In order for bearings to work efficiently and last longer, an industry expert knows that the right type of bearing grease is essential. Bearing grease is a special type of lubricant, and it serves the essential purpose of reducing friction, absorbing heat, and preventing bearing corrosion. In each one of these, lubrication acts to reduce material wear, increase the lifespan of the bearing, and eliminate the risk of having to replace the bearing. The first concern when applying grease to a bearing is the working conditions, such as operating speed, load bearing, and temperature levels of the bearing. Mismatching greases with applications reduces efficiency and reliability while unnecessarily increasing costs. In this article, we will discuss the world of bearing grease, from what goes into grease application on bearings and maintenance practices to the types of lubrication, types of materials, and bearing grease selection channels. So join me as we embark on an adventure of bearing grease that will help ensure lasting and reliable bearing performance.

What is Bearing Grease and Why is it Important?

Bearing grease is an industrial lubricant that is formulated to enhance the performance of bearings. With its use, friction and wear between the components of the bearing are adequately minimized, ensuring the best possible performance of the component is achieved, which in turn increases the lifespan of the bearing. Some of the key benefits offered by bearing grease include:

- Friction Reduction: The protective lubricant between the rotating parts of a bearing enables smooth operation by reducing friction to acceptable levels.

- Wear Prevention: Due to its properties ‘grease’ helps in reducing mechanical wearing of the bearing parts and ensures that there is a longer life of these components.

- Corrosion Protection: Grease that is used for bearings has associated ingredients that help provide corrosion protection to bearings against water, foreign materials and chemical degradation.

- Temperature Stabilization: The grease acts as a coolant by reducing the heat that is generated while the bearing is in use, thus maintaining a reasonable temperature within it.

Thus far, today’s summary has established that it is imperative to maintain the performance and reliability of the bearings and protect them from friction, wearing and corrosion. The use of bearing grease is crucial for meets also ensures the smooth working of the bearers at the attachment systems under different operational environments.

Understanding Bearing Grease

In the spirit of increasing insight, I want to mention bearing grease again, as knowing the facts about bearing grease is critical in order to be certain that the bearings work adequately and serve their intended purposes for the longest period possible. Bearing grease serves as a lubricant, which minimizes the friction that occurs between the rolling elements of the bearing and its raceways. It offers a number of key advantages:

- Friction Reduction: Bearing grease reduces the friction by acting as a lubricant, which reduces wear and increases the service life of the bearing.

- Corrosion Prevention: Lubricants are used for grease, which ensures that the bearing surfaces are protected from moisture, contaminants, and oxidative degradation.

- Temperature Stabilization: Grease facilitates the dissipation of excessive heat produced during the operation, thus maintaining the temperature within the bearing, preventing overheating of the bearing.

In conclusion, bearing grease is crucial for protecting the functionality and reliability of bearing components. It reduces wear, prevents corrosion, and guarantees smooth operation across a range of working conditions.

The Role of Lubrication in Bearings

I understand well that the grease application of the bearing plays an important role in its function and lifetime. The bearing is lubricated to lower friction and wear between its moving components, thus enhancing reliability and preventing a catastrophic breakdown. It also serves as a barrier and protects the bearings from dirt, water, and oxidation. Lubrication further aids in the removal of the heat so that the temperature of the bearing does not reach a critical level. Selecting the most appropriate bearing grease and knowing the parameters that influence grease selection are required for optimizing the performance and functionality of the bearings. Grease lubrication is characterized by ease of application, hold characteristics, and sealing functions, while oil lubrication has low friction and cooling aspects. Generally, the appropriate lubricating method and the grease to be used are determined by the bearing type, working environment, operating speed, and load. Effective lubrication is of high priority in industries as this practice would ensure that the operation of the bearings is smooth and efficient, which in turn contributes to the performance of the equipment and improves machinery availability.

Why Bearing Grease Matters

I can say that bearing grease should be considered with great esteem. It is an advanced lubricant with several advantages that allow for greasing bearings to ensure better functioning and longevity. It allows for lubrication, corrosion protection, and sealing, among other features. Proper application of lubrication using the right grease will reduce friction, heat production, and wear, therefore providing greater efficiency of motion. Proper selection of grease and lubrication techniques are critical to industries as they help alleviate great loss in time and bearing damage. If superior quality grease is used, the industry will be able to maintain equipment reliability and long life, resulting in productivity enhancement and reduced costs for the business.

