Hello and welcome to our complete guide on how to choose a suitable bearing for your application! In this interesting and informative article, we will explain what bearings are and their functions and explain the need to choose the correct type for your needs. Whether you are a machinery guru or an engineer or you just want to know more about bearings, this article is designed to give you some insights and information that would allow you to make reasonable decisions. Therefore, let’s start this trip together to unveil the most important aspects of the bearings and help you select the right one to allow your application to achieve the best balance between performance and durability.

What is a Bearing and Its Purpose?

We appreciate that, you might have some questions regarding bearings and their functions. To put it simply, a bearing is an integral part usually found in machines and mechanical devices that allows these parts to move smoothly in a circular or straight line. Bearings are designed primarily to bear and allow relative motion between the moving parts so that they can function smoothly without excessive friction or wear. Bearings provide the surfaces of components that have a low friction interface, thus helping to enhance the kinetic effectiveness of the machine, its performance, and its service life. The aim of this guide is to make sure that you understand the bearing ecosystem and the working of the machinery better in order to be able to make an informed purchase, irrespective of your association with machinery, whether you are an engineer, a machinery lover or have taken an interest in the amazing world of bearings. We would begin this article with an overview of the workings of bearings, which means the components of the bearings that preclude the failure of application, and by understanding this, we will be able to find out the suitable gearbox that enhances the application performance and enables longevity.

Understanding the Role of Bearings in Machinery

I have recognized the critical importance bearing has upon various machineries. Indeed, bearings are amongst the most important components that bear load and control friction in many mechanical devices; they enable the device to work smoothly and efficiently. They are located in between two interacting surfaces and allow for motion, either circular or straight, with minimal possible friction and abrasion. With the use of bearings, energy losses are kept to a minimum, and thus, the efficiency is increased, and the wear of the machinery is reduced. It is essential to grasp the complex structure and function of the bearings in order to achieve the maximum performance level and increase the application’s lifetime. To this end, it would be instructive to consider the most important bearing characteristics and information required for the appropriate selection of bearings for the machinery. Together, we shall explore how best bearings can be beneficial in optimizing your operational success.

How Bearings Support and Reduce Friction

Donate bearing is an intriguing topic, which is why there are many resources available on the subject. I have come across information that states that a bearing in its essential role will perform the function of reducing frictional forces. Kothari & Sundaram made an excellent observation: “Bearings support rotating shafts by providing a low-friction interface between the shaft and the surrounding casing.” They act as an interface between the part that is moving and the other part that is stationary. In fact, bearings are always present in special relation to moving and stationary parts, regardless of whether the bearing is a bushing, a rolling element, or a magnetic type. In this sense, it is worth mentioning that a better understanding of how bearings support and subsequently reduce friction enables decisions that maximize the operational success of applications such as bearing supports, interfaces, and assemblies.

Common Types of Bearing Used in Different Applications

I am crucial in picking the suitable type of bearing for its various applications. There are many common types of bearings that serve particular purposes and ranges of operation. Let us look at some of them:

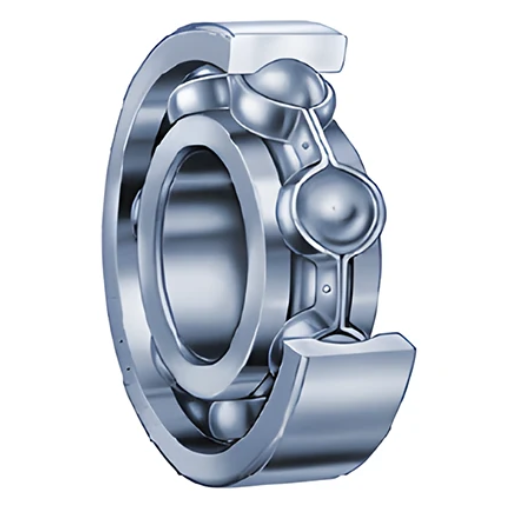

- Deep Groove Ball Bearings: Because of their capability to accommodate both axial and radial loads, these bearings are most commonly used in devices such as wheels, motors and pumps.

