Anti-friction bearings are crucial components of many industries, making their operations efficient and their mechanical processes reliable. Among the different types of bearings, the most effective are metal bearings, providing robustness, the ability to carry loads, and precision in high-performance settings. This article covers the key properties of metal bearings, explains their merits, and describes the segments where they have outperformed themselves. In other words, we would uncover the aspects and the environments where metal bearings are used most and explain why they are popular among engineers and manufacturers. In this article, we highlight the interests of both engineers and those readers who are interested to know more about the technology that enables machines not only to work but also to work without problems. So, if you want to understand more about anti-friction bearings and their applications, this blog is for you.

What are anti-friction bearings, and how do they work?

Unlike some traditional options, anti-friction bearings are different as they assist in low friction or hardly any friction. They achieve this by integrating rolling elements like rollers or balls which are placed between an inner and outer circular member. With the help of these rolling elements, the area of contact gets reduced, which changes the lubrication and sliding from the surface into rolling, thus decreasing the resistance substantially. Such a simple concept allows anti-friction bearings to augment the efficiency and working life of all kinds of machines in many industries.

Understanding the basic principles of anti-friction bearings

I can personally attest that one of the most important things to do when aiming to optimize the performance of a machine is to have an understanding of the basic functionality of anti-friction bearing. Apparently, the bearings are made to substitute rotary sliding with rotary rolling in order to reduce energy loss and wear, which is extremely difficult to implement. By installing these units into a piece of equipment, I believe that trouble-free functionality and high effectiveness coupled with extended use will be guaranteed, which are very much needed when it comes to the now ever-demanding and reliability-driven fields.

Types of anti-friction bearings: ball bearings vs. roller bearings

It is essential to differentiate between ball and roller bearings, including their specific features and uses. As was the case in my experience, both are great for minimizing friction, but due to their design, they are applicable to different situations.

As the term suggests, the function of these types of bearings is to maintain a distance between the races with the use of spheres. They are used in many applications because of their ability to take radial and axial loads, but they work best with lighter loads. The main requirements of ball bearings are – their maximum load to be supported, their rotational speed, and the angle of alignment at which they can operate efficiently. Their small size enables them to be used in places like electric motors, kitchen appliances, and even in automotive wheels, practically anywhere where high speed and low drag are essential.

In contrast, roller bearings are composed of cylindrical rollers rather than balls. This allows them to apply pressure on a wider area, which makes them suitable for areas where heavy radial loads are necessary. However, they tend to perform poorly for axial loads in comparison to ball bearings. The important factors for roller bearings are; the roller length, the diameter of the roller and the materials used in their hull as all of these determine the bearing strength and the load the roller can take effective. Similarly, roller bearings are commonly used in machines such as conveyor belts, gearboxes, and turbines where the machinery needs to lift heavy material and sustain extreme conditions.

In the end, it is a matter of choosing between the ball bearings and roller bearings depending on the requirements of the application,n including but not limited to load, speed, alignment status, and environmental conditions. Once understood, we can determine the most suited bearing type so that the purpose is achieved.

How anti-friction bearings minimize friction and wear

In the bearings industry, I firmly believe that anti-friction bearings are one of the best devices fully equipped to handle the minimization of friction and wear with the excellence of their design. Such bearings incorporate rolling elements, such as balls or rollers, which reduce the surface contact with the sliding parts and, hence, the friction between the two parts. Furthermore, if provided an adequate amount of lubrication and made of good materials, they make the movement smoother, reduce the heat generation, and prolong the life of the components. Such a strategy not only improves performance but also increases efficiency in the most demanding applications.

Where are anti-friction bearings typically used in machinery?

