The next consideration is selecting the correct bearing grease, which is only referred to as grease. There are many kinds of greases, i.e., different types, grades, and forms, and performing the optimal selection for a particular use can greatly impact the bearings’ performance, service life, and maintenance levels. This guide sets out to explain bearing grease in detail so that at the end, you will be in a position to appreciate the differences and factors that one should consider when looking for the most appropriate grease for any application. This article mentions all the essentials for practice, so if you’re looking to do a more advanced vehicle modification and don’t have the knowledge, this post is for you. From the chemistry of grease through the grades that are suited to various applications, we will give the complete information that you need so that your wheels will be running smoothly at all times.

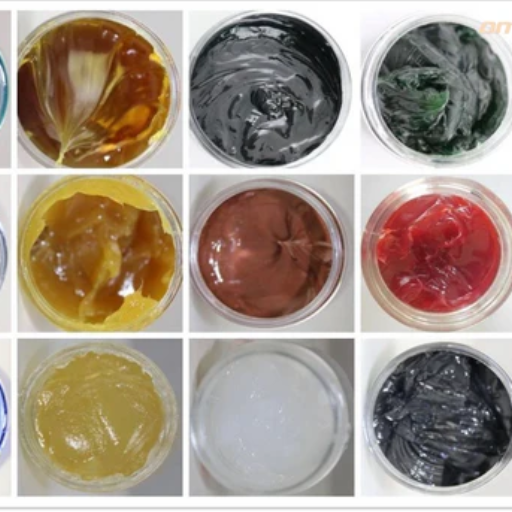

What are the different types of bearing grease?

Bearing grease falls into various types according to its composition and application. Some of the most common ones are lithium grease with excellent multipurpose and high heat stability performance, calcium grease which is waterproof, polyurea grease which is suitable for high speed and sealed grease applications, and synthetic grease for highly extreme temperature and harsh environment applications. All of these types of grease are designed and constructed for particular operating and environmental conditions, making it important to select the appropriate grease to achieve the desired bearing performance.

Understanding lithium grease and its applications

lithium grease is among the simplest and most popular lubricants utilized across numerous industries. Such redeeming qualities as sound thermal stability, resistance to water, and surface wetting are the reasons why it is used so often by many industries. I’ve watched it work superbly in cars, factories, and even at home, be it lubricating bearings or hinges and all other moving parts that require smooth and consistent performance. You can turn to lithium grease not only for improved performance but also for protection against wear and corrosion, which will surely extend the service life of any machine or equipment.

Exploring calcium-based greases for specific uses

Calcium-based greases are quite an interesting option in terms of certain applications, and it’s my pleasure to elucidate the circumstances and conditions under which such greases excel. To put it simply, these greases are especially praised for their ability to resist water, which makes them fit for use in damp or sea ecosystems. Several parameters explain the preference of calcium-based greases in certain situations:

- Water Resistance: One of the most significant qualities of calcium-based greases is their capability to resist washout by water, which enables the greases to work effectively in extremely wet conditions. This makes them suitable for use in boat trailers, docks, or any other machinery that frequently comes in contact with water.

- Operating Temperature Range: Calcium greases are suitable for operation within moderate temperatures, but their capability does not extend to extremely high heat. Their optimum performance is in machines that are used in the norm without much thermal variation.

- Corrosion Protection: A valuable asset of calcium greases is the ability of these lubricants to serve as a good barrier to rust and corrosion, which is necessary for the storage of machinery that is used in highly humid or salt regions.

- Load-Carrying Capacity: On the other hand, these lubricants can withstand low to moderate pressure without getting damaged; however, calcium-based greases are not used in high-pressure operations as these applicators do not require them for extreme applications.

For applications involving the lubrication of farm machinery, marine equipment or applications in wet environments, greases of calcium base are used. However, it might be advisable to consider first the environmental and mechanical requirements of your application before determining whether this is the suitable oil for your application.

Polyurea grease: A high-performance option

polyurea grease seems to often prevail among other lubricants showing effectiveness applied to extreme operations as its thermal and oxidative stability is comparatively higher. Polyurea grease has many flexible, desirable properties, including water-resisting characteristics and mechanical stability. The use of this kind of grease bears better results in environments of higher temperatures. Because of those features, it stands out in the use of electric motor bearings and sealed-for-life applications. However, it is prudent to incorporate specific requirements of machinery and the existing types of grease sought out for compatibility prior to the change.

How do NLGI grades affect grease performance?