- Tapered Roller Bearings: With the ability to withstand high axial as well as radial loads, these bearings find their application mainly in the automotive industry, particularly in wheel hubs and gear boxes.

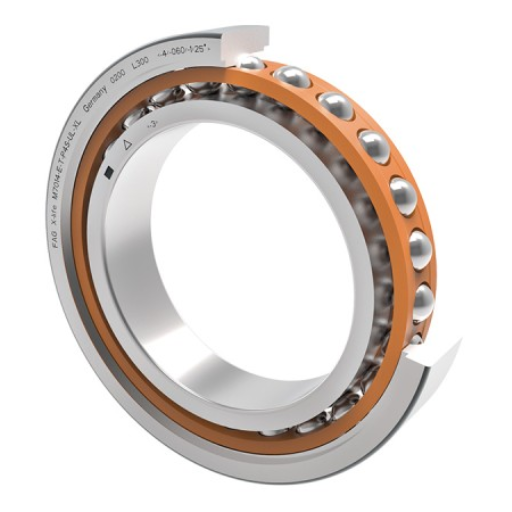

- Angular Contact Ball Bearings: These bearings are specifically designed to withstand combined axial and radial loads and are thus employed in machine tool spindles, robotics and agricultural arrangement.

Choosing the correct type of bearing is dependent on the type of application, the load to be lifted, the speed at which the application rotates, the physical conditions in which it will function as well as spatial constraints. It is vital to take these features into account and look for professionals in order for your installation to work and be reliable in a proper way.

Bear in mind that the selection of the correct bearing can enhance productivity, increase the service life of machines, and reduce breakdown time. It is also true that knowledge of the various types and uses of bearings should enable rational decisions to be taken which will enhance the successful operation of machinery.

How do you select the appropriate type of bearing?

It can be impossible not to agree that the decision to select the specific type of bearing falls under the consulting category, as it cannot simply be done hastily. Let’s list a few points that must be emphasized:

- Load Requirements: Understand the radial and axial loads which your application will face. This will assist you in finding a bearing which is able to withstand the specific load in a safe and cost-effective manner.

- Speed and Operating Conditions: What is the speed and the temperature at which the machine works? High revolutions and need for more cooling during these applications would call for special bearings.

- Space Limitations: Analyze the amount of axial space available for the bearing within the structure of the machine. Some applications need small, light and compact bearings in order to fit within small areas.

- Environmental Factors: Put into consideration the environmental conditions in which the bearing is expected to work e.g. moisture, dust, or chemicals. Get the bearing complete with the right kind of seals or coatings to withstand the harsh environment.

- Consult Experts: Consult manufacturers or industry professionals who have sufficient technical knowledge and experience. They can guide and advise you regarding the requirements related to your application and its parameters.

Taking these parameters into consideration, as well as consulting with relevant specialists, allow you to make an accurate choice of a specific type of bearing which will enhance the performance, reliability, and the lifespan of the equipment.

Factors to Consider When Choosing a Bearing

Choosing the right bearing for a particular use requires thorough consideration of several parameters. As an industry professional, you need to look out for the following parameters:

- Load Requirements: Identify the type of bearing loads, including the radial loads, axial loads, and any other forces or moments that the bearing is required to support.

- Speed and Operating Conditions: Take into account the speed at which the component is designed to rotate, the working temperature, the need for lubrication and the possibility of contamination. These aspects may affect the functioning and life of the bearing.

- Space Limitations: Assess the size of the area available for the bearing in the machinery or equipment that you have. Check that the bearing selected is able to fit and work satisfactorily in the places available.

- Environmental Factors: Consider the working environment for the bearing, for example, humidity, corrosive environment or hazardous chemicals. Based on these factors select a bearing which will meet such environmental conditions for a prolonged period of use.

