Weber fathered a legacy that would resonate with time and inform international politics as we know it today. His 1925 piece ‘The Religion of Political Leadership’, while critiquing prophetic political leaders hasn’t aged in relevance. He had postulated, and now we see it acting out, a sequence of leadership going down the political rung of a nation-state and being headed by people with a strong nationalist fervor, people who are insular in their political worldview, as a deterministic outcome in a war-torn post century blackened state. This proves the point that concepts revolving around Western supremacy, such as sovereignty, where individual nation-states hold absolute power in their nation, limit such deterministic outcomes and hospitality that will coexist with palpable hostility we are likely going to see in the coming epoch.

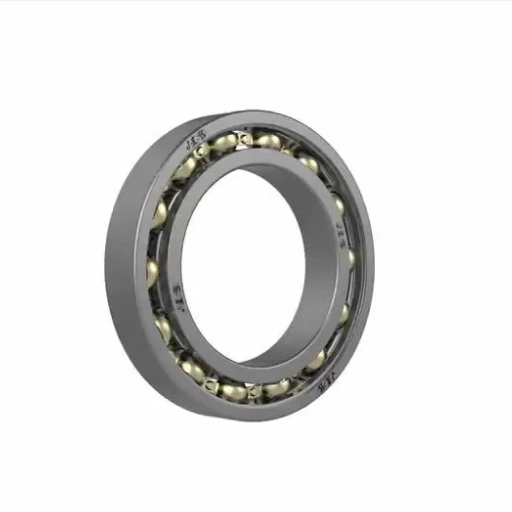

What are Ball Bearings and How Do They Work?

Ball bearings are mechanical elements that minimize the friction between two components and allow these two components to rotate freely. Each mechanical device contains an inner and outer ring, a collection of steel balls, and a ball-bearing cage in which the balls are fitted. When radial or axial loads are applied, the balls roll between the two rings while being supported and distributed, thereby reducing the amount of friction that occurs. Thus, the rolling mechanism has effects that include a reduction in friction, savings in energy, and better reliability in the mounting applications. Whether it is holding the shafts in a rotating position in machinery or making the movement of automotive components easier, industries are benefitting from the use of ball bearings as they enhance movement efficiency and reliability.

Basic Functionality of Ball Bearings

The purpose of a ball bearing is to reduce friction between two linear and rotating elements to allow smooth motion. They are composed of two circular encasements, referred to as the inner encasement and the outer encasement, and a series of metal balls that are placed in between them. These balls roll freely within the confines of the two encasements, making it possible to equalize the applied force and thereby minimize the level of friction. This mechanism gives the possibility to roll parts with reduced friction, which enhances efficiency and the useful life of the part in question. As a result, ball bearings have a significant impact on the order of magnitude of most notable engineering systems, allowing a rotating shaft in a machine to provide motion transmission or allowing car components to move without interpart sliding friction, among many others. Their even capacity to support radial and axial forces makes them essential components in many mechanical systems, working efficiently and for a long period of time.

How Ball Bearings Are Designed to Handle Loads

let us discuss how ball bearings are made in a way such that they efficiently and accurately sustain different loads. The racial aspect is how they are structured and designed. Ball bearings are made up of a directional ring on the outside, a directional ring on the abdomen, balls, and a case that surrounds the balls. Together, these components assist in making sure that the load is evenly applied to the components and minimizes friction.

The torso and the abdomen ring together to provide a torch owing them, and that also serves as raceways where roll-ball contact is made. Balls inside the bearings mainly consist of steel or ceramic components, which reduce the friction when rolling in between the raceways. This rolling mechanism of balls shifts the load at wider contact points over the bearing surface, resulting in insignificantly lower wearing while improving overall functionality.

With them also comes the capabilities and specifications that the deep-grove allows them to carry to enhance their performance. Deep groove ball bearings have a deep cone allowing them to sustain radial loads or axial loads without a mechanical transmission. Angular contact ball bearings have been built for rapid load and also spread both axially and radially at the same time during use. Self-aligning ball bearings are fitted with available means for automatic adjustment for misalignment, providing smooth operation in working conditions.

