A defective wheel bearing may appear to be quite a trivial matter; however, if ignored, it can turn into a massive safety concern. A wheel bearing is perhaps one of the most important parts of your car or truck as it facilitates the movement of the wheels. As a wheel bearing begins to weaken, it will cause the wheels to make strange sounds, the tires to wear out in an uneven fashion, or even the steering to twitch. A bad wheel bearing is definitely not something that you want to be driving around with as it is a danger not only to yourself but other road users as well, and it also might end up in costly repair if not rectified on time. In this article, we’ll take a look at 10 unmistakable signs that will help you understand what bad wheel bearing feels like and when to seek help. If you’re aware of these signs, it will be easier for you to detect potential issues and prevent compromising the safety and effectiveness of your car.

What are the most common symptoms of a bad wheel bearing?

When a wheel bearing is failing, the typical symptoms noticed are abnormal noises such as humming, grinding, and roaring from the offending wheel while driving, especially when accelerating or turning outwards. Humming may also be associated with vibrations in the steering wheel, tire wear, and even swaying when driving. Also, a faulty wheel bearing can lead to loose fitting of wheels, the ABS warning light may flash on and off, or more effort than normal is required to roll the vehicle. Being able to identify these symptoms early can help reduce the extent of damage and enhance your safety whenever you are on the road.

Unusual noises: grinding, humming, or whirring

Tremors, hissing, or irregular noises like grinding are indicators of a worn out or broken wheel bearing, this is how I diagnose such problems most of the time. These are most of the times audible at high speeds and can change in sound on acceleration and deceleration. These issues should be dealt with as soon as possible because a wheel bearing cannot be neglected; its failure will affect the vehicle’s operation and handling. These signs shouldn’t be ignored, or at the very best, you’ll risk even bigger damage or, worse, the vehicle breaks down voicelessly. Always remember, if in doubt, to get the car checked professionally.

Steering wheel vibrations and wobbling

Every so often, I receive queries connected to steering wheel vibrations and oscillations; namely, the questions include what could be the contributing factors or what could help ameliorate the situation. Given my experience, there are several common reasons why your steering wheel might vibrate or wobble. So let’s explore them one by one:

- Unbalanced Tires: As tires become unevenly balanced, you may notice vibrations while driving, especially at high speeds. The solution to this issue is quite simple: a quick tire balancing service. For that reason, this phenomenon is one of the leading causes of the majority of frequency-related issues.

- Wheel Alignment Issues: Incorrectly aligned wheels can make your steering wheel shake or pull to the side. On the other hand, it can also lead to excessive wear and tear on the tires. Fortunately for everyone, it is a simple issue that is resolved with proper wheel alignment.

- Damaged or Worn Suspension Components: Damaged parts, such as tie rods or ball joints, are pivotal components in maintaining the steering’s stability. Such components ensure a tighter hold and minimize wobbling or vibrations in the steering wheel even when driving over uneven surfaces.

- Warped Brake Rotors (if vibrations occur while braking): If enough stress is applied to the brake pads while the brake rotors are worn or warped, the uneven pads will cause a wobble. The appropriate remedy for that situation would be replacing or resurfacing the rotors.

- Loose or Faulty Wheel Bearings: Forget the low-speed scenarios; a broken or loose wheel bearing makes noise and affects handling while causing vibrations. The above two problems are only multiplied when broken or loose wheel bearings are not replaced at higher speeds.

- Tire Damage or Degradation: Tire dilemmas can be directly related to the bulges, flat spots, or uneven wear of the tire. Therefore, it’s highly recommended that you inspect your tire regularly to prevent these problems from occurring.

Any steering vibration has to be addressed straight away; sometimes, people say oh I will wait it out, it isn’t that bad”. However, in fact, something small has the possibility of expanding into something larger or becoming a danger to the individual. A professional understands how to assess all of those parameters and customizes the vehicle’s characteristics so that it runs smoothly.

Uneven tire wear and increased friction

The causes of friction are improper alignment, unbalanced tires, or varying tire pressure, which, in turn, leads to uneven tire wear. These problems will ultimately affect fuel efficiency and vehicle control and cause rapid depreciation of the tires. To avoid these issues and to enhance comfort and security while driving, routine care, tire rotation, alignment and monitoring of pressure should be done.

