Turbochargers belong to a class of devices and machines where the type of bearing has an important influence on performance, notably on 揑nitial spooling time’ and efficiency. Ball and journal bearings are among the most used options, but they have different designs intended to meet different performance needs. This article outlines the differences between ball and journal bearings used in turbochargers in the hope of helping you understand the effect of these two types on turbocharger spool speed, durability, and performance in the long term. If the goal is to simply achieve maximum horsepower or the best cost-to-performance ratio, it is always important to understand the advantages and disadvantages of using ball bearings over journal bearings and vice versa in your setup.

What are the main differences between ball bearings and journal bearings?

In terms of design and working principles, ball bearings and journal bearings are different from each other. To reduce friction in a ball bearing, a set of small spheres is included, which allows it to have fast spool-up times as well as an increase in efficiency, thus giving it a useful application where performance is essential. In contrast, journal bearings employ a thin film of oil to decrease friction, making it more economical and eco-friendly. However, it generally causes longer spool-up times. To sum it up, ball bearings allow for a better overall performance, while journal bearings are cheaper and more reliable.

Understanding ball bearing design and components

As for the components and the design of a ball bearing, I like to simplify it and take it in steps so that one can easily comprehend the purpose of such systems. Their operation principle is simple: spherical balls in motion are separated by a layer of low friction, which is caused by their rotation, and the design of the bearing is actually a very comprehensive factor to take into consideration about the performance in the case of application. Here’s an overview of their assembly, starting with the most important qualities of a ball bearing and their specifics:

- Material Composition: Factors like durability and performance depend heavily on the material used for the balls and raceways. Typical materials include steel for strength and ceramic for lightweight and high-speed applications.

- Ball Size and Quantity: Quite a lot. The number of balls or the size of the balls used is very important. More balls or larger ones can provide better load distribution, which in turn increases durability, while fewer or smaller balls might allow for higher speeds with less rotational resistance.

- Lubrication: A lubricant is necessary and important to decrease wear and tear and enable smooth movement. In this regard, oil or grease is chosen, which would affect heat dissipation and longevity.

- Sealing Mechanism: Seals keep dirt and moisture from reaching the bearings. While good sealing helps to increase durability, it can slightly raise friction, and so this is a compromise.

- Load Capacity: All ball bearings are designed to work for certain loads, whether radial or axial or a combination of both. What loads, axial or radial or both, the bearing will endure must be known so that the correct bearing is selected for the application.

Historically, any performance is designed with such precision, and therefore, any application can afford to compromise on some parameters depending on the need. Hence, one sees ball bearings in high-speed turbines, electric motors, and any other equipment, providing the best possible design and performance characteristics.

Exploring journal-bearing technology and structure

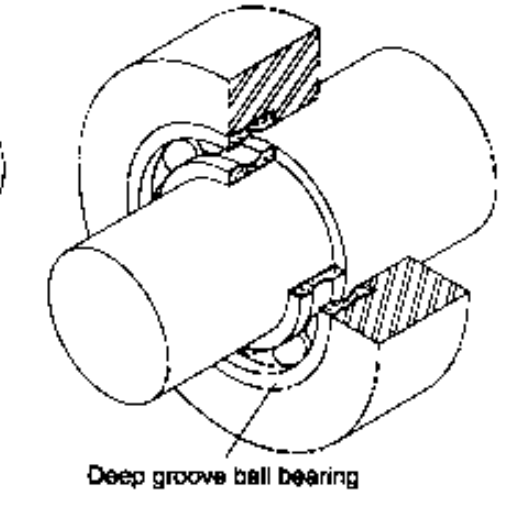

According to my observations, Journal bearings operate in various industrial applications. It is critical to have a precise design and appropriate materials in order to produce better performance. They support the shaft by offering minimal surface fluid friction adequate to operate under substantial loads and slow rotation. They must endure great forces, and it is not easy to comprehend this factor,t considering their construction is wonderfully uncomplicated; they comprise circular shafts fitting within circular sleeves. I have watched as the industry has changed into a more modern place due to the great technical improvement in the material and lubrication aspect of such areas. Considering the mechanical implications of hydrodynamic lubrication is critical in understanding the function of these bearings.