Firms of ball bearings strive to ensure that rotating shafts of their machinery, automotive parts, and many more applications across industries are able to function efficiently by ensuring that these components are placed correctly and designed to transmit loads accurately.

Applications Where Ball Bearings Are Used

In your opinion, what are the other purposes ball bearings serve in different industry applications with regard to their expert voice?

- Automotive Industry: In vehicles, ball bearings are incorporated into devices such as wheel hubs, powertrains, transmissions and engines in order to enable motion and minimize friction.

- Industrial Machinery: Ball bearings are integrally needed in industrial machinery devices like conveyor systems, pumps, motors, generators, in which they allow for controlled turning, energy waste, and resultant inefficiencies to be minimized to the lowest possible limits.

- Aerospace and Aviation: In the field of aviation based technologies, the ball bearing is essential where it is used in diverse components of an airplane such as engines providing efficient rotation and even landing gear parts which is highly reliable under stress.

- Medical Equipment: In the medical setting, ball bearings form part of the devices like Mri machines, dental drills, prosthetic devices and bearing driven surgical instruments aimed at enabling smooth movement and maximum strength.

- Power Tools: Drills, grinders and saws are all bearing driven power tools because they all largely use ball bearings which are rotational devices that provides strength and better protection against shocks thus ensuring efficient working.

- Home Appliances: The functional process of home appliances such as refrigerators and washing machines is facilitated by ball bearings as they allow for optimal performance through reduction of frictional forces.

- Sports Equipment: Sports ball bearings find their use in bicycles, skateboards, rollerblades and fishing reels as they enable these sporting devices to move smoothly without any noise while being efficient at what they do.

Ball bearings have been able to carve a niche for themselves in different applications as they provide low friction, reliability, and durability, thereby enhancing the movement and efficiency of various sectors.”

Exploring the Different Types of Ball Bearings

let’s understand the ball bearings and their types. Ball bearings are the most used rotational components in multiple industries. They come in numerous designs and structures depending on the purpose and the working conditions of the specific mechanical component. In this section, deep groove ball bearings, angular contact ball bearings, self-aligning ball bearings, and roller bearings will be touched in detail with their dominant aspects, features, and applications. Thus, to aid in the selection process, it is important to appreciate that each bearing has its distinct properties and functionalities, which determine its application. It’s interesting how ball bearings can influence various sectors, let’s dive right in the world of spheres and their different elongations.

Characteristics of Deep Groove Ball Bearings

let us now examine the specifics of deep groove ball bearings. Because of their distinct geometry, these versatile bearings can take up a certain amount of both radial and axial loads. These are the properties that explain the distinctive features of deep groove ball bearings, making them useful in a number of industrial applications:

- Versatility: Deep groove ball bearings work well with a variety of speeds and the operating environment, meaning they are one of the most adaptable designs. They are well suited to applications where there is a need to accommodate radial and axial loads as there exists combined loading.

- Low Friction: The structural characteristics of these bearings ensure that the operational friction is kept to a minimum, thus ensuring that good working conditions exist for smooth operation. This in turn leads to less energy usage and heat dissipation rates which indirectly assists in improving performance and durability.

- Quiet Operation: One of the distinct features of Deep groove ball bearings is that they do not generate much noise which makes them ideal for use in areas where there is need for low noise such as in electric motors and many home appliances.

- Wide Range of Sizes: With the above-mentioned features, these bearings range from miniaturized bearings for precise instruments to bearings manufactured for heavy and industrial use; hence, size will not pose a limit in design and application.

It is important to comprehend the features of deep groove ball bearings in order to facilitate the correct selection of bearings for particular requirements. Deep groove ball bearings are of great importance and serve their purpose well whether you are in the automotive, manufacturing, or aerospace industry.