- Consult Experts: Talk to bearing manufacturers or other bearing specialists who have sufficient experience and knowledge in this field. They are likely to have good suggestions concerning your application’s requirements.

Taking these criteria into account and speaking with specialists, you can make sure that the type of bearing chosen will improve performance, reliability, and durability of the machinery.

Comparing Ball Bearing and Roller Bearing

During the process of selecting a bearing, the two types which are often considered are ball bearings and roller bearings. Though both have a similar function of reducing friction and enabling smooth rotational movement, they possess different features and are designed for different applications.

Ball Bearings:

- Construction: Ball bearings are composed of spherical balls that rotate in between two rings called the inner and outer raceways.

- Advantages: They exhibit low friction as well as good speed, and are thus well suited for applications under moderate loads with relatively a high rate of rotation.

- Common Uses: Ball bearings are found in electric motors, automotive systems, and electric-powered household appliances.

Roller Bearings:

- Construction: Instead of balls, cylindrical rollers or tapered ones are used in roller bearings. The use of such rollers spreads the load over a wider area.

- Advantages: Roller bearings are capable of bearing more weight and are more resilient to pressure and blows. They are suitable in cases where there is an increased radial or axial load.

- Common Uses: Heavy machines, construction machines as well as industrial ones operate using roller bearings.

To conclude, between ball bearings and roller bearings, the selection is based on load capacity, speed and application. By evaluating the requirements for a specific construction and discussing with practitioners the most appropriate type of bearing that will provide efficiency, dependability and durability of the equipment can be established.

Understanding Radial Load and Axial Load in Bearing Selection

I suppose you are in the position of bearing expert within the industry, in which case one must be able to grasp the specific ideas concerning radial load and axial load when determining which type of bearing suits the application.

Radial Load: Radial load is the force which is directed in the radial direction towards the bearing from the side toward its center. It occurs when the compre horzontal load is applied not parallel to the shaft. The bearings which are mainly intended to support radial load are made to accommodate forces which are uniformly distributed over the circumference of the bearing.

Axial Load: Distracting rotating together at the same time, which means both directions are spinning in a Y shape. Axial load results tend to twist in different directions with rotation, which causes tension in the Y-shaped axis. It happens when a force is applied in the direction parallel to the shaft; therefore, it is called a thrust or a push. The bearing, which is primarily applied with axial load, is made to withstand the force that is exerted along the axis of the shaft.

When it comes to bearing selection, it is worth noting that radial load and axial load are both critical factors, as different types of bearings are more efficient at these loads. Deep groove ball bearings, for instance, would suffice for applications involving radial loads. However, using tapered roller bearings would be ideal as they are better equipped to handle axial and radial loads. There are Angular contact ball bearings that are able to meet both needs and are, therefore, applicable where there is the presence of radial and axial forces.

Suitable bearings can hence, be chosen by adjusting to the specific machinery load and by seeking industry experts so that the performance, reliability and endurance of the equipment are improved.

Exploring Different Types of Bearings

Bearings come in numerous types. Each type is manufactured with specific application and load criteria in mind. In this guide, we shall focus on three commonly used bearing types and their applications:self-lubricating bearings ‘

Deep Groove Ball Bearings are one of the most common bearings and are used in a variety of applications. These bearings are designed to cover both axial and radial load making them useful in machines which need to sustain both types of loads. In the modern world, deep groove ball bearings can be found in every automobile part, in electric motors, and in-home appliances.

Tapered roller bearings have the capability to support very high radial and thrust workload hence can be used where tough exercising is done. Tapered roller bearings are used to construct automotive wheel hubs, gear boxes, and also construction equipment.

Angular contact ball bearings have special ability to bear loads radially and axially at the same time. There usage depends on their ability to bear any kind of force, so they are used in machine tools and pumps and even centrifugal compressors.

The bearings you decide to go for in your machinery can be greatly influenced by the way in which you use the bearings and the characteristics they come with so talking to a few experts might help you to further comprehend bearings and thereby also enhance the performance and the reliability as well as the lifetime of your machinery.

