and compatibility of the bearing with the structure’s lifespan, it is critical you comprehend the contact angle and its implications for both the load dynamics and the application needs. Critical parameters like the size of the loads (radial vs axial), the speed of operation, and the particular mechanical positioning of the loads should always be justified for the best result.

How angular contact bearings handle axial and radial loads

angular contact bearings are uniquely designed to deal with combined loads, axial and radial if used in the right manner. Therefore, the angle with which the contact occurs is very important; if the angle is increased, the bearing will tolerate axial loads better, but at the cost of its radial load capacity. This involves installing the bearings, preferably in pairs or sets, for applications where both loads are present. Knowing the load alignment and distribution requirements properly is essential for making the best use of angular contact bearings in your machinery.

What are the main uses of angular contact ball bearings?

The angular contact ball bearings provide great axial and radial load handling and are used in applications where precision is of utmost importance. Such bearings are specifically adapted for the aerospace, automotive, and manufacturing sectors where high speed, accuracy, and load capacity are at a premium. Typical applications include most machine tool spindles, gearboxes, pumps, and high-performance motors and generators, which require smooth operation and reliability in most circumstances.

Applications in high-speed spindles

I can state with expertise that angular contact ball bearings are absolutely essential for high-speed spindles. They are designed in such a way that they can take both radial and axial forces with great accuracy so that the spindle can function in the best possible way, even when the operating conditions are very severe. Such bearings aid in the cutting down of vibrations and improving the rotational tolerance, which are important attributes in the aerospace manufacturing and precision machining sectors. When considering bearings for high-speed spindles, selecting those that are of good quality and well-designed will ensure better end results.

Use in electric motors and gearboxes.

Taking into consideration the practice I have come across, it is evident that high-precision bearings are a must in electric motors and gearboxes so as to enhance the efficiency and durability of the machines. These elements are essential in the control of the loads involved in mechanical movement, which contributes to ease of use and decreased energy wastage. In the electric motors, bearings of higher precision level support during the operation cycle, minimizing losses due to friction in high-speed applications. On the other hand, for the gearboxes, the application of these bearings makes sure that the parts rotate in a centered position without overloading, which is crucial in reducing the chances of failure and improving dependability under high stress.

Angular contact bearings in precision machinery

Due to their versatility in handling radial and axial loads, angular contact bearings oftentimes find a place of significance in precision-engineered machinery and components. Such applications have high precision and reliability requirements. Thus, to appreciate their significance further, let us disintegrate the relevant key parameters that warrant their performance:

- Contact Angle

In most cases, relationships between boundary layers among solids can be described using Contact Angle (CA). High CA allows an increase in the distance between two surfaces, which translates into more comfort for users.

- Load Capacity

Due to the fact that an axial load is applied in one direction, it is possible to design the bearings so that radial loads can be transferred as well. All common outer dimensions have complied with DIN regulations so that the geometrical characteristics are as standardized as possible.

- Rotational Speed

All arrangements subjected to hydrostatic bearings have a clearance gap that permits rotation. Angular contact bearings’ primary intention is to maximize force transmission and, therefore, will limit slippage as best as possible.

- Preload

In its simplest form, sinusoidal loading will place a load in the opposite direction once per rotation so that the selected sinusoidal elements will ooze while other elements compress. Such an imperfect configuration reduces the stiffness of the actuator and must be solved with smarter control architectures.

- Material Selection

Smoother surfaces or precision cut edges can improve stress concentration in machinist use, however caution has to be taken as softer materials, especially string ones, can deform easily. Point loading can be applied from clutch springs during engagement so that a singular linear stress load can be created on the edge or surface.

For the implemented parameters, angular contact bearings are of great assistance for the performance and durability of precision machines, facilitating smoother running, higher efficiency, and lower downtimes. Their adaptability to the required load conditions constitutes them as a standard part of many industry categories, including aerospace, robotics, and precision tooling.

How do angular contact bearings compare to deep groove ball bearings?

that equipment with angular contact bearings is a better option compared to deep groove ball bearings for axial and radial combined loads. While radial loads on deep groove ball bearings are quite suitable for multipurpose applications with low to average loads, a bearing type with angular contact is used when the application requires high precision and a great bearing capacity. Also, due to their geometrical configuration, they are also capable of carrying a higher unilateral axial load, which can be further enhanced by having them in pairs. Deep groove ball bearings, by contrast, possess greater flexibility, are low cost, and are maintenance-free with the normal application. Ultimately, everything depends on the performance requirements of your equipment, which will determine the selection of one or the other of the bearings types.