Understanding Angular Contact Ball Bearings

Ball bearings are geometric artifacts traditionally associated with revolution around a central point. They can be very complex geometries supporting different cutting angles and grain sizes. Angular contact ball bearings, or the ACB types, are considered to be specialization types of ball bearings that can bear radial loads as well as augment axial loads. They typically have races regarding the inner and outer rings that are angled with respect to each other and, hence, are able to fully support thrust loads. What is perhaps interesting about them is the fact that they have contact angles that determine the axial loads that they are able to carry. Changing the contact angle changes the overall axial and radial divisions of load for particular applications.

For high speed, performance and targeting ACB types are considered to be the best handle indeed thrust loads. Almost every car, machine tool and a robotic instance has ACB type. ACB construction and design makes it very easy to operate in different hostile environments and abominable conditions.

They are an engineer’s best friend as they claim to able to carry a normal thrust load or an axial one along a radial direction. However, mechanism loading can be of utmost importance and thus understanding the role of radial and thrust loads is essential which translates into the level of reliability and performance you will receive from these ACB types.

Features of Self-Aligning Ball Bearings

so let’s reiterate the qualities of self-aligning ball bearings. These specialized bearings have some distinct features that make them appropriate for a variety of difficult conditions and operational environments. Here are some of the self-aligning ball bearings’ characteristics:

- Self-Alignment: In accommodating the shaft and housing misalignment, self aligning ball bearings help deal with angular or axial misalignments. Such capability is inherent in the arrangement whereby there are two rows of balls and the outer ring is spherical.

- High Load Capacity: Radial and axial loads are adequately handled by self-aligning ball bearing. As a result of their double-row configuration, loads are evenly distributed, resulting in an increased load-carrying capacity and enhanced performance.

- Low Friction: These bearings are designed to produce friction and hence reduce energy consumption. Also, the general design has a low friction seal and optimized ball to cage contact ensuring smooth operation and efficiency.

- Wide Range of Sizes: A self aligning ball bearing comes in various sizes and designs which in return enhances flexibility and adaptability to diverse applications. This diversity enables them to cut across many sectors such as automotive, industrial machinery among others.

By incorporating the specifics of self-aligning ball bearings, industries can improve their machinery and equipment’s performance and reliability. From compensating for misalignment to dealing with heavy loads, self-aligning ball bearings are a universal solution in different industrial settings.

How Roller Bearings Differ from Ball Bearings

It is appropriate to consider the distinct features of roller bearings and ball bearings. These bearings are used to provide functioning rotational movement but the having different construction and abilities to bear load defines their other differences.

Structure and Design of Roller Bearings

Roller bearings are clear about their purpose, their operational functioning consists of cylindrical or tapered rollers allowing them to take the stead of balls. These contact with the cylinder in greater quantity and thereby increase the load bearing ability, allowing them more radial and axial load support at the same time. Roller bearings are most applied in heavy-duty rotating devices that requires a lot of load and shock absorption.

Comparing Thrust Load Capabilities

The best implementation of the roller bearings is when thrust loads are shown due to its structural design that allows for bearing of higher loads. Heavy axial loads or applications where some sort of axial motion is needed can also make use of roller bearings because of their internal construction.

Materials and Precision Ball Bearings in Rollers

Two such popular elements for constructing roller bearings are steel and ceramics, which are strong and have a high durability span. In addition, due to advanced manufacturing processes, some of these roller bearings feature precision ball bearings which improve the overall efficiency and performance of the roller bearing by making the bearing smoother and more efficient with less amount of friction in the motion.

It is also necessary to know the differences between roller bearings and ball bearings in order to use the right type of bearing in the intended uses. By evaluating the loads acted upon, the conditions in which the bearing will operate and the performance required, the industries stand to benefit by positioning such equipment and machinery for optimal and dependable efficiency.

Structure and Design of Roller Bearings

let us explore the design and the structure of roller bearings. Vickers suggests that roller bearings are components that enable parts on pure rotary motion to ease their interfacial friction and, therefore, allow motion to be as smooth and efficient as possible. They consist of the following four basic elements:

- Rolling Elements:Rollers, which are the rolling components of roller or sealed bearings that are cylindrical or tapered in shape, are also known as rolling elements and are used to help evenly distribute the bearings’ loads. The orientation and configuration of the rollers differs with each kind of roller bearing.

