Especially with regards to machinery and industry, it is these components that allow machines to work smoothly: bearings. Out of the many bearing types available in the market, Babbitt and journal bearings appear to be one of the most favored, considering their applicability and efficiency across various fields. However, how do these bearing types differ from one another, and, more importantly, how does one decide which of the two to use? The article touches upon the key differences between the two, their strengths and weaknesses, as well as the advantages and challenges posed by both Babbitt and journal bearings. This should provide ample information to help you make a more informed choice. If you work with machinery at some level — be it designing or even just looking at the basics of engineering components, and you want to understand how these bearings are different and what each of them is designed for, this is a must-read. Lastly, let us examine the properties that define these bearings and determine the best one out of all. Let’s start by categorizing them.

What are the key differences between Babbitt and journal bearings?

The construction and uses are the main areas where Babbitt bearings and journal bearings diverge. Babbitt bearings are a kind of journal bearing, more specifically fitted with a low friction alloy Babbitt metal, which helps reduce wear and allows for small displacements. However, the term journal bearings is the more generic term used to describe a bearing that is used to guide rotating shafts and allow relative movement in a controlled manner. It may include more than one composite for that purpose. Even though Babbitt bearings are suited for high load and low-speed contexts because of their self-lubricating capability, the other types of journal bearings are proposed to be suitable for high speed with a composition of bronze or even synthetic polymer.

Understanding the basic structure of Babbitt bearings

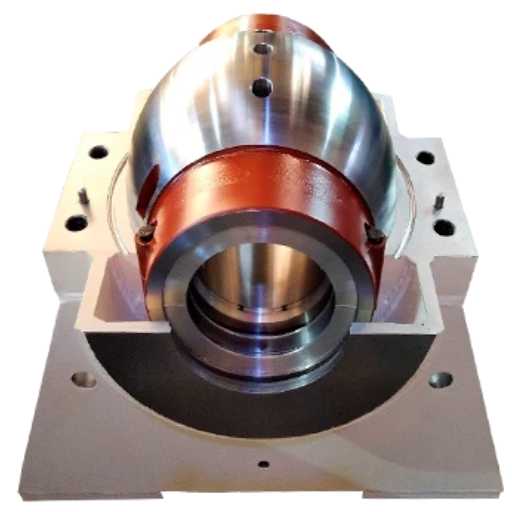

the grand design of Babbitt bearings is simple yet brilliant. These bearings fundamentally comprise a metal casing with a backing of Babbitt alloy – a special metal composite suited for its remarkable anti-friction and wear resistance features. This backing is critical as it serves its purpose of being a failsafe and embeds tiny debris to guard the shaft while being in use. The entire alloy mostly contains tin, copper, and antimony, which ensures a surface that enhances the load-bearing capacity of the bearing while also being anti-wearing. To value the capabilities of Babbitt bearings in regards to their efficiency and durability aspect, it is important to fathom the design and composition of the Babbitt bearings for the given harsh working environments.

