This manual offers tips on the bearing types as well as their uses in detail. In general, the motion of two rotating components is facilitated by bearings, which also reduce intercoupling friction. The mechanics of bearings, where they are used, and the merit of characteristics of several bearing types would be addressed in this article as well.

We will start from the vast topic of differing designs which encompass ball bearings, roller bearings, and plain bearings as well as the basic function principles of a bearing. We will also mention some bearings too like magnetic bearings and fluid bearing as well as some features and factory uses which are on the high speed precision scale bearings.

If you work in engineering or you are an ordinary person who is wondering what and why bearings are interesting, this article will explain the variety of bearing types, their purpose, and areas of application. Come with us and enjoy this lively trip around the bearings and their variety of applications and understand how to make the right decisions in terms of the selection of the relevant type of bearing used in your particular case. Let us understand the scope of work!

What is a Bearing, and How Does it Work?

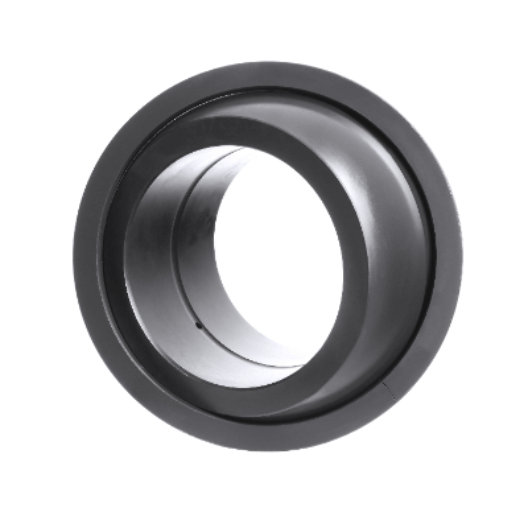

We all suspect that you have an interest in bearings and what role they perform in a moving machine. The bearing is a machine element that allows motion in one direction or rotation, which diminishes friction of contact between moving elements. It comprises two major parts: an outer, also known as the outer ring, and an inner, also known as the inner ring. Cyclonic objects are called rolling elements positioned within them to enable movement. The purpose of the rolling elements, spacer, is to surround and bear the inner ring and inner ring, allowing the two parts to turn or move almost freely in respect to one another. The distribution of load around the bearing occurs with respect to the rolling masses whereby, enabling the restriction of any relative motion between the rigid elements and thereby making movement possible in any application. This could be the case with the wheel of a car, the drive system of a conveyor, or a perfect working turbine. Hardly modern technologies need to be imagined that would not use the phenomenon of bearing, which makes it possible to rotate the machines easily and exactly and reduces their destruction.

Purpose of Bearings

Bearings have vast applications; hence, it’s important to know what bearings are. The motion of bearings, in the simplest terms, can be defined as a means of reducing friction and distributing load over rolling elements so as to render controlled motion. They are built to permit the rotation or relative movement of two parts against each other with the least amount of effort so as to reduce the chances of parts being damaged while in motion. From the wheels in cars to conveyor belts, from turbines to industrial machines, bearings are used across many industries to enable movement and enhance the performance of ‘machines.’ Their high load-bearing capacity, friction reduction properties, and provision of stability make them key parts in achieving motion in any mechanical system in an efficient and dependable manner.

Basic Principles of Bearing Operation

Conversely, there are some fundamental principles of the operation of bearings that are essential to know. The basic function of bearings is the reduction of relative motion, and they provide the means for smooth and accurate motion. In such a way, they provide provisions to carry and transfer the load and help all the parts of diverse mechanical systems to work normally. Let us examine the mechanical fundamentals of bearings and how they are important in bearing industries.

To begin with, bearings work on the principle of rolling or sliding motion to overcome friction and improve efficiency. This is accomplished by rolling elements that include balls or rollers that are contained inside a raceway. These rolling elements are introduced to separate the two surfaces that come into contact, thereby reducing the frictional forces when the two surfaces move against each other. This reduces energy loss and minimizes the high consumption from rotating parts and the wear resulting from the rubbing contacts between parts.

Also, bearings are working based on the load distribution principles. They can be designed to carry or a load by dispersing the rolling elements and the raceway to the breaking surface to make certain that the load is contained and to avoid local tensile stresses. This capacity to bear load and distribute it, it allows the bearings to be able to bear huge loads or torque without moving or turning even in adverse operating conditions.