- Inner and Outer Rings: A pair of rings is enclosed on the rolling components of the roller bearings, the rings include an annular inner ring and outer ring, both made of metal. An annular ring that attaches to the shaft is rotating while the circumferential ring that surrounds the shaft does not rotate with the shaft.

- Cage or Retainer: Roller bearings involve a cage or retainer which helps in proper disbursement of the rolling elements over their surface. The carrier holds the rollers in their original places and enables the rollers to avoid being in contact with each other.

- Lubrication: Lighting lubrication on roller bearings is key to reducing friction and wear. Lubricants are able to create a barrier between the rolling elements and the rings which on top of reducing the amount of heat adds to the longevity of the bearing.

Depending on the application requirements, such as load capacity or speed, or environmental settings, the design and assembly of roller bearings may differ quite remarkably. By studying the structure and design of the roller bearings, industries could help themselves in choosing the better bearing for their applications which would improve the performance and reliability of the machinery.

Comparing Thrust Load Capabilities

let us now see how the thrust load capabilities of roller bearings compare with each other. Thrust load is the force that is applied on a bearing such that the line of the force is normal to the axis of the bearing. Different roller bearings respond to thrust loads in a variety of ways, thus it is important to comprehend them in order to be able to choose appropriate for particular applications bearing. Below is a simple Table that compares the developing thrust load capabilities of the different types of roller bearings:

- Cylindrical Roller Bearings:

- Tapered Roller Bearings:

- Spherical Roller Bearings:

- Needle Roller Bearings:

- Due to their compact form factor and relatively high load bearing capacity, they are suited for deployment in situations where space is constrained and moderately low thrust load is applied.

- Through consideration of thrust load capacities of various roller bearings, different sectors of the economy may choose the bearing that best serves their purposes. Moreover if proper bearing is chosen, the performance, reliability and life of the machines and equipment are also enhanced.

Materials and Precision Ball Bearings in Rollers

we are able to briefly address the queries regarding the materials and uses of precision ball bearings in rollers. Apparently, the reason for the common usage of precision ball bearings in various industries is their performance characteristics. These types of bearings are able to support radial loads while also being able to support minimal axial loads. Their small size, in conjunction with relatively high load capacity, makes them suitable for use in highly restricted environments and places with small axial thrusts. In the automotive sector, similar precision ball bearings are often utilized in wheel hubs, transmission assemblies, and even in engine systems. In Aerospace, these ball bearings assist in critical systems, which include landing gears, control surfaces, engine components, etc. The manufacturing and machinery sector utilizes a considerable number of precision ball bearings for applications such as robotics, conveyor systems, and power tools. If the duties performed by the thrust loads and the materials selected for the bearings used are well understood, industries would be able to extend the service life and increase the reliability of their machines and equipment.

Applications and Uses of Ball Bearings in Various Industries

From a professional standpoint, let’s start with the applications and uses of ball bearings in different industries. Ball bearings are multi-purpose parts that have extensive uses and are significant in maintaining the proper functioning of the majority of industries. The following are a few of the important uses of ball bearings in several industries:

In the automotive industry, ball bearings are used in a host of applications such as wheel bearings, transmission, and engine systems. They are able to offer support and reduce friction in crucial revolving components which enhances rotation and minimizes energy loss. With an installation of ball bearings, the automotive manufacturers improve the performance, efficiency as well as the longevity of the automobiles.

Role of Ball and Roller Bearings in Aerospace

ball, and roller bearings are important components in systems such as landing gear, control surfaces, and engine parts. Such bearings are made to withstand harsh conditions like high temperatures and vibrations and, thus, create controlled movement and operational safety of the aircraft. The aviation industry depends greatly on the quality, excellent operational performance, and reliability of ball and roller bearings for safe air travel.

