Bearings can be considered as the cardiovascular system of numerous machines and components in the world. In addition, they are present in almost every moving part of machines. These include automotive industries as well as in the aerospace sector, bearings are among the essential components of these industries as they boost energy efficiency, reliability and accuracy. The goal of this article is to provide readers with information about the main purposes of bearings, their various classes, and the industries in which they are most widely used. These considerations are necessary because I want the readers to appreciate the role of bearings in ensuring the smooth functioning of machines as well as their importance in the modern industrial world.

What are the main types of bearings used in industrial applications?

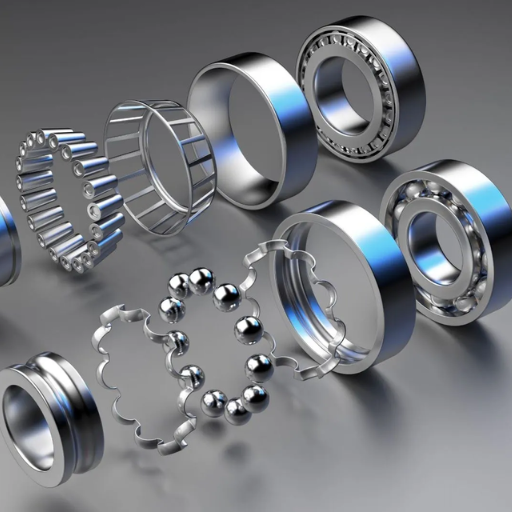

The principal types of bearings mainly employed in the industry are ball bearings, roller bearings, thrust bearings, and plain bearings. With ball bearings, their versatility is? They are admirable since they can withstand both radial and axial loads. Various types of roller bearings, such as cylindrical roller, spherical and tapered roller, are suitable for heavy-duty operations as they have high load-carrying capacity. Thrust bearings of single row and multiple rows are used in automobiles as well as for aerospace purposes, and they only require a lot of attention on axial loads. Finally, plain bearings are suitable for linear motion applications, and performance is achieved without rolling elements, therefore maintaining a relatively low requirement for upkeep. Each type meets particular operational requirements resulting in operational efficiency and longevity in use.

Understanding ball bearings and their uses

To better comprehend ball bearings and their functions, I refer to my years of experience in the previous industry to understand their place in mechanics. In fact, ball bearings are designed for the purpose of load support, both radial and axial load, while at the same time reducing friction, thus allowing a number of motions to be performed smoothly and efficiently. They have performed marvelously for me in industrial machines, household appliances, as well as bicycles and fans. Their practicality makes them effective and choosing the right one, whether single-row, double-row, or custom can also improve efficiency and reliability in any operation.

Exploring roller bearings: Cylindrical, tapered, and spherical

Cylindrical roller bearings are well suited for high-speed uses and can carry large radial loads, thus they are suitable for electric motors and gear boxes. Tapered roller bearings, on the other hand, are used to support radial as well as axial loads, preferably in automobile hubs and heavy machines that demand precision and strength. Spherical roller bearings are particularly good at accommodating misalignment and heavy loads, which makes them favorable for use in loading mining and construction industries. Each type has its own target area thereby ensuring effective use depending on the exact requirements of the task.

The role of needle roller bearings in compact designs

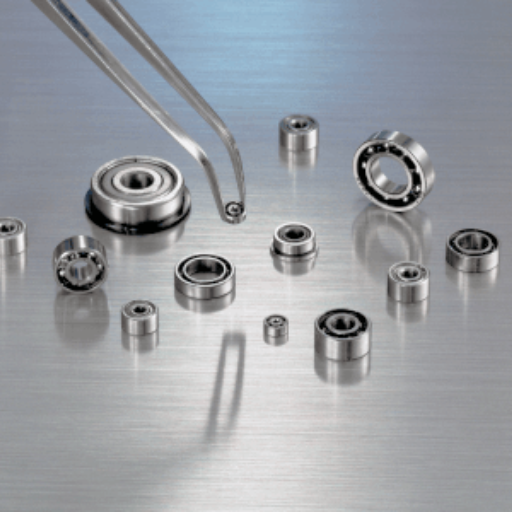

low cross-section and high load-carrying capacities are the properties that make needle roller bearings valuable; There’s no other bearing like it on the market. I’ve often used them in places where space is limited, for example, transmission systems in automobiles or in power tools where both efficiency and reliability are unquestionable designs. Their low cross-section is accomplished by means of using thin-walled enclosures and elongated rollers, which are efficient in load distribution, thus reducing friction and increasing service life expectancy. These bearings are a clear manifestation of the advances aimed at providing high performance while being smaller and smaller.