Recognizing how bearings function, including their limitations, allows us to value their significance in motion in various mechanical systems. In the auto industry, in manufacturing plants, tuna furniture and so on – bearings are the important relatively cheap elements, which contribute to the enhancement of performance and controlled movement.

Common Applications of Bearings

In this document, I would like to outline the most common uses of bearings around the world. To emphasize their importance, let’s also take into consideration the fact that there are numerous other mechanical systems where bearings are taken as being fundamental devices. Here are some key industries and applications where bearings play a crucial role:

- Automotive Industry: Bearings play a crucial part in a wide variety of vehicles, engines, transmission systems wheels and suspension systems. Bearings enable perfect roll friction surfaces and assist in boosting performance and increasing fuel economy.

- Manufacturing Plants: Bearing are one of the elements in the industry which is used for in machines such as conveyor systems, pumps motors and generators. These components allow machine builders to perfect and smooth engine movements thereby improving the productivity of the machines’ operations.

- Aerospace and Defense: Depends on a more stable and reliable functioning of bearings which are used in harsh conditions and high stress in aircraft engines, landing gear, control systems and the guidance system of missiles.

- Power Generation: Generators, wind turbines and turbines are incorporated with bearings that assist in the swift rotation of motors increasing power generation and efficiency. Bearing are well integrated in machines that are under stringent loads ensuring dependability.

- Household Appliances: Various devices that include refrigerators, washing machines, fans and air conditioners utilize bearings. This enables the device to function quietly and without hindrance, improving the experience for the user.

- Medical Devices: Motion control is provided in numerous medical tasks such as patient beds, tools for surgery, and imaging machines using bearings. This provides motion and control in the recommended position, ensuring the required precision in medical applications.

These are merely a few illustrations of the various fields in which bearings are utilized. The diverse input in the various lines of industries espousal their significance for the accomplishment of efficient and dependable motion in the numerous mechanical systems.

Exploring Ball Bearings and Their Uses

I can’t say how many times ball bearings came to life because they have made a transition from easy components to components, which now play a central role across numerous engineering segments. As an industry expert with years of experience in the field, I am excited to explore the evolution of ball bearings and their application along with you. It would be fair to mention that it was the only means by which economies were able to achieve better performance and precision in ineffective work.

They allow for rotation to occur between two parts while minimizing friction by utilizing small spheres – this is the definition of a ball bearing. They are intelligent components because they provide masses of advantages compared to other types of components.

We will begin by defining relevant terms, for instance, the distinguishing features of ball bearings and perhaps mentioning their application across various sectors using diverse types of ball bearings. Further on, we will explain how roller bearings work, and detail the properties and applications of plain bearings. And lastly, we will make some notes on some nonstandard and their application in the industry.

Stay focused because more detailed information concerning the design workings, as well as the usage of ball bearings, has been left for later in the article. Let’s begin with an examination of how large the factors of intimidation behind other fascinating elements of the ball bearings.

Types of Ball Bearings

Taking expertise into consideration, let’s begin by looking into the different types of ball bearings that are present. Ball bearings are mechanical assemblies that facilitate the reduction of friction in the motion or spinning of an object or material. They have an outer ring, inner ring, and balls, and they are used to facilitate even spacing of the balls. Locking mechanisms prevent one ball from touching its neighbors. Below are several types of ball bearings:

- Deep Groove Ball Bearings: These ball bearings are of the most common applications. They have a design that incorporates a wide, deep groove that enables the bearing to take radial and also axial stresses. Due to their design, the ball deep groove bearings can be used in electric motors, automotive components, and domestic electronics among others.

- Angular Contact Ball Bearings: The design of these bearings allows them to sustain radial and axial forces at the same time. They have contact angles which enable them take much axial loads than deep groove ball bearings. They are mostly used where high speeds with accuracy are required and such applications include machine tools, pumps and gearbox applications.

- Thrust Ball Bearings: These are intended to allow for axial loading in a single direction. Comprising two washers, a set of balls, and a cage, which holds the balls in place, these bearings are made to suit a specific design. Automotive, industrial, and other machinery, which fit into the categories, are the most common areas where these bearings are found.

- Self-Aligning Ball Bearings: Self aligning ball bearings do not need to be concentric with the housing’s axis and those of the shaft making them perfectly suited for operations as they do not require very strict alignment of parts. Conveyor systems, farming machinery and other applications where shaft inequality or deflection is common are common places where this bearing is used.

Every ball bearing variety has its own particular features, usage, and benefits. You are able to understand those essential distinctions and therefore select the best ball bearing which fits your particular requirements and subsequently the machine or equipment usage is flawless.

