Ball-bearing transmissions are an important component in many mechanisms as they enhance smoothness, precision, and the lifespan of the mechanism. In cars, industrial equipment, and even more so in small and everyday devices, these parts reduce friction and help in the movement of the other parts. This guide is designed to be a reference tool on the subjects related to ball bearing transmissions, including their conception and application, and for what purposes the enhancement of the shaft’s performance was implemented. The follow-up article intends to present a diversity of types and uses and maintenance problems so that the users would possess enough concepts for the usage of their appliances in such a way that they would be functional and operate in their optimal mode.

What is a ball-bearing transmission, and how does it work?

The smooth performance, operational longevity, and precision of almost all mechanical systems depend significantly on the performance of ball-bearing transmissions, making them vital components. In vehicles, industrial equipment, and especially in small and ordinary devices, such elements reduce the friction between moving parts. This guide is structured to serve as a reference source for everything that concerns ball bearing transmissions, their design, purpose, and for what shaft performance optimization they were made for. Such an article will be dedicated to the use and modification of many types and forms of machines, such as the provision of necessary information on where and how to operate to avoid premature failure or disturbance of the machines.

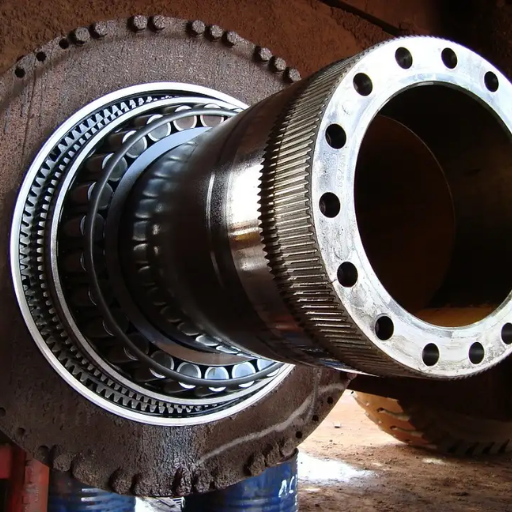

Understanding the basics of ball bearings in transmissions

the significance of any ball bearing within a transmission assemblage is crucial, to say the least. It is their support who should be credited for the smooth and constant turning of the shafts of any machinery. If it were not for their crafted geometry and strength to take both radial and axial loads, friction, wear, and finally, failure of any machine would be commonplace. The likely interferences can be avoided by reasonable oiling, prudent care of the component, and selection of the suitable type of ball bearing. I will advise you that ball bearings should not only be looked at as an investment but also an understanding of their function, which is crucial to the optimal performance of any transmission system.

The role of ball bearings in reducing friction and enhancing performance

let me elaborate on how ball bearings are able to reduce motion friction and improve performance. The functioning of ball bearings is chiefly concerned with the transfer of the contact surface from sliding to a rolling surface, which is more advantageous. This greatly decreases friction, which is the force opposing the motion when the elements slide across one another. Now, here are the relevant parameters that explain their importance in enhancing the performance:

- Material Quality -The ball bearings ought to be made out of high-quality materials, like stainless steel or ceramic, so that they are strong enough to withstand extreme loads whilst reducing deformation or wear& tear processes.

- Precision Manufacturing -It is also important to stress the great importance of bearing design and its manufacturing precision. Low tolerances and compact controls allow for smooth operation, which greatly decreases friction and noise and increases efficiency.

- Load Capacity -The ball-bearing units are designed to take up advanced loads, both radial and axial. By using a bearing of the specified rating correct for the load, the bearing would be under rip and pressure, ensuring no other resistance is created apart from that which is needed.

- Lubrication -Consistent and proper lubrication is one of the key ways of minimizing friction. Grease or oil acts as a lubricant and helps prevent wear between moving surfaces by providing a thin film coated on the two surfaces, thus increasing the longevity of the bearing.

- Speed Ratings – Because of their design, different ball bearings can operate only for a limited speed range. Always make sure to use the right bearing for the right speed of application. Doing so helps to prevent the bearing from overheating, keeping it functional for the long term.