Comparing friction levels in both bearing types

In layman’s terms, rolling-element bearings are the best choice for slow-moving applications, while plain bearings work best in high-speed applications. Rubbing of metal surfaces in plain bearing is minimal due to hydrodynamic support, so friction generated is less. In this sense, we can say that simple plain bearings produced less friction than rolling-element bearings during high-friction conditions such as motion. In which the film in the lubricated plain bearing has the possibility of not being developed sufficiently, rolling-element bearings could have lower friction compared to plain bearings. The selection of the right bearing type will depend on the operational speed, the load, and environmental conditions.

How do ball bearings and journal bearings affect turbocharger performance?

Niedawno miałem okazję pracować w przemyśle, a to sprawiło, że zauważyłem, że ważnym tematem do przedyskutowania dla turbosprężarki jest również jej wykonywanie tych momencie jak decyzja, czy stosować łożyska kulkowe, czy też łożyska ślizgowe. Łożyska kulkowe będą pozwalały na mniejsze opory w ruchu, co z kolei pozwoli turbocharget zgżynać się w mniejszych czasie, a to zauważalnie poprawi jej efektywność, zwłaszcza przy dużych prędkościach. To czyni te łożyska idealnymi w sportach motorowych, gdzie występuje wymaganie do szybkiej zmiany prędkość. Jednak z drugiej strony, łożyska ślizgowe będą się charakteryzowały długoletnią wytrzymałością oraz niższą ceną, co sprawi, że będą się niezawodnie zachowywały w stanie ustalonym przy dużych obciążeniach. Intuicyjnie, jest to decyzja, która powinna być związana z wymaganiami zastosowania – czy mamy na celu duże osiągi, czy długowieczność.

Impact on spool time and turbo responsiveness

Ball bearings increase the speed in rotation on spool times and the responsiveness in turbo. Therefore, ball bearings can be utilized in cases where quick spool acceleration is needed. On the other hand, journal bearings are slow in spool times but deliver a smoother performance when there is a heavy load, which is a parameter used in some applications that require stability and reliability.

Differences in bearing durability and lifespan

The distinctiveness of the bearing industry concerning the lifespan or durability of these products, according to my understanding, is the application and its maintenance history. Ball bearings tend to be the most efficient and are very durable given the right conditions, however some durability can be compromised while working in harsh environments as they are quite lubrication and contamination sensitive. In contrast, journal bearings are more resilient, having the capacity to withstand higher loads as well as harsh environment working conditions, and most times, when such conditions prevail when working with ball bearings, ball bearings will wear out earlier and eventually be replaced by journal bearings. Proper care and correct usage indeed decide the life span of both types.

Effect on overall turbocharger efficiency

I can also say that bearings can influence the total turbocharger efficiency, but their effect depends on a range of parameters. Let me explain to you in simpler terms:

- Friction Levels: Quite a few people actually prefer to use ball bearings as they usually tend to experience much lesser friction in comparison to journal bearings. On that note, less friction, in turn, also ensures that less energy is wasted whilst the turbine is in operation, which ultimately helps out in making the turbocharger more efficient.

- Load Handling:On the other hand, there are turbochargers that need to operate at extreme temperatures with high loads, heavy equipment, and much harsher conditions, which is where journal bearings make all the difference and take the top position as they have a high load-carrying capacity and log operational capabilities. Hence, when withstanding extreme conditions, journal bearings are able to provide the required stability alongside great performance for maximum efficiency even after a long period of time.

- Response Time: The reason why some people wish to utilize ball bearings is due to the fact that with them, the spool-up time is reduced considerably, enabling a better toggle mechanism. In so doing this, boost efficiency will be optimized given that these applications concentrate on performance.

- Maintenance Requirements: For proper functionality, both bearing types need sufficient lubrication. However, ball bearings are more susceptible to contamination and lubrication precision, which is a downside. On the bright side, journal bearings and ball bearings will still manage to work perfectly even without the utmost care.

- Operating Environment: People often overlook the fact that exposure to a specific environment does indeed have an impact ( including but not limited to temperature, contamination levels, and pressure ). On the other hand, bore bearings would be preferable for that environment if they were located at controlled temperatures and conditions where there were no sudden interruptions.