Advantages of Using Ball Bearings

let’s discuss the ball for bearing advantages. There are numerous benefits offered by balls which is why they are widely used in many applications:

- Reduced Friction: These bearings are constructed in a manner that minimises the friction encountered between the moving sections which promotes the enhanced efficiency and the effectiveness of the equipment and the machines. This means saving energy and increasing efficiency and performance while also reducing damage and destruction.

- High Load Capacity: Even though ball bearings are tiny, they possess a wonderful ability to load. They can take both axial and radial loads and having such loads positioned equally to the bearing facilitates the pbulb to be in good working condition for an extended period.

- Low Noise and Vibration: One interesting aspect of the ball bearings is that they do their work with low levels of noise and also vibratings which makes the environment less hostile. This makes them best suited for places where a minimised sound impacts the working process like automotive engines and precision machinery.

- Versatility and Availability: Their construction includes numerous forms, sizes and materials which puts them in a position to be suitable for a lot of applications. With such ubiquity in the market distribution range, they can also be easily sourced from the market and replaced when needed.

- Cost-Effective Solution: These ball bearings are cheap throughout their life as they are durable and do not wear out easily. Furthermore, they do not necessitate considerable repairs, which reduces repair and replacement costs and the cost of downtime.

It is possible to increase the productivity in a field of work by improving the performance, efficiency and reliability of machines and equipment when using ball bearings which support these characteristics.

Where Ball Bearings Are Used

ball bearings are used in most industries that incorporate rotational movement and need accuracy. Here is a list of industries that use ball bearings very frequently:

- Automotive Industry: To say that automotive applications do not need ball bearings would be stretching the truth. Ball bearings do find their application in automotive systems such as the engine, transmission, wheel hub and steering assembly. Ball bearing usage enables the transfer in motion of the energy from one part to another in a vehicle driving system. Furthermore, utilization of ball bearings minimizes the friction forces which’s very beneficial since it increases the vehicle overall efficiency and safety as well.

- Industrial Machinery: One can boldly say that the significance of ball bearings is felt in almost all industrial applications as they find their use in almost any machinery. They can be mass pumps, compressors, motors, conveyors, lathes or machine tools. Rotating components, heavy loads and delicate motions are controlled by ball bearing displacement.

- Aerospace and Aviation: It would be fair to say that the aerospace segment is probably the one industry where ball bearings rule the roost. They are required for aircraft engines, landing gears, control surfaces, and a myriad of equipment installed on board. Bearings are also known to enhance the performance of an aircraft, making it safer to operate.

- Power Generation: Ball bearings are applied in power generation facilities such as turbines, generators, and wind turbines, although the latter has two types. One is the axial flux synchronous type that employs the use of ball bearings, while the other is the geared type. In all these applications, ball bearings are used because they allow relatively smooth rotary motion and provide the essential load ratings that allow the transfer of forms of energy into electrical energy.

- Medical and Dental Equipment: Ball bearings are used in medicine and dentistry, including micromotor drives, surgical instruments, imaging devices, dental drills, and prosthetics. These applications further enhance seamless interactions, making complex procedures easier.

- Electronic and Semiconductor Manufacturing: Ball bearings work in the electronic and semiconductor manufacturing processes where accuracy and consistency are required. They are used in devices like robotics, wafer loaders, and assembly apparatus.

Certainly, there are many more illustrations of an array of industrial sectors that utilize ball bearings. Their broad applicability, structural reliability, and operational efficiency ensure their importance in the smooth functioning and achievement of different industries.

How Do Roller Bearings Differ from Other Types?

In order to better understand the roller type of bearing, one needs to see the basic differences between roller bearings and other types of bearings. In contrast to other types of bearings, roller bearings contain cylindrical or tapered rolling elements as opposed to balls, as the name suggests. This characteristic provides a number of benefits. The first one is that roller bearings have a larger area of contact, which means they are able to bear greater load and radial forces. The second is that their geometry allows them to absorb alignment and axial loads more efficiently. Lastly, compared to ball bearings, roller bearings are characterized by higher stiffness and lower friction, which leads to better efficiency and durability. These qualities make roller bearings especially applicable in areas where heavy equipment, such as automotive construction and industrial equipment, are used. By selecting the appropriate bearing type for application conditions, engineers and other professionals in the industry can achieve excellent performance and reliability in their applications.