All of the defined parameters reinforce one another to guarantee that ball bearings ensure easier movement, lower energy losses due to friction, and greater operational life of the machines. If these aspects are considered more carefully, the performance and reliability of any mechanical system involving ball bearings can be enhanced.

Types of ball bearings used in automatic and manual transmissions

Different types of ball bearings are used in automatic and manual transmissions according to their own requirements. The most common are deep groove ball bearings, which are good for transmitting radial and axial loads, and angular contact ball bearings, which are characterized by their high-speed rotation and ability to cope with combined loads. In some transmissions, thrust ball bearings are used to deal with the axial forces acting during the working of the propulsion mechanism. These wear out sensible bearings, and therefore, the smooth working, life, and efficiency of the transmission are assured.

Why are ball bearings crucial for transmission efficiency?

I consider ball bearings as one of the most important components of a transmission. When I say that their primary focus is to lower the friction of any moving part, which, in the end, cuts down the loss of energy and maximizes efficiency, I do so from experience. Because it assists in the precise support of the rotating movement, the ball bearing contributes to the transmission’s efficiency and durability. Quite honestly, I’ve witnessed how ball bearings, if appropriately selected, can lessen the effects of wear out, cut overheating, and assist the entire system in working reliably in various conditions. Their importance as part of the transmission system cannot be understated; it is through them that the transmission works and lasts.

How ball bearings improve gear engagement and power transfer

The use of ball bearings on gears aids in friction reduction when they are in motion, thus enhancing the smooth transfer of power and motion. They guarantee correct center-distance between the gears, hence minimizing energy wastage by improving mechanical efficiency. Such dependability in performance is said to not only enhance the efficiency of power transmission but also restrain the unnecessary strain of the system, thus promoting its durability and stability.

The impact of ball bearings on transmission longevity and durability

My practical experience with mechanisms leads me to believe that ball bearings are crucial elements for prolonging the life and durability of transmissions. They greatly minimize friction and wear between components which is essential to prevent performance degradations and to achieve system efficacy in the long run. Well-designed and maintained ball bearings increase the mechanical efficiency of transmission and also protect it from expensive repairs, which makes them a vital part of any good system.

What are the signs of failing transmission ball bearings?

Several key warning signs and indicators might provide information regarding the possibility of the failure of the transmission ball bearings. Such would include the sounds of grinding, humming, or even growling, as the use of the bearing will often be a sign the parts are extensively worn out or damaged. The presence of vibrations and rough use during its operation also would suggest the possibility of bearing defects, including improper alignment or simply worn out. Further, the presence of overheating and discoloration are indicators of friction problems, and more damage to the part might be on the way. Lastly, performance drops such as the failure to achieve a smooth transition during the use of the part or efficiency dropping all of a sudden are signs that the bearings have already failed and need looking at them as soon as possible. Timely examination and maintenance of the bearings are essential to enable the shaft to operate within acceptable bearable levels of stress.

Common symptoms of worn or damaged ball bearings in transmissions

Ball bearings exhibit telltale signs of wear and tear that cannot be ignored. This is one of the lessons I have learned and been able to carry through the years. If you could only begin by understanding these signs, you would save a lot of money on repairs. Here’s an easy rundown of the crucial factors and their underlying meanings:_

- Unusual Noises – Sounds such as Grinding, clicking, or humming noises could be the main indicators that something is wrong. In cases of wear or debris, these noises can be a result of insufficient contact between the bearing surfaces.

- Excessive Vibrations –Bearing systems losing their perfect alignment can be felt through the entire transmission system, unpleasing, abnormal vibrations. This splintering distortion makes it difficult to smoothly rotate the various components.

- Overheating – Focusing on the internals, if the bearing housing is found to be unusually hot or has changed color, it may be a result of excessive friction caused by inadequate lubrication or internal bearing damage.