How do different bearing types support various industrial loads?

Through my exposure to industrial engineering, I have learned that bearing type selection is based on the application domain and is of great importance. As an example, ball bearings are ideal for applications with low to medium axial and radial loads since they operate efficiently at high speeds with reduced friction. However, for cases involving heavy radial loads, roller bearings are more suited due to the larger contact area. Additionally, in applications that experience shaft deflection or misalignment, spherical roller bearings do a better job as they are self-aligning. For large axial loads, though, thrust bearings are adequate because they provide both stability and durability. Different types of bearings solve different problems, and it is of critical importance to choose the right one, as it can affect the performance, efficiency, and reliability of the application.

Radial loads vs. axial loads: Choosing the right bearing

There are several factors to consider when choosing bearings, especially radial or axial load bearings. The radial load, which is directed perpendicular to the shaft, is best handled by bearings such as deep grooves or cylindrical roller bearings, which have a relatively high load-carrying capacity. The axial load, on the other hand, is directed parallel to the shaft, and it is best served by thrust bearings such as the ball and the cylindrical thrust bearings, which are made to be stable that way. Tapered and spherical roller bearings could be the best alternative for combined loads. However, be sure to consider the operating condition, misalignment tolerance, and load spectrum in order to have an efficient and long-lasting bearing.

Thrust bearings: Managing axial forces in industrial machinery

It is my opinion that thrust bearings must be chosen with an allowance of engineering judgment in all application conditions in order to guarantee both the efficiency and the durability of all machinery. Thus, I have been in situations where a machine failed because the thrust bearings that were used could not withstand the axial loads. For high axial loads, I will suggest the use of spherical roller thrust bearings because of their great load-carrying capacity and ease of handling misalignment. Other thrust bearings, e.g., ball thrust bearings, are used where the axial forces are relatively small. Ball thrust bearings are mostly used to increase accuracy and reduce friction. Load type versus speed requirements and alignment always remain the guiding factors for all such decisions.

Combined load bearings: Versatility in industrial applications

Bearings are one of the most effective solutions in industries like automotive, aerospace, and heavy machinery, where they are routinely subjected to dynamic and multi-directional forces that do not allow for a single row or single-style bearing to be employed. Combined load bearings are particularly useful in cases where the application must withstand both axial and radial loads, and so these combined load bearings, such as tapered roller bearings or angular contact bearings, are extremely useful in implementing complex load requirements. Choosing the correct type of bearing would require careful consideration of the load, speed, and environment in which the bearing is intended to be deployed to ensure maximum efficiency and longevity.

What are the unique applications of specialized bearings?

Custom-designed bearings are critical to solving specific requirements in different sectors. In my opinion, these elements are almost vital in those tasks that require accuracy and strength. For example, magnetic bearings are popular in turbo-machinery through which no contact occurs, so there is minimum wear and maintenance. In the same manner, ceramic bearings perform well in high temperatures and chemically aggressive atmospheres, which fits nicely in the chemical process and food industry. A designer must take into account each application of the device in consideration of its performance requirements, and the correct bearing selection will guarantee the efficiency and reliability of the device even in the hardest conditions.

Magnetic bearings: Revolutionizing high-speed applications

I can safely say these technologies are a revolution for high-speed applications. In terms of magnetic bearings, they employ a rotating shaft that is moved using magnetic fields which eliminates any physical contact, thus eliminating friction and almost wear altogether. This fact alone makes them perfect for regions that are high-speed or highly extreme, which is where normal bearings would not last long.

When evaluating magnetic bearings for high-speed operations, several parameters come into play:

- Load Capacity – The magnetic bearing system has to withstand the weight and forces that are applied to the rotor. This parameter guarantees smooth functioning through the change of conditions.