Understanding Roller Bearings

For engineers and other industry-related persons, a complete understanding of roller bearings is crucial. In the simplest terms, roller bearings are mechanical parts that allow relative movement between two or more surfaces with minimal friction. They have cylindrical or tapered rolling elements that can bear load evenly across them and, therefore, are stronger and more efficient. Because of these features, roller bearings are specially designed to withstand stress when applied to heavy machinery in automotive, construction, industrial equipment, etc.

Compared to ball bearings, roller bearings offer higher stiffness and load-carrying capacity, making them well-suited for harsh environments with high loads. Different types of roller bearings can be employed for different tasks so the engineers are able to achieve the desired performance in their applications. In the next sections, we will discuss the different types and classifications of roller bearings, the applications of roller bearings, and other specialized bearings so that you will have a complete picture of how to select the required bearing.

Applications of Roller Bearings

Let’s take a look and consider the few selected applications of roller bearings, which were in great demand during our deepest transformations. These strong and multi-purpose elements have broad usage in many branches of industry as well as in arduous conditions. Presented are some of the principal applications of roller bearings:

- Automotive Industry: Among the significant components are the wheel bearings, transmission systems and various engine components, which require the use of roller bearings. They are dependable in providing a rotational function while also cutting down on friction.

- Industrial Machinery: Heavy machineries up to small precision instruments make use of roller bearings in their industrial applications. These are also used in conveyor belts, construction equipment, machine tools, and manufacturing machinery, where heavy loads are being transferred allowing movement.

- Aerospace and Aviation: As aircraft engines, landing gears and many more systems require them, there is an evident necessity of roller bearings in this industry. They are efficient to use as they can endure heavy weight, are very durable and the extremity does not affect the precision.

- Railways and Transportation: Focusing on the rail system, roller bearings are utilized in the railway wheel axle and even the remote system, which makes them vital. Additionally, they work to manage friction and assist in the smooth functioning of trains and other rail systems.

- Renewable Energy:Punching in a key role in a wind turbine and a solar power system are the roller bearings making it possible for rotating systems to work. Especially in harsh environments, they work by reducing friction ensuring the turbine works efficiently and the energy produced is maximized.

- Heavy Equipment and Mining: Roller bearings are crucial components in heavy machinery that support mining, construction, and material handling. They bear heavy loads and impact and vibration and thereby, are able to deliver dependable service performance even in harsh working conditions.

These are just a few examples of manifold applications where roller bearings provide essential support and reliable motion. Their versatility, durability, and efficiency make them indispensable components in a wide range of industries, contributing to enhanced performance, productivity, and longevity of various machines and systems.

Types of Roller Bearings

let us explore the diversity of roller bearings and their uses for better comprehension. Roller bearings are manufactured in various patterns which offer varying properties and benefits. The following are some of the most commonly used types:

- Cylindrical Roller Bearings: These bearings feature cylindrical rollers and provide high radial load carrying and moderate thrust load carrying. These types of bearings are used on machine tools, electric motors, gearboxes etc.

- Tapered Roller Bearings: These bearings can carry radial and axial loads because of their shape; they are tapered with one face angled downward. These bearings are widely used in automotive applications in wheel hubs, transmission and the differential gear.

- Spherical Roller Bearings: These are cylindrical roller bearings with barrel-shaped rollers that can take heavy radial loads and angular misalignment. Bearings of this nature are used in mining equipment, paper mills, crushers and many more.

- Needle Roller Bearings: Needle roller bearings are composed of thin and elongated cylindrical rollers. They have great radial load resistance and are applied in places with small openings, such as the interior of automotive transmissions and industrial machines.

- Thrust Roller Bearings: Thrust roller bearings consist of rolling elements in the form of cylindrical or tapered rollers and are meant for axial loads only. They are applied in automotive transmissions, crane hooks, and heavy equipment, among other places.

Once engineers and designers comprehend the various types of roller bearings, they are then able to make informed decisions on which bearing is most suited for a particular application thus ensuring efficiency and reliability of the bearing selected.

What Are Plain Bearings and When Are They Used?

as I believe the topic and recommendation will go more to mechanics of bearing and of components for the generation of Wybr step sideways in contrast to the linear motion system used by Kinetic. As an expert in the industry, it would be better to check how you define bare bushes and bush bearings as three ways of saying they appear seamless. Without friction, these bearings may be made from self-lubricated bronze or plastic, and they bear uniform loads during sliding or rotational motion. Commonly, you will only use these bushes when particular applications indicate either limited space, high loads, or low operational and/or noise levels. Automotive parts, industrial equipment, household appliances, and aerospace and defense components often use similar elements. Applications for plain bearings are diverse, durable, and economical, so they are widely used in many fields.