- Reduced Efficiency –Performance would also drop; indicators like increased difficulty in smooth power transmission/smooth difficulty in accomplishing the desired output suggest that the bearings may not be operating as they should, owing to surfaces wearing close to them or other misaligned elements.

My proposal would also be that there is a continuous observation of noise levels, vibrations, operational temperature, and efficiency of the transmission in tandem with the routine maintenance of the equipment. In fact, monitoring these would confirm that the bearings are operating normally which would also avert any major breakdowns in the system.

How to diagnose ball bearing issues in your transmission

If you want to have a good understanding of the transmission problems related to the ball bearing, you should know the parameters that can help in diagnosing the problem. Here’s a quick but detailed guide on what, in particular, look for as these indicators help in sorts of telling what the issues are:

- Noise Levels

An abnormal working noise like a grinding clicking or even a humming sound would mean that the bearings are either damaged or not aligned or are not well-oiled enough. It is critical to conduct an operational risk assessment since irregular sounds are the first signs of impending danger.

- Vibration Measurements

Bearings that are in perfect condition are always smooth and would cause the need for as little vibration as possible. However, excessive or even erratic vibration should be a concern and it is possible that a shaft is misaligned or where the bearings are tight or loose,. To get accurate results, consider using vibration analysis tools.

- Operating Temperature

Too hot bearings always mean something is wrong with the friction, with the right lubrication or installation placements. High temperatures during the operation of the transmission should be checked regularly, as being too high for too long means faster breakdowns and damage.

- Transmission Efficiency

Harsh rotation of the energy-consumable parts can imply that the bearings are of subpar quality since they revolve but are not smooth. Rotating not smoothly can put pressure on the system, such as pollutants, distortion, and other factors.

It is also possible to take proactive measures which may lessen damage to the system. Incorporate lubricating and cleaning processes with these diagnoses in order to improve the performance and life span of your bearings.

When to seek professional help for transmission-bearing problems

In the event that your transmission bearings start to make strange sounds, generate excessive vibrations, or exhibit a substantial reduction in performance even after proper service, you will need to consult an expert. I have always suggested consulting an expert in case they try some standard diagnostic or repair procedures to rectify the issue. Operating the system in that situation can cause further complications and expensive repairs. Professionals are armed with the right tools and skills to deal with the problems caused by advanced wear, misalignment, or hidden contaminants and help the user recover the system in the most effective and efficient manner.

How do you choose the right ball bearings for your transmission?

Choosing the appropriate ball bearings for your transmission system requires attention to detail since there are a few key factors that should always be considered. The first consideration is the load, determining whether application consideration is for radial, axial, or combined requirements. Another key factor is the speed of the application because bearings are made to take in only specific average speeds. Also consider material selection, good bearings may be made from steel or ceramics as they would be resistant to wear and tear. Also, check the environmental conditions, such as temperature, moisture, and contaminants, to be sure the actual operating environmental conditions are within expectations. When you are all done performing the checks, refer to the manufacturer’s specifications and work with reputable suppliers in order to be certain that the components will work according to the transmission system and in the best possible manner.

Factors to consider when selecting transmission ball bearings

I think an appropriate selection of transmission ball bearings can be perfected by understanding the complexity and uniqueness of the specific demands of the system. I always begin with load capacity evaluation, and more importantly, I ensure that the bearings can withstand the axial and radial forces. A critical point of concern is endurance, and in situations such as these, I suggest using stronger materials like ceramic or high-grade steel to withstand debris and other environmental factors. It is equally important to consider defining the performance rating, for instance, the speed and lubrication requirements of the bearing with respect to the operating conditions. Working closely with the right vendors has worked well in resolving issues related to functional tolerances and achieving the desired performance efficiency over a period of time.

OEM vs. aftermarket ball bearings: Which is better for your transmission?