The different NLGI grade types affect the performance level and usage of grease. Such classifications as 000 or 0 have low NLGI grades and are soft in texture, which makes them suitable in applications that include centralized lubrication systems or low-temperature conditions. While NLGI grade 2 and 3 are on the other end of the pole as they tend to have a firmer texture which makes them adhere well to surfaces during high temperature and high load situations. The correct NLGI grades are even more important in ensuring optimum lubrication, less wear and longer operational life of the equipment as per the specific use conditions.

Decoding NLGI grades and their significance

Based on the field for quite a while, I have learned that proper comprehension and selection of the NLGI grade is an integral element for the reliability of your machinery and equipment. To explain it in a simple way, grease has NLGI grades that essentially measure its firmness or softness. This is important because different applications require some functional characteristics in order to be able to lubricate and protect effectively.

Here are the points to keep in mind when choosing the best NLGI grade:

- Operating Environment

- Temperature: The lubrication performance for cold conditions would be satisfactory if soft grease with lower mass grades such as 000, 00, or 0 is used, as these grades flow easily and provide lubrication even at low temperatures. However, at high-temperature applications, higher mass grades such as 2 or 3 provide more stability and the capability to withstand ‘bleeding’.

- Moisture and Dirt Exposure: Soft grease is more easily washed off or incorporated into contaminants, so firmer grease is generally considered better in abrasive or dirty environments.

- Application Type

- Speed and Load: In applications with a high speed, if the amount of friction is to be lowered, a softer type of grease is more effective. On the other hand, applications that deal with high load or high pressure require thickened grease which will create a protective layer.

- Centralized Lubrication Systems:For equipment that uses such systems, NLGI grades 000 up to 1 are optimal because they have a good texture and fluidity and can be easily pumped through distribution systems.

- Adhesion Requirements

- The superior solidity of certain greases allows for better adhesion to important surfaces, making them fit for a machine with great vibrational or impact stress. In such cases, the use of a softer grease might not be as effective in retention.

Instrumentation and equipment must be operated in solid conditions. In order to achieve a good NLGI suited for one of those, a certain amount of thought has to be put into it. That’s fundamental for an organization, as it cuts down when the equipment has been fitted. Apply the grease appropriately to the application, and everything will be good!

Matching NLGI grades to different bearing applications

In the case of matching NLGI grades to various bearing applications, I always recommend beginning with the specific environmental parameters in question. For instance, in high-speed applications like electric motors’ bearings, my recommendation would be to use lower NLGI grades, such as 1 or 2, to reduce friction and the heating effect. On the contrary, when dealing with slow-speed load applications, say heavy machinery, an NLGI grade of 3 has been my preferred selection as it withstands the load better. In my opinion, choosing the correct bearing grade is crucial as it not only improves efficiency but also increases your equipment’s lifespan, which is an essential factor in every maintenance plan.

What factors should I consider when selecting the right grease?

Choosing the right grease involves the consideration of operating temperature, load conditions, speed, and environmental exposure. The grease compatibility with the lubricants already in use and the properties of water and corrosion resistance specific to the equipment are also important. Moreover, the NLGI grade is quite significant in regard to the proper degree of consistency for your application. Always follow the recommendations given by the manufacturers in order to achieve the best functioning and lifetime of your machinery.

Assessing temperature requirements and dropping points

In terms of temperature requirements and dropping points, the first aspect I consider is the operating temperature of the machinery. Grease starts to lose its consistency at higher operating temperatures, so it is critical to choose a product that has thermal stability relevant to the maximum temperature of the machine. The dropping point, which is the temperature at which grease changes from a semi-solid to a liquid form, is particularly important. The dropping point does not set operational limits, but I do use it as a parameter to estimate the upper heat limit for the grease and determine if it can withstand this heat. In colder regions, I check the pumpability and flow characteristics of the grease to avoid movement issues at the extremities. Such a detailed evaluation enables efficiency and upholding of the lifetime of the equipment.

Evaluating water resistance and load-bearing capabilities

I have a tendency to analyze factors such as load-bearing capacity and water resistance quite methodically, assessing whether or not the grease is suitable for the surrounding conditions. This is how I partition it:

- Water Resistance

The water resistance indicator informs me about the extent of these properties being lost by grease under moist conditions such as rain, washdown, or high humidity. To assess how much of the grease gets removed due to water, I usually check the water washout test results of that grease, ASTM D1264. For these types of tests, it is assumed that good-quality grease will not wash out significantly. Furthermore, I take into account the Water Spray-off Tests when the equipment is subjected to high-pressure spray in an industrial cleaning application.