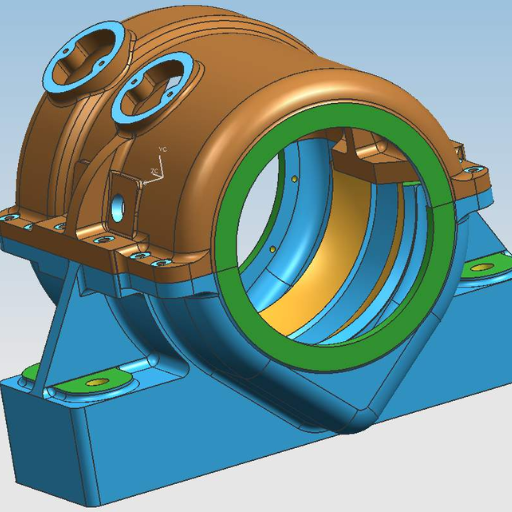

Exploring the design of journal bearings

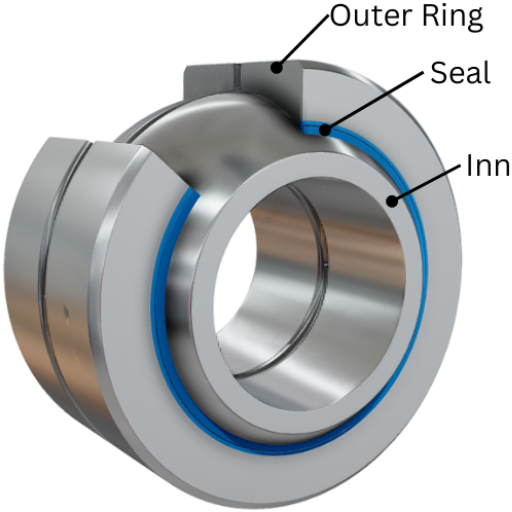

A journal bearing can be defined as a bearing that supports a rotating shaft and reduces the friction between the parts in relative motion utilizing the application of a lubrication system. It usually consists of a cylindrical shell that rotates on a shaft and is lined on its inner surface with a babbitt or some other soft metal or alloy that provides the bearing surface. Their main features include alignment, lubrication sufficient to form a hydrodynamic film, and load capacity in both radial and axial directions. These parameters guarantee performance, a long service life, and prevention of damage to the shaft in operation.

Comparing materials used in Babbitt and journal bearings

the selection of material for Babbitt and journal bearings is crucial. Babbitt is a ductile and malleable alloy that assists in reducing wear and tear by embedding foreign materials and distributing the contact pressure over the vicinity of the bearing. Thus, it can be used in applications where cushioning and precision are required. On the other hand, journal bearings, in general, are composed of structural components forging tougher bronze and steel materials, which are much stronger and more resistant to extensive loads. These combinations of materials would also enhance the operational reliability of the bearing during just about its entire operating lifetime and, furthermore, increase its resistance to adverse operating environments in an industrial atmosphere.

How do Babbitt bearings perform in terms of lubrication?

When it comes to providing the essential lubrication, Babbitt bearings are top-of-the-line performers, and I will explain why that is in detail:

- Surface Compatibility: When Babbitt metal is coated on the bearings, there is minimal friction, and the chances of wear and tear are also lower. This can be attributed to the fact that babbitt metal is smooth and this reduces the friction between the lubricant and the surrounding surface. In other words, Babbitt Metal and lubricants have an astonishing compatibility.

- Oil Retention: When Babbitt bearings are manufactured, a high level of porosity is achieved when oil is applied on the surface, allowing a thin film of oil to get embedded within the surface. This enhances the retaining ability of the Babbitt bearings, and amazingly consistent lubrication is achieved through the use of oils.

- Load Distribution: Another significant advantage that Babbitt bearings have is their ability to withstand high loads and overwhelming pressure; this is also mainly due to the malleable properties present within the metal. Due to the malleability, the pressure gets distributed uniformly, and there are no particular stress areas that would shatter the lubricant film.

- Temperature Performance: In simpler terms, Babbitt materials are able to sustain moderate thermal temperatures and are best suited for lubricants due to their characteristics. With babbitt materials, the heating of oil is significantly low, and that increases the viscosity of oil, ensuring that effective lubrication is present throughout.

- Contaminant Resistance: The final advantage that Babbitt bearings use trimmers for is that they incorporate or encompass any dirt or metal particles that might have been able to ruin the shaft rotation. This assists the lubrication layer and the system in remaining operational.

To sum up, oils and lubricants are essential in maintenance of Babbitt bearings, along with a good oil film and proper greasing under almost any loading condition these bearings are able to withstand wear and tear and perform reliably, thus making them a widely used solution in the industrial environment.

The role of oil film in Babbitt bearing operation

During operation, the oil film in the Babbitt bearing plays a vital role in preventing the bearing surface from making contact with the shaft. It reduces friction, minimizes wear, and effectively conducts heat, hence enabling proper functioning and extending the bearing’s operational lifespan. This delicate froth of lubrication is critical for sustaining efficiency as well as reliability under diverse load and speed situations.

Lubrication methods for Babbitt bearings

The lubrication methods of Babbitt bearings are relative to the given application requirements and the particular working conditions. Over my years of experience, I’ve observed that the most practiced methods incorporate hydrodynamic, hydrostatic, and boundary lubrication techniques. In this respect, hydrodynamic lubrication is best suited for operations at high speeds as it derives a sufficient oil film from the motion of the shaft. On the contrary, hydrostatic lubrication employs the use of a pump to sustain oil pressure which in turn offers support at low speeds and heavy loads. For operations that are conducted in an intermittent manner, boundary lubrication with a constant oil or grease film comes in handy. Speed, load, and environment are the factors that determine the choice of the method, and attention to these factors is fundamental for the bearing to perform optimally.

What are the advantages of journal bearings over Babbitt bearings?