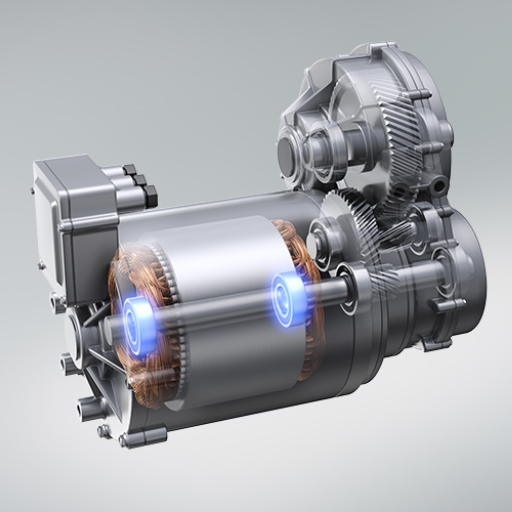

Anti-friction bearings are found in many types of machine tools, enabling rotation or linear movement with reduced friction. Appearing in automotive engines, gearboxes, turbines, and pumps, as well as conveyor systems and milling machines, they serve quite a number of purposes. Given their efficiency and functionality, they form an important operational element for mechanical systems in many industries.

Common applications in industrial equipment

According to what I have seen, friction bearings are very crucial in many types of industrial machinery as they can carry heavy loads and reduce wear. For example, transport devices provide an uninterrupted flow of materials, which is essential for effective production. In the same way, vertical knee and bed-type milling machines allow the spindle to rotate at desired angles, thus ensuring proper cutting and machining operations. Their mechanical strengths and flexibility make them most suitable for industrial installations where reliability and lasting operation are needed.

Use of anti-friction bearings in automotive systems

Anti-friction bearings are very important in any automotive system, and they need no elaboration. Having worked in the industry, I can emphasize that these bearings are central to the proper and dependable functioning of vehicles. Let me explain this in a step-by-step manner. First, I will explain the specific parameters where anti-friction bearings make a difference.

- Reduced Friction: Bearing manufacturers prominently place a broad emphasis on the reduction of friction between moving parts. This has a direct relation in optimizing fuel efficiency and/or other forms of energy loss. Such is important in specialized units such as wheel hubs, transmission, and engine components where the parts are in perpetual motion of some kind.

- Load-Bearing Capacity: Anti-friction does appeal to certain horsepower ratings as there is an integrated engineering capability that permits them to withstand quite hefty radial and axial loads. For instance, in the case of the drivetrain, these bearings are able to take on hefty horsepower loads without compromising on their bearing capabilities.

- Enhanced Durability: The ability to establish a certain time period in motion is of paramount importance in automotive systems, and the anti-friction bearings do well in this area. Due to the fact that wearing out of such materials is not an issue, such performance is sustainable in the long run, and extreme environments such as extreme heat or cold can be tolerated.

- Reduction of Noise and Vibrations: The sound and the vibrations from the wheel hub can prevent the user from getting the full satisfaction of enjoying their car, especially if the user is residing in a country where such is common, so such a requirement need not be overemphasized where the components of the machinery include the hub or air. The good news is that such requirements can and are being met by automotive manufacturers with the inclusion of fitments like suspension systems.

- High-Speed Capability: Most automotive components operate at fast speeds, especially the ones used inside turbochargers or in the engines. Anti-friction bearings are advanced and, therefore, good enough to deal with such applications and further assist the components in functioning to a high degree without any damage to the equipment.

- Ease of Maintenance: Anti-friction bearings only need little to no time-consuming upkeep with regards to whether a substantial cost has been incurred on purchase, which means less time, cost, and resources for vehicle owners in the future toward maintenance of the vehicle with the right kind of lubrication.

These are the factors that explain the necessity of anti-friction bearings in automobiles. They assist in enhancing the performance and reliability of modern cars due to reduced wear, improved efficiency, and increased life of the components.

Aerospace and high-speed applications

In my years of being engaged with the industry, it is apparent that one of the key elements in aerospace and high-speed operations is the anti-friction bearings. Such working conditions exhibit huge amounts of force and, therefore, require a high level of accuracy, dependability, and endurance. Anti-friction bearings perform optimally in such environments by requiring lesser energy, maintaining precise rotation, and resisting extremely high temperatures and pressures. Operating conditions such as superheat for turbine engines, fuel-controlled jet engines, and critical control surfaces pose extreme performance parameters, but their use in such applications does also ensure safety. Such design advances and efficiency in anti-friction bearings allow the aerospace industry to excel in the speed of innovation and precision.