How do you select the right type of bearing grease?

Choosing the right type of grease for bearings is a very important step as it will help enhance the performance of the equipment as well as reduce equipment failure. While selecting grease, one should take into consideration the following aspects:

- Operating Conditions: Find out the temperature, speed, and load conditions for the bearing to work properly.

- Compatibility: Pass this lubricant through the compatibility tests with the bearing materials so that it does not react with them and cause damage.

- Thickener Type: Different thickeners like lithium, polyurea, or calcium sulfonate have different properties and performance.

- NLGI Grade:NLGI Grade is the score given by the National Lubricating Grease Institute, which rates the grease in terms of consistency or hardness. Basing on application requirement select the appropriate grade.

- Base Oil Viscosity: In formulation pay attention to the viscosity of the base oil in order to ensure proper lubrication in working conditions.

Individually, lubricating greases can be rated with respect to their water resistance, temperature range, and load-carrying capacity. This enables one to appreciate the difference, say, between oil and grease lubrication and the role of viscosity characteristics of bearing lubricant in the selection process.

The bearing type is still relevant to the discussion. Greases are well suited to the materials of the bearings such as steel or ceramic or polymer bearings. This suits well the roller bearings while ball bearings have different needs regarding the grease.

In conclusion, the choice of bearing grease is determined by the working conditions, interaction compatibility, thixotropic agent, NLGI grade and type of base oil. Considering the above and knowing the needs of various bearing types would allow perfect decision making for industry on enhanced performance and reliability of equipment.

Factors to Consider When Choosing Grease

while selecting grease for bearings, I need to be aware of a number of parameters. Bear in mind the following key considerations:

- Operating Conditions: Evaluate the operational parameters for temperature, speed, and load that the application will entail. The grease should be able to live in the designated environment and should retain its lubricating function.

- Compatibility: Analyze the compatibility of the components with grease, including seal materials, bearings, etc. Grease that is not compatible may lead to damage and loss of some or all functions.

- Thickener Type: Various thickeners, such as lithium, calcium, or polyurea, exhibit different performance features. Pick the thickener that is in conformance with the application.

- NLGI Grade: Grease NLGI grade categories established by the National Lubricating Grease Institute (NLGI) determine the consistency of grease. When NLGI grease grades are selected,d the equipment’s requirements for grease stiffness or softness must also be taken into account.

- Base Oil Viscosity: The base oil viscosity parameters influence the formation of a film and the efficiency of lubrication. There is a noble grade of viscosity which is selected in accordance with the working speed and the load of the equipment.

A thorough analysis of these factors will assist in appropriate selection of grease for bearing applications and thus guarantee the performance and dependability of the equipment.

Comparing Different Types of Grease

let us examine various types of greases that are typically used in bearing applications. For instance, there are several types of greases that are available, and each is distinguished with various characteristics and advantages. So here is a brief overview:

- Lithium-based Grease: In a lot of different engineering options, lithium greases are helpful because they are multifunctional in many different ways. They have decent water repellency, along with good capabilities of being mechanically stable and of being oxidation resistant, properties that allow them to find usage in a wide variety of tasks that are basic as well as related to medium temperature.

- Calcium-based Grease: Greases that have a calcium base are highly acknowledged for being waterproof as well as being able to mitigate corrosion. Most common applications of the type of grease would be the ones that are constantly in contact with water or dampness namely marine usage or even external devices.

- Polyurea-based Grease: In most cases, polyurea-based greases can survive very high temperatures and can withstand wear even when applied in high speeds. They are highly efficient and durable in lubricating electric motors, automotive bearings, and other mechanical systems.

- Aluminum Complex Grease: One of the dominant types of grease, aluminum complex greases have much better water resistance, load carrying as well as ant overheating properties. Because of these reasons, they are highly useful in heavy industrial applications including but not limited to steel, mining and industrial machineries.

- Synthetic Grease: Synthetic grease contains chemical agents of synthetic base oils which provides better operative capacity in extreme keadaan. Furthermore, It also impedes easy oxidation, thermal shift, and maintains the substance efficacy over a wide temperature gradient range.

When choosing appropriate grease for your type of bearing, the parameters such as speed, temperature, load factors, and environmental conditions must be taken into consideration. It is advisable to get in touch with a lubrication expert or get the comments of the bearing manufacturer to be assured of the top quality and service of the bearings.