In a nutshell, selecting the correct type of bearing considering these parameters is critical for turbocharger design optimization. My recommendation? Always complement the bearing’s requirement not only to the turbocharger’s design but to the conditions in which it will be used.

Which bearing type offers better lubrication and cooling?

I would venture to claim that journal bearings have an edge over other types of bearings, particularly when it comes to the lubricating and cooling mechanisms they provide. Their hydrodynamic oil film is suited for high temperatures and prolonged speed, which makes managing heat very efficient. Just as the explanation goes, this increase in oil flow will reduce friction but will also act as a very good cooling agent. Ball bearings, on the other hand, require lubrication as a whole in a lesser amount but depend more on the pathways of lubricating protrusions, but again, their cooling effect seems to be lower than that of journal bearings at very high temperatures. All in all, the specifics of the application make the redactor’s choice; however, journal bearings usually make it to the list of my preferred bearings whenever outstanding lubrication and cooling are required, especially when speaking of the performance range.

Lubrication systems in ball-bearing turbos

In order for the ball-bearing turbo to perform to the best of its effectiveness, it needs to be precise in terms of bead placement and lubrication applications as well. These systems use a lower volume of oil compared to journal bearing setups which decreases overall drag and increases spool times. With controlled lubrication, oil has a way to prevent friction that increases the wear and tear of the system but also provides decent functionality whenever needed. Proper repair and constant use of quality oil are paramount in these advanced turbo designs, which tend to be costly, so the aim is to ensure they remain efficient and long-lasting.

Journal bearing lubrication methods

In my professional practice with sophisticated mechanical systems, the methods of lubrication of journal bearing stand as an everlasting concern. Such bearings presuppose a hydrodynamic fluid film to lift the shaft from contact with the bearing surface in order to prevent wear and tear. As the oil is put under pressure, it is possible to maintain a continuous supply of lubrication in a consistent manner, which is why these journals are effective. As I have discovered, the temperature to which the pump oil can tolerate and its consistency are important in fully bearing the loads of operation. The scope of journal bearings can be broad in most processes with appropriate servicing and management of the lubricant supply,y which would reduce the wear and tear of the bearing and thus increase its endurance.

Cooling efficiency comparison

When assessing cooling efficiency, a number of parameters must be taken into account during the design phase, like thermal efficiency, heat removal units, and design techniques. In conditions where more heat is to be removed, one could say that liquid cooling is superior to air cooling as the first is able to take out the heat and maintain the temperature, unlike the air cooler. On the flip side, air cooler systems may be less expensive and adequate in case the heat load is minimal. It all comes down to what the need is, the environment in which the machine is used, and how much one is willing to spend.

Are ball-bearing turbos worth the extra cost over journal-bearing turbos?

In my opinion, as a professional in the field, the question of whether ball-bearing turbos are worth the extra expense is primarily related to the application and, in some instances, focus. Compared to journal bearings, ball-bearing turbos have quicker spool-up, higher efficiency, and greater resistance to extreme conditions. Thus, it is reasonable to suppose that these items would be most effective in helping achieve the performance requirements for high-performance or motorsport applications. Conversely, for regular or less intensive setups, the use of journal-bearing turbos provides great performance at a lower investment. All in all, though, I think it is crucial that this decision is made in relation to the performance targets set, budget, and prospective applications for the vehicle.

Analyzing performance benefits vs. price difference

From a cost perspective, there are several factors to consider when comparing the performance advantages of ball-bearing turbos and journal-bearing turbos. Its comprehensive cost analysis is given below:

- Spool Time (Responsiveness)

- Ball Bearing Turbos: Multiplying the power of the ball-bearing turbo is inherent to this design, and it is self-centering when fitted in a compressor assembly or a turbine casing. This even results in a much shorter spool-up time, approximately 15% to 20% lower than that of a journal-bearing turbo. This type of turbo is ideal for high-performance demanding applications such as motorsports, where superior responsiveness is critical.

- Journal Bearing Turbos: There is an improvement when the turbocharger is fitted in a motor because it spools slower. Proprietary models have different properties; hence, lead times may vary distinctly.