What are the advantages of using anti-friction bearings over sleeve bearings?

Anti-friction bearings have many clear advantages over sleeve-bearing materials, especially in terms of performance. By incorporating rolling elements such as balls or rollers, So they greatly reduce friction which leads to saving of energy and heat. Besides, they are to be able to lead to a more accurate capability of handling larger loads at larger speeds and lesser lubrication and maintenance than sleeve bearings. These features make anti-friction bearings essential in places where high operational efficiency, reliability and durability are a must.

Comparing friction reduction capabilities

Based on my experience in the industry, anti-friction bearings have a structural and functional advantage over sleeve bearings in terms of minimizing friction. The rolling elements of anti-friction bearings greatly reduce the contact area, thus minimizing mechanical resistance and heat generation. Even though sleeve bearings are effective in simple, low-speed applications, they use a thin layer of lubricant to operate, which is not as effective as anti-friction bearings, which use rolling motion to operate. Where the level of precision, speed, and energy efficiency is a high priority, anti-friction bearings are preferred.

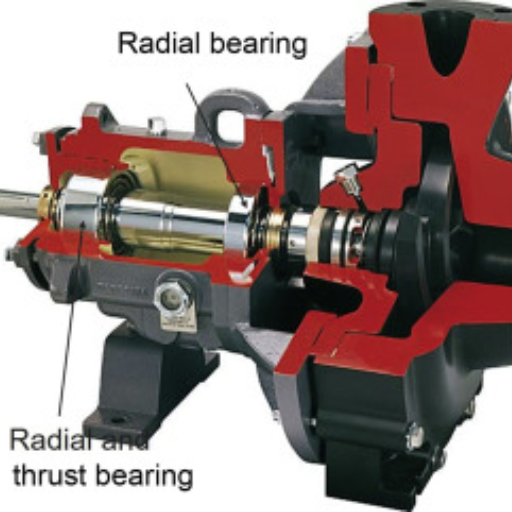

Load-bearing capacity: radial and thrust loads

When it comes to load capacity factors, both radial and thrust loads are important in the selection of a bearing for specific applications. Such is my approach:

- Radial Loads – When it comes to an axis of rotation, radial loads are perpendicular to that. The raceways and rolling elements of radial load type bearings are quite robust and strong, hence, radial overload are not a problem. In perspective, a great structural variety facilitates the construction of grooved ball bearings and cylindrical roller bearings, which can deal with considerable radial forces.

- Thrust Loads – When we talk about the axis of rotation, thrust loads are parallel to it. Thrust ball bearings or angular contact ball bearings are made to bear these forces. But their structure permits, or rather allows, the considerable capacity of supporting axial loads during rotation.

- Load Combinations – There are applications that involve axial loads and radial loads, and the bearings that are to be designed should facilitate both loads effectively. Good examples of this would be angular contact and tapered roller bearings. These bearings, by adjusting the geometry and contact angles, are able to bear quite a combination of complex loads reliably.

When choosing a bearing in view of the load, make sure that you keep in mind three parameters:

- Amount of load that guarantees the mechanical-working life of the bearing without deformation.

- Load direction, either radial, thrust, or both, determines the type of bearing to be used.

-

Operational conditions like speed and lubricating oil ensure that the service pack interface remains consistent with the demand for that particular application.

Considering these aspects thoroughly allows me to provide the bearing with an optimal and reliable function within its specific field of application.

Lifespan and maintenance considerations

My strategy for enhancing performance while simultaneously reducing downtime has always been focused on increasing lifespan and reducing maintenance requirements. A bearing’s longevity is largely determined by its proper installation, lubrication, and wear and tear monitoring. As some contamination or improper alignment may cause the bearing to have a shorter life span, I would make sure the bearing is installed properly. Periodic maintenance, such as re-lubrication and checking for fatigue or signs of damage, is crucial for preventing unexpected failures. Hence, through best practices and the use of quality materials, I would also increase the reliability of the operation over time and the bearing’s service life.