Characteristics of Plain Bearings

let us explore the features of plain bearings that make them a fundamental element in many applications:

- Versatility: There are different operational conditions in which these mechanical components can be used and this ranges from low speeds and high loads usages – plain bearings are quite versatile meaning performing as expected in tough conditions. These mechanical components are also radial and axial in nature hence can accommodate various workings of machinery and equipment.

- Durability: These bearings are made for high use and abuse. They can withstand very high temperature, can be exposed to corrosion or wear and tear – plain bearings are dependable and durable.

- Cost-effectiveness: Given how simple the structure of plain bearings and its installation process is, plain bearings are a low cost measure. The maintenance required is almost non-existent, and the cost is significantly lower than bearings.

- Low Friction: Any movement performed by these bearings is easy and such any operation is effective with low resistance. The presence of minimal resistance helps in saving power and reduces the heat which is even beneficial to the overall performance.

- Noise Reduction: For their quiet performance, they are used in applications where noise is an important consideration such as medical equipment or household appliances – known as plain bearings, offer a quiet working environment.

With a grasp of the bearing with no rolling elements bearings which are mandatorily self lubing, engineers and designers are able to select a bearing that will perfectly fit the application requirements likely to be encountered.

Advantages and Disadvantages of Plain Bearings

Hoy en dia en mucho de las aplicaciones Plain bearings son la opción más utilizada son muchos los beneficios que estas brindan. De todas formas, hay que acordarse de las desventajas también. A continuación una visión global:

Advantages:

- Simplicity and Cost-effectiveness: Plain bearings do not have a complicated structure. They have fewer components in comparison to other bearing types. That is what allows plain bearings to be produced or maintained at a lower cost.

- High Load Capacity: Plain bearings are able to withstand massive amounts of weight and can cover the load’s weight over a relevantly larger contact area. This property makes them appropriate for applications that require heavy-duty work.

- Low Friction Operation: Plain bushings are said to have low-friction devices and thus promote saving energy and generating low amounts of heat. This allows better performance and efficiency.

- Noise Reduction: An attribute of plain bearings is that they are silent in operation, which makes it applicable to those applications where noise production is undesired, such as medical devices or household machines.

Disadvantages:

- Lubrication and Maintenance: For plain bearings, it is important to have the necessary lubrication to reduce friction and wear as much as possible. Appropriate regular maintenance and inspection help achieve efficient performance and increase the bearing service life.

- Limited Speed Capability: Considered among the simpler types of bearings, plain bearings are generally characterized by low rotational speed capabilities which partly limits their use for high speed applications.

- Potential for Wear and Clearance: As time passes, plain bearing surfaces fitted to shafts may wear and exhibit a degree of clearance when the two bearing surfaces are fitted together. This causes certain applications to become less accurate and increases vibration levels.

A clear knowledge of the merits as well as demerits of plain bearings helps engineers and designers to choose the correct bearing solution for the given problem.

Typical Uses of Plain Bearings

It is quite evident that plain bearings are employed for a wide variety of tasks, considering their industry expert experience. Some of the areas where plain bearings perform exceptionally are discussed:

- Automotive Industry: Sleeves or cylindrical shell are employed in multi-purpose automotive components such as suspension system, engine and drivetrain parts. Such critical components provide support and motion within mechanisms in order to enhance vehicle performance and safety.

- Industrial Machinery: In heavy machinery and equipment, plain bearings also find application in rotary or sliding motion found in conveyor systems, pumps and agricultural machinery. Their ability to carry heavy loads under pressure makes them functional in harsh industrial settings.

- Home Appliances: Mild or medium duty plain bearings are found in several household gadgets such as washers and spin dryers, refrigerators and fans. They help control friction and facilitate motion while quietening the appliance ensuring smooth operations.

- Power Generation: Wind, hydroelectric and thermal power plants all make use of plain bearings in their generation of electricity. Their application allows rotation without clamping and in rotating equipment, components are restricted which further assists with smooth electric work generation.

- Aerospace and Defense: Reliability and Precision are critical performance attributes of the plain bearings which are used in aerospace and cabinet defence applications. They are mostly used in gear systems, control surfaces and engine components where smooth operation and strength of structure is required.

Apart from a few, these are the other instances where plain bearings have been used. Their application is in the manufacturing of other goods. Their adaptability and dependability render them essential in many sectors, where it is essential that they are able to bear considerable weight, withstand wear and tear, and enable ease of movement.