- Durability and Longevity

- Ball Bearing Turbos: Owing to their reduced friction and improved resistance to heat, these can withstand extreme circumstances, thereby enhancing their reliability over time. Such abilities diminish the burden placed upon the turbo, thereby increasing its potential operational reach in strenuous works.

- Journal Bearing Turbos: These are relatively weaker compared to other products when dealing with high stresses, but nevertheless these are strong enough to meet average performance needs and can last long with routine maintenance.

- Cost Difference

- Ball Bearing Turbos: A good option to consider provided you can spend the extra bucks, generally, they are 30%-50% more than their journal-bearing counterparts. For example, a ball-bearing turbo starts from a price range of around $1,500 and goes up to $2,500 based on the model and manufacturer.

- Journal Bearing Turbos: These are the better options if you are operating on a budget, generally priced between $800 and about $1,500. This also makes it excellent for those enthusiasts who want performance upgrades that are cost-effective.

- Application Suitability

- Ball Bearing Turbos: performance vehicles target every millisecond. They work exceptionally well in environments that require high acceleration and unvarying performance.

- Journal Bearing Turbos: Best suited for regular use or vehicles achieving moderate performance targets. Since the investment return ratio is lower, it is cost-effective for people who would still want to boost their engine output without worrying about the expenditure.

In this way, showing great understanding regarding your requirements and wishes, you can make the final decision that you consider the most appropriate and reasonable to you. Even though ball-bearing turbos are advantageous in performance, journal-bearing turbos are ideal for normal use because they are cost-effective and economical.

Long-term reliability and maintenance considerations

In my opinion, the reliability of a specific turbocharger model in long-term use, as well as how much maintenance it requires, depends heavily on the questions of turbo choice and turbo maintenance, respectively. The performance of ball-bearing turbos tends to be greater than that of the alternatives due to the technology employed in their construction, which aids in reducing friction and wear over time. However, they do require more specific maintenance, and their failure incurs high costs in repairing. Conversely, the journal-bearing turbos are a bit more complex yet generally easier to work on but will have to be checked often to maintain the performance level target. Routine oil changes, addressing wear early, and using high-quality parts are able to hugely increase the life of either. Most importantly, I have found that regular maintenance and paying attention to the turbo’s requirements will increase reliability.

What are the pros and cons of dual-ball-bearing turbochargers?

As someone with an industry expert opinion, I believe there are a few pros and cons that can be considered regarding dual-ball-bearing turbochargers. One of the main goals of every turbocharger is the minimization of spool-up time, and thanks to the dual ball bearing turbochargers, they achieve a quicker throttle responsive spool downtime than turbos with journal bearings. This not only allows for more power and efficiency to be generated but also assists engineers in tuning an application that meets their objectives, which is a great win for applications where power delivery is critical a hundred percent of the time. Furthermore, owing to their enhanced reliability and ease in heat load handling, they can withstand greater stress, which is a huge benefit in difficult environments.

Nonetheless, the dual-ball-bearing turbochargers have an improvement in performance, but that performance increases the selling price, which unfortunately makes them less appealing to projects with a limited budget. Last but not the least, their design can be complicated for a layman so servicing or repairing them can at times be troublesome, however, they do require less maintenance overall. The only downside is the spare parts required, which can be expensive and, in some cases, require a professional to conduct the task. All in all, it all comes down to whether or not the cost is worth the performance gain, as that would determine if you are willing to install the dual-ball-bearing turbocharger in your car.

Advantages of dual ball bearing design

The use of dual ball bearing turbochargers brings out some notable benefits, which include advanced spool time owing to a faster boost, which in turn boosts the engine’s performance. Their structure minimizes rotational friction, which achieves increased efficiency, improved performance, and longevity even in extreme conditions. Furthermore, they are also much more durable as they can endure greater loads and are more resistant to destruction, thus best suited for high-performance usage. It is for this reason that dual ball bearing designs are popular among users who want the best possible strength and reliability.

Potential drawbacks and limitations

Although dual ball bearing designs are advantageous, they are not without their limitations. In my view, the primary limitation is their cost. Such systems are usually more expensive than regular journal bearings, which can be a disadvantage for cost-sensitive applications. Moreover, their intricate design makes them costly to fabricate and maintain. Noise levels could be higher as well, which in high-performance environments might be of little importance but could be an issue in more silent setups. It is crucial to remember these inferences when considering the pros and cons of certain plans or the criteria of particular projects.