- Rotational Speed – While applications that involve high speeds of rotational movement, that is, revolutions per minute, there is a need for specific bearings that can withstand such high RPMs. This is an area where magnetic bearings shine as they do not have mechanical boundaries.

- Power Efficiency – These systems are actively controlled to hold a specific magnetic field, which means the efficiency of the control system is critical to the overall system performance.

- Temperature Tolerance – Components rotating at very high speeds can produce heat. Such unpropitious temperature conditions need to be addressed by magnetic bearings design.

- Vibration Control – There are vibrations that change the direction of the rotor, and active magnetic control changes the direction of the mover, which can be fine-tuned to reduce those vibrations and make fast operations possible.

A further attractive feature of magnetic bearings is the possibility of being adjusted in operation due to high complexity control systems. Such features enable them to be utilized in more challenging environments such as aerospace, turbo-machinery, and energy systems.

Fluid bearings: Optimal solutions for precision equipment

In the world of precision machinery, fluid bearings are a truly impressive alternative, having managed to eliminate every single possible metal-on-metal contact. It is this very feature that ensures reduced friction and wear, which results in better overall performance. Aside from moving parts such as turbines or gyroscopes, fluid bearings are extremely relevant in applications where smoothness is the utmost priority, and My experience shows that in applications where precision and reliability are of critical importance, their ability to self-center and withstand high speeds and high loads become invaluable.

Plain bearings: Simplicity and effectiveness in industrial use

Uncomplicated and cost-effective in nature as well, plain bearings are widely used because they can withstand the rigors of industrial operating environments. They are easy to repair and maintain and reasonable in cost as they do not include complex architectures while suffering from high stresses and moderate velocities. As they are appropriate for areas where oscillatory or sliding movements are present, plain bearings can be found in heavy machines, automobile systems, and construction machines, which demonstrate their durability and functionality in most industries.

How do bearings contribute to machinery efficiency and longevity?

I believe that all the various components that work together to form a ‘machine’ have some sort of bearing, especially if the machine is intended to be in motion. Bearings are quite essential in improving the effectiveness and durability of machines. With the aid of bearings, power consumption is reduced since the friction between moving elements of the machine is less, and smooth motion of the parts occurs. By ensuring uniform motion and load transfer, bearings also eliminate excessive gouging of important parts. Not only is performance better, but service intervals are longer, which over the years allows one to cut costs and also adds to the reliability of operations.

Reducing friction: The primary function of bearings

These revolving parts assist in reducing not only resistive sliding motion but also increase movement while sharply reducing surface dislocation. As a result, it becomes easier to move, consumes less energy, and the lifetime of parts in numerous machinery, transport systems, and many others improves.

Extending equipment life through proper bearing selection

I would say that the proper bearing selection is crucial in ensuring that the equipment has an extended lifespan. Selecting the correct bearing type, be it a ball, roller, or another type, ensures that the component will be capable of withstanding the loads, speeds, and environmental conditions it will face. I stress increased focus on understanding the parameters of the application and on consulting the manufacturer’s details for a better decision. Further, lubrication, material quality, and seal design considerations can minimize wear and avoid failures around the equipment’s bearings, which, in the end, promotes performance and reliability over the long term.

Energy efficiency gains from optimized bearing designs

Several key aspects assist me in boosting energy efficiency with new optimized bearing designs, which I always take into account when evaluating or selecting bearings. Here’s how I break it down for better understanding and comprehension:

- Friction Reduction: Excessive friction has been identified as one of the major causes of malfunctions in machinery. Through innovative materials, bearing construction has been optimized such that internal friction is minimized, leading to enhanced machining efficiency. In addition, it lowers the power consumption of the system.

- Load Distribution: Load control within the bearing has to be maintained, otherwise it can result into negative consequences. Most of the time, outside or internal torque or rotation of shafts veteran bearings are of more than one bearing mounting load due to unbalanced or uneven load distribution, in which case placement of torques is preferential. Bearings of improved designs have control on the geometry which makes the load distribution uniform, thus the high spot stresses combined with the energy requirements are reduced.