Specialized Bearing Types and Their Industrial Applications

Since we are on the subject, let us turn now to some specific types of bearing as experts in the field. Such bearings are produced with specific features and capabilities to suit a particular need in a particular industry. To mention but a few:

Magnetic bearings are a special type of bearings that do not have physical contact between the rotating parts and their bearing surfaces. Instead, they employ magnetic force to levitate and support the rotating machinery. Such bearings are used in high-speed machines, for instance, in turbines, turbochargers, and centrifugal compressors. It has the disadvantage of having lower friction loss and friction, which enhances the operational characteristics.

Fluid bearings support rotating shafts by means of fluid films, lubricants or gas, and are used in precision equipment such as machine tools, semiconductors, and scientific instruments. Thus, one of the major applications for such type of bearings is in machinery which operates within the high tolerances. Fluid bearings have ultra low friction, high precision, and also a very strong vibration damping property.

High-Speed and Precision Bearings

The specialty of high-speed and precision bearings is their ability to work under extreme conditions such as very high rotary speed and close tolerances. These bearings are used in industries such as aerospace, automotive, and medical devices where performance involves a lot of precision, accuracy and smooth operation. They enable accurate control and reduction of friction as well as stabilization even under high speed applications.

These special kinds of bearings are only some of the many bearing types that can be useful in various industrial applications. The choice of bearing designs is dependent on the load and stress levels the bearings must work with, the working environment, and other requirements such as speed. Knowledge of these parameters and the selection of the right bearing type for each application is fundamental in the quest for standards in performance, durability, and reliability.

On the other hand, as society evolves, the trends in bearing technology change as well, for instance, integrating advanced sensor systems into structural components or developing safer, more energy efficient bearings. The introduction of these trends will rely on industrial strategies that will further improve bearing designs.

Exploring Magnetic Bearings

Let us begin with magnetic bearings, which I deem an interesting section on bearing technology. Magnetic bearings are designed to hold and stabilize a rotating shaft by means of a magnetic field through magnetic bearings without actual contact. This outstanding structure has several benefits, such as lower friction, wear and tear, and increased accuracy. Owing to such features, magnetic bearings can also operate at very high speeds due to the application of electromagnetic forces, making them ideal for high-speed and high-precision applications. Moreover, since there is no physical contact, there is no requirement for lubrication, thereby further reducing maintenance and improving reliability. In the subsequent aspects, we will analyze the working of magnetic bearings, the application and the advantages to appreciate the ingenuity and the scope of application that these innovations bring to different industries. I would like to welcome you to the world of magnetic bearing technology.

Understanding Fluid Bearings

Bearing concepts are not complete without fluid bearings, and the following will combine the followers’ knowledge with the experienced team as an industry expert. Fluid bearings are used to support rotating and stationary bodies and reduce friction between them. They are usually developed in oil or air. Fluid bearings have many benefits in comparison to classical mechanical bearings, and among them, these are the main ones: High load-bearing capability, Low noise and vibration, and High reliability. Using principles of fluid dynamics, they operate particularly well in high-speed and precision environments that require smooth movement. In the next chapters, fluid bearings will be outlined in detail, describing their creation, operation, functions, and applications. Join us in a fluid-bearing technology perspective, and inspiration will come from the new horizon.

High-Speed and Precision Bearings

while engineering a suitable bearing type for high-speed and high-precision applications, there are several factors that have to be considered. These factors purely depend on the particular needs of your application. For a better understanding, here are a few useful tips:

- Load Capacity and Speed: First, establish parameters for load capacity and rotational speed for the load technical document. The versatility of bearing types allows the entire range of loads and speeds to be covered. Assess factors like dynamic load which is the one in motion, static load which is the one at rest, and the required RPM (rotation for every sixty seconds) for perfect locking.

- Friction and Heat Generation: Understand how friction and heat generation optimize performance of the different drawings bearing. Precision and high-speed operations require very low heat dissipation since too much heat contributes to overheating that causes wear.

- Precision and Tolerance: What is the precision that is necessary for your application? Application of contact ball bearings; Application of angular or centrically propelled contact ball bearings; Higher precision as well as close tolerance enables applications to obtain higher accuracy.

- Lubrication and Maintenance: What type of lubrication or redress does the bearings require? Some bearings in certain applications may need occasional or continual lubrication for effective operation.

These factors need to be taken into account while selecting the bearing type for your application. By knowing the particular requirements during your high-speed and precision application, one can choose the proper type of bearing for maximum performance, reliability, and efficiency. As we look to the future, we will examine the trends that are expected to influence the bearing industry very optimistically.