- Load-bearing Capabilities

For load-bearing capability, I focus on two primary parameters:

- Four-Ball Weld Test (ASTM D2596): This test defines the upper limit that the grease can withstand before a fracture occurs, which is helpful in determining the grease’s usability for heavy or high-pressure conditions.

- Timken OK Load Test (ASTM D2509): This measures the anti-wear characteristics of the grease while in a linear press focus with a volumetric shear force action. The greater the value, the better performance under more adverse conditions.

Upon evaluation of these parameters, I guarantee that the chosen grease can withhold water ingress and bear heavy loads and harsh pressures. Such an understanding of these qualities assists me in further recommending better products for various applications without compromising on performance and reliability.

Considering viscosity and lubricating properties

In terms of viscosity and the lubricating properties of grease, I aim to choose a grease that offers the best possible structure at the desired working temperatures and use conditions. A viscosity level is a critical indicator since it defines the capability of the grease to perform its intended task, which is the reduction of the friction forces and wear between moving parts. I check whether the grease is viscous enough to remain in place and fluid enough to flow to key features requiring lubrication. Also, I consider its lubricating properties to ensure that a protective layer will be modulized to allow very minimal metal contact, thus improving the durability of the parts. With these factors in consideration, I am able to provide recommendations that help provide consistent and effective equipment operation.

How do grease additives enhance performance?

Grease additives enhance performance by improving key properties such as wear protection, oxidation resistance, and load-carrying capacity. These are antiwear agents, corrosion inhibitors, and extreme pressure additives, which function in synergy to enhance the efficiency of the machine, increase the time before failure under extreme temperatures, and enable effective functioning even under the harshest working environments possible.

Common additives and their functions

In order for greases to attain effective performance, several important additives are incorporated in their formulation. Let’s break down the most common additives and the important functions they fulfill:

- Anti-Wear Agents

These additives are especially of use in protective services from extreme abrasion, especially in harsh frictional conditions. They decrease the wear and tear on metal components by creating a thin barrier and consequently assist in prolonging the service life of the equipment.

- Corrosion Inhibitors

Top coatings defend discolored metal elements from rust and damage arising from dampness and atmospheric conditions. They create a shield that prevents water and any corrosive agents from interacting with the metallic surfaces.

- Relevant parameter: Improvement of metal surface quality when exposed to moisture or other corrosive surroundings.

- Extreme Pressure (EP) Additives

Employing EP additives in situations that involve massive loads as well as high pressures essentially creates a lubricant film that prevents welding and scoring of surfaces under stress. They guarantee operational efficiency even under harsh circumstances.

- Relevant parameter: Enhanced strength and stability when under extreme stress overload.

- Oxidation Inhibitors

Such additives retard the oxidation of grease, which can result in hardening, slack deposit formation, and decreased lubrication efficacy. Oxidation inhibitors support thermal stability and, hence, enhance the life of grease.

- Relevant parameter: High-temperature oxidative degradation resistance.

- Thickeners

Although in many cases, they are not purely regarded as additives, thickeners are essential for the stability of the grease and also for its lubricant’s holding capacity. They affect the thermal and mechanical endurance of grease.

- Relevant parameters: Consistency and structural stability.

- Tackifiers

Tackifiers are essential in ensuring that the grease has a firm attachment to the intended surface without dripping or being displaced. They are suitable in places that deal with high-speed or high-movement tasks.

- Relevant parameter: Improved adhesion and retention on complex or moving surfaces.

The introduction of such compounds in the preparation of grease formulations ensures that the manufacturers have met the requirements of wear protection, durability, and performance of the grease over a wide range of operational conditions, and thus, these compounds are crucial for the unreleased and increased efficiency of the equipment.

Selecting greases with appropriate additives for specific needs

a common question that I encounter pertains to the process of choosing the most suitable grease along with the corresponding additives for a certain purpose. My response almost always begins with an appreciation of the operating conditions of the equipment in question. These may include, but should not be limited to, operating temperature, load, environment, and types of movement. For instance, a formulation containing EP additives will be very advantageous in a high-pressure system, while greases that have high shear stability will be the most appropriate for high-speed applications. In addition to this, always check if the grease has good adhesion properties, which are necessary in order to be effective in the contact of complicated or rapid surfaces. To sum up, the processes of selecting grease and the relevant additives are derived from the functional demands that the equipment configuration is supposed to achieve, looking at the various properties of the grease.