Differences in load-carrying capacity

Owing to their innovative contact angle design, which permits forces to be effectively oriented within the axial plane, such bearings are able to endure greater axial loads. On the other hand, deep groove ball bearings are radial load-centric and provide limited axial support, which is inadequate when compared to the great axial loads catered for by the angular contact variants.

Comparing axial and radial load capabilities

the right way to evaluate axial and radial load capabilities is based on looking first at the application in question. For applications involving high axial loads, I prefer angular contact ball bearings because their geometry allows them to withstand these loads. In contrast, deep groove ball bearings are the best for applications with radial loads due to their ability to bear radial loads without fail. The choice of bearing depends, however, on the tilting angle, load level, and other operating conditions to obtain efficiency.

Speed limitations of each bearing type

Roller bearings are usually speed-rated lower than ball bearings because line contact increases friction. In contrast, deep groove ball bearings have a point contact structure which reduces rolling resistance, thus allowing them to effectively operate at higher rotational speeds. To address high-speed applications, bearings having controlled lubrication mechanisms are highly required in order to limit heat and wear.

What are the advantages of using angular contact ball bearings?

I can state that angular contact ball bearings are one of the most useful ways of supporting radial and axial loads. The specific configuration of these bearings, as they contain an angle of contact, enables the combined loading to be managed effectively. Such features make these bearings suitable for high-performance applications, including machine tools, pumps, and motors. Furthermore, these bearings are extremely stiff and precise while being structurally resilient, thus performing well in various applications that would otherwise be very challenging and require a lot of accuracy. Proper design, installation, and maintenance ensure consistent performance and a long life of these bearings, even under harsh operational situations.

Superior performance under combined loads

Definitely, allowing equipment to operate satisfactorily under combined loads, both radial and axial, requires bearing selection and bearing application of particular types. To be precise, angular contact ball bearings are good examples in this case. This is because:

- Contact Angle

Contact angle quantifies the level of interface between a solid and a liquid. It is a storage and strain point for angular contact bearings. In turn, it allows the simultaneous transmission of both radial and axial forces. These bearings may be manufactured with an increased contact angle (allowing them to be designed other than the paternal 15° or 25°) according to the load distribution concentration required by a particular application, for instance, inside a machinery sprocket, all of which are designed for a larger load bearing axial angle force.

- Load Carrying Capacity

Due to the unique design features incorporated into their structure, these bearings can accept off-center (tilting) radial and axial forces at the same time, thereby increasing their load-carrying capacity. This enables their use in areas of relatively large load, such as pumps and high-speed spindles where transmissive force and diversity are relatively high.

- Rigidity and Precision

The high rigidity of the precision-class angled contact bearings minimizes their deformation characteristics under the action of heavy load conditions,s which is achieved through the design features inherent in the bearings. Such a condition is paramount in areas such as CNC machines, where an immaculate appearance is preferred for the end result, which is the machinery output.

- Lubrication and Maintenance

For such a mechanization system to work effectively, performance lubrication and adequate maintenance of such systems is crucial. Additionally, high-quality lubricants should be used to minimize wear and major friction, thus enabling the bearings to withstand extreme conditions for a longer time and ensuring that the bearings keep functioning reliably.

In this way, these factors, together with the correct specification of the bearing requirements, don’t hinder the combined loading. Whether it is for high-end industrial or precision machinery, angular contact ball bearings truly perform better when properly applied.

Benefits in high-speed applications

angular contact ball bearings always appear to be an absolute must in high-revolving situations. The fact that they are able to bear large axial and radial loads at the same time guarantees accuracy and steadiness even at high resolutions. Because of the innovative internal structures and advanced factors, vibration and heat production are improved to give smoother and extended operating life. These characteristics effectively extend their areas of use, such as in turbines, motors, and high-speed engines where dependability and maximum efficiency are needed.

Improved axial load handling capabilities

Capabilities to handle axial load increases through advanced materials and optimized geometry in the bearing design. These modifications enable better force application, reduction in wear, and the risk of failure under high axial load, which boosts applications that require endurance along with tight tolerances.

Are there different types of angular contact ball bearings?