Deep Groove Ball Bearings and Their Uses

let’s dive into deep groove ball bearings and their applications. Among the types of bearings, deep groove ball bearings are the most elastic in the sense that they can take up axial forces and radial forces and operate at a high speed with low power consumption. This is due to the fact that they possess deep cross-sectional raceways, which provide the possibility of different bearings experiencing a wide variety of rotational and non-rotational force components. These types of bearings are extensively used across multiple industries and applications as – but not limited to:

- Automotive Industry: Deep groove ball bearings are substantially used in automotive parts such as wheels, transmissions, engines and air conditioning systems.

- Industrial Machinery: They are heavily used in industrial machines such as pumps, compressors, electric motors, and conveyors.

- Home Appliances: Deep groove ball bearings can be found in many home appliances such as fridges, washing machines, dish washers and fans.

- Power Tools: Power tools such as drills, saws, and grinders, through the use of deep groove ball bearings, function and last longer.

- Electronic Devices: They are also used in electronic devices such as computer hard drives, printers,s and audio equipment.

Due to their wide operational range, deep groove ball bearings are favorably used in many industries. Appropriate selection of deep groove ball bearings greatly enhances the performance, reliability and durability of machinery and equipment.

The Advantages of Tapered Roller Bearings

I would like to explore the benefits of tapered roller bearings. Tapered roller bearings are employed in applications where both radial load and thrust or heavy combined loading conditions are expected. Some of the benefits of utilizing tapered roller bearings include:

- Load Distribution: Load displacements in tapered roller bearings are made uniformly over the roller and the racetrack hence the bearings have optimum load carrying capacity. This helps Avert early failure thus extending service life of the bearing.

- High Axial and Radial Rigidity: Tapered roller bearings have high rigidity around the axial as well as radial planes. This rigidity enables the bearings to sustain heavy loads and work under extreme conditions without performance deterioration.

- Precision and Smooth Operation: In the course of production, tapered roller bearings are made to high precision which results in smooth efficient rotation during operation. With high accuracy, it leads to low friction and energy losses making the machinery more efficient.

- Versatility and Application Range: Tapered roller bearings are available in many sizes and designs giving them the ability to be employed in many industries and applications. They are best in performance in a great range of Industries from automotive, aerospace to industrial machinery and equipment.

Tapered roller bearings deary provide various potential which facilitates industries to improve the performance, reliability, and durability of the machinery and the equipment. These bearings form the basic element in applications involving high thrust, heavy loads and more severe operating conditions for smooth running and best performance.

Applications of Angular Contact Ball Bearings

In this segment of the discussion , let us, through the lens of its applications, understand Angular Contact Ball Bearings that have a ubiquitous presence in various industries aimed at increasing performance and reliability. Such bearings are designed for high thrust and heavy loads under the most severe operating environments, and there is a great need in applications where the need for smooth functioning and maximum performance is critical.

Examples of the application of the Angular Contact Ball Bearings include:

- Machine Tools: Angular Contact Ball Bearings are particular types of bearings that are predominantly deployed in machine tool spindles, which do not only have high rigidity, but also a great margin of strength and precision. They facilitate rotation and particular movements with optimal ease for the effectiveness and quality characteristics of the parts that are machined.

- Automotive Industry: For different application areas in the automotive field, such as wheel hubs, transmissions, and engines. They are highly efficient even under rotational forces that exceed one hundred revolutions per minute thereby minimizing friction and loss of transmitted power.

- Aerospace Industry:Angular contact ball bearings are constantly used in the aerospace industry which includes powerplants and landing gears for the aircraft. Due to their construction characteristics which enable them to operate at high operating speeds whilst taking heavy loads, reliability of the aircraft components is guaranteed.

- Power Generation: For power generation applications such as wind turbines and generators, angular contact ball bearings afford adequate support to the rotating parts of the machines encouraging effective operation and energy conversion.