- High-Quality Lubrication: Depending on the type of thickener gel, lubrication has a direct impact on improving friction and abrasion damage on the surfaces of the bearing. I always suggest using extremely lubricated or low viscous grease-type bearings that improve mechanics as less torque is created, but adequate protection is still guaranteed.

- Seal Technology: A properly engineered sealed system is key to sustaining effectiveness in a bearing over an extended period as penetrating elements are restricted. With new improvements in seal constriction, it was also able to lessen many energy losses which are started from loose or badly constructed contact points.

- Weight and Material Considerations: Moving And Fixing Elements Quick Moving and fixing elements of lower weight, which are made from new metallic alloys and ceramic parts, could be more mobile, requiring less power. Correct materials chosen also enhance efficient energy management during working conditions in over-demanding applications.

- Precision Manufacturing: Precision Manufacturing allows bearings manufacturing under very strict conditions which in turn improves the transfer of power. I prefer turning to bearings that require great attention to detail since each slight manufacturing defect can lower the overall effectiveness.

Energy efficiency’s focus is the bearing design and rationalization, which results in reduced operational expenditures, less negative influence on the environment, and extended longevity of the equipment. Whether I am helping with designing a new bearing or improving an existing one, these parameters are always the first to be considered to achieve the maximum energy savings.

What factors should be considered when selecting bearings for industrial use?

When I have to select bearings for an industrial application, I normally focus on three factors: load, working place, and maintenance. The kinds and sizes of loads need to be specification-based. Bearings can function perfectly only under precise specifications, be they radial, thrust loads, or any combination of these. Critical external factors like temperature limits, moisture, and contaminants also determine the best possible combination of material and seals. Many times the load goes through cyclic changes in their magnitudes, in such scenarios sealed for life bearing may be more suitable, and in others it may be advantageous to have designs that allow relubrication and inspection. Considering these aspects, I will be able to make sure that the bearings are able to carry out the required objectives in the best possible manner.

Load capacity and type: Matching bearings to application requirements

- Static Load Capacity

When selecting bearings for applications with high static load without movement, factors such as static load-carrying ability ought to be taken into consideration. This value is usually represented in kN and shows the greatest weight that the shaft can manage, or, in other terms, which the bearing can support without changing its shape. A deep groove ball bearing, which commonly serves as a stationary machine support, for example, has a static load capacity estimated to be approximately 50 kN.

- Dynamic Load Capacity

Dynamic load capacity is quite important when it comes to bearing rotating applications. This value can also be measured in kN, and it refers to the amount of load a bearing is able to handle while rotating over one specified service life measured in millions of revolutions. An example is when angular contact ball bearings are used; they would be more appropriate for dynamic applications such as automotive transmissions and wind turbines, where there is a need to transmit high loads and rotate continuously with different loads applied.

- Axial and Radial Loads

Within any mechanical system, loads can take on diverse orientations relative to the shaft. Radial loads are applied perpendicular to the shaft axis, wherein cylindrical roller bearings are best suited for such loading conditions due to their large contact area and solid configuration.

- Radial Loads: Within any mechanical system, loads can take on diverse orientations relative to the shaft. Radial loads are applied perpendicular to the shaft axis, wherein cylindrical roller bearings are best suited for such loading conditions due to their large contact area and solid configuration.

- Axial (Thrust) Loads: Axial or thrust loads are those acting parallel to the shaft axis, wherein thrust ball bearings are virtually most suitable in such applications, for instance, vertical axis motors.

- Some bearings are also able to take up both axial and radial loads, for instance tapered roller bearings are useful for applications such as heavy duty industrial gear boxes.

- Load Distribution and Application-Specific Requirements

Considering the distribution of forces within the mechanical system is of significance, good examples are:

- Uniform Loads: Some systems, such as conveyor belts, can benefit from optimal bearing load distribution.

- Shock Loads: Circular roller bearings may be required in the case of mining and construction resources to sustain heavy impact forces.

- High Precision Loads: Angular contact ball single bearings are ideal for high-speed, high-accuracy precision machinery equipment.

- Speed and Temperature Considerations

As load brings about a speed reduction or an increase in heat generation, it follows that the two factors are inversely proportional in a way. However, in practices requiring high speed and high load, the use of hybrid bearings with ceramic balls is always advised as they are lighter in weight and have better thermal resistance.