My viewpoint regarding the choice between OEM and aftermarket ball bearings for your transmission will be influenced mainly by your requirements and expectations. An OEM ball bearing is manufactured by the original equipment manufacturer, which certifies them to fit seamlessly with your transmission system and, as a result, works reliably. They fit the purpose well when the system is cosseted by a warranty or when the system is highly sophisticated; in such cases, it is critical to leave the initial build intact. In contrast, there is aftermarket which allows more room but usually at a cheaper price; they can also offer entirely new approaches or raw materials that help meet specific needs. Nonetheless, the quality of aftermarket products can differ greatly, and because of that, an individual must conduct thorough research and purchase from trusted distributors. Personally, I prefer OEM bearings for close-tolerance applications, and I recommend aftermarket for lightweight applications and customizations. An individual has to come up with a good balance between the cost, performance to goal, and compatibility of the parts.

Understanding bearing specifications and their impact on performance

The bearing performance, durability, and efficiency all heavily depend on the bearing specifications; therefore, dovetail bearing specifications require attention. Among the most important parameters are load capacity, speed limitations, materials, and tolerance class. Bearings with higher-rated precision classes, e.g., ABEC –American Bearing Engineering Committee– or ISO classes, result in better performance and less wear at higher speeds and in applications where precision is critical. Moreover, the selection of sealed vs open bearings also affects the contamination protection and maintenance intervals. With compliance with adequate bearing specifications, the performance and durability of the bearing will be maximized with the application requirements.

What is the proper installation process for transmission ball bearings?

To ensure the seamless functionality and durability of transmission ball bearings, utmost attention is needed during the installation phase. The beginning of the process, in my perspective, is always ensuring that the shaft and housing are cleaned well to avoid any foreign matter getting in during installation, as dirt is a primary agent of wearing. The next step is checking whether the bearing to be installed is the one that is supposed to be used for the particular application, type, and size. During mounting, I make it a point to always have a bearing press or mounting sleeve; if there is a direct application of force on the rolling parts of the bearing, I try to avoid it as much as I can in order to not damage the parts. Ensuring there is proper alignment is also critical; failure could result in uneven wear or chances of the device failing to work at the right time. Testing it under load after verifying the lubrication is correct, and the bearing has been pressed tightly into the socket is the last procedure. Adhering and executing these steps accurately gives a stronger, more conducive environment for the transmission to operate.

Step-by-step guide to replacing transmission ball bearings

Reconstructing this elaborate piece of machinery seems like an overwhelming task, but I assure you, with a little time, patience, and practice, you will get there. I personally prefer breaking the procedure into parts I like to call ‘modules’. Here’s how I go about it.

- Preparation and Safety

Before using the tools and components, I make certain that all surfaces that will be worked on are dry, clean, and well-lit. Additionally, I always take precautions to avoid harm by donning safety glasses and protective gloves. To keep the process safe throughout, I make sure that the necessary items, such as pullers, bearing press, torque wrench, and soft-faced hammer, are all ready to use.

- Remove the Transmission Case

One by one, I start to take apart the transmission while noting both the unit and location of every single element. This sometimes means funneling out the fluid and separating related items like the housing or the clutch assembly. The purpose is so I don’t get confused when I try putting everything back together; when it comes to the tiny bits, I take bag labels, and for some others, I take photos.

- Extract the Old Bearing

In this phase, care should be taken not to apply great force or unevenly strike an old bearing which was installed during shaft fabrication, rather, a specialized puller should be used. If necessary, slightly heating the shaft may be useful, but the temperature must not go over the level stated by the manufacturer. Otherwise, the component can suffer from distortion.

- Inspect Surrounding Components

In my practice, it is a tendency I am accustomed to check the housing, the shaft, and their encompassing regions for wear and tear or any signs of damage or neglect. I make sure to attend to any kind of scoring, cracks, or irregularity that I may have seen, as it can cause the proper functioning of the new bearing to deteriorate or the life span to be significantly reduced.

- Install the New Bearing

While I remain seated, I take a new ball bearing and bear pressing or a soft-faced mallet to insert it in the seat while ensuring developed parameters to aid such fixes in the bearing itself, such as an alignment to fit the case. This step incorporates an important passive aspect since I am ensuring that the bearing is squarely seated and a critical function since I am assuring that it does not wobble free. Furthermore, I need to check whether I’ve fitted the correct type and size downstream bearing as outlined in the transmission manual.