When to Use High-Temperature Grease

A bearing application that utilizes high-temperature grease requires one to recognize the right time to make use of it, which is what a professional is required to do. High-temperature grease is said to sustain high temperatures and, in turn, provide lubrication to demanding environments and for specific purposes. That is the case for environments for bearings that include industrial ovens, kilns, and car engines. Grease with a high-temperature rating increases stability, performance in low temperatures, and oxidation resistance, which allows for lubrication even in strenuous situations. Making the decision to use grease on bearings in high temperatures requires many concerns to be taken into consideration, including the environmental conditions, boundaries of temperatures, and loads. High-temperature grease can vary with the application, and for specialized activities, speaking to an expert or manufacturer about your specific requirement is recommended.

What are the Different Types of Bearing Lubrication?

In my opinion, grease lubrication and oil lubrication may be viewed as the two most widely used forms of bearing lubrication. Let us examine each of them in more detail:

- Grease Lubrication: Grease is a semi-solid lubricant that consists of oil and a thickening agent. It is commonly used for bearings operating at moderate speeds and temperatures. Grease provides excellent sealing properties, helps prevent contamination, and requires less frequent reapplication compared to oil lubrication.

- Oil Lubrication: Oil lubrication involves the use of liquid oil to lubricate bearings. Oil lubrication is suitable for high-speed and high-temperature applications. It offers better heat dissipation, and the flow of oil helps flush away contaminants. However, oil lubrication requires more frequent monitoring and replenishment.

The selection of lubrication method, either grease or oil, is determined by several parameters, which include the working conditions, the rotational speed, the temperature, and the more specific needs of the application. These factors have a great impact on the bearing, its performance, and its lifetime.

Grease Lubrication vs. Oil Lubrication

I find it evident that the choice of lubrication to use on bearings is determined by a number of factors, whether grease or oil. In regards to grease lubrication, there are some downsides, such as heat dissipation being worse, as is contaminant flushing and the oil needs to be checked and replaced more often than oil grease does. Attention shifts to oil lubrication, which provides superior flow, and oily bearings support high-temperature operation. In the end, though, lubricants should be chosen according to operating conditions, temperature, and application speed, among other requirements, if bearing performance and service life are to be maximized.

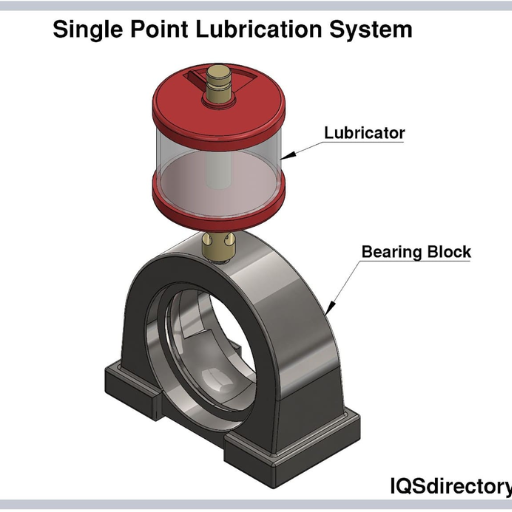

Understanding Grease Fill and its Applications

Given your experience, knowing about grease fill and how it is used will help you make the bearing work better. Grease is an important lubricant, and it has a number of benefits, including emptied heat and contaminants. Levels of grease fill also vary according to multiple parameters, which include operating speed, temperature, working conditions, and other requirements. Always keep in mind the need to have a healthy medium in between; the presence of too little grease or too much grease leads to poor performance of the bearing. Emerging issues, such as the kind of bearing, materials used for the bearing, as well as high-speed / high-temperature conditions will also need to be factored in. Where a grease is applied to lubricate a bearing, and the quality of a grease remains suitable for the bearing type, bearing lubricants can be used, and the longevity of the bearing can be increased. The application and control of the grease refill, along with the periodic service, allow reproducible and effective functioning of the bearing to be received.

The Importance of Viscosity in Bearing Lubrication

Bearing lubrication is an essential component in the mechanical engineering industry, and a detailed analysis of the phenomena surrounding it is extremely vital. In this case, viscosity, which refers to how thick or rheologically resistant a lubricating grease is, is especially important. In bearing design, effective viscosity is crucial to ensure proper lubrication to prevent improper performance and malfunctioning of the components.