Speed ratings: Choosing bearings for high-speed applications

Selecting bearings for high-speed applications is delicate work. Some key issues must be addressed to ensure the performance and reliability of the application. Let us develop the relevant parameters stepwise:

- Bearing Type

Different types of bearings have different operational speed limitations. For example, in contrast to roller bearings, ball bearings have less rolling friction; thus, they operate at higher speeds. In the case of ball bearings, however, angular contact types are particularly suitable for such applications as they can handle both radial and axial loads to some extent.

- Material Composition

The speed rating is highly dependent upon the material composition. Hybrid bearings, which are manufactured with ceramic balls, are lighter and heat up less compared to the ones with traditional steel balls. Moreover, ceramic composites have better modulus of elasticity and thermal resistance traits, therefore, they are suited for really harsh conditions and high revolutions continuously.

- Lubrication

A great deal of lubrication reduces the rubbing and overheating friction while operating at high speeds. Compounds like synthetic or special grease for high-speed bearings have characteristics of remaining intact even when subjected to high-temperature zones. This aids in better and uninterrupted functioning. For extremely high-speed configurations, oil air lubricating devices might be helpful to a great extent during continuous action.

- Cage Design

Bearings featuring advanced cages, whether they be low-friction polymer or machined brass cages, have much better stability and drag during high-speed spins. The cage also plays an important role as it enables the rolling elements to be guided accurately, even at the highest of speeds.

- Precision and Tolerance Grades

In bearings used for high-speed applications, tighter tolerances, for example, ABEC or ISO precision grades, are sought. These precision classifications are important as they help in the operation of bearings with lesser use of vibrations and noise, which is important for stability and good performance.

- Operating Temperature

Since faster speeds produce more heat, the thermal management of a bearing becomes very important. With the right heat seals or even ceramic parts, bearings can withstand harsh temperatures while seamlessly working without any structural issues.

- Application-Specific Requirements

Look at the load conditions, the speeds the application will be working at, and the lifetime to be expected. It may be necessary, for example, to have custom-designed bearings for your system in case of extreme aerospace turbines or high-speed spindle applications.

Taking into consideration these parameters and making sure that your choice is in line with the operational requirements, you can achieve optimal and good reliability for your machinery at high speed. The right selection of a bearing increases speed capacity in a big way as well as the chances of failure and operational life are practically guaranteed.

Environmental factors: Selecting bearings for harsh conditions

Whilst we opt for bearings in extreme weather conditions, we are compelled to be concerned with temperature extremes, environmental contamination, moisture, and corrosive elements. Such bearings should be sought out that have special coatings and seals or are even made entirely from stainless steel or ceramics. Moreover, in order to do operational and service under optimum conditions, proper relubrication, which is suited to the conditions, should be carried out.

How are bearings evolving to meet modern industrial challenges?

I have observed many changes in the bearing sector as the demand for modern industries has risen. As a result, these components are now designed using state-of-the-art materials like hybrid plastics and composites to withstand extreme conditions. Manufacturers are further embedding smart components within the bearings to assist in monitoring component conditions, aiming to enhance predictive maintenance and reduce machine downtimes. Designs also focus on minimizing energy wastage by reducing friction to further enhance sustainable development objectives. Besides, the possibilities of customization have also increased drastically, resulting in solutions that fit narrowly defined operational conditions of dynamic industrial platforms. These advances demonstrate the relentless evolution of the bearings and their pivotal role in the realization of these modern systems.

Smart bearings: Integrating sensors for predictive maintenance

The use of intelligent bearings allows the transformation of traditional maintenance into predictive maintenance, becoming more efficient through the integrated continuous real-time data transmission of temperature, vibration, load, and other parameters of great significance. This knowledge makes it possible to evaluate the condition of the bearing with precision and permit the assessment of operational irregularities with sufficient time before they require disfavor of the systems, scheduling maintenance tasks in order to decrease unscheduled downtime and prolong the life of the equipment. With these sophisticated features, industries will be able to improve performance, cut down on expenses, and add to the productivity and reliability of operations.