- Lubrication

Lubrication must be performed adequately. Before I close the transmission case, I make sure to apply the appropriate amount and type of oil and grease suggested by the manufacturer. An excessive or insufficient quantity of lubricant can lead to overheating or even to differential wear and tear.

- Reassemble and Test

Once done, I reassembled the transmission with the help of an undo sequence of pre-disassembly procedures, and on completion of the same, I carried out a test on load with the aim of ensuring the bearing and the transmission didn’t generate any odd sounds or vibrations.

I always get satisfactory results for the service of replacement of the transmission ball bearings when I use these detailed step-by-step instructions. The main aspects of the construction realization that ensures the reliable long-term functioning of the transmission take place, including its alignment, lubrication, and retention of the components.

Tools and equipment needed for ball bearing installation

When installing ball bearings, the necessary tools, machinery, and equipment should be mastered in order to guarantee precision and efficiency throughout the procedure. I have listed below the most important tools that I consider to be of importance concerning this task, along with what their uses are:

- Bearing Puller or Extractor

- This was applied to prevent any damage to the adjacent parts when taking out the existing bearing.

-

Regarding the impact on the tool, it’s appropriately distributed volume and synchronizes the grip force with the tool’s pulling action.

- Bearing Heater (Induction Heater)

- The procedure for heating the bearing surface before inserting it into the shaft greatly increases its effectiveness and efficiency.

-

Applying some heat expands the bearing, making the insertion into the shaft easy, thus ensuring a secure fit.’

- Press Kit (Hydraulic Press or Manual Press)

- Indispensable for the controlled insertion of the new bearing within its housing or on its shaft.

-

It avoids the possibility of such misalignment, which might occur due to the application of force in an inappropriate way.

- Soft-Faced Hammer

- Used to carefully drive the bearing into position, if necessary, but ensuring that it did not get injured in the process.

-

It remains in the process of being used with care and helps in slight tweaking while doing the fitting.

- Clean Cloth or Lint-Free Wipes

- Verify that all adhering surfaces together with a bearing do not contain any scrap or contamination before fitting them.

- Torque Wrench

- Wekikesura usiku mikanda na kiti, za aina ya bolt na fasteners, kujunga kwa pamoja ili kuzuia kumalizika si kipindi kisichokuwa sawa hekalu, wala kumaliza kiti na kujunga mno.

- Lubrication Tools (Grease Gun or Oil Applicator)

- Use the proper amount and type of lubricant as prescribed for the bearing. Appropriate lubrication is indispensable to the minimization of friction and heat generation.

- Measuring Tools (Calipers, Micrometers, or Dial Indicators)

- It is essential to measure the shafts, housings, and bearings so that each of them can be properly fitted.

-

It is useful in verifying the alignment and parallelism during and after the assembly.

The appropriate use of these devices guarantees that the use of ball bearings is performed with proper precautions and is done in a manner compatible with industry standards. Additionally, these tools’ good preparation and attention to detail improve the quality and durability of the transmission system. The Manager’s sophisticated creaking assistant has now explained to you the importance of maintaining the appropriate quality.’

Common mistakes to avoid during transmission bearing replacement

- Improper Cleaning – Neglecting to adequately clean the bearing housing and the shaft prior to deploying the bearing is a sure way to cause contamination of that bearing and lead to its premature failure.

- Incorrect Bearing Selection – The use of bearings with irrelevant specifications, loading capacity, and size can threaten system performance.

- Overheating During Installation – Excess heat needed to expand the bearing possibly results in damage to it.

- Neglecting Proper Alignment – Installing bearings out of alignment invariably leads to additional wear and a reduction in bearing life.

- Skipping Lubrication -Wrong or lack of lubrication leads to faster wearing out and decrease of the bearing longevity.

- Excessive Force Application – Using the wrong tools or excessive force in the bearing assembly process may cause deformation or damage to the bearing.