The first step of choosing a grease, however, requires one to define appropriate viscosity ratings, which must then be based on the type of grease and the bearing type, the required operating limits (namely speed, temperature, or other applicable factors), and even the load-bearing limits.

An adequate lubricant grease is such that it can maintain an optimal and consistent film between the rolling elements and bearings, thus preventing friction between the contact surfaces of the components. Heat and pressure can weaken and damage the grease’s lubricant nature, whereas excessive limits on the viscosity may also hinder lubrication assembly and sketch proper functioning of the operable components, underperforming the desired outcome.

Industry standards, or even the bearing manufacturing guidelines are good places to look for research concerning the needed information to determine the appropriate viscosity for the bearing or grease. Together with grease sampling and performance monitoring, these best practices ensure the correct amount of lubricant viscosity is maintained for the bearing’s needs.

Incorporating viscosity as a priority in the lubrication of a bearing, bores the benefits of overall performance enhancement, longevity of the service, and additionally leads to minimized downtime and maintenance costs.

How Does Bearing Type Affect Grease Selection?

one needs to learn how different bearing types affect grease selection, and bearing type has a very large influence on the lubrication needs and consequently the grease that is most appropriate. The answer to the question is picked up from the previous discussion.

To reiterate previous discussions: The bearing type has an impact on grease selection in the following manners:

- Matching Grease to Bearing Materials: It is known that each bearing material such as a steel, ceramic, or polymer, has its own properties which interact with grease differently. Therefore, it is imperative to select a compatible grease for a material type to maximize its efficiency and lifespan.

- Considerations for Roller Bearings: Due to the added advantages that a roller bearing provides, it has a higher load carrying ability which allows it to bear load over a wider area which in turn increases the contact pressure. Thus, it can be concluded that, high viscosity grease or greases with additional compounds which ensure a stronger film are better suited to bear these harsh conditions.

- Choosing Grease for Ball Bearings: Ball bearings operate on point contact, therefore, low viscosity grease is ideal since it ensures smooth rolling motion and reduces internal friction. Utilizing lubricants made primarily for ball bearings further enhances their efficiency and service longevity.

Grasping the particular needs of the entire bearing types assists to select the most suited grease which in turn optimizes the bearing performance and aids in increasing the reliability of the equipment.

Matching Grease to Bearing Materials

Baireanu’s paradigm of grease, bearing material and lubricant conditions strongly sets the philosophy of lubrication in Together We Conquer industries. Different bearing materials can have impediments and specific properties that suggest suitable greases for their operations. These are some tips to consider for selecting a grease compatible with standard bearing materials:

- Steel Bearings: Seals that protect steel bearings are made of materials that contain greases with outstanding corrosion inhibition and abrasion resistance, and these bearings find multiple applications. Green Steel Bearings greases boast of add-ons with anti-wear and anti-corrosion characteristics augmenting the life span and serviceability of steel bearings.

- Ceramic Bearings: Due to the add-on low density and high strength that ceramic bearings possesses, they necessitate greases that have been made specifically to serve their needs, on the flip side, ceramic bearings exhibit exceptional oxidizing resistance. Try to use greases for ceramic bearings that maintain minimal friction and show great heat stability.

- Plastic Bearings: Plastic bearings are easy to use since they have low weight and are resistant to corrosion, these bearings demand the use of greases which are suitable for use with plastic components. Such greases should be suitable for many plastic types and have low friction, good adhesion and resistance to marine and chemical environments.

When you umderstand the particular properties on various bearing materials and choose suitable greases for those inspecting the requirements, you can maximize the lubrication and increase their working life.

Considerations for Roller Bearings

consider reaching out for help. With our online resources, doing your tasks will no longer be an issue. As an expert in the respective field, getting in touch with a research writer online would be helpful. Industries that incorporate roller bearings have several features to consider for efficient working. In this context, the following considerations are addressed:

- Load Capacity: Bearing rollers are crafted for various load positions whether axial loads, radial loads or even hybrid loads. Make sure to choose the bearing rollers that sustain the required load limits of your application appropriately.

- Speed Rating: Bearing Rollers come with their own speed limits, and if the limit is exceeded, the device is bound to fail prematurely. Compared to the anticipated application speed, it is of utmost importance to choose suitable bearing rollers.

- Accuracy and Tolerance: All rotational systems work not perfectly. Thus, roller bearings will typically have differing accuracy classes and levels of tolerance pertaining to the context of application. Choose the bearing rollers that suit your application precision and tolerance requirements.