Comparison to single ball bearing and journal bearing setups

In my opinion, the type of bearing used, singular ball bearing journal bearing, or any other more complex bearing systems in practice appears to be determined by the requirements and purpose of the application. Single ball bearings are great for situations where low cost and low complexity are required. They are suited for average loads and speeds, hence the reason why they are found in everyday machinery. On the contrary, journal bearings excel in high loads and low speeds because they tend to be tougher and allow for smoother operation. The major disadvantage is they do need sufficient lubrication and maintenance in order not to wear out. Although High precision or high speed systems work much better, they are however more expensive and complicated to set up. All these differences must be appreciated if one were to make an optimal choice in the task at hand.

How do journal bearings and ball bearings compare in terms of load capacity?

Journal bearings, such as radial bearings, bear quite a possible advantage in terms of load capacity because of their wider contact area, thus enabling more efficient pressure distribution and resulting in few stressed parts. Ball bearings, on the other hand, can be more effective in lower loads, where their rolling contact is functional and reduces movement friction. It is evident that journal bearings can be utilized in high-workload applications, while ball bearings are more convenient and effective in low-operational-load applications.

Thrust bearing capabilities in both designs

Based on my experience, every thrust-bearing design has specific areas of strength depending on the application. Such unique selling points of each would help in the selection process. For instance, given their larger surface area and hydrodynamic lubrication, journal bearings do offer good support for high axial loads. On the contrary, garage doors with ball bearings perform exceptionally well in applications with low axial loads and high speeds due to their low friction and high precision performance. It really comes down to the operational requirements and the design goals of the system, where one application is chosen over the other.

Radial load handling differences

Journal bearings are great at handling radial loads due to their large surface area for contact and conventional hydrodynamic lubrication which helps to relieve stresses. Although ball bearings can handle radial loads, they are better for moderate radial loads and higher-speed applications because of their smaller size and lower friction. The decision rests on load and speed and efficiency equilibrium.

Impact on turbocharger size and power output

The size and performance characteristics of a turbocharger will, to a large extent, depend on the type of bearing system. This permits a greater radial load which means larger turbocharger units with larger power outputs can be undertaken. They give robustness at elevated loads and might be said to be bigger in shape. On the contrary, ball bearings are the solution where turbo lag characteristics must be eliminated, and a rapid turbo spool is essential, as are small-sized and lightweight components. In the end, and in conclusion, the choice of these systems is essentially dependent on the desired enhanced performance and engineering limitations of the project.

What future developments can we expect in turbocharger-bearing technology?

I’m an industry expert, and I see the potential calls for the turbocharger bearings to be enhanced. The durability and efficiency of the turbocharger bearing won’t stay the same due to the progress in the materials and lubrication systems. More importantly, ceramic and hybrid innovations should be able to create more heat-resistant and lighter components. Moreover, major ventilation methods such as advanced coating, and self-lubrication processes can be contests to reduce friction Yeah, why not, additionally sense and monitor systems can also be there. The value of these technologies lies in their capability to analyze the turbocharger’s wear while it is operating, predict when potential failures may occur, and determine how this kind of tension increases its reliability in LRU’s utilization.

Innovations in ball-bearing and journal-bearing designs

Сombining the propensities of ball bearings and journal bearings, I notice a strong tendency toward hybrid technologies that integrate both systems’ powers. Improvements in speed characteristics of ball bearings are achieved through precision engineering and lightweight, heat-resistant materials for the bearings. At the same time, efforts to improve journal bearings are concentrated on the application of modern composite materials and adaptive lubricants to enhance the load-carrying capacity and reduce wear during the operation. Such advances are likely to provide an even greater level of reliability and efficiency in the harshest working conditions.