Choosing the Right Bearing Type for Your Needs

Bearing in mind the nature of our activity, we give a quick response to what most people would consider to be a rather difficult question which is how to choose the most appropriate bearing type for the given application. Choosing an appropriate bearing is never an easy task, as there are many aspects that can fundamentally affect its performance, reliability, or even efficiency. Let us now look at some of the factors that will make it more comfortable for you to make a decision:

- Load Capacity and Speed Requirements:

- Study the load capacities and speed requirements that fit your needs. It is also necessary to know that the different types of bearing can accommodate different amounts of load and speed, so adapters should be chosen that are relevant to the application._

- Environmental Conditions:

- Evaluate the environment in which the bearing is going to be used. Dust, chemicals, temperature, and humidity could affect the performance and service life of the bearings. Select a bearing which is suitable to overcome the environmental situations it has to face.

- Precision and Accuracy:

- Identify what degree of precision and accuracy ought to be set for the application. Certain type of bearings offers angular contact ball bearings and cylindrical roller bearings which have the most precision and tightest tolerances which would be suitable for use in instances where accuracy is very important.

- Lubrication and Maintenance:

- Bearings have been categorized based on lubrication needs as well as maintenance perspectives. If left unchecked, some bearings may need a slew of services including lubrication from time to time in order to provide maximum reliability as well as lifetime.

A detailed analysis of these criteria, along with the selection of the suitable bearing type for application needs, translates into maximum performance, dependability, and effectiveness. Follow along as we venture into bearing technology trends that will revolutionize the industry in the future.

Factors to Consider When Selecting a Bearing

there are numerous factors that need to be taken into account before deciding to use a certain bearing in your application:

- Load Capacity and Durability:

- Asses the required load capacity and durability of your application. Different types of bearings support different loads and conditions of operation. Also, make sure that the bearing you have prepared can sustain the considered load and can be abused for a long time.

- Operating Speed:

- For your application to function effectively, attention must be paid to the necessary working speed. On the other hand, deep groove ball bearings or tapered roller bearings with lower heat losses and higher speed suitability are used on high-speed applications, for example automotive or aerospace.

- Environmental Conditions:

- Evaluate the conditions under which the bearing will operate. Thus, conditions like a specific temperature coupled with humidity levels and contact with chemicals can lead to detrimental effects on the functionality as well as the lifespan of the bearing. Opt for a bearing which is built for the specific absorptive conditions in your application.

- Cost and Availability:

- Focus on the price and availability of the bearing. Bear in mind the cost of installation plus the eventual cost of repairs and the cost of shifting the equipment. Furthermore, ensure that the bearing selected is commercially available from the reputed stockists to reduce idle time.

All in all, attending to these issues will help you make an appropriate selection of bearings that are sufficient for your application in every aspect, functionality, reliability, and effectiveness of the system.

Matching Bearing Type to Application

there are specific considerations that you must bear in mind when selecting a bearing type in order to place it into any application and ensure that the application achieves satisfactory performance levels, reliability, and efficiency. In matching the bearing type to the specific application, the following considerations will be of aid:

- Load and Speed Requirements:Determine the load capacity and speed requirements of your application. Different types of bearings may support radial, axial loads or both. Check the load and speed limitations of the bearing and select a type which supports the expected load and speed requirements.

- Operating Conditions:Make sure to assess the operational characteristics of your application as they include temperature, humidity as well as contamination factors. Some bearing types tolerate quite well high temperature environments while other are good for corrosive and eroding conditions. Consider using a bearing that is compatible with the particular operating environment of your application for durability and better performance.

- Precision and Rigidity:Evaluate the type of tolerances and stiffness that are relevant for your application. For instance, bearings are generally categorized by the degree of precision required in their manufacturing. If the application is to be precise with little deformation, choose an appropriate bearing type which meets that requirement in terms of accuracy and stiffness.

- Lubrication Requirements:PVC, polyamide, and PTFE facings are all self-lubricating, which means that they don’t require additional lubrication, but if it is required, which facing performs best in the bearing? Some bearing types, such as pry or fuel pin, have complex internal geometry and low clearance that makes them quite error-susceptible elements – hence, they require future overhaul and predictable measures to sustain; however, they are compensated by less operational friction. It is advisable to select the rolling bearing type which bears in mind your maintenance skills as well as the type of lubrication.