In comparison to Babbitt bearings, journal bearings have various merits, especially in high-end use cases. Thanks to their hydrodynamic lubrication characteristics, they are very reliable and can endure significantly greater loads. Also, unlike Babbitt bearings, plants utilizing journal bearings function with quiet and low vibration, so their operation is smoother. Their configuration also allows greater heat dissipation, making them more effective in high-speed conditions. All in all, these characteristics seem to make journal bearings great for high-end industrial applications which are of high durability.

Load capacity and speed capabilities of journal bearings

As regards the load capacity and speed capabilities of journal bearings, I would say that these components do well in both aspects, which explains their extensive range of industrial applications. In Detail, their operation performance is as follows:

- Load Capacity: Journal bearings can withstand enormous loads as a result of hydrodynamic lubrication. This form of lubrication creates a film on the moving components, allowing the bearing to ‘fly,’ limiting contact and enhancing the load dispersal efficiency. The most important factors that influence the load capacity are:

- Bearing material: The incorporation of strong alloys or composite materials aids in load tolerance.

- Lubricant properties: The viscosity and category of the lubricant are crucial in safeguarding the hydrodynamic film present around the bearing.

- Surface area: An increase in surface area enhances the ability of the bearing to apply forces more evenly.

- Speed Capabilities: Due to maintenance-free lubrication film, they exhibit very low friction loss and minimal wear even for long-term use, making these bearings suitable for high-speed applications. Some of the key aspects that have a prominent effect on speed performance include:

- Surface finish: An increased surface finish finish assists in minimization of bearing friction hence, able to function optimally at higher rotational speeds.

- Lubrication flow rate: Consistent operations devoid of overheating are made possible due to adequate cooling and a steady lubrication flow rate.

- Clearance fit: The distance between the bearing and the journal must be perfectly defined in order to control excessive torque or inefficient movement at elevated speeds.

With the proper attention to detail, as cited here above, journal bearings can be designed and manufactured in a manner whereby the rigorous requirements of heavy load and high rotational speed machines can be met. Because of their capability to control the load and the speed, they stand as an important part of purely industrial systems where dependability is of utmost importance.

Durability and longevity of journal bearings

We can get a clearer picture of the durability and lifetime of journal bearings by segmenting their performance into key parameters and considerations in the following way:

- Material Selection: The journal’s bearing material can significantly determine how durable the journal will be. The bearing is required to be able to endure high levels of pressure as high-quality alloys or blended materials are made able to withstand quite a lot of stress and heat without deteriorating quickly.

- Lubrication: Correct lubricant selection and usage are essential for ensuring sufficient bearing life since improper maintenance often leads to bearing failure as the friction becomes comparatively high which in turn results in wear and tear. As lubrication requires care, having a maintenance plan in place that implements regular checks along with the reassurance of lubricant quality helps in increasing the life cycle of the bearing.

- Load Capacity: Journal bearings are load-rated, so they can only be used for a specific load. When a bearing is used within its load rating, it eliminates undue internal forces and excessive stress on the bearing surface, extending the life of the bearing.

- Operating Speed: The Friction present within high-speed equipment leads to a significant amount of heat being produced by the bearings. Proper installation of the correct clearance fit, along with the inclusion of heat dispersion means such as cooling systems, reduces operational issues greatly, thus providing a longer life cycle.

- Alignment and Installation: For long-term performance, frequent adjustments are critical since improper installation or usage can lead to imbalances in load that are not foundational and may lead to wear or damage in the bearings.

- Environmental Factors: Journal bearings’ longevity can be affected greatly by dust, dirt, moisture, and other particles, which have the same consequences as seals. To prevent such issues, regular rescues and adequate seals are enforced.

The principal condition in the operation of journal bearings, which guarantees their optimal performance and long service life, is the optimum parameters set for specific operating conditions. For the assuring of bearing reliability in the broad band of manufacturing conditions, Maintenance, fault diagnosis, and operational rules are necessary

In which applications are Babbitt bearings preferred over journal bearings?

Babbitt bearings are particularly suitable for applications that require reduced load capacities and low-speed operations, such as wind turbines; journal bearings are less favorable in those cases. From my heritage, they stand out while working on turbines and electric motors, along with compressors, which require higher speed and accuracy, but the load is not very excessive. They can even embed small contaminants while providing good conformability and can work in fairly misaligned conditions, which makes them a good fit in those applications. Also, they are in general most often used in situations whereby the mating parts will score them, so the bearing has to be softer, this gives the equipment appreciable longevity and certainly dependable functioning.