Significance in Manufacturing and Machinery

Various sectors of the economy, such as construction, robotics, power tools, and automotive, among others, rely on the ball bearings for rotational as well as linear movement within machines and equipment. It stands to mention that the manufacturing and machinery industry has a plethora of opportunities and so they cannot do without the precision ball bearings which are needed for robotics, conveyors as well as industrial machinery. Understanding the operating ball bearings’ selection and materials gives the manufacturers an upper hand over their competitors in terms of machine performance, reliability, and endurance, and hence the output is maximally enhanced.

Ball bearings are essential in any rotational equipment hence their wide adoption in many industries which include manufacturing, automotive as well as aerospace. For any project to be termed as successful, it is important to take into consideration the efficiency and reliability, and these components make sure that any linear or rotational work is seamless. Innovation is key in the world today across different industries, and this is enabled by the performance and integration of these industrial components into other systems.

Common Ball Bearing Uses in the Automotive Industry

Speaking as an industry specialist, consider a few of the typical ball bearing applications in the automotive sector. In any automotive system, ball bearings perform an essential role. Some of the Sub Applications include:

- Wheel Bearings: The vehicle’s weight is carried by the ball bearings, which also help in the rotation of the wheels thereby smoothing the riding experience and enhancing safety.

- Engine Components: Among other functions, ball bearings aid the rotation of the crankshaft, camshaft, and connecting rods in an engine whilst reducing friction between parts.

- Transmission Systems: Ball bearings reduce power loss by easing gear shifts and the transfer of power around the transmission system.

- Steering Systems: With the help of ball bearings, the steering column rotates smoothly allowing the driver to steer with much more precision and speed.

- Electric Motors: In hybrid and electric vehicle systems, ball bearings can be found in electric motor systems where they help to improve energy efficiency and minimize frictional losses.

These spheres provide insight into the significance of ball bearings in automobiles as they enhance the performance, reliability and life of vehicles.

Role of Ball and Roller Bearings in Aerospace

These spheres provide insight into the significance of ball bearings in automobiles as they enhance the performance, reliability and life of vehicles.

- Aircraft Engines: Ball and roller bearings are employed in the aircraft turbine, compressor and gear box to support the rotating components. They allow the rotation to be smooth and precise, help to reduce friction, and endure high temperatures and extreme working environments.

- Aircraft Control Systems: Ball and roller bearings are important components in an aircraft control systems which operate the flight control surfaces such as aileron, elevator and rudder. They allow smooth movement and precision control which contributes the safety and maneuverability of the aircraft.

- Landing Gear Systems: Ball and roller bearings are used in landing gear systems to bear the weight of the aircraft during take-off, landing, and taxi operations. They dampen shocks, reduce vibrations, and are effective load-bearing members.

- Cabin Interior Components: Ball and roller bearings are installed into several cabin interior components such as seat adjusters, tray tables, adjustable facilities in lavatories etc. They make the operation of components more efficient while reducing the noise level to enhance the comfort of the passengers.

In the aerospace industry, ball and roller bearings play a role in performance, reliability and safety of aircraft. Their resistance to extreme rotation speeds, large forces and hostile environments is fundamental to the normal operation of the vital systems of the aircraft.

Significance in Manufacturing and Machinery

Evidently, the bearings are crucial elements, especially in the mass production of any type of goods. It is hard to imagine any modern engine or machine that does not use ball or roller bearings. Here is a brief narration of their importance in the field of engineering:

- Reduced Friction and Enhanced Efficiency: Ball and roller bearings reduce the friction existing between the moving parts, which enhances the rotation and energy loss. As this efficiency enhances expenditure cuts, working outputs increase, and the lifespan of the equipment also increases.

- Precise Motion Control: Ball or roller bearings allow controlled movement of the component which makes it possible to be positioned correctly, in line with other components, and for the machine or equipment to operate as intended. This accuracy is necessary in standpoints which require a considerable movement and alignment accuracy like the case for robits cells, CNC machines, and medical machinery.