How do you choose the right anti-friction bearing for your application?

There are a number of factors that need to be evaluated when you are choosing an anti-friction bearing for your needs. The first step is to determine the type of load that is to be applied, axis – radial, axial, or combined, operating speed, and what temperature levels are to be expected. Consider the contaminants that may exist in the environment, moisture, and vibrations as those may warrant the need for certain seals or materials. Determine the lifespan, reliability, and maintenance needs of the application you are required to develop. Lastly, compare with the manufacturer specifications and industry standards to ensure they match. With such an approach, it is also possible to ensure that the selected bearing will provide optimum performance and meet the stability requirements for your application.

Factors to consider when selecting an anti-friction bearing

I am one of those engineers who place high emphasis on their very first job, which, in this case, involves selecting an anti-friction bearing. This bear always starts with evaluating the load requirements, the size, and the direction, as these factors determine whether one should go for a ball bearing, a roller one, or some other type. Such previous criterion measurement leads to one of the most essential stages in the selection process – the environmental factors! The climate, rubbish and exposure to moisture or certain chemicals, if any, need to be also investigated in depth as they impact on the material and sealing.. I am rather obsessed with speed and rotation factors because these determine the bearing’s tolerances and lubrication. I also make sure that the designs are in line with the expected lifespan of the asset and maintenance plans in order to reduce the number of downtimes required. I finally turn to the manufacturer-given guidelines and check the rationality and numbers compliance with the necessary standards. All these factors help me to make sound decisions and truly focus on performance.

Matching bearing type to specific load requirements

Odpowiednie dopasowanie łożyska do spełni loża wymaga szczegółowej analizy kilku parametrów. Tak w skrócie wygląda kolejność moich działań:

- Load Type (Radial, Axial, or Combination): The very first thing that I have to assess is the type of bearing load biofactors that it has to endure. For example, deep groove ball bearings are favorable when dealing with primarily radial loads, but in the case of axial or combined loads, angular contact ball bearings or tapered roller bearings are more effective.

- Load Magnitude: The effectiveness of the load largely impacts my decision. For lighter loads, standard bearings suffice the requirement, but for moderately heavier loads, bearings like spherical roller bearings or cylindrical roller bearings are recommended.

- Load Direction Stability: In the case that the loads and the operating direction are either frequently changing or fluctuating, I would instead opt for a bearing that is more effective at radial and axial load. Bearing such as thrust bearings can do quite well in withstanding certain axial loads.

- Speed Requirements: I still try to consider how quickly the bearing would need to function as well. High-speed applications call for a requirement of a precise bearing designed with low-friction seals, while low-speed systems differ only in the application bearing criteria.

- Environmental Factors: Another major factor to consider is the working environment. For instance, if the bearing is in a working environment that bears contamination, water, or very hot temperatures, I buy bearings with the proper lip seal on them, the proper coating on them, or suitable lubrication systems.

Moja meta jo kadh khush hote hai, ye Chakra har dosh kay raj ko parda fosh karte hue us bearing ki accha tarah talaqi karte hai.

Importance of proper lubrication in bearing selection

The importance of lubrication cannot be overstated in bearing selection, and in my opinion, it can make or break the efficiency and life cycle of a system. Minimization of friction, elimination of wear, and prevention of overheating are some of the functions that the lubricant performs and bear a direct impact on the performance of the bearing. Even in good quality bearings, I’ve seen cases where poor or wrong lubrication has caused them to fail. For each application, I try to study the operating speed and load as well as environmental conditions so as to select the appropriate lubricant: grease, oil, or solid lubricants. This way, I make sure that the bore and the seal are lubricated, enabling smooth operation of the bearings and ensuring the required lifespan for tough applications.

What are the challenges in using anti-friction bearings?

the significance of ensuring proper rotary lubrication in order to reduce friction wear of anti-friction bearings is among the major issues. Moreover, choosing a bearing material and design for a certain application is also very important in dealing with loads, speeds, and environmental conditions. Likewise, contamination, displacement during operation, and faulty installation are also a few causes of poor performance and short bearing life. Overall, the prevention of these factors requires maintenance, engineering, and following manufacturer notes.