How can I tell if my wheel bearing is going bad while driving?

Whenever I’m out on the road, I’ll listen out for specific sounds like humming, grinding, or growling that may indicate a wheel bearing going awry, and such telltale sounds seem to change as the vehicle speeds up. Another would be feeling excessive vibrations from the while vehicle while it seems to steer towards one side while on the move. Loose steering or uneven wear on the tires are also some other signs of a defective wheel bearing. It is important to deal with the problems without delay because any negligence towards them would make the drive unsafe or have higher repair costs.

Noticeable changes in steering responsiveness

With regards to the steering of a vehicle, noticeable problems are likely to arise from the suspension or steering systems. There are multiple possible causes for this vector change, some of which are worn tie rods, a failing ball joint, lack of steering fluid, or wheels being misaligned. Moreover, warped tire pressure would also alter the feel of the steering. Correcting such factors should be done promptly to attain the desired vehicle control and driving bliss.

The feeling of looseness or play in the wheel

when a driver reports a feeling of looseness or play in the steering wheel, it’s most likely a result of wear or damage somewhere in the steering system. Tie rods, the steering rack, and even the steering column components might be loose or excessively worn out as well. Slightly loose ball joint(s) and low power steering fluid might also be a contributor. Such issues need to be treated urgently as they tend to create bigger complications and put the safety of the vehicle at risk.

Increased noise when turning or changing lanes

Regarding elevated sounds when cornering or switching lanes, I have no doubt that this is a sign of a fault developing in the suspension or the steering system of your vehicle. Below are the basic areas that I would suggest looking into to determine the cause:

- Power Steering System – A low level of power steering fluid may be the cause of your system’s whining noises or the people turning the wheel may be causing the system to groan as a result of strain on the sensors. Check your power steering fluid levels and add if required. A whining sound could also mean that your power steering pump is going bad.

- Ball Joints – Creaking and/or clunking sounds when turning might be the result of dry or worn-out ball joints. These parts are also important in the smooth transfer of motion from the steering wheel and suspension, so inspection, lubrication, or replacement is called for.

- Tie Rod Ends – Make sure your tie rods are properly secured; if they are loose or hitching, you might constantly hear a rasping when making steering movements. The tie rod serves as the link between the steering rack and axle wheels, and damage in this area contributes to rattling and the impairment of the vehicle’s handling.

- Wheel Bearings –Poorly built wheel bearings might begin to hum and grind, particularly when turning the wheel. This is a serious matter because it may affect the perfect balance of your wheel structure, so take effective steps.

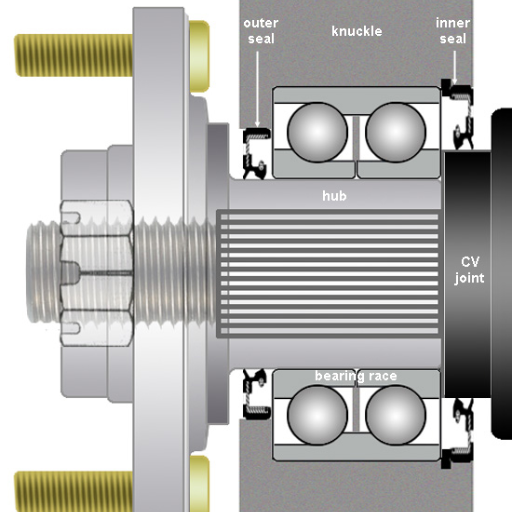

- CV Joints – If you notice a clicking or popping sound whenever you make a sharp turn, the chances are you have worn out CV (constant-velocity) joints. Such joints are essential in delivering torque to the wheels from the gearbox. Therefore, a failure in such a situation would not be surprising.

In most cases, these issues are solved through an inspection of the affected region by a professional mechanic who determines its cause with specificity. This way, you prevent any more worsening of the condition and functioning of your car.

What are the dangers of driving with a damaged wheel bearing?