Emerging hybrid bearing solutions

In my opinion, what is perhaps the most exciting part of the hybrid bearing development essentially stands to change the game for the industry. The intricate designs create an ideal amalgamation by utilizing the best that journal and ball bearings have to offer in terms of load transfer capabilities and accuracy. Practical implementations of these solutions in areas where speed is crucial but so is the ability to endure heavy loads are, as I have mentioned, to be effective. The hybrids are now reaching unchallenged levels of performance and reduced service requirements through the use of advanced material composites, polymers like ceramics, and cutting-edge intelligent lubrication systems. As this combination of solutions blended together becomes the substantiate of new standards, the new benchmarks for reliability and performance of several industries are being raised.

Advancements in bearing materials and manufacturing techniques

In my personal viewpoint, the development of materials for bearings, as well as production technologies, is poised to propel seismic growth in performance and endurance. Materials like ceramic hybrids and advanced metal alloys are now being utilized to enhance wear resistance, thermal stability, and load capacity. Advancements in production are also prominent, for example, the combination of precision additive manufacturing with advanced surface treatment processes enable unprecedented levels of precision and complexity. I have observed that these trends lead to a reduction in operational downtimes and extensification of the service life, which all in all translates into diminished industrial operation costs. These hallmark strategies of modern bearing technology point to a paradigm shift required to address the weaknesses of conventional designs and increase the efficiencies of these components.

Reference

- Journal Bearing vs. Ball Bearing Performance – This source discusses the performance benefits of Garrett ball-bearing turbochargers, including faster spool times.

- Journal Bearing VS Ball Bearing Turbos – A forum discussion that covers various aspects of ball bearing and journal bearing turbos, including oil requirements and durability.

- Journal vs. Ball Bearing Turbo – This forum thread highlights the advantages of ball bearings in handling higher thrust loads compared to journal bearings.

Frequently Asked Questions (FAQs)

Q: What is the main difference between ball-bearing and journal-bearing turbos?

A: The main difference lies in their design and performance. Ball-bearing turbos use rolling elements (balls) between the shaft and housing while journal-bearing turbos use a thin film of oil. Ball bearings generally offer less friction and faster spool-up times, while journal bearings are simpler and often more cost-effective.

Q: Do ball-bearing turbos spool faster than journal-bearing turbos?

A: Yes, ball-bearing turbos typically spool faster than journal-bearing turbos. The rolling elements in ball bearings create less friction, allowing the turbo to reach its optimal speed more quickly. This results in improved throttle response and reduced turbo lag compared to journal-bearing turbos.

Q: What are the advantages of journal-bearing turbos?

A: Journal-bearing turbos, also known as sleeve-bearing turbos, have several advantages. They are generally more durable, have a simpler design, and are less expensive to manufacture. Journal bearings also tend to be quieter in operation and can handle higher temperatures better than ball bearings.

Q: Are ball-bearing turbos more expensive than journal-bearing turbos?

A: Yes, ball-bearing turbos are typically more expensive than journal-bearing turbos. The more complex design and manufacturing process of ball bearings contributes to their higher cost. However, many enthusiasts feel the performance benefits justify the additional expense.

Q: How do maintenance costs compare between journal and ball-bearing turbos?

A: Maintenance costs over time can vary between the two types. Journal bearing turbos may require more frequent oil changes to maintain the oil film crucial for their operation. Ball-bearing turbos, while initially more expensive, may have lower long-term maintenance costs due to their reduced friction and wear.

Q: Can you use a turbo timer with both ball-bearing and journal-bearing turbos?

A: Yes, you can use a turbo timer with both ball-bearing and journal-bearing turbos. Turbo timers are designed to keep the engine running for a short period after shutting off, allowing the turbo to cool down properly. This is beneficial for both types of bearings to prevent oil coking and extend turbo life.

Q: Are there different types of journal bearings used in turbochargers?

A: Yes, there are different types of journal bearings used in turbochargers. The most common type is the plain journal bearing, but there are also floating journal bearings and semi-floating journal bearings. Each type has its own characteristics and is chosen based on the specific application and performance requirements.

Q: How do angular contact ball bearings compare to standard ball bearings in turbos?

A: Angular contact ball bearings are a specific type of ball bearing often used in high-performance turbos. Compared to standard ball bearings, they can handle both radial and axial loads more effectively. This makes them particularly suitable for turbos that experience high thrust loads, offering improved stability and performance in demanding applications.