- Pumps and Compressors: These bearings are widely used in the axes of some pumps and compressors because they are subjected to greater radial and axial thrust, which enhances fluid locomotion and energy transmission efficiency.

Deployed in these applications, the angular ball bearings provide industries with better performance, reliability,y and durability of their machinery and equipment.

Why Are Bearings Important in High-Speed Applications?

In my opinion, and of course, , the utility of bearings in high-speed revolving machinery is critical for several reasons. One, bearings reduce the extent of motion between parts, which can cause heat loss. This is particularly important during fast operation so as to avoid wear on the components. Two, bearings assist the rotor apparatus by allowing it to rotate without unnecessary disturbance of the axis of the rotor during high speeds. Furthermore, bearings are able to sustain loads and transmit force across several points on a single bearing element, thus avoiding excessive concentration on a single point. It goes without saying that their reliability in high-speed operations enables better functioning, longer life, and dependable machinery and equipment.

The Role of Precision Bearings in Enhancing Performance

I can say that precision bearings improve performance in almost any given application. These specialized bearings offer several key advantages that enhance the efficiency, reliability, and life of different types of machinery and equipment. As a result, with the use of bearings, load, and high-speed motion can be subdued greatly. They are crucial in friction reduction, wear minimization, and component failure avoidance which guarantees the best functioning of all rotating components and increases the rotating machines’ life cycles. In situations where high speed is required, heavy loads are expected, or there are specific tolerances, dynamic solutions can be achieved with the performance of precision bearings, and the productivity is enhanced overall.

How Magnetic Bearings Offer Unique Solutions

Having gained a lot of experience in the industry, magnetic bearings are distinguished by their uniqueness and innovation in bearing technology. There is no friction in the bearing through physical contact of components, as is the case with magnetic bearings; rolling element bearings utilize physical contact between components. This approach is not only revolutionary, but also has several advantages, including:

- Reduced Friction and Wear: Due to the absence of contact forces, magnetic bearings have no friction as well as wear. This not only enhances the machinability but also increases the lifespan of the equipment which in turn, minimizes the costs of maintenance and replacement.

- Enhanced Stability and Control: The use of magnetic bearings helps in controlling the location and motion of rotating tools flawlessly. The magnetic forces are variable and can be adjusted instantaneously, making it easier to implement active control for motion in all rotational and load situations.

- Vibration Damping: Let it be known that magnetic bearings are damping devices and do not transmit excessive vibrations to others. This is of particular importance in cases when it is necessary to ensure effective operation without sudden surprises then it is necessary to ensure smooth running when ensuring precise operation, as in the manufacturing industry or delicate instruments in the field of science.

- Maintenance-Free Operation: As there are no contact areas and as the magnetic bearings do not need any oiling, maintenance free operation can be achieved which facilitates reduction in downtime and the expenses incurred with losses.

Magnetic bearings are an admirable form of technology for usage in applications wherein high precision, stability, and efficiency are the norm. Their uniqueness in characteristics makes them well suited for such industries as aerospace, power generation, and advanced manufacturing whereby performance and reliability is of optimal concern.

What Are Rolling Element Bearings and Their Uses?

The text mentioned rolling element bearings, which stand out in the industry. So, as an industry expert, it is worth noting that different types of bearings are used in different industries. For instance, in all other varieties, bearings consist of balls or rollers divided by two rings: inner and outer. They help enhance the efficiency and effectiveness of rotatory movement by reducing the rubbing between the moving parts. Due to such attributes, rolling element bearings are used in numerous items, including but not limited to:

- Automotive: Rolling element bearings represent such parts as a mentioning of vehicle systems along with an engine, a transmission and a wheel assembly allowing for a reliable operation.

- Industrial Machinery: In manufacturing as well as in mining or construction rolling element bearings are the parts of such equipment as heavy machinery and precision instruments ensuring controlled motions of the components.

- Power Generation: Generation facilities use such equipment as turbines and generators which employ rolling element bearings providing high performance indicators.