This isn’t an ideal situation. Whenever you find yourself driving a vehicle with a damaged wheel bearing, just don’t. Based on my experience, a bad wheel bearing is unpleasant and could cause abnormal wear on the tires as well as loss of stability in the car when cornering or at high speeds. If the bearing were to fail completely, the most plausible scenario would be that the wheel locks whilst you are still operating the vehicle which causes you to completely lose control. You lose your peace and increase the cost of the repairs when you do not deal with such issues in a timely manner.

Risk of wheel separation and loss of control

it’s clear to me that the risk of a faulty wheel bearing leads to loss of control of the vehicle, and separation of the wheel is a major issue, and here’s why. A wheel bearing is a crucial device that is responsible for the rotation of the wheel and holding the weight of the vehicle. Its absence raises a multitude of issues, and this can be best comprehended by assessing the concerned parameters:

- Heat Buildup: A damaged or degrading wheel bearing increases friction to a significant extent, thereby contributing to heat buildup. This may potentially lead to warping or breaking of parts around the wheel assembly, making the prospects for separation greater.

- Uneven Load Distribution: The bearing’s job is to carry the weight of the car and to distribute it evenly. Hence, if the bearing gives way, stress is placed on the wheel hub, together with other components, which over time makes them mechanically weak, and the configured specific torque may be released, resulting in a scenario where the wheel may part ways with the vehicle.

- Loss of Lubrication: Lubrication is the mainstay of bearings, A defective or a worn-out bearing can lose seals or the lubrication within said components which will result in a lack of lubrication. Excessive friction will be present within the metal components, which would quicken the deterioration of the equipment and raise other safety concerns.

- Alignment and Stability Issues:: A worn out bearing can lead to football shapes snap in the horseshoe, contemplating the wheel bearing indenting tool coming out until faked out. It results in the vehicle steering toward one direction, being less responsive to directional adjustments, and having an amalgamated sensation of driving that may lead to incapacitation when it matters.

- Unusual Noises and Vibrations: To most of society, most do not have patience in draining away the fluid to help others aid in repair. Rather, their sleep or peace is broken towards mechanical work, and that too towards the specific side of… the indigenous kneeling commodity. This really disintegrates one’s chances of believing they would come back for repairs as soon as they are called out or signaled by the vehicle.

To mitigate these risks, I recommend regular compositional examinations and maintenance of your wheel bearings. Any sign of trouble, such as noise, vibration, or change in handling, should be reported to Wen Consulting. These problems look minor, but remember, dealing with them late can compromise your safety and the safety of the car.

Potential damage to other suspension components

damaged or worn wheel bearings, if left unattended, may contribute to severe damage to other suspension parts. For example, loose or too much friction bearing may stress your axle, shocks, and struts, making them wear faster. Also, the rocking of wheels or uneven weight distribution may cause the vehicle to be out of alignment which affects your tires and steering as well. Taking care of the wheel bearing problems in the first place helps in saving further repairs as well as preventing the whole suspension system from premature aging, saving you expenditures in the future.

Compromised braking performance and safety

Worn wheel bearings can also endanger the effectiveness of the brakes and the stability of your automobile. A faulty bearing can lead to an imbalance in the wear of brake pads, increased distance during stopping, and shaking of the vehicle during braking, which poses a danger to the driver and other people around. Being able to use your brakes safely and effectively is highly dependent on your ability to keep the wheel bearings in good working order.

How long do wheel bearings typically last before showing signs of wear?

A standard driving experience will allow for wheel bearings to have a lifespan between 85,000 miles and 100,000 miles. Other road conditions, habits of the driver, as well as debris and water exposure, might affect these bearings’ longevity; they could be worn out much earlier than expected. Regular checks can help assess the situation and resolve potential issues.

Factors affecting wheel bearing lifespan

there are a couple of aspects that, in my mind, dictate how long wheel bearings may last. To begin with, let’s consider rough road conditions. How many of us have suffered a busted wheel bearing because of potholes or bumpy roads? These definitely affect the life span of the wheel bearing. The same can be said for exposure to water, mud, or too much debris, which may cause bearing corrosion or contamination. Constant wear and tear of this nature makes the bearing unusable over time. Further to this, it is also possible for the bearings to come under strain from hard stops and steering aggressively. But with proper care and driving, a wheel bearing can last as long or even longer than the average expectancy of a bearing in terms of mileage.

