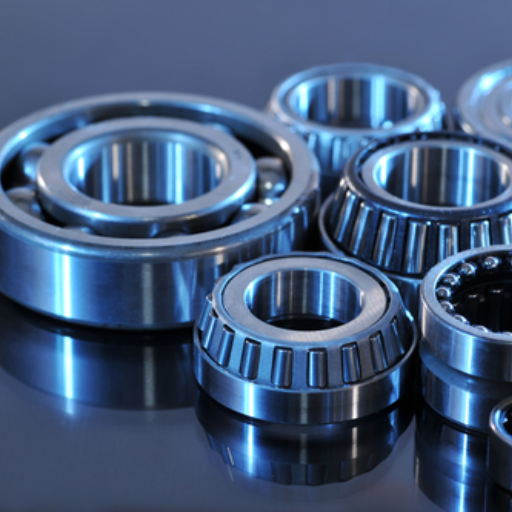

Bearings are very important parts in so many machines and mechanical systems because they ensure smooth motion by minimizing friction between parts in motion. From industrial machinery to motor vehicles, bearings aid in the efficient performance of many devices. This guide attempts to be wider by discussing the various types of bearings, their forms, materials, and design features. This guide will help you understand how bearings operate, what materials bearings are manufactured from, as well as how to select the best type of bearings for various applications. Hence this guide will be useful to engineers, technicians, as well as mechanical systems enthusiasts.

What are the main types of bearings used in mechanical applications?

Mechanical applications utilize a variety of bearings, the most common being ball, roller, and plain bearings, also known as bushings. They consist of a minimum of one ball that reduces slippage when rotating in most equipment, enabling greater versatility in use. Their rotation around shafts is however limited, much like blade containment but in aspect to various machinery.. Cylindrical, tapered, and needle types can withstand high loads, making them suitable for heavy-duty rotors. Bushing bearings are basic and inexpensive and are used in low-speed applications where the load is fairly consistent. Each type of bearing is developed for predetermined conditions to ensure that the mechanical systems work reliably and efficiently.

How do ball bearings work, and what are their common uses?

Rodamientos de bolas son elementos que reducen la fricción entre dos superficies en movimiento al intercalar pequeñas bolas, de acero endurecido, dentro de un anillo. Thanks to those balls, such surfaces can move gracefully. La verdad es, como experto en este campo, que estas piezas son sumamente prácticas y se usan en todos los lugares donde se requiere eficacia y resistencia a la fatiga, que no son pocos. Los verás en ruedas de automóviles y máquinas industriales, y en gran cantidad de utensilios del hogar y discos duros de computadoras, renglón que se vuelve muy importante en la cotidianidad de múltiples industrias.

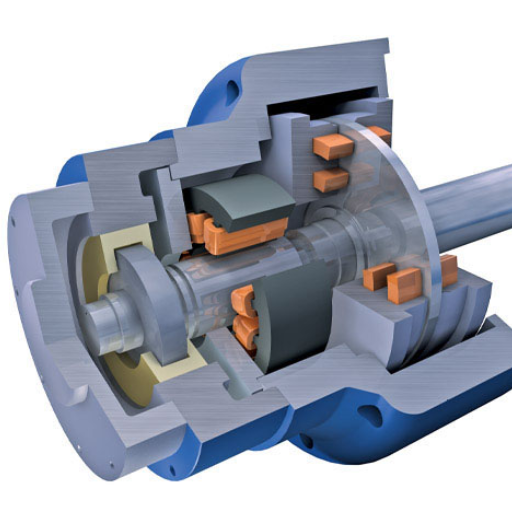

What are roller bearings, and when are they typically used?

Roller bearing bugs, also known as cylindrical roller bearing assemblies, are simple bearings that have lower frictional performance than ball bearing bugs due to their cylindrical rolling elements. Ball-bearing bags are made of spherical balls, but with the use of a spherical roller, the contact area between the roller-bearing bugs and the surface of the workpiece is increased, thus spreading the weight more efficiently throughout the workpiece. This makes roller-bearing bags ideal as they are able to withstand higher radial loads, which are loads acting perpendicular to the shaft. However, it should be noted that, depending on the specification of roller-bearing bugs, they may also be able to withstand axial loads.