Yes, there exist different varieties of angular contact ball bearings, each designed to serve a specific purpose. The types range from single-row angular contact ball bearings to double-row and four-point contact bearings, which all bear specialized features. A single-row design is only able to support thrust and radial loads in one direction, but two or multiple-row structures allow these loads to be supported in both directions, increasing their effectiveness. On the other hand, four-point contact bearings are great for applications with limited space since they take a low-profile design yet also allow for axial loads to be used at both ends. As I have learned, the choice of which type one uses and applies depends more on the load requirements and the intended speed and place of use.

Single-row vs. double-row angular contact bearings

One of the deciding factors in whether to use single-row or double-row angular contact bearings is also the deflection characteristics of the particular application and the amount of space available. Single-row bearings are best suited for applications that require thrust and radial loads in one direction only and where unilateral support and complexity are adequate. In contrast, double-row bearings are capable of supporting cases where the load is applied on either side due to their increased number of rows, which in turn provides more versatility and effectiveness in complicated systems. As a rule of thumb, double-row bearings are preferred if room permits and greater adaptability is required.

Four-point contact ball bearings explained.

Four-point Contact Ball Bearing can be a specific and efficient solution for a given engineering problem, and I suggest them very often in situations where both push and pull loads have to be accommodated within constricted geometry. The unique construction of these bearings enables them to accommodate axial loads in both directions and a small amount of radial load in an axial assembly. Such an arrangement has a level of ‘two point’ contact between the split inner ring and its single groove outer race which reinforces the four ‘ball and race’ interface for low friction and high precision operation of the assembly. Based on my experience, they are very well suited for rotary tables or gearbox systems, especially when weight, volume, and flexibility are important.

Matched pair configurations for angular contact bearings

The use of matched pair configurations in angular contact bearings is required when the application operating conditions include combined loads and need greater stiffness or precision. In my opinion, these configurations are achieved when two bearings are placed in a manner where they can support each other to reduce the load on the bearings. This is how it works, and this is what is important:

- Load Distribution – We can manage imposed coupled axial loads in both directions as well as pull radial loads. This holds true, such as in the case of first-order machine tool spindle application, which requires a high level of stiffness under tough working circumstances.

- Preload–loading is one of the parameters of utmost importance when installing matched pair arrangements. Applying appropriate preloading means you improve rigidity and reduce deflection when under load, which directly translates into better accuracy. The level of preload will, however, depend on the expected performance of the application, whether light, medium, or heavy preload is required.

- Configuration Types – The most generally used systems are back-to-back (DB), face-to-face (DF), and tandem (DT). Each has a specific function:

- Back-to-back (DB) has the ability to utmost rigidness as well as effectively measure tilting moments.

- For some applications where alignment deficiency may be the case, face-to-face (DF) is preferable.

- Tandem (DT) is useful when one-way axial loads must be handled.

- Contact Angle – Another key aspect associated with a ball is the contact angle with the raceway. For angular contact bearings, the angle also defines the degree of axial load that the bearing can support. As a rule, increasing contact angles improves axial load handling abilities, but their high-speed performance is impaired.

- Precision Class – Finally, the bearing’s precision grade is also important,t but not to the extent as for those designed for use in aerospace or advanced robotics. Bearings manufactured with tighter tolerances can be very effective but are more expensive.

Considering those factors, I am now inclined to suggest the use of matched pair arrangements of angular contact bearings with two crucial characteristics in mind: they are intended for applications with a high level of load, stiffness,s, and operational accuracy.

How do you select the right angular contact bearing for your application?

During the selection of angular contact in a bearing, focusing on a few factors is important. The first axis of evaluation involves loading requirements, both axial and radial, in relation to the contact angle since it determines the capability of the bearing to handle axial loads. Next, I consider the speed of the application; if high-speed rotation is essential, a reduced contact angle and subsequent lubrication are critical. Materials, especially the cage design, are also essential, notably for applications in extreme conditions where temperature or corrosion resistance is required. The precision class is also another key aspect – in my case, I always use angular contact bearings that have the tolerance grade suitable for the accuracy requirements of the application, be it for general industrial equipment or precision robotics. By harmonizing these factors, I managed to select the bearing suited to the requirements of the project, giving assurance of optimal performance and reliability.

Factors to consider when choosing an angular contact bearing

Focus on bearing load type and magnitude when angular contact bearing is selected. Make sure that axial and radial demands are determined to select the right degree of contact angle. Inspect operational speed and make sure that proper lubrication is applied in order to permit high-speed operation. Evaluate material and cage configuration for environmental compatibility, such as temperature and corrosive conditions. Last but not least, choose the correct precision class in accordance with the desired accuracy in performance and maximum efficiency for your application.