Average mileage expectations for wheel bearings

the average lifespan of the wheel bearings falls between 85,000 and 100,000 miles, although this is likely to differ greatly across a wide range of parameters. To elaborate on this:

- Driving Conditions: For those who regularly drive on difficult and bumpy roads, there might be more stress on the wheels, making the bearings wear faster. But on the other hand, having a majority of the drive on calm and proper roads allows the bearings to last longer.

- Quality of Wheel Bearings: High-quality bearings are those that are well built and made of strong material, earning them a longer lifetime. In such a case, sticking to known brands always makes a lot of sense.

- Vehicle Maintenance: Consistent checking and regular service can recognize early indicators of damage like strange sounds or vibrations, and can intervene before the damage becomes extensive. Keeping parts lubricated reduces friction and the chances of parts getting damaged due to overuse.

- Driving Habits: Aggressive maneuvers, hard stops, and sharp turns tend to apply excessive pressure on wheel bearings, which can reduce their expected lifetime. Staying gentle with the wheels will allow them to last longer.

- Exposure to Elements: If the parts of the vehicle are constantly in contact with water, mud, or road salt without cleaning them properly, the bearings will be in great danger of getting contaminated or corroded, which will greatly lower their durability.

If you observe these metrics and maintain your vehicle properly, it is realistic to help your wheel bearings reach or maybe exceed their expected mileage. The best way to guarantee a longer lifespan is to drive and maintain them in an ideal way.

What causes wheel bearings to fail prematurely?

wheel bearings tend to fail prematurely due to a combination of mismanagement and extreme working conditions. Contamination by lubricant infiltrators, including dirt, water, and road debris, is one of the most common causes of contamination; these substances lead to the breakdown of lubricant and also result in overbearing damage. Similarly, overload is necessary; exceeding the recommended weight ratio puts a lot of stress on the bearings, increasing their degeneracy. Moreover, if they are not fitted properly or are fabricated using bad bearings, either alignment or the lubrication is poor enough to void a lot of life expectancy. Good practices such as proper replacement of parts after wear is due and proper inspection of the vehicle can solve all of the aforementioned concerns.

Impact of poor road conditions and potholes

When roads are in bad shape, including having potholes, wheel bearings feel the brunt of excessive jolts and vibes, which will force them to age quickly and structurally suffer. The cyclic application of said forces alters the relation or position and causes stress to the bearing parts which frequently leads to overheating or failure. Taking care of these effects begins with routine maintenance and attentive driving on rough road areas.

Effects of water contamination and inadequate lubrication

I have witnessed how the wheel bearings fail due to water ingress and poor lubrication. When water penetrates the bearing structure, rust occurs, and protective surfaces start to break down, causing efficiency to drop tremendously. Likewise, an insufficient lubricant increases the coefficient of friction, which causes the bearings to heat up and wear out faster. If both problems persist, they can damage the entire bearing, and you’ll be looking at a hefty repair bill. For these reasons, I always emphasize the need for good sealing systems and lubricant management to maintain bearings’ durable performance throughout the bearing lifetime.

Consequences of improper installation or overtightening

Examples of problems that arise from improper installation or overtightening of wheel bearings are numerous, and I’ve come across quite a few in the course of my work. For starters, misalignment is primarily caused by the improper installation of the bearing – it is not properly positioned within the housing. It can, in turn, cause uneven load during its operation which would in due course of time induce something termed as “Wear and potential failure”; because the bearing is not properly positioned. While installation takes place, ensuring alignment accuracy is vital for the subsequent function of the bearing.

Over-tightening, on the other hand, causes an extreme preload on the bearing. This, in turn, amplifies the level of friction, which generates heat that can destroy the materials and lubricate the bearing. All these, in the long run, can lead to parts locked up or shattered under heat, which could, in turn, lead to the obliteration of the bearings in the course of their operation. So, to counter this problem, it is best to tighten the bearings following the manufacturer’s recommended torque values, as these values have been predicted to help smooth out the operations without compromising the load capacity.