Industries that commonly use Babbitt bearings

I can assure you that they are extremely important in numerous activities where the reliability and durability of machines are of utmost importance. Some of the leading industries that use Babbitt bearings and the reasons why they use them are given below:

- Power Generation – Industries dealing with hydropower, wind energy, or thermal energy use Babbitt bearings in turbines, generators, and pumps. These bearings have great elastic properties and structural integrity, and they also have the capacity to withstand peak loads, making them useful in this application.

- Marine Industry – Numerous vessels at sea, including ships, utilize Babbitt bearings, particularly for propulsion systems and auxiliary machines. These bearings enable smooth transfer of motion and further provide protection from misalignments, which are integral to the vibrations and movements of water.

- Oil and Gas –Within this sector, Babbitt bearings are present in oilfield drills, oilfield refining units, compressors, pumps,s, and steam turbines. Babbitt bearings perform reliably in environments where there are fine abrasive particles due to their ability to embed small foreign matters.

- Steel and Metal Processing – In this industry, heavy machinery such as rolling mills and continuous casters utilize Babbitt bearings due to their ability to handle heavy loads while shielding sensitive components from damage.

- Pulp and Paper Industry – In the paper making process, rollers and pumps are used and a series of Babbitt bearings tends to be employed. Their properties regarding thermal transfer and friction are helpful since they ensure that machines are able to work efficiently and effectively even if it is running for a very long time.

- Transportation and Railways – For a long time, train engines and large vehicles have seen the extensive use of Babbitt bearings, owing to their endurance and high-speed stress-proof characteristics.

Every one of the industries in the world requires bearings that will reduce downtime, have smooth functioning in extreme environments, as well as prevent wear of the critical components. Babbitt bearings are affordable and extremely dependable which is why they continue to be in great demand throughout different industries.

Specific machinery suited for Babbitt bearing installation

I can confidently state that Babbitt bearings are well-matched for application in a range of equipment that demands high operating characteristics. These are the parts used in industrial pumps, compressors, turbines, and electric motors where working precision and durability are essential. Furthermore, due to their capacity to support large loads and operate in harsh conditions, you are likely to see them fitted in big marine engines and power generation equipment. Given the broad spectrum of speed and stress conditions that Babbitt bearings can tolerate, they are considered appropriate for machines working under considerably high burdens, including stress.

How does the maintenance of Babbitt bearings compare to journal bearings?

With respect to inspection and maintenance, Babbitt bearings may necessitate more effort on their linings than journal bearings because the Babbitt lining is made of softer materials. This lining chemically and physically can undergo change with time and most particularly heavy loading or inadequate lubrication will compel frequent re-lining or repairing. However, considering their construction, they are relatively easier to refurbish and repair when compared with journal bearings, which are made from tougher materials that are not easy to service at a site. The two types of bearings perform in a satisfactory manner and endure if their proper lubrication and constant inspection are available.

Routine maintenance requirements for Babbitt bearings

regular upkeep of Babbitt bearings is vital to avoid early deterioration and to enhance performance. The very first step always, of course, is one of these in every case: a visual assessment for the possibility of wear, such as scoring clearances or high amounts of axial end play. Proper lubrication is imperative, this includes the inclusion of the correct oil and its adequacy in volume which shields the bearing face and reinforces endurance. Further, staff can help reduce operational disturbances by observing operating parameters such as temperature or load. When such a condition is recognized, immediate attention should be given in terms of restoration or replacement of the line to prevent further damage. Adhering to these practices actively guarantees the performance and durability of Babbitt bearings in highly demanding applications.

Journal-bearing maintenance procedures

Having been involved in journal bearings’ work for quite some time now, I’m convinced that proper maintenance of such components is indispensable for the sound operation and reduction of outages. Here is how I do this step by step:

- Regular Inspections

I advocate for carrying out periodic check-ups to determine if the component has any wear on the bearing surface, for instance, scoring or if there is excessive clearance. Such measures will prevent the aggravation of the issue,e leading to expensive repairs being required in the future. Also, make sure to examine the condition of the bearings during the scheduled maintenance or if a fault operation is suspected and a more detailed inspection is needed.