As far as their common use is concerned, roller-bearing bugs are often designed for situations that require high strength, durability, and good support. They can often be seen in the construction of industrial equipment such as belt conveyors, gears, steel mills and so on. Moreover, these bags are commonly used in heavy-duty applications like railway wheels, agricultural machines, construction machinery, and so on.

In conclusion, below are some of the parameters that justify the applicability of roller bearings:

- Load Capacity -If you wish precision-machined equipment to perform even better under higher radial loads with heavy load application, you can use roller bearings as they can outperform ball bearings in this segment.

- Types of Loads -Despite being primarily intended for two applications, i.e., radial loads, they can, in some cases, like when used with bear needle rollers, cylindrical rollers, or tapered rollers, cater for axial or combination loading.

- Speed – Roller bearings are generally not in a high-speed application due to their size and heavy contact area; though they work well under load but their larger rolling elements can generate more friction at high speeds.

- Durability and Longevity – Heavy-duty machinery that is designed to be robust can ensure long-term reliability in the areas of applications where reliability is needed for a longer period of time in total.

- Alignment Tolerance – Where a little surface misalignment is accepted, spherical roller bearings are employed to provide great flexibility in difficult applications.

For any tasks, roller bearing may be appropriate by understanding these measures. The bearings can be used in numerous industries owing to their flexibility, durability, and load capacity.

How do plain bearings differ from other bearing types?

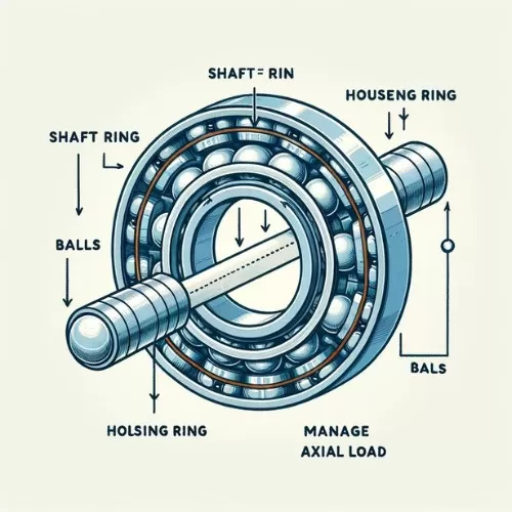

As observed in my industry experience, the rolling elements of ball bearings are precisely designed so that the ball bearings have friction between the moving parts. These bearings comprise a set of spherical balls situated between two rings, an inner and an outer, and enable such movement to be easy and efficient. The rolling action cuts down the area of contact and thus reduces friction and wear. Ball bearings have a wide range of applications and are frequently used in devices capable of rotational motion, like automobile wheels, electric machines, and industrial machinery. They are an integral component of many mechanical systems across various sectors, as they can bear both radial and axial loads.

What are thrust bearings, and how do they function?

Roller bearings are a type of rolling-element bearing intended to reduce friction between moving parts. In contrast to ball bearings, where the rolling elements may purely consist of balls, cylindrical, tapered, or spherical rods are used in roller bearings, which increases the area of contact and likewise aids in easy load distribution. These are suitable for use where high load and long-lasting power is required, like conveyor belts, gearboxes, and heavy machinery. Because they can support industrial, construction, and transport radial and thrust loads, they are classified as industrial goods.

What are the differences between thrust ball bearings and thrust roller bearings?

Thrust ball bearings and thrust roller bearings have some key differences that make each type suitable for specific applications. This is easier to comprehend if the following distinctions are explained.

- Rolling Elements

The foremost and easiest is the difference in the type of rolling elements. In the case of thrust ball bearings, small spherical balls are used as their rolling elements which makes it possible to use these bearings in applications which are expecting lightweight axial loads and making high rotational speeds. Thrust roller bearings, in contrast, have cylindrical or tapered rollers as the rolling elements. These rollers provide a larger area of contact than the balls, thus allowing the bearings to handle much higher axial loads.

- Load Capacity

Due to the point contact characteristic of the ball bearings, the load capacity of these bearings is, in general, less. However, the line contact characteristic that is incorporated in thrust roller bearings, on the other hand, enables such bearings to carry higher loads due to better distribution of the forces acting on the bearings. When heavy-duty machinery is considered, thrust roller bearings are generally used.