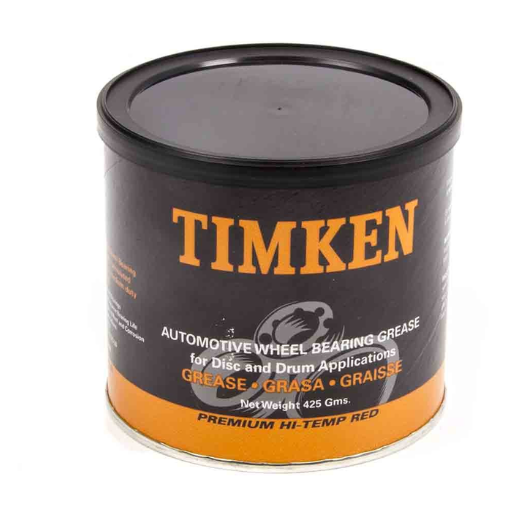

What are the best greases for automotive wheel bearings?

Generally, I would insist on looking for high-temperature, high-performance greases that are classified as having a minimum of NLGI Grade 2 specifications so as to meet the requirements of automotive wheel bearings. The NLGI lubrication chart can be found on their official page. As for the types of greases to be used, I prefer using lithium complex or synthetic greases that have robust water resistance and anticorrosive properties that would guarantee their durability in extreme conditions of use. Many professionals and do-it-yourselfers turn to trusted brands such as Mobil 1 Synthetic Grease and Timken Red Type U, which guarantees reliable performance and a good lifespan. Therefore, always check the grease you intend to use to align the automotive wheel bearings with the recommendations given by your respective vehicle manufacturer.

Top-rated greases for high-speed bearings

For high-speed bearings, the correct greases are those that are able to keep working under high temperatures while permitting minimal friction. The mobility of synthetic greases such as Mobil 1 Synthetic Grease and SKF LGHP 2 is praised for high-speed performance, good thermal stability, and stability against oxidation. In this context, greases aid in preventing wear and tear and ensure long-term usability, thus making them suitable for such complex requirements. Before use, check that they are suitable for your particular bearing for maximum efficiency.

Greases suitable for heavy-duty automotive applications

I have a habit of suggesting greases that are specially engineered for heavy-duty automotive applications, which have to endure a great deal of loads, extremely high pressures, and work in different conditions. Such greases stand up to the rough and tough experience of heavy-duty equipment such as trucks, construction machinery, or agricultural vehicles. From my experience, these parameters are of significance when selecting the right grease:

- Load-Carrying Capacity: Selected lubricating grease must possess good lubricating properties and high levels of anti-wear so as to provide effective grease lubrication for heavy-duty applications. Where an extreme pressure (EP) protection grease’s sole purpose is to prevent excessive wear. An examination of grease packs indicates that such additives are present including molybdenum disulfide or lithium-complex thickening agents.

- Temperature Tolerance: Synthetic or lithium-complex greases can be very beneficial since they can provide thermal stability under extreme conditions and for a wide range of applications, including grease lubrication

- Water and Dirt Resistance: Due to dust and dirt, it is important for grease to have resistance to water. The vehicle can also apply mudding or drastically move through the dust. In addition to good water washout resistance, grease should also be able to block enough dirt to make sure it performs optimally and protects itself from damage.

- Oxidation Stability: Maintenance of clean grease is important in slow-moving, heavy-duty applications as such quick contamination would lead to oxidation. The equipment would use high loads which means that not much violence or action is placed when moving. Therefore, the resistance defined maintenance-free good service intervals.

- Adhesion to Metal Surfaces: The adhesive forces exhibited by the grease can also be important; a load or intense vibration can bind it strongly onto a surface. This way a grease can reduce the chances of failure when lubrication might be an issue due to too much load being applied.

Shell Gadus S3 V220C and Mobilgrease XHP 222 are both products that meet the requirements and, in heavy-duty conditions, have always yielded superb results. Please also remember that the manufacturer’s recommendations must always be checked to ensure that the selected grease meets the requirements of the application.