- Proper Lubrication

Oiling is the heart of each journal bearing. In such cases, I make sure that the oil being used is according to the manufacturer’s requirements, especially with respect to the viscosity and the thermal stability. Furthermore, maintaining the proper level of oil and supplying the lubricant properly are indispensable for consolidating the bearing surface against friction and heat.

- Monitoring Key Operating Conditions

It is my practice to pay attention to essential parameters such as:

- Operating Temperature: Both elevated or low temperatures would degrade the oil and spoil the bearing. Hence, it is essential to monitor the temperature to avoid excessive heat problems.

- Load Conditions: Knowing the load imposed on a bearing is important so that it does not exceed the designed limits.

- Vibration Levels: An increase in vibration level can be a sign of an imbalance, misalignment, or excessive bearing wear.

- Timely Repairs or Re-lining

When it comes to a damaged or scratched bearing surface, which is also unevenly worn out, first and foremost, I concentrate on re-lining the bearing with a new Babbitt material. These practices are valuable risk-mitigation strategies since they save a lot of time and money in the long run.

- Documentation and Maintenance Records

In my opinion, maintenance activities should always be documented. Such activities assist in tracing the history of the bearing and in spotting trends that may require some alterations in the maintenance strategies or the operational routines.

Sustained effort in adhering to correct practices ensures optimization of the performance and life of journal bearings in any application, thus reducing the chances of failure and maintenance. Prevention is more effective than waiting for the problems to arise, so understanding the operational settings and parameters is clearly vital.

Comparing bearing life and replacement frequency

in order to compare the bearing life and replacement frequency, it becomes necessary to first study the individual operational requirements of each application which can either be withstand or endured. Bearings in most controlled environments have a relatively long lifespan, However, those which experience higher loads, contaminants, or extreme conditions, will have a shorter life span for they naturally would be worn out faster. I’ve also learned that regular attention and monitoring and/or any predictive maintenance interventions may help one who’s anticipating wearing to last longer than if none of those actions were taken. The replacement frequency, on the other hand, is determined on a cost-benefit analysis against reliability restoring: if a component is replaced too early, expenses are high, but if a component is replaced too late, there are chances of unanticipated failures. Therefore I utilize performance statistics as well as maintenance history so that such decisions are made under trends in actual practice instead of abstractions, thereby improving efficiency without sacrificing reliability.

What are the cost considerations when choosing between Babbitt and journal bearings?

In making a decision between Babbitt and journal bearings, the key factor is cost, both in terms of initial installation and operational costs throughout the lifetime of the bearing. Because of the technologies employed in their manufacture, Babbitt bearings tend to be more costly on installation but they have impeccable versatility across a wide range of loading conditions and offer repair and re-lining options, increasing their lifespan. On the contrary, journal bearings seem to be more economical in the short term and appropriate for general usage, but they are less durable in heavy load settings and need timely replacements. In most cases, the choice is guided by the characteristics of the application, expected wear in different zones, bearing value over time, and so on.

Initial investment comparison

While lending out my services as a consultant to a number of clients in investment, I tend to recommend they first analyze their operational needs and requirements. While I do understand the necessity for having an upfront investment, I make it quite clear that for demanding usage, Babbitt bearings provide considerable benefits over others without the nostalgia for repair. It’s logical to think of these bearings as an investment in strength and quality. The same cannot be said about journal bearings – they might be more appropriate for those on a lower budget and where operational stress is lesser. Their standardized way of functioning allows for them to be ordered and mounted easily, thus lowering the starting costs. In all cases, the best decision is to rationally approach the choice of investment level with the specified needs along with the predicted functioning of the system.

Long-term operational costs

In regard to the long-term running expenses, I like to think the decision is always framed around the requirements of an application specifically. Although Babbitt bearings are more expensive in the beginning, they tend to be more economical in rigorous environments over time. Low transport costs due to the high availability of spares and long life contribute to reduced downtime and cost of replacement, thus making them well-suited for heavy or high-load systems. On the other hand, journal bearings tend to be cheaper to install and are less expensive but have the potential of having a higher maintenance cost when installed in an environment beyond its tolerances. A balance between the total life cycle cost and the operating requirements must be struck to ensure that the solution implemented is the most viable in the end.

How do Babbitt and journal bearings handle high-speed applications?

Babbitt bearings are the most suited for demanding high-speed applications because of their remarkable resilience and adaptability. They have excellent load-carrying ability and friction properties, which enable them to act stably even under high speeds. On the other hand, journal bearings work in high speed scenarios too but they’re efficiency relies heavily on the lubricant regime and working conditions. Ideally, from what I have noticed and observed in practice, Babbitt bearings seem to have better and more stable operation in high-speed applications where reliability is of great importance.