Here are the key parameters to consider when addressing these issues:

- Torque Specifications – It is crucial for the installer to observe the manufacturer’s specified torque levels during installation to avoid excessive ‘overtightening’.

- Alignment – Confirm whether the bearing is mounted to the housing section correctly and symmetrically with precision measuring tools.

- Lubrication Check – Make sure the Lubricant is properly placed onto the components during assembly in order to reduce the chances of friction and overheating from a poorly assembled part.

- Material Expansion Tolerance – Take into account the expansion and contraction tolerance of the material, whereby overtightening may restrict the expansion and contraction of the components’ natural causes with changing temperatures.

Consequences such as costs incurred from faulty installation or over-torquing, which could prove to be dangerous, can be evaded by following best practices and paying attention to these aspects.

How much does it cost to replace a bad wheel bearing?

The expense of changing a worn-out wheel bearing can be determined by several factors which include the model and the make of the vehicle, which wheel bearing is needed, and the labor rates in one’s locality. I have found that the average cost is usually $150 to $500 for each wheel bearing. Prices of bearings may be around $50 to $200, while labor costs can be around $100 to $300. Note that the prices can be higher for luxury or performance cars because of specialized parts and services. To get a better idea of the amount of work involved, it is always a good idea to speak to a trusted mechanic who can give you a quote.

Factors influencing wheel bearing replacement costs

Replacing a wheel bearing can be quite costly, depending on the type of vehicle owned, as luxurious and performance vehicles can use some expensive parts. Labor costs in your region also have a material bearing on the overall; if the replacement is complicated or takes a long time, then costs can go up. To finish off, the cost of the replacement parts also can affect it, as more expensive OEM parts are known to provide better durability and performance, hence, in turn, costing more.

DIY vs. professional replacement considerations

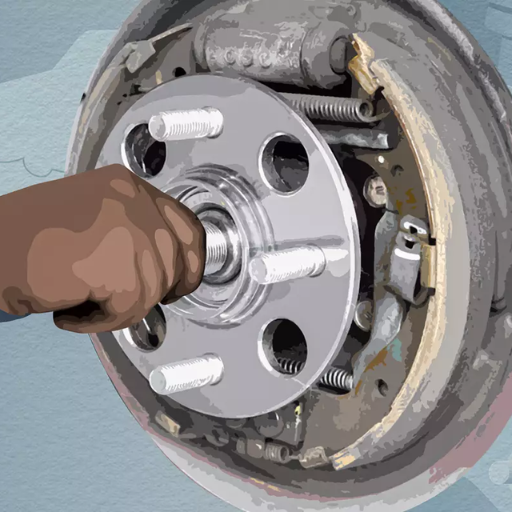

replacing a wheel bearing often comes down to a choice between DIY and hiring a professional, which factors into your experience and tools. For instance, many home mechanics don’t have a bearing press, which is required for the job. The DIY approach is beneficial only if you are well aware of vehicle repairs and have the confidence to deal with small intricacies. It calls for a lot of caution so as to avoid issues like poor fitting or accidental damage to the surrounding parts. In contrast, a professional replacement gets the task accomplished correctly the first time. Professional technicians not only possess the machines but also the required knowledge so as to get the job done properly, along with warranties for protection.

Can I continue driving if I suspect a wheel bearing problem?

Driving without addressing a suspected wheel bearing issue still puts one’s safety in jeopardy. A damaged bearing may later worsen damage to the vehicle’s handling. If feeling odd is accompanied by steering wheel sounds, some shaking, or loss of control stability, a vehicle should definitely be checked out and fixed straight away to prevent more dangerous impacts or repair expenses.