How often should I replace bearing grease?

the need to change bearing grease revolves around multiple factors, such as the type of equipment, environmental conditions, and even what the manufacturer states. As a general principle in non-specific situations, grease can be reapplied in intervals of 1000-2000 hours of use. Extreme conditions such as high temperatures and heavy loads may probably require lubrication at least once a week. For this not to happen, always keep an eye on the grease and the bearings because increased noise, vibrations, or higher temperature might mean that there is a problem, and you need to maintain it immediately. If they are taken care of regularly, they can avoid costly downtime and ensure the longevity of your machines.

Signs that indicate it’s time to change your grease

- Excessive Noise

Strange sounds are likely to signal low levels of lubrication grease on the machinery. Constant noise while operating the machine means the metal is coming into contact with metal during operation due to wear down or lack of sufficient grease, thereby needing instant remedy.

- Higher Operating Temperatures

The older grease or the grease not formulated appropriately is likely the reason for the sudden rise in the operational temperature. Grease, which breaks down or gets dirty, is not able to relieve intermolecular forces, thus resulting in adding fuel to the fire and overheating the equipment; for a seamless process, the temperature needs to be controlled and monitored frequently.

- Vibration or Oscillation

Wearing and oscillating bearings often result in a needless grease application. Parts with greater vibration are more likely to cause grease contamination or harden or, in the worst case, dry up, resulting in inadequate lubricant amount. All these factors could then result in a breakdown.

- Visual Condition of Grease

If possible, look at the grease and aim to use that as a guide for further maintenance practices. Grease that is new typically has an even color and an even texture; any discoloration texture or presence of contaminants means that it is time to toss out that grease.

- Manufacturer Recommendations

Never ignore the rules issued by the equipment’s manufacturer, as they present good approaches for deciding lubrication intervals. The recommendations are given because of particular values like speed, load, and ambient conditions.

Maintaining close monitoring for these signs, in conjunction with customer-specific maintenance directives, aids in safeguarding your equipment and its optimal utilization.

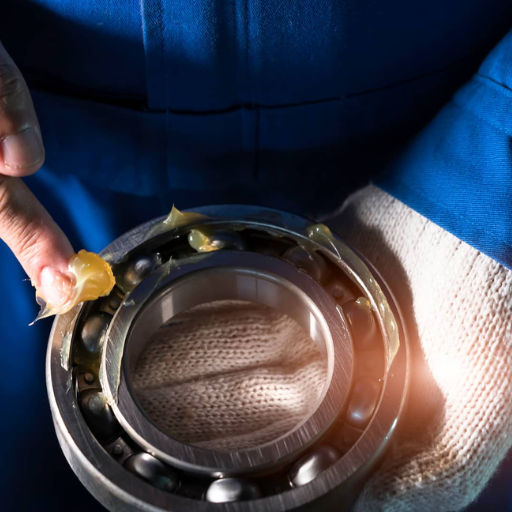

Proper techniques for removing old grease and applying new grease

grease management is one of the key aspects of maintaining the integrity of the equipment. For the purpose of tackling old grease, the first thing I do is always clean the grease fitting and slather the area with a cloth or a spray in order to prevent contamination of the system. Then, I see to it that some old grease, particularly around the difficult areas, has been wiped out. For very dirty or old grease, a degreaser or a grease removal tool should do the trick.

When it comes to installing new grease, there’s no room for mistakes. With the aid of a grease gun, I administer the required amount of new lubricant to the machine as stipulated by its manufacturer. Over-greasing can be as dangerous as greasing under the required amount since it causes overheating and seal damage. Thus, practice prevents too much strain on the system, hence enabling smooth working while also guaranteeing that there is minimal strain on the system. A detailed approach guarantees the efficiency and longevity of the equipment.

What are the consequences of using the wrong grease type or grade?

Greases have become an integral part of operating and maintaining various machines. However, using the wrong types or grades can have a dire impact on the said machinery and equipment. When grease is applied to any mechanical assembly, it is expected to lubricate each of its components. If an incorrect type of grease is applied that does not meet the requirements, it increases the friction which results in overheating and faster wear and tear of the components. Compatibility issues between greases also have chemical repercussions, leading to the nonsolvents that harden and crust and degrade the overall performance. Over and above, the use of a nonsuitable grade relates to an adverse impede on working effectiveness under certain working conditions like very high/ low temperatures or high loads, leading to lower efficiency, sudden breakdowns, and high repairs. Therefore the correct grease is necessary for the equipment’s reliability as well as its lifespan.