Performance of Babbitt bearings at high RPM

Babbitt bearings are rated well at high rpm due to their ability to bear heavy loads with low friction coefficients and high RPM while having excellent conformability. Since the rubbing surfaces require to be lubricated, doing so would improve their effectiveness as it reduces wear and tear and allows the rubbing surfaces to work seamlessly while under operational stress. They are strong, practical, and reliable and, therefore, are ideal for use in high-speed settings that require accuracy and stability for long periods of time.

Journal bearings in high-speed rotating machinery

When correctly designed and serviced, a journal bearing can be quite efficient with high-speed rotating equipment. Such hinges on the provision of a well-formed lubrication film that aids in reducing friction and dissipating heat produced during high-speed rotation. They do provide considerable strength to sustain dynamic loads, but there are factors such as good alignment of the bearing and proper supervision of their working conditions to be maintained to optimize performance and extend their service life under such unrelenting conditions.

Reference

- Advantages of Babbitt Bearings | Journal Bearing Design & Practices

- Babbitt Bearing: Types, Characteristics & Applications

- Journal and Rolling Element Bearings: Advantages & Disadvantages

Frequently Asked Questions (FAQs)

Q: What are the main differences between Babbitt and journal bearings?

A: Babbitt bearings are a type of plain bearing made from a soft alloy that provides good wear resistance and low friction. Journal bearings, on the other hand, are a broader category that includes various designs, such as sleeve and thrust bearings, which can be made from different materials. Babbitt bearings are often preferred for applications requiring a thin layer of babbitt for cushioning, while journal bearings can accommodate more robust designs.

Q: What is the life of the bearing in Babbitt vs. journal bearings?

A: The life of a Babbitt bearing typically depends on factors like lubrication, load, and operating conditions. Babbitt bearings can wear out faster due to metal-to-metal contact if not properly lubricated. In contrast, journal bearings, especially those with rolling-element designs like ball or roller bearings, tend to have a longer lifespan due to their reduced friction and better load distribution.

Q: How does contamination affect Babbitt and journal bearings?

A: Contamination can significantly impact both Babbitt and journal bearings. In Babbitt bearings, contaminants can lead to accelerated wear and failure of the thin layer of Babbitt. For journal bearings, contamination can also cause increased friction and wear, potentially leading to metal contact and a decrease in the bearing’s overall life and performance.

Q: Can Babbitt bearings be easily replaced compared to journal bearings?

A: Yes, Babbitt bearings can be considered easily replaceable due to their construction. When a fitted babbitt wears out, it’s often possible to re-babbitt the bearing shell. Journal bearings, particularly those that are integrated into complex assemblies, may require more effort and time to replace.

Q: What types of loads can Babbitt and journal bearings support?

A: Babbitt bearings are designed to support radial loads and can handle moderate thrust loads, while journal bearings, including thrust bearings, are engineered for both radial and axial loads. The choice between them often depends on the specific application requirements, such as the direction of the load and the bearing clearance.

Q: How does temperature affect the performance of Babbitt versus journal bearings?

A: Temperature impacts both types of bearings differently. Babbitt bearings may suffer from reduced performance at high temperatures, which can lead to softening of the babbitt material. Journal bearings, particularly those with fluid film lubrication, can maintain better performance at elevated temperatures, as the fluid helps with cooling of the bearing.

Q: What is the role of lubrication in the performance of Babbitt and journal bearings?

A: Lubrication is crucial for both Babbitt and journal bearings. For Babbitt bearings, proper lube prevents metal-to-metal contact and extends the life of the bearing. In journal bearings, especially those operating under high load, lubrication forms a fluid film that supports the shaft and bearing, reducing friction and wear during operation.

Q: Are there specific applications where one type of bearing is favored over the other?

A: Yes, Babbitt bearings are often favored in applications such as engine bearings where high load and low speed are common. Journal bearings, particularly rolling-element designs like needle bearings, are preferred in applications requiring high speed and efficiency, such as in motors and turbines.

Q: How do Babbitt and journal bearings handle misalignment?

A: Babbitt bearings are more forgiving of misalignment due to the soft material that can accommodate slight deviations. Journal bearings, however, may be more sensitive to misalignment, particularly rolling bearings, which require precise alignment to function correctly and avoid premature wear.