Taking these considerations into account and getting in touch with bearing specialists, you will be able to choose the correct bearing solution for your application in respect of functioning conditions and maintenance requirements.

Future Trends in Bearing Technology

Considering their significant role in numerous industries, the development of bearing technology should evolve into an era of limitless potential. Bearing technology never ceases to progress, which in turn impacts multiple sectors and improves their effectiveness and reliability. Some exciting trends expected for the future are as follows:

- Smart Bearings:With the embedding of sensors and wireless connections in the bearings, it is now possible to track and view useful values like temperature, vibration, and load. Such information makes it possible to use predictive maintenance methods aimed at performance improvement and minimizing downtimes.

- Advanced Materials:The bearings weight can be reduced by using more innovative materials. Such materials include ceramics and hybrid bearings that can withstand extreme conditions including temperature and corrosion which ultimately lead to an improvement of performance in the most difficult environments.

- Miniaturization: In view of the advances made in the miniaturization technology, bearing technology will need to advance in order to meet the challenges presented by the increasing need for smaller and lighter devices. Miniature and micro bearings can enable precise motion control of a compact system and can be used in endless applications especially in the fields of robotics, electronics and medical devices.

- Energy Efficiency: Bearing technology is also helping in the quest for energy efficiency. Updates on low friction coating and washing systems along with improved configuration are working towards reduction in the amount of energy required and hence improving how eco-friendly the operations are.

- Industry 4.0 Integration: The Internet of Things will make it possible for remote management of bearings which will include monitoring as well as, diagnostics and preventive maintenance as future advancements are further integrated into automation and robots combined with data analysis.

This is just a fragment of what the bearing technology will look like in future. Bearing systems modelling and research have recorded stunning progress, and bearingism has more dynamic transformations in store which will create new industries and enhance erasures and relations. Pending further future events in the field of bearings, remain active.

Reference

- JVN Bearings: Types of Bearings and Their Applications

- Factory: Types of Bearings | Uses & Working Mechanisms Explained

- Lily Bearing: Technology & Technical Data Information

Frequently Asked Questions (FAQs)

Q: What are the two major types of bearings?

A: Bearings can be divided into two major types: ball bearings and roller bearings. Ball bearings provide smooth rotation and are widely used in applications where lower friction is required. Roller bearings include cylindrical, tapered, and needle designs, which are used for heavier load applications.

Q: What is a thrust bearing, and where is it used?

A: A thrust bearing is a special type of bearing designed to handle axial loads along the bearing axis. These bearings are usually found in automotive applications, turbines, and machinery where axial force is significant. They include both thrust ball bearings and roller thrust bearings.

Q: How does a tapered roller bearing work?

A: Tapered roller bearings are designed to handle both radial and axial loads. The rolling elements are shaped like a cone, allowing them to manage complex loads effectively. These bearings are widely used in automotive wheel hubs and other machinery requiring high load capacities.

Q: What are the applications of cylindrical roller bearings?

A: Cylindrical roller bearings are used in applications where space and bearing rigidity are important. They are ideal for heavy radial loads and are often found in electric motors, pumps, and gearboxes due to their ability to handle high-speed operations.

Q: What makes an angular contact ball bearing unique?

A: Angular contact ball bearings are unique because they can withstand both radial and axial loads simultaneously. The angle of contact allows for greater support of axial forces, making them suitable for applications like machine tool spindles and high-speed engines.

Q: Why are needle bearings preferred in specific applications?

A: Needle bearings are preferred in applications where space constraints are a concern. They have a high length-to-diameter ratio, providing high load-carrying capacities in a compact design. These bearings are commonly used in automotive components and gearboxes.

Q: What is the difference between deep groove ball bearings and other ball bearings?

A: Deep groove ball bearings are the simplest type of bearing and are designed to handle both radial and axial loads. They have a deep raceway groove, allowing for higher load capacities and improved performance. These bearings are one of the most common types and are used in various applications, from appliances to conveyor systems.

Q: How do roller thrust bearings differ from other thrust bearings?

A: Roller thrust bearings differ from other thrust bearings in that they use rolling elements instead of balls. This design allows them to handle larger axial loads and provide greater bearing rigidity, making them suitable for heavy-duty applications like cranes and excavators.

Q: What are passive magnetic bearings, and how do they work?

A: Passive magnetic bearings are a type of bearing that uses magnetic forces to support loads without physical contact. This reduces friction and wear, making them ideal for high-speed applications such as flywheels and energy storage systems. They are distinguished by their ability to function without the need for lubrication, increasing efficiency and lifespan.