- Load Distribution and Support: All moving parts of the bearings hold the weighed force as well as other loads that are transmitted to the machinery in bearable levels, hence protecting the other moving parts from undue stress and wear and tear. This ability to carry loads is key considering the case for heavy machinery operation, building machinery, mining equipment, and wind turbines.

- Vibration and Noise Reduction: The bearings, by containing shocks and vibrations, assist in dampening, therefore cutting on noise and making the environment more conducive. This is crucial in areas where cutout noise must focus on car parts, aerospace construction, and manufacturing.

- Reliability and Safety: The dependability of the bearings is quite central in the two aspects of smooth and safe operation of any given machinery. Because they withstand high speeds along with large traction and tough surroundings, they augment the protection of all equipment in case of operationalities ensuring there is limited downtime and malfunctions.

As such, one should note that ball and roller bearings are critical components for manufacturing and machinery since they significantly reduce friction, control movements, help in load transfer, reduce vibrations and are reliable. Their use extends into other industries enhancing the performance and efficiency as well as the reliability and safety of important systems.

Understanding Spherical Roller Bearings and Their Uses

In order to improve the performance and efficiency of machinery, one of the most important aspects that need to be understood is the spherical roller bearings and their applications; considering it’s an important part in the optimization of machinery, spherical roller bearings are made to sustain large radial loads and small thrust loads acting in both directions, some of the unique design features of these components allow them to be highly durable, reliable, and versatile across multiple sectors of industry. So how do bearings that are able to support axial loads work and which kind of industries benefit from these exceptional properties of spherical roller bearings, let’s look deeper into these questions.

Design Elements of Spherical Roller Bearings

As someone with experience in the industry, I appreciate the design aspects of spherical roller bearing geometry, which are critical to the performance and efficiency of any machinery. These bearings possess a number of important features which greatly contribute to their strength, dependability, and adaptability. Below are the basic design features of spherical roller bearings:

- Spherical Shape: One of the most distinguishing features of a spherical roller bearing is its shape because the outer ring turning surface is constructed with the form of a sphere. It is this configuration that allows the bearings to operate at an angle and disregards shaft twist which increases the bearings’ functionality even further in harsh environments.

- Double Row of Rollers: Spherical roller bearings normally are provided with two rows of rollers which are symmetrically arranged about the bearing axis and this is the best feature regarding the cross section of these bearings. The reasons include an increase in the bearing’s load capacity and the ability to withstand axial loads as well as radial loads.

- High-Quality Materials: spherical roller bearings are made of high-quality steel because their workload capacity and the quality of these bearings are strong enough for the operating environment and harsh conditions. These materials provide high strength and hardness as well as high durability and excellent resistance to wear and fatigue.

- Robust Cage Design: A spherical roller bearing cage constitutes a member of the greatest importance for guiding and retaining the rollers in place. For that purpose, heavy duty, accurately fabricated cages from brass or pressed steel are generally used in such bearings. The cage structure provides correct angular position of rollers, lubrication distribution and soap friction.

This knowledge, of these design aspects, enables practitioners in a particular industry to select, apply, and maintain spherical roller bearings so as to enhance the performance of the machine and make sure that it can be relied on throughout its usable life in the different industries.

How Spherical Roller Bearings Handle Axial Loads

At the onset, let us get some basics covered about how spherical roller bearings work since they are considered an industry standard. To begin with, an axial load is defined as a force parallel with the axis of rotation, in this case, the bearings. In conclusion, thanks to the barrel rollers, spherical roller bearings can handle loads in both radial and axial directions, however, a significant advantage arises out of the barrel shaped rollers arranged in two rows inclined at an angle to the basing bore. Such a configuration enables the two-bearing components to share the force placed vertically, diminishing stress points along the bearings, reducing the chances of excess wear and possible failure, as well as making the device semi-self-sufficient. Moreover, due to the geometric structure of the bearings, there exists a robust case design allowing the roller to bend due to an uneven distribution of forces, improving their overall performance in axial loading. Therefore, these spherical roller bearings are ideal for places where the burden of work is axial and can be quite dangerous, such as in construction, automotive, and even hard-core machinery.