Common issues in anti-friction bearing installation

Based on what I have gathered from working in the industry, one of the greatest problems preventing the proper installation of anti-friction bearings is the fact that they are not properly aligned. The effect of even a slight misalignment is that the loads are not evenly distributed, which will translate into increased wear and shortened bearing life. Another major problem is contamination, if dust, dirt or moisture get into the system, performance is greatly reduced in no time at all. I have also come across scenarios where the bearings were not lubricated sufficiently, or the wrong lubricant was used, which caused the failure of these components far earlier than should have happened. What needs to be done, therefore, is to ensure that the bearing is fitted properly, remains clean, and is well lubricated at all times if operational success is to be attained.

Preventing bearing failure and extending bearing life

In my opinion, it all begins with bearing installation techniques and knowledge of the operational environment – everything from working temperature zones to working load – all of it must be taken into account. I always stress the use of highlights during assembly and the importance of proper alignment in order to limit even load on each individual roller. Regular checking and periodic servicing are a must for me – they offer the best remedy against soiling and abrasions. I also encourage the use of necessary oils as prescribed by the maker while making sure those oils are applied accurately, for this step can only boost the lifetime of the bearing. Lastly, those simple practices coupled with an active sense of maintenance and magnetism make it easier to use and flourish bearings.

How do anti-friction bearings contribute to energy efficiency?

Anti-friction bearings have even greater potential in enhancing the energy economy as they diminish the friction between the components in motion. In my opinion, their configuration is such that the energy loss is reduced, and as such, machines work against lower levels of resistance and, therefore, consume less power. By ensuring better movements and efficiently distributing loads, they reduce waste of energy quite remarkably. I have witnessed how the delay in replacing the anti-friction bearings after the planned term results in cost escalating and the systems becoming less efficient.

Reduction of power loss in machinery

By lowering any component interaction forces, anti-friction bearings help minimize power losses and energy usage, as well as minimize over-use. Their effective load distribution reduces working, and hence power requirements, and thereby aids in performance.

Impact on overall system performance

In my view as an expert in the field, one cannot neglect the role and the impact of anti-friction bearings on the performance of the entire system. These components are critical in the proper working of the machine and in its efficiency. Their proper functioning reduces friction and therefore, increases the reliability of the energy consumption. I have seen how, in properly fitted and serviced machines, the life of bearings is increased, thus reducing the number of downtimes and improving productive output in any high-level system.

What future developments can we expect in anti-friction-bearing technology?

It can be anticipated that an increase in anti-friction bearing technology will concentrate on improved materials and smart integration. Other than advanced composites and nano-coatings, which I expect to be used to further lower wear rate and increase the lifespan some more, we will witness the installation of IoT-based sensors, which will allow the bearings to be intelligent components, continuously self-monitoring and predicting future failures. Such innovations would enhance the connectivity, efficiency, and reliability of high-performance systems.

Advancements in bearing materials and designs

The focus on the advancement of bearing materials and designs is directed at performance enhancement and durability, all the while lessening ecological ramifications. These hybrid bearings, which incorporate elements of steel and ceramics, have greater toughness and resistance to heat. Furthermore, self-lubricating designs and novel coatings including diamond-like carbon (DLC) are minimizing maintenance interventions while improving the efficiency. Such innovations are transforming the industry, providing more durable products developed for contemporary engineering requirements.

Integration of smart technologies in anti-friction bearings

Smart technologies and their application in anti-friction bearings will be the next revolution in our industry. I believe the direct incorporation of IoT-enabled sensors within the bearing system constitutes a new dimension in monitoring these systems as it facilitates real-time supervision and predictive maintenance. As a result of this transition, we are able to measure and monitor specific parameters like temperature, vibration, and load – and, most importantly, predict possible failures before they happen, which improves the overall maintenance of the machine. More critically, this sensor data feeds into machine learning algorithms, and the systems appear to be capable of dynamic adjustments that could optimize performance and efficiency in previously inconceivable ways. These trends are indeed the future of more powerful and intelligent self-sufficient solutions in the industrial sphere.