The life of maintenance can be extended by ensuring the avoidance of errors, as pointed out above, which also helps in broadening and reinforcing the efficiency of the service held of the transmission bearing replacement.

How to maintain ball bearings in your transmission for optimal performance?

As far as the performance of a transmission unit is concerned, it is paramount to keep the ball bearings in good condition if they are functioning consistently and precisely. In my case, very important requirements are regular check-ups and cleaning. It is often the case that impurities or grime do build-up, which hampers performance, and therefore, I would always advise washing bearings with a suitable solvent and drying them up entirely before lubricating them. Speaking of lubrication, the correct kind and amount must be used because if not, it can often drown the bearings, which is as equally harmful as running dry bearings. Identifying any anomalies would be beneficial, for example, an unusual sound or excessive vibration – such signs often assist in the timely identification of the problem, preventing more expensive problems in the future. Another protective measure I adopt is to make certain that the transmission housing is sealed off and dirt-free. The good news is that performing all the above tasks has reinforced my belief about practicing a proactive approach by actually yielding positive results, smooth functioning, and longer bearing life.

Regular maintenance tips to extend the life of transmission ball bearings

it takes three critical actions – constant care, adequate lubrication, and early diagnosis of problems – to fully utilize the operating time of the transmission ball bearings. Such steps as routine inspection of the bearings for contaminants, ensuring seals’ integrity, and using the right amount of the right lubricant help in preventing abuse. Also, not neglecting any unusual sounds or vibrations can save time and expensive repairs. Being observant and active has always worked for me in ensuring and maintaining efficiency in all systems.

The importance of proper lubrication for ball bearing longevity

the right lubrication is absolutely pivotal in assuring the longevity of a ball bearing. A good lubricant system, on the other hand, will reduce friction, heat, wear, and corrosion. I always stress the importance of the lubricant used in regard to the working environments as well as temperature, speed and load, and the timeframe for re-lubrication. Such simple but crucial practices can improve performance and avoid unnecessary breakdowns.

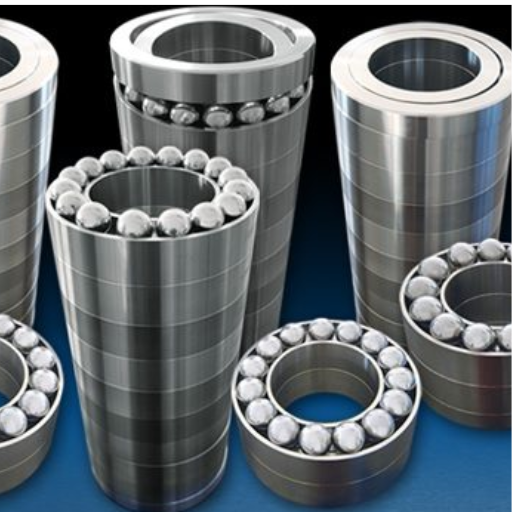

What are the latest innovations in ball-bearing technology for transmissions?

the most fascinating development in ball bearing technology concerning transmissions is the evolution of hybrid ceramic bearings. Ball bearings incorporate steel races and ceramic balls, making them more resilient, lessening friction, and better performing in a high-speed environment or even high temperature. Such breakthroughs, for instance, the newest progress in coatings like DLC, polymers, bearings corrosion, and wear resistance, have considerably increased bearing life as well. Another innovation is intelligent bearings, consisting of sensors designed to monitor parameters such as temperature, vibration, and speed and send the information to the central control unit for analysis in real time. Such developments have a substantial effect on the energy efficiency and reliability of modern transmission systems and units.

Advanced materials and designs in modern transmission ball bearings

The state-of-the-art materials and geometry of modern transmission ball bearings are directed toward performance, durability, and efficiency optimization. Harsh operating conditions are addressed by hybrid ceramic designs, which most often consist of steel races and ceramic rolling elements. Further surface treatments, such as diamond-like carbon (DLC) coatings, greatly enhance wear resistance and the overall lifetime of the equipment. Moreover, the new ideas concerning cage geometry enhance the flow of lubricant and reduce the noise level, while internally embedded sensors facilitate remote surveillance of the equipment condition. These developments are raising the bar for the reliability and efficiency of transmission systems.