- Aerospace: Aircraft employ rolling element bearings on flight engines, landing beams and flight control systems allowing the landing gear and other systems to work under various high strain situations.

- Medical Equipment: Imaging equipment and surgical instruments as well as laboratory devices use rolling element bearings to work smoothly and accurately.

- Renewable Energy: Rolling element bearings enable wind turbines and solar panel tracking systems to produce energy and have mechanisms that track it reasonably.

The applications of rolling element bearings are vast, of which some have been presented here. Their adaptability, accuracy and reliability make them vital elements for many industries, enabling the proper operation of machines and equipment in every respect.

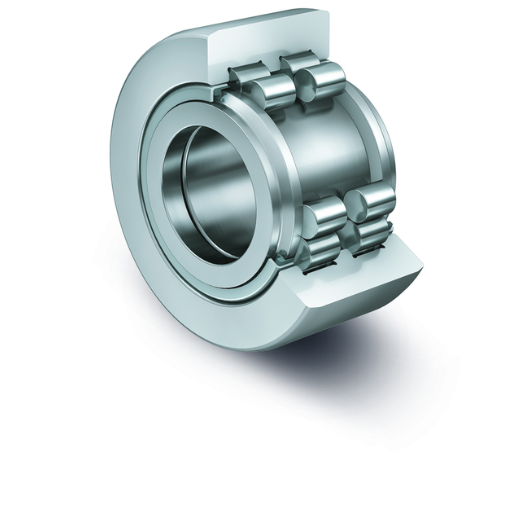

Understanding Cylindrical Roller Bearings

If you work in this field, the knowledge and relevance of cylindrical roller bearings should be understood. These bearings are shaped such that they can take up heavy radial loads and axial loads while spinning at high speeds and with minimal friction. They have rolling elements that are cylindrical in shape and a cage that assists in reasonable distribution of load so that the rolling elements do not come into contact.

Such multi-purpose bearings are widely used in the automotive, aerospace, industrial machinery, and power generation industries. Some of their applications include :

- Automotive Industry: Smooth motion of engine parts, wheel hubs, and transmissions is provided by cylindrical roller bearings.

- Machine Tools: In lathes and milling machines, these bearings are of utmost importance in providing controlled and precise motion to the rotational components.

- Gearboxes:The cylindrical roller bearings are definitely used in gearboxes for load support and load transmission between rotating shafts.

- Pumps and Compressors: These bearings are important for the reliable working of pumps and compressors and for reducing energy wastage.

- Electric Motors: Electric motors make extensive use of cylindrical roller bearings to support and provide low friction while rotating.

The knowledge of the configuration, properties, and applications of cylindrical roller bearings is important for engineers, technicians, and other professionals in all fields since it allows them to pick a bearing best suited for particular purposes and enhance the operation of machines and equipment.

Spherical Roller Bearings in Heavy Load Applications

In dealing with heavy load applications, the choice of heavy duty bearings rests with spherical roller bearings, according to the industry authorities. These bearings have a fundamental design that is configured to translate high-level radial and axial loads – conditions that prevail in high-performance environments. They are constructed with misaligned shafts or deflected shafts in view, thanks to the remarkable engagement of the barrel-shaped rolling elements in their structure. It virtually eliminates heavy friction, which can cause failure to operate effectively. In mining and construction equipment, spherical roller bearings have proven their worth and effectiveness in various demanding applications across steel and paper manufacturing industries. Spherical roller bearings are able to tolerate severe conditions whilst performing efficiently and lasting long. Due to their robustness and ability to tolerate high levels of force while also being able to withstand misalignment, where machinery works in tough situations, the bearings are engineered to perfection, providing vital support in the production processes.

Needle Roller Bearings: Benefits and Applications

I have some expertise in this field, so I would like to discuss the benefits and uses of Needle Roller Bearings. Needle roller bearings are a special type of bearing that uses long cylindrical rollers. Such a design makes it capable of withstanding high radial loads with a very small radial cross-section. Their small size and large load-carrying capacity have made the use of Needle Roller Bearings widespread in different industries and applications where space is a constraint but load capacity is high.