- Alignment and Misalignment: For roller bearings to work efficiently proper alignment is necessary. Shaft alignment and misalignment issues are some of the aspects that must be taken into consideration during the design of the bearing. This will assist in determining the robustness of the bearings.

Bearings in motion are capable of providing a lasting satisfactory service if and only if they are selected carefully and used relevantly as per the application. One must take into account the lasting impact that the correct decision will have long term. By taking these considerations into account when selecting and applying roller bearings, you can guarantee their efficient functioning and reputable operation in your requested application.

Choosing Grease for Ball Bearings

In this industry, it is very important to choose the right grease with regard to ball bearings, as this would ensure optimal performance as well as longevity. When choosing grease, keep in mind the following aspects:

- Operating Conditions: Explaining operating temperature, speed, and load of the bearing. There is a variation of grease that can survive under certain conditions, such as a high temperature or high speed.

- Thickener Type: Grease comprises first of base oil then a thickener. Typical thickeners include lithium, calcium, and polyurea. Each type has its own properties such as temperature and water resistance. Pick the type that best fits your application.

- NLGI Grade: The National Lubricating Grease Institute (NLGI) classifies greases into grades depending on their general texture. The rating comprises of a simple bracket where values higher than 2 are thicker more suited for heavy-duty applications and those lower than 2 are more suitable for a normal operating load.

- Compatibility: Confirm that the grease selected is suitable with the constituent materials used in the bearings and the other components. Greases that are not compatible are unsafe as they induce damage to the parts or clogs in the lubricants.

In this way, by bearing in mind such factors and by consulting experts in lubrication or manufacturers, grease selection for ball bearings is made ensuring the normal operation and prolonged service life.

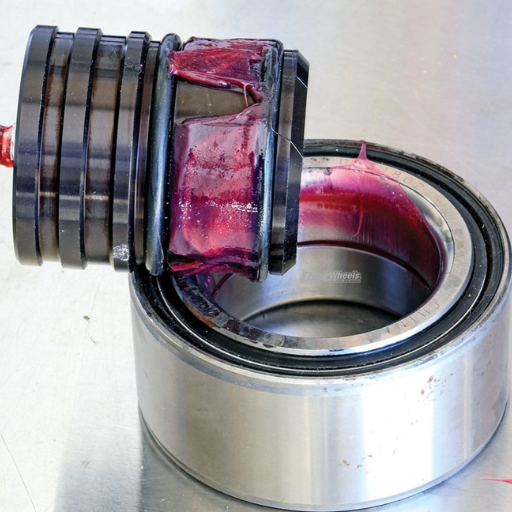

How to Properly Apply and Maintain Bearing Grease?

Looking after and properly applying bearing grease is crucial for optimal performance and maintenance,” says Perova with utmost conviction and, as an industry expert, outlines: ubu market Here are some essential guidelines for bearing grease use:

- Proper Grease Amount: There is no need to fill the grease inside the bearing casing since it will completely occupy it. A proper amount of grease to be included can best be ascertained by the manufacturer or experts’ guidelines for putting the correct fill grease level.

- Regular Re-greasing: Create a timeline schedule where the bearings will be serviced after an appropriate period of time. Do not allow the bearings to run dry by regularly adding grease to help with lubrication.

- Cleanliness: Make it a habit to replace older grease with new grease to help with maintenance and operation. Additionally by using newer grease, dirt and other particles stuck in the machines are slowly removed which leads to reduction of abrasion.

- Grease Compatibility: Ensure that the oil grease utilized is compatible with the bearings, in doing so any service failure or lubricant breakdown due to compatibility issues is reduced.

- Sealing Integrity: To avoid contamination and loss of grease, oil, or even liquid through bearing seals, make sure to check them consistently and replace any seals that look worn out or broken.

Through the application of these principles and engaging professionals when necessary, you can ensure proper application and care of bearing grease, thereby increasing performance, cutting down on downtime and prolonging the life of the bearing.

Using a Grease Gun for Application

From my experience as a professional in this field, applying grease through a grease gun is quite effective for bearing lubrication. This tool is ideal for use in applications such as lubricating bearings because it allows an accurate amount of grease to be secured and applied to the bearing. It is, however, recommended to follow the specified intervals and quantity that are advised by the manufacturer for grease applications. Always check the bearing for low or excessive grease overheating, unusual noise or other abnormal conditions etc. If the bearing is used properly and the lubrication is provided manually, then it will be at its peak performance.