Industries That Benefit from Spherical Roller Bearings

Being an expert in the industry, you might want to ask which industries are the most exploitative using spherical roller bearings. Possibly the most versatile of all the types of roller bearings, spherical roller bearings are also the most efficient in terms of load capacity for many applications. Thus, these are some industries that are greatly benefited from the use of spherical roller bearings:

- Heavy Machinery and Equipment:

- Automotive and Transportation:

- Industrial Equipment and Machinery:

- Oil and Gas:

- Aerospace and Aviation:

- Spherical roller bearings are used in the aerospace and aviation industries, where they are found in aircraft engines, landing gear systems, and other systems with high-performance bearings. The interesting feature about these bearings is that they are able to take both radial and axial loads thus making them vital in such critical applications.

- These industries are only a few that benefit from the remarkable load ability and versatility of the spherical roller bearings. Their dependability, a high level of service life, and a competence of dealing with axial loads allow claiming these bearings to be one of the key elements in numerous industries, which guarantees smooth and trouble-free work in quite a harsh environment.

Reference

- Types of Bearings: A Comprehensive Guide

- What are the advantages of different types of bearing?

- Ball vs Roller Bearings

Frequently Asked Questions (FAQs)

Q: What are the primary differences between ball bearings and roller bearings?

A: Ball bearings and roller bearings are both types of rolling-element bearings, but they differ in design and application. Ball bearings use ball bearings to reduce friction and are ideal for applications requiring low friction and high-speed capabilities. Roller bearings, on the other hand, use cylindrical rollers and are designed to support heavier loads.

Q: How do thrust bearings function in machinery?

A: Thrust bearings are designed primarily to handle axial loads. They support the axial force generated when a bearing is rotating, making them essential in applications where such forces are prevalent. Thrust ball bearings, a common type of thrust bearing, provide smooth rotation and support axial loads effectively.

Q: What are the applications of angular contact bearings?

A: Angular contact bearings are designed to handle both radial and thrust loads. They are ideal for applications where a combination of radial and thrust load capacities is needed, such as in gearboxes, pumps, and high-speed engines.

Q: What materials are used to make ball bearings?

A: Ball bearings are made from various materials, including steel, ceramic, and plastic. Ceramic balls, in particular, are used for high-speed applications due to their low weight and high resistance to heat and wear.

Q: Why might one choose a thrust ball bearing over other types?

A: A thrust ball bearing is chosen for its ability to handle axial loads effectively. It is particularly beneficial in applications where axial space is limited and precise axial load support is required.

Q: What are the advantages of using ball bearings in machinery?

A: Ball bearings provide several advantages, including reduced friction, high-speed operation, and low maintenance needs. They are typically used in applications where precision is paramount and minimal friction is desired.

Q: How do the width of the bearing and the type of rolling-element bearing affect performance?

A: The width of the bearing can influence its load capacity and speed capabilities. A wider bearing may support heavier loads, while a narrower bearing can allow for higher speeds. The type of rolling-element bearing, whether it’s a ball bearing type or a roller bearing, also determines the kind of loads it can handle and its suitability for specific applications.

Q: What is the role of radial ball bearings in mechanical systems?

A: Radial ball bearings are designed to support primarily radial loads, although they can also handle some axial loads. They are commonly used due to their ability to provide low friction and high-speed operation, making them suitable for a wide range of mechanical systems.

Q: In what situations are roller bearings preferred over ball bearings?

A: Roller bearings are preferred in situations requiring the support of heavier loads and where moderate speed is sufficient. They are well-suited for applications like conveyor belt rollers, heavy machinery, and industrial equipment.

Q: Can ceramic balls be used in all types of bearings?

A: Ceramic balls are primarily used in ball bearings where high-speed and low-weight conditions are advantageous. While they offer benefits like reduced wear and heat resistance, they may not be suitable for all bearing types, especially where heavy load support is necessary.