Benefits of Needle Roller Bearings:

- High Load Capacity: Since needle roller bearings can bear very high radial loads this allows them to be used in heavy-duty applications.

- Compact Design: Their small radial dimensions also facilitate compact installations, which are suited for applications where envelope dimensions are restricted.

- Versatility: In addition, Needle Roller Bearings are also available in several configurations – drawn cup, machined raceways and retaining rings, to meet the demands of varying applications.

- High Rigidity: Structural rigidity of the Needle Roller Bearings is ensured through the roller and cage assembly which allows the bearings to be used in high-speed applications.

- Alignment Capability: This self aligning design can translate relative to the rolling elements of the bearing which results in compensating for misaligned shafts or shaft deflection during operation.

Applications of Needle Roller Bearings:

- Automotive Industry: Need roller bearings find application in engines, transmissions, and differentials and are able to withstand rigid performance needs of the automotive industry.

- Industrial Machinery: Machine tools, printing presses, and even textile machinery utilise needle roller bearings which allow smooth functioning of the various industrial equipment.

- Power Transmission: Gearboxes, speed reducers, and belt drives make use of needle roller bearings in transmitting power but at the same time help in reducing friction and energy loss.

- Aerospace: The aerospace sector makes use of needle roller bearings for various applications including but not limited to aircraft engines, landing gear systems and helicopter rotor systems.

To put it simply, Needle Roller Bearings make a great combination of small size, high load capacity and high versatility which makes their usage extremely widespread across multiple branches. Their characteristics of supporting heavy weight, being able to bear some degree of misalignment and having small overall dimensions are crucial for systems that have high requirements for reliability, performance and space saving.

Innovative Bearings for Specialized Needs

let’s explore the innovative and specialized bearings that cater to unique industrial needs. These bearings are designed to address specific challenges and deliver exceptional performance in their respective applications. Here are three types of bearings that have revolutionized the industry:

- Four-Point Contact Ball Bearings:

- Four-Point Contact Ball Bearings have been developed with the purpose of supporting radial and axial loads in one bearing unit. This is accomplished through a specific geometry allowing for four points of contact between the balls and the raceways thereby increasing their load capacity and rigidity. These bearings find application in robotics, industrial machines as well as medical devices that require high accuracy and axial load.

- Linear Bearings for Precision Movements:

- Linear Bearings provide friction-free linear motion and reliable positioning requirements. They can be found in automation, semiconductor manufacture, and CNC machines, among others. Linear Bearings are capable of high load and have low friction which allows smooth and stable movement along a straight line which requires repeatable action.

- Thrust Bearings: Handling Axial Loads Effectively:

- Thrust bearings are used to bear considerable axial forces and provide support for applications that do not require any rotation. On a more specific note, they are used in automotive, heavy engineering, and aerobatics systems. Thrust bearings can be of ball bearings, roller bearings or needle bearings types among others, depending on the load to be supported and the working conditions.

Such novel bearings are part of the upgrade in bearing technologies and provide geared solutions for the various industries. Due to their superior operating characteristics, high reliability and radially and axially the optimization of space and load capacity, they have become essential parts of the modern industrial environment.

Exploring Four-Point Contact Ball Bearings

Considering the vast experiences gathered in the industry, let us now explore the world of Four-Point Contact Ball Bearings. They can be employed in situations where only axial loads or radial loads are required due to their construction. Four-Point Contact Ball Bearings possess raceways that permit four points of contact between the balls and the bearing race which also improves the stability and load distribution of the bearing. In this way, such design enables loads to be rotated in a more efficient manner, thus making the bearings ideal for any form of machinery and equipment that requires movement to be performed rapidly. Four Point Contact Ball Bearings are very common in applications ranging from robotics and medical devices to machine tools where tolerance, angles, and many other aspects are important.