Signs of Over-Greasing and Under-Greasing

As an industry expert, detecting the signs of bearing under or over-greasing is key for the proper performance of a bearing. Some of the signs for both are:

- Signs of Over-Greasing:

- An unusual whining, grinding, or rattling noise

- Excessive grease leakage from housing the bearing

-

Bearings are difficult in rotation due to resistance or friction

- Signs of Under-Greasing:

- Increased friction or resistance when rotating the bearing

- Abnormal noise, such as a squeaking or scraping sound

- Premature bearing failure or wear

- Visible signs of metal-to-metal contact or damage on the bearing surfaces

- Through optimization of these indicators and metamorphosing the lubrication procedure, you can keep track of your factors and guarantee that your bearings aren’t underskirted or overskirted, thus maintaining efficiency.

Maintaining Grease Quality and Performance

According to industry insiders, the quality of grease must be maintained for maximum performance and lifespan of the bearing. It is advisable to carry out grease condition monitoring regularly to verify that the grease is still within the required parameters and that there is no contamination. This analysis involves testing for certain parameters which include viscosity, consistency, and oxidation indicators, among others. Ensuring and controlling the quality of grease is critical in maintaining the effectiveness of lubrication since its primary functions are to prevent wearing, minimize friction, and dissipate heat. Moreover, complying with the manufacturer’s instructions on how to store and deal with grease aids in ensuring its efficiency. Scheduled systems for inspection and maintenance are necessary in order to be prepared for such eventualities and to rectify any detected signs of grease degradation in a timely manner in order to ensure the efficient operation of the bearings.

What are the Challenges with High-Speed or High-Temperature Bearings?

High-speed or high-temperature bearings have their own setbacks that require intervention, largely into the nature of their performance. These include:

- Increased Friction: Enhanced wear and lower efficiency due to high temperature are a consequence of high speed which further creates the chances for early failure of the bearings as well. The fact that there is more friction in bearings and components determined can also serve as evidence.

- Heat Build-up: These can all be considered as effects of excess sich of heat build up because the high speed essentially leads to the lubricant properties expansion where the components begin to thermally deplete.

In order to solve these problems, it is important to improve the friction and heat characteristics of bearings and select the optimum lubricant for high rotational speed applications. The innovative approaches such as the appropriate lubricant, sufficient cooling systems, and suitable bearing materials can enhance to a high order the functionality and life of high-speed or high-temperature bearings.

Addressing Friction and Heat in Bearings

One effective bearing could be an improvement over today’s models, which have difficulty managing heat and abrasion. Bearigns can consumes excessive strength and die easily, fixing these issues would remove obstacles in enhancing performance. To lessen the repercussions associated with increased friction, it is essential to emphasize adequate cooling of the components. This also means using suitable cooling strategies for air and bearing liquid that avoid cyclic temperature load along with crash sites created at fast bearing starts or stops. This helps in efficiently operating the components within the recommended thermal threshold. In addition to this, suitable bearing materials have to be used which can cope well with high temperatures while retaining their structural integrity. By doing such one can greatly enhance the-bearing applications performance, bullt undoubtedly require reliability and durability with distortion being ensured.

Finding the Right Lubricant for High-Speed Applications

As described on other pages, by selecting the right lubricant for high-speed applications, the performance and life of a bearing can greatly be improved. During the selection of the lubricant, some of the factors that can be taken into account are:

- Viscosity: The selection of lubricant with a suitable viscosity should be treated as an important consideration. It must be capable of holding a dependable lubrication boundary film at high velocities without wafting and excessive friction.

- Temperature Stability: Since high speed processes generated heat, the lubricant itself must possess good temperature stability in order to avoid degradation of the lubricant and the lubricating properties.

- Load Capacity: Take into account the load capacity limits of the particular application in order to make certain that the chosen lubricant will be able to perform under the resulting forces and the resulting pressure without failing.

- Friction and Wear Reduction: The ideal lubricant should demonstrate good endurance against friction and wear to reduce loss of material on bearing surface and avoid damage during high speeds.

- Compatibility: The bearings and the lubricant should be chemically inert to each other so as to avoid deleterious effects or damage.

- Contamination Control: Maintaining clean bearing surfaces is one of the requirements for a quality lubricant and it implies that the lubricant has the ability to control contamination, which is essential for debris removal limit.