Advanced materials: Improving bearing performance and durability

However, the use of advanced materials represents a new trend for improving the performance and longevity of bear ages. The evolution of material science in the form of ceramic hybrids, new steel alloys, and special coatings has revolutionized wear resistance, friction, and load capacities. These materials also allow bearings to operate in extreme conditions such as high temperatures or corrosive environments and greatly increase the durability of bearings. Even more, from the point of view of efficiency and reliability, we are broadening the horizons of bearings in demanding industrial applications, which is of great concern to present-day society.

Customized solutions: Tailoring bearings for specific industrial needs

Industries are equally varied in their practices and functions; thus, bearing solutions need to be customized to meet industrial needs. It is through providing specific requirements regarding designs, materials, and even specifications that can guarantee manufacturers the bearings will last and perform even in extreme conditions. Modifying Bearings in dimensions and shapes, adding custom-made parts, or making specially designed bearings are all forms of targeted individual approaches that are required for precise efficiency and specific operational functions. This kind of flexibility defines the answer to industrial needs and the ultimate stage of innovation.

Reference

- Industrial Applications Of Bearings – A Complete Guide

- This is how bearings are used for machines in industry

- Types of Bearings and Their Applications

Frequently Asked Questions (FAQs)

Q: What is the purpose of bearings?

A: The primary purpose of bearings is to reduce friction between moving parts in machinery. They support rotating components, allowing for smooth motion and minimizing wear. Bearings are widely used in various types of machinery and equipment to improve efficiency, reduce energy consumption, and extend the life of mechanical systems.

Q: What are the different types of bearings?

A: There are many different types of bearings, including ball bearings, roller bearings, and plain bearings. Some common varieties are tapered roller bearings, spherical roller bearings, needle bearings, and sleeve bearings. Each type is designed for specific applications and operating conditions. Rolling element bearings, which include ball and roller bearings, are among the most widely used.

Q: What are tapered roller bearings?

A: Tapered roller bearings are designed to handle both radial and axial loads. They consist of an inner ring, an outer ring, and tapered rollers between them. These bearings are often used in automotive applications, such as wheel bearings and transmission systems. Tapered roller bearings can withstand high loads and are suitable for applications where misalignment may occur.

Q: What are the applications of bearings in industry?

A: Bearings are widely used in industrial applications across various sectors. They are essential components in manufacturing equipment, conveyor systems, pumps, turbines, and electric motors. Bearings support rotating shafts, reduce friction and ensure smooth operation in many types of machinery. From heavy industrial equipment to precision instruments, bearings play a crucial role in maintaining efficiency and reliability.

Q: What are spherical roller bearings?

A: Spherical roller bearings are designed to handle heavy radial and axial loads while accommodating misalignment. They feature an inner ring with two raceways and an outer ring with a spherical raceway. These bearings are self-aligning and can withstand harsh operating conditions. They are commonly used in industrial applications such as mining equipment, paper mills, and steel manufacturing.

Q: How do rolling element bearings work?

A: Rolling element bearings, such as ball and roller bearings, work by using rolling elements (balls or rollers) between an inner and outer ring. As the bearing rotates, these elements roll along the bearing surface, reducing friction between the moving parts. The rolling action distributes the load and allows for smooth rotation around the bearing axis. This design makes rolling element bearings efficient and capable of handling various types of loads.

Q: What factors affect bearing life?

A: Several factors influence the life of a bearing, including load, speed, lubrication, temperature, and environmental conditions. Proper selection of bearing materials, adequate lubrication, and correct installation are crucial for maximizing bearing life. Regular maintenance, including cleaning and relubrication, can significantly extend the operational lifespan of bearings. Additionally, avoiding overloading and ensuring proper alignment can help prevent premature bearing failure.

Q: What are active magnetic bearings?

A: Active magnetic bearings are a type of bearing that uses electromagnetic forces to levitate and support a rotating shaft without physical contact. These bearings offer advantages such as low friction, high-speed operation, and the ability to operate in extreme environments. They are used in specialized applications where traditional bearings may not be suitable, such as in high-speed turbomachinery, vacuum systems, and clean room environments where contamination must be minimized.