Matching bearing specifications to application requirements

Revolutionizing the bearing specification to suit the requirements of the application, begins with a proper understanding of the working conditions. The load parameters, both axial and radial, are assessed in order to arrive at the most suitable bearing type and contact angle. For high-speed units, I check whether the bearing limits the speed and, at the same time, ensure that the required speed can be delivered without impacting the performance of the lubrication system. Temperature variances or even exposure to contaminants decide the properties of the materials used and the coatings applied to them. Considering precision is key, the required accuracy of the system is taken into account when specifying the tolerance class of the bearing. The application of this systematic procedure helps to implement a bearing into an application with ease, and the ever-highest efficiency and durability are provided.

When to use angular contact bearings vs. other bearing types

When a system is exposed to both radial and axial forces, angular contact bearings allow the system to withstand combined loads and are very suitable for high axial loads due to their design. As a result, they can operate at higher speeds and are capable of functioning when the elements of the system are accurately aligned and rigid. For example, angular contact bearings are commonly used in machine tool spindles, pumps, and gearboxes. However, if the application only has radial loads or a simpler structure, a rotational deep groove ball bearing or cylindrical roller bearing would work more efficiently at a lower cost. The correct type is selected according to the system’s load conditions, speed, and the accuracy of alignment of the components.

Reference

- Radial Ball bearings vs Angular Contact

- Radial Ball Bearings Versus Angular Contact Ball Bearings

- Angular Contact (Spindle) bearings

Frequently Asked Questions (FAQs)

Q: What is the main difference between radial ball bearings and angular contact ball bearings?

A: The main difference lies in their design and load-bearing capabilities. Radial ball bearings are primarily designed to handle radial loads, while angular contact ball bearings are designed to handle both radial and axial loads. Angular contact bearings have raceways in the inner and outer rings that are displaced relative to each other in the direction of the bearing axis, allowing them to support axial loads in one direction.

Q: How do angular contact ball bearings handle axial loads compared to radial bearings?

A: Angular contact ball bearings are superior in handling axial loads compared to radial bearings. They are designed with angled raceways that allow them to support axial loads in one direction, making them ideal for applications where both radial and axial forces are present. Radial bearings, on the other hand, are primarily designed to handle radial loads and have limited capacity for axial loads.

Q: What are the advantages of using double-row angular contact ball bearings?

A: Double-row angular contact ball bearings offer several advantages. They can handle higher loads in both radial and axial directions compared to single-row bearings. These bearings are often used in applications requiring increased stiffness and precision. Additionally, they can support axial loads in either direction, making them versatile for various industrial applications.

Q: In what types of applications are angular contact bearings typically used?

A: Angular contact bearings are often used in applications that require high precision and the ability to handle combined loads. They are commonly found in machine tool spindles, pumps, compressors, and gearboxes. These bearings are also frequently used in pairs or sets to increase load capacity and provide greater stability in high-speed operations.

Q: How does the contact angle affect the performance of angular contact ball bearings?

A: The contact angle in angular contact ball bearings significantly influences their performance. A larger contact angle increases the bearing’s ability to handle axial loads but may reduce its radial load capacity. The angle also affects the bearing’s speed capabilities and heat generation. Manufacturers offer various contact angles to optimize bearing performance for specific applications.

Q: Can angular contact ball bearings replace radial bearings in all applications?

A: While angular contact ball bearings offer many advantages, they cannot replace radial bearings in all applications. The choice between the two types depends on the specific load requirements, speed, precision needs, and environmental conditions of the application. In some cases, a combination of both types might be the optimal solution for a bearing assembly.

Q: What are the key benefits of angular contact ball bearings in high-speed applications?

A: In high-speed applications, angular contact ball bearings offer several benefits. They provide excellent runout characteristics and maintain high precision even at elevated speeds. The angled raceways allow for better control of the balls, reducing skidding and improving overall bearing performance. These features make them ideal for machine tool spindles and other high-speed rotating equipment.

Q: How do angular contact ball bearings compare to radial bearings in terms of load capacity?

A: Angular contact ball bearings generally have a higher combined load capacity compared to radial bearings. They can handle both radial and axial loads efficiently, making them suitable for applications with complex loading conditions. However, for purely radial loads, radial ball bearings might still be the preferred choice due to their simpler design and potentially lower cost.