Reference

- Antifriction Bearings Market Growth Trajectories – This article discusses the market size and growth projections for antifriction bearings.

- Comprehensive Study of Anti-Friction Bearing Market – A detailed study on the market growth and future trends of anti-friction bearings.

- Railway Antifriction Bearing Market Analysis – Provides insights into the railway antifriction bearing market, including competitive analysis.

Frequently Asked Questions (FAQs)

Q: What is an antifriction bearing, and how does it work?

A: An antifriction bearing is a type of bearing designed to minimize friction between moving parts. It typically consists of rolling elements (such as balls or rollers) between two rings or races. These bearings work by replacing sliding friction with rolling friction, which significantly reduces the coefficient of friction and allows for smoother rotation of shafts or other components.

Q: What are the main types of radial bearings?

A: The main types of radial bearings include ball bearings, roller bearings, and needle roller bearings. Ball bearings use spherical balls as rolling elements, while roller bearings use cylindrical rollers. Needle roller bearings are a special type of roller bearings that use long, thin rollers. These bearings are designed to support loads perpendicular to the shaft axis and are essential in many mechanical applications.

Q: How do thrust bearings differ from radial bearings?

A: Thrust bearings are designed to support axial loads (forces parallel to the shaft axis), while radial bearings support loads perpendicular to the shaft axis. Thrust bearings can be flat or spherical and are often used in applications where axial loads are significant, such as in propeller shafts or vertical pumps. Unlike radial bearings, thrust bearings are specifically engineered to handle forces that push along the length of the shaft.

Q: What is the primary function of bearings in mechanical systems?

A: The primary function of bearings is to reduce friction between moving parts, allowing for smoother and more efficient operation of mechanical systems. Bearings support rotating shafts, minimize wear, and help maintain the proper alignment of components. They also play a crucial role in distributing loads, reducing energy consumption, and extending the life of machinery by minimizing friction and heat generation.

Q: How do antifriction bearings minimize friction compared to plain bearings?

A: Antifriction bearings minimize friction by using rolling elements (balls or rollers) between the bearing surfaces. This rolling contact results in significantly less friction compared to the sliding contact found in plain bearings (also known as journal bearings). The reduction in friction leads to lower operating temperatures, reduced energy consumption, and longer component life. In contrast, plain bearings rely on a thin film of lubricant to reduce friction between sliding surfaces.

Q: What factors should be considered when selecting the right antifriction bearing for an application?

A: When selecting the right antifriction bearing, several factors should be considered, including: 1. Load type and magnitude (radial, axial, or combined) 2. Rotational speed 3. Operating temperature 4. Environmental conditions (moisture, contaminants) 5. Space constraints 6. Lubrication requirements 7. Precision and stiffness needs 8. Noise and vibration considerations 9. Cost and maintenance requirements Proper selection ensures optimal performance and longevity of the bearing in its intended application.

Q: What are some advantages of metal bearings over other bearing materials?

A: Metal bearings, particularly those made from high-quality steels, offer several advantages: 1. High load-carrying capacity 2. Excellent durability and longevity 3. Good heat dissipation properties 4. Ability to withstand high speeds 5. Dimensional stability under various operating conditions 6. Wide range of sizes and configurations available 7. Compatibility with various lubricants These characteristics make metal bearings suitable for a wide range of demanding applications in industries such as automotive, aerospace, and heavy machinery.

Q: How does the Anti-Friction Bearing Manufacturers Association contribute to the industry?

A: The Anti-Friction Bearing Manufacturers Association (AFBMA) plays a crucial role in the bearing industry by: 1. Establishing and maintaining industry standards, 2. Promoting technological advancements in bearing design and manufacturing 3. Providing educational resources and training for industry professionals 4. Facilitating collaboration between bearing manufacturers and users 5. Advocating for the interests of bearing manufacturers in regulatory matters 6. Conducting market research and providing industry insights. The association’s work helps ensure the quality, reliability, and continuous improvement of antifriction bearings across various industries.