How new ball bearing technologies are improving transmission efficiency

I can satisfactorily articulate that the new technologies of ball bearings are enhancing transmission efficiency in several ways. The use of hybrid ceramic ball bearings has greatly improved aerodynamic efficiency through internal friction and heat generation. Coatings, such as DLC, enhance performance and protect components from wear and microscopic voids that cause energy losses. Furthermore, the introduction of sensors is a revolution since they allow measurements and diagnostics to be performed while the machine is working. All these inventions ensure that transmission works with minimal interruptions, thus saving on overall energy consumption.

Reference

- Bearings for Use in Transmissions and Differential Gears – This source provides insights into bearings designed for long service life and low-friction torque.

- Bearings for Automatic Transmission – This page discusses various components of automatic transmissions, focusing on efficiency and design.

- Transmission Bearings: Reducing Friction and Enhancing Durability – This article explains how ball and roller bearings reduce friction and enhance durability.

Frequently Asked Questions (FAQs)

Q: What are the main benefits of using ball bearings in transmission shafts?

A: Ball bearings in transmission shafts offer several advantages, including reduced friction, improved efficiency, and enhanced shaft performance. They allow for smoother rotation, better load distribution, and increased speed capabilities, making them ideal for high-performance applications in cars and other machinery.

Q: How do ball bearings compare to roller bearings in automatic transmissions?

A: While both ball bearings and roller bearings are used in automatic transmissions, ball bearings generally offer lower friction and higher speed capabilities. Roller bearings, on the other hand, can handle heavier radial loads. The choice between the two often depends on the specific requirements of the transmission design and the intended application.

Q: What materials are commonly used in high-quality ball bearings for transmissions?

A: High-quality ball bearings for transmissions are typically made from durable materials such as chrome steel, stainless steel, or ceramic. These materials offer excellent hardness, wear resistance, and corrosion resistance, ensuring long-lasting performance in demanding automotive environments.

Q: How do I determine the correct fit for a ball bearing in my transmission shaft?

A: To determine the correct fit, you need to consider factors such as the shaft diameter, housing bore, load requirements, and operating conditions. It’s crucial to consult the original manufacturer’s specifications or seek advice from a qualified transmission specialist. Proper fit ensures optimal performance and prevents premature bearing failure.

Q: Can ball bearings improve the shift quality in manual transmissions?

A: Yes, ball bearings can significantly improve shift quality in manual transmissions. By reducing friction and allowing for smoother rotation of shafts and gears, ball bearings can lead to more precise and effortless gear changes. This results in a better driving experience and potentially increased transmission longevity.

Q: What is preload in ball bearings, and why is it important for transmission performance?

A: Preload refers to the internal load applied to a bearing during assembly. In transmissions, proper preload is crucial for maintaining optimal shaft alignment, reducing vibration, and ensuring smooth operation. Correct preload can enhance bearing stiffness, improve load distribution, and extend the overall lifespan of the transmission components.

Q: How often should ball bearings be replaced in a transmission?

A: The replacement interval for ball bearings in transmission can vary depending on factors such as vehicle usage, driving conditions, and maintenance practices. Generally, ball bearings in well-maintained transmissions can last for the life of the vehicle. However, if you notice unusual noise, vibration, or shifting problems, it’s recommended to have the bearings inspected and replaced if necessary.

Q: Are there any special considerations when ordering ball bearings for transmission repair?

A: When ordering ball bearings for transmission repair, it’s essential to ensure you’re getting the correct part for your specific transmission model. Pay attention to the bearing dimensions, load ratings, and any special features required. It’s also advisable to purchase from reputable shops or manufacturers to guarantee quality and proper fit. Always check the return policy in case you need to exchange the item.