Risks associated with ignoring wheel bearing symptoms

Neglecting the symptoms of a failing wheel bearing is one danger I wouldn’t ever recommend taking. Because, in my experience, the situation can deteriorate quite quickly. A damaged or worn-out wheel bearing can create excessive heat, which can result in a wheel failure while in motion. Needless to say, it is very dangerous for both the driver and the people in other vehicles. Also, if the problem is not addressed on time, it can damage other associated parts, such as the hub or axle, making it a repair that requires more time and is costly of being a simple issue. For truckers, the first sign of trouble is not only sensible, but it is also critical for the truck’s development as well as the driver’s safety.

Importance of prompt ,professional inspection and repair

a prompt electrician service expert offers invaluable service. That is why I always emphasize the necessity of quick action the moment clients note a potential bearing problem. It is astonishing, but I have seen many cases in which postponing the repairs transformed a simple problem into life-threatening conditions or an overly expensive solution. Master mechanics know the right tools to use, and they can conduct the appropriate examination to correctly ascertain the problem and prevent it from getting worse. Without a doubt, bail out and keep me using my car with confidence, guarantee me peace of mind, and, most importantly, save a lot of cash.

Reference

- Kelley Blue Book: How Do I Know if I Need a Replacement?

- MOOG Parts: How Long Do Wheel Bearings Last?

- SKF Vehicle Aftermarket: Symptoms & Signs of a Bad Wheel Bearing

Frequently Asked Questions (FAQs)

Q: What are the most common bad wheel-bearing symptoms?

A: The most common bad wheel bearing symptoms include unusual noises like grinding, humming, or whirring, especially when turning or at certain speeds. Other signs include uneven tire wear, steering wheel vibrations, and a feeling of looseness in the wheel. You may also notice the ABS light coming on or your vehicle pulling to one side while driving.

Q: How can I tell if my wheel bearing is bad?

A: To check for a bad wheel bearing, listen for unusual noises coming from the wheel area, such as grinding or humming. You may also feel vibrations in the steering wheel or notice your vehicle pulling to one side. Jack up the car and try to shake the wheel; if there’s excessive play, it could be a sign of a worn bearing. Additionally, uneven tire wear or an illuminated ABS light can indicate a bad wheel bearing.

Q: What does wheel bearing noise sound like?

A: Wheel bearing noise often sounds like a grinding, humming, or whirring sound that changes in intensity as you accelerate or turn. It may start as a faint noise and gradually become louder over time. The sound might be more noticeable when turning left or right, depending on which wheel bearing is affected.

Q: How long do wheel bearings last?

A: On average, wheel bearings can last between 85,000 and 100,000 miles, but this can vary depending on driving conditions, vehicle type, and maintenance. Some wheel bearings may last the lifetime of the vehicle, while others may need to be replaced sooner. Regular inspections and proper maintenance can help extend the life of your wheel bearings.

Q: What can damage a wheel bearing?

A: Several factors can damage a wheel bearing, including: 1. Poor road conditions and impacts from potholes 2. Driving through deep water or mud 3. Uneven tire wear or improper tire balance 4. Overtightening or under-tightening during installation 5. Normal wear and tear over time 6. Contamination from dirt, debris, or moisture inside the hub

Q: How often do wheel bearings need to be replaced?

A: There’s no set schedule for wheel bearing replacement, as they often last for many years or even the lifetime of the vehicle. However, it’s recommended to have your wheel bearings inspected during routine maintenance, typically every 30,000 to 50,000 miles. If you notice any signs of wheel bearing failure, such as unusual noises or vibrations, have them checked and replaced as needed.

Q: Can you drive with a broken wheel bearing?

A: While it’s possible to drive with a worn or damaged wheel bearing for a short distance, it’s not recommended. A broken wheel bearing can lead to serious safety issues, including loss of steering control, wheel detachment, or damage to other components. If you suspect a bad wheel bearing, have it inspected and replaced as soon as possible to ensure your safety and prevent further damage to your vehicle?

Q: What happens if wheel bearings are not replaced?

A: If worn wheel bearings are not replaced, the consequences can be severe. The bearing may eventually seize, causing the wheel to lock up while driving. This can lead to loss of control, accidents, or extensive damage to other components, such as the hub, CV joint, or axle. Additionally, driving with worn bearings can cause uneven tire wear, reduced fuel efficiency, and damage to the wheel hub assembly.