Linear Bearings for Precision Movements

In their profession, a linear bearing truly is the best among the rest when they talk about the best tools for movement. A perfect axial load-carrying device facilitating edge, line ambulance, and broad assistance in various applications successfully witnesses the expected qualitative motion. Their construction is based on the ratios applicable for the flexing and extending of multiple sliders along a single axis. Linear Bearings find their application within the extent of motion control in automation devices, CNC rotary cutting machines, robotic systems, and more. Carrying large loads with long travel distances refracts the outer casing, guaranteeing precision performance in all movements, thus highly demanded in segments requiring performance in exceptional standards level in every orifice across the globe.

Thrust Bearings: Handling Axial Loads Effectively

I appreciate the fact that Thrust Bearings are the final interface when it comes to dealing with axial loads. They are special kinds of bearings made for applications that require the ability to rotate about an axial direction while supporting and transferring significant axial (thrust) loads. Thrust Bearings are designed to transfer axial thrust and to take forces in one direction, thereby making it possible to pass through the axial loads easily. Such elements are relevant for heavy types of machinery, automotive transmission systems, and even aerospace systems where axial loads are of key importance. Due to their rigid structure and outstanding ability to bear loads, Thrust Bearings provide effective and dependable service and now have become a compelling factor for industries that require handling axial loads with accuracy and reliability.

Reference

- Bearing Selection Guide by GMN Bearing USA

- The Best Type of Bearing for Your Application by Emerson Bearing

- How to Choose the Right Bearing for Your Application by IBT Industrial Solutions

Frequently Asked Questions (FAQs)

Q: What is the purpose of bearings in mechanical applications?

A: The purpose of bearings is to reduce friction between moving parts and support the load, ensuring smooth and efficient operation of machinery. Bearings also help in maintaining the correct alignment of components and can handle both radial and axial loads depending on the type of bearing used.

Q: What are plain bearings and how are they used?

A: Plain bearings are a type of bearing that consists of a simple surface without any rolling elements. They are used in applications where high load capacity and low speed are required. Plain bearings have a smaller footprint and are often used in linear or oscillating movements.

Q: How do radial ball bearings differ from other types of ball bearings?

A: Radial ball bearings are designed to support radial loads, which are perpendicular to the bearing axis. They are the most common type of ball bearings due to their versatility and are used in various applications where moderate to high speeds and low to moderate loads are involved.

Q: What are the different types of ball bearings and their applications?

A: There are various types of ball bearings, including angular contact bearings, thrust ball bearings, and radial ball bearings. Angular contact bearings are used for high-speed applications requiring combined radial and axial loads. Thrust ball bearings are designed for axial loads only, while radial ball bearings handle primarily radial loads.

Q: Why are angular contact bearings used in high-speed applications?

A: Angular contact bearings are designed to support both radial and axial loads, making them suitable for high-speed applications. Their construction allows for higher load capacities and greater rigidity, which helps maintain precision and stability at high speeds.

Q: What are thrust roller bearings used for?

A: Thrust roller bearings are specifically designed to handle axial loads, which are parallel to the bearing axis. They are used in applications where high axial load capacity is needed, such as in gearboxes and heavy machinery.

Q: How are various types of bearings categorized?

A: Bearings are categorized based on their design and functionality. They can be divided into rolling bearings, such as ball and roller bearings, and plain bearings. Rolling bearings are further classified depending on their load-bearing direction, such as radial bearings for radial loads and thrust bearings for axial loads.

Q: What considerations should be made when choosing a bearing for an application?

A: When choosing a bearing, consider factors such as load capacity, speed, environment, and alignment requirements. The type of load (radial or axial), available space, and desired lifespan are also critical in selecting the appropriate bearing type.

Q: How do bearings handle both radial and axial loads?

A: Bearings can handle both radial and axial loads depending on their design. For instance, radial ball bearings primarily support radial loads, while angular contact bearings and specific types of roller bearings can accommodate combined radial and axial loads, providing flexibility in various applications.