Potential damage to bearing surfaces and moving parts

I have experienced earlier how important it is to select the right grease because otherwise, serious impacts can occur on bearing surfaces together with moving parts. Applying the wrong bearings can increase wear and tear, and this leads to excessive friction when surfaces ought to fit properly. Such wear and tear, in the long run, affects accuracy and precision, increases chances of breakdowns, and often, expensive downtimes are the end result. Protecting your machine requires proper lubrication, and this is not merely advice but a critical procedure because neglecting it can seriously threaten the performance of the machine.

Impact on friction reduction and overall performance

Machine parts require lubricants to minimize friction between different moving parts and ensure optimum efficient functioning. The right grease also helps to avoid excessive wear and tear of the components by eliminating excessive contact between metals, which would generate heat. The appropriate choice of lubricant not only helps in improving efficiency but also allows the equipment to operate dependably and consistently for a longer period of time.

Reference

- The Ultimate Guide to Bearing Greases: Types, Properties, and Applications

- SKF Bearing Grease Selection Chart

- How to Choose a Perfect Grease

Frequently Asked Questions (FAQs)

Q: What are the different types of grease commonly used for wheel bearings?

A: The most common types of grease used for wheel bearings include lithium-based grease, calcium grease, and synthetic grease. Lithium-based grease is widely used due to its excellent stability and water resistance. Calcium grease offers high water resistance but may not perform well at high temperatures. Synthetic grease is engineered for extreme conditions and often provides superior performance in high-temperature applications.

Q: What are the key grease properties to consider when choosing a lubricant for wheel bearings?

A: When selecting a lubricating grease for wheel bearings, important properties to consider include viscosity, consistency, dropping point, and water resistance. The viscosity affects the grease’s ability to flow and coat surfaces, while consistency determines how easily it can be pumped or applied. A high dropping point indicates that the grease can withstand higher temperatures without melting. High water resistance is crucial for protecting bearings from moisture and corrosion.

Q: What are the main components of grease used for lubrication?

A: Grease typically consists of three main components: base oil (70-95%), thickener (3-30%), and additives (0-10%). The base oil provides the primary lubrication, while the thickener gives the grease its consistency. Additives enhance specific properties such as oxidation resistance, extreme pressure performance, or anti-wear characteristics. The right combination of these components determines the grease properties and its suitability for specific applications.

Q: How do I choose the right grease for high-temperature applications?

A: For high-temperature applications, look for greases with a high dropping point, typically above 260°C (500°F). Synthetic-based greases or those with special high-temperature thickeners like polyurea or complex soaps are often suitable. Consider the maximum operating temperature of your application and choose a grease that maintains its properties well above this temperature. Always ensure the grease is compatible with the bearing materials and seals.

Q: What factors should I consider when selecting wheel bearing grease?

A: When selecting wheel bearing grease, consider factors such as the operating temperature range, load conditions, speed, environment (exposure to water or contaminants), and compatibility with bearing materials and seals. Also, take into account the relubrication interval required and whether the application involves ball bearings or roller bearings. The right grease for the right application will significantly extend bearing life and improve overall performance.

Q: How do grease grades affect lubrication performance?

A: Grease grades, typically defined by the National Lubricating Grease Institute (NLGI), indicate the consistency or stiffness of the grease. NLGI grades range from 000 (very fluid) to 6 (very stiff), with NLGI 2 being the most common for general-purpose applications. Softer grades (0-1) are often used for centralized lubrication systems, while stiffer grades (2-3) are suitable for bearings operating at higher speeds or temperatures. The correct grade ensures proper distribution and retention of the grease within the bearing.

Q: How can I determine if I’m using the right type of grease for my specific application?

A: To determine if you’re using the right type of grease, consider the following steps: 1) Review your application’s requirements (temperature, speed, load, environment). 2) Check the manufacturer’s recommendations for your specific bearings. 3) Analyze the performance of your current grease – look for signs of degradation, leakage, or inadequate lubrication. 4) Consider having a grease sample analyzed by a laboratory to assess its properties. 5) Consult with a lubrication specialist if you’re unsure. Using the wrong type of grease can lead to premature bearing failure, so it’s crucial to make an informed decision.

Q: How often should I reapply grease to wheel bearings?

A: The frequency of reapplying grease to wheel bearings depends on various factors, including the type of bearing, operating conditions, and the quality of the grease used. As a general rule, wheel bearings should be inspected and regreased every 30,000 miles or annually, whichever comes first. However, heavy-duty applications or extreme operating conditions may require more frequent regreasing. Always follow the vehicle manufacturer’s recommendations and avoid over-greasing, as this can lead to overheating and seal damage.