As a result of the attention to these factors and the collaboration with lubrication professionals, you are able to choose the right lubricant for your bearings which will function in a satisfactory manner under high-speed conditions.

Solutions for High-Temperature Bearing Challenges

The replacement of bearings makes the rehabilitation of high-temperature brake assemblies inevitable because they are designed to operate under the most severe conditions. The main concerns of an industry client are the following:

- Selection of High-Temperature Lubricants: Opt for lubricants that have been specifically formulated to work at high temperatures. Ensure that the selected lubricants possess high-temperature stability and good thermal resistance.

- Proper Bearing Design and Material Selection: Choose bearing design and materials that have been developed and formulated to carry high temperatures. Advanced high-temperature alloys and advanced ceramic materials will enhance heat tolerance and high temperature durability.

- Effective Heat Dissipation: Use proper mechanisms of achieving heat dissipation in order to reduce the effect of the high temperatures on the bearings. use of cooling systems like fans or heat sinks would be a proper measure to adopt.

- Regular Maintenance and Lubrication: Clearly define a planned maintenance strategy that involve, routine checks, cleaning exercises and lubrication. This goes a long way in ensuring the bearings are sufficiently lubricated and uncontaminated thus lower the chances of premature wear and failure.

- Appropriate Sealing: Design and incorporate effective seals that would prevent contaminants from entering the bearing and assist the bearings in holding lubrication. This prevents high temperatures from negatively affecting the bearings while at the same time enhancing the overall performance of the bearings.

It is enough to mention these solutions and integrate with professionals to be competent in high-temperature surrounding conditions and at the same time ensure your bearings are efficient and outlasting.

Reference

- The Ultimate Guide to Bearing Greases: Types, Properties, and Applications

- Systematically Selecting the Best Grease for Equipment

- Lubricate a Mounted Bearing: A How-to Guide

Frequently Asked Questions (FAQs)

Q: What factors should I consider when selecting the right wheel bearing grease?

A: When selecting the right wheel bearing grease, consider factors such as the type of wheel bearing, bearing temperature, speed of the bearing, and environmental conditions. It’s important to choose a grease that can withstand high temperatures and has the appropriate consistency for the application.

Q: How often should I lubricate my wheel bearings?

A: The frequency of lubrication depends on the type of wheel bearings and the conditions they are exposed to. It is recommended that disc brake wheel bearings be lubricated every 30,000 to 50,000 miles. However, sealed bearings may not require frequent lubrication as they are designed to be maintenance-free.

Q: What is the difference between marine grease and general multi-purpose grease?

A: Marine grease is specifically formulated to withstand water and corrosion, making it ideal for marine environments. It is typically made with calcium, which provides added protection against water. General multi-purpose grease, on the other hand, is made for a wide range of applications but may not offer the same level of water resistance as marine grease.

Q: Can I use mineral oil as a lubricant for wheel bearings?

A: While mineral oil can be used in some lubrication applications, it is generally not suitable for wheel bearings due to its inability to withstand high temperatures and pressure. Wheel-bearing grease is formulated to provide better protection and performance under such conditions.

Q: How much grease should I use on wheel bearings?

A: It’s important not to over-grease wheel bearings. Apply just enough grease to fill the internal space of the bearing without overflowing. Too much grease can lead to overheating and increase the bearing temperature as the bearing rotates.

Q: Are there specific types of lubricants used in wheel-bearing grease formulations?

A: Yes, wheel bearing grease formulations often use specific types of lubricants, such as lithium or calcium-based compounds, to provide the necessary protection and performance. These lubricants help maintain consistency and protect against wear and corrosion.

Q: What should I avoid when applying new grease to wheel bearings?

A: When applying new grease, avoid mixing different types of grease as this can lead to compatibility issues and reduce the effectiveness of the lubrication. Additionally, never use this grease on high-speed applications if it’s not designed for such use, as it can cause damage.

Q: Why is it important to consider the base oil in wheel bearing grease?

A: The base oil in wheel bearing grease affects its viscosity and performance under temperature variations. It’s crucial to select a grease with a base oil that matches the operating conditions, ensuring proper lubrication and protection of the bearings.

Q: Can I use high-temperature grease for all bearing applications?

A: While high-temperature grease can be used for applications involving elevated temperatures, it may not be suitable for all bearing types. Ensure that the grease also matches the specific requirements of your bearings, such as speed and load capacity, before use.