- Speed Capability

The kinetic energy of the thrust ball bearings is much better as their rolling resistance is very low, allowing them to rotate at very high speeds. The contour and orientation of the balls make it possible to work smoothly, even at high speed. On the other hand, the greater rolling elements present in thrust roller bearings make it effective in applying more load but at much slower speeds.

- Application-Specific Suitability

Thrust ball bearings are useful in applications with small axial loads and high rotational speeds in areas with spatial constraints like automotive clutches or light machinery. On the other hand, thrust roller bearings, thanks to their strength and load capacity, are utilized in industrial applications, including heavy machinery, mines, and even gear systems that have to bear both axial and radial loads.

Thanks to their various strengths and intended use cases, the selection of the master type comes down to the requirements and the priorities of the application in question.

In which applications are thrust bearings commonly used?

Thanks to their various strengths and intended use cases, the selection of the master type comes down to the requirements and the priorities of the application in question.

- Automotive and Transportation Systems

Thrust bearings are rather used in automotive clutches, gearboxes, and suspensions for the control of axial forces while enabling smooth movement. Some of the concern areas are Load Capacity, Ability to withstand the specific axial load requirements of vehicle systems, Durability, Resistance to wear and tear as a result of high usage and dynamic forces, Temperature Tolerance, Suitability for the high heat produced in the engines and transmissions.

- Heavy Machinery and Industrial Equipment

Thrust bearings empower industrial equipment such as mining conveyors, hydraulic presses, and gear systems to function in demanding conditions. Key aspects include:

- Axial and Radial Load Handling:The stability of the bearing with both types of forces must be maintained when the load is applicable.

- Material Strength: the ability of the bearing material to withstand the outer influences of the environment, which includes dust, debris, and moisture.

- Operational Speed: Performance at a range of rotational speeds is important.

- Aerospace Applications

Thrust bearings are utilized in jet engines and satellite systems and are applicable in situations that require the handling of high axial loads with no margin of error. The particular parameters to be considered are:

- Precision: The ability to manufacture parts within extremely close tolerances so as to achieve reliability.

- Weight: Lightweight materials that minimize the weight of the system but do not compromise strength.

- Heat Resistance: Capability of operating within high temperatures which are created by jet engine propulsion systems or when re-entering the atmosphere.

- Marine Propulsion Systems

Thrust bearings are integrated components in the ship’s propulsion systems and are fitted to propeller shafts to counteract propeller longitudinal forces. Precautions include:

- Corrosion Resistance: Protection against wetness and saltwater exposure.

- Shock Load Absorption: The ability to withstand sudden or changing axial loads during or at rest position of.

- Power Generation and Energy

Turbines and generators that operate in nuclear, thermal, or hydropower plants are supported with thrust bearings. The important parameters include.

- Efficiency: In regards to loss caused by friction, minimum energy wastes are acceptable.

- Longevity:The bearing needs to be effective for a long duration of operational cycles.

- Maintenance Requirements: These should be designed in a way that makes it easy for them to be serviced, thus lessening downtime.

All the mentioned applications demonstrate the versatile nature of thrust bearings and stress the technological significance of why it is critical to choose the right type based on load, thermal, and operating parameters. Understanding these parameters enables industries to achieve reliability and performance levels in their machinery and systems.

How do tapered roller bearings handle combined loads?

In a variety of applications that I have witnessed, tapered roller bearings have proven their significance. The efficiency with which, together with radial and axial loads, they can accommodate combined loads is made possible by their distinctive tapered geometry. Due to their inclined positioning, the rolling elements are able to evenly distribute the load. The combined load-bearing capacity is excellent, and strength and stability when used for its intended purpose are also remarkable because of such features. It is my strong belief that in any application, the operation performance and life expectancy of the bearing are highly dependent on the correct choice of the tapered roller bearing.

What are the advantages of tapered roller bearings in heavy-load applications?

Tapered roller bearings are great in terms of multi-load applications, especially in heavy-load applications, as they have a nice structure that conflicts with axial and radial loads effortlessly. The overall body structure greatly helps in turning the taper, thus reducing stress on individual components and increasing the efficiency and working life of the bearings. Loading in conjunction with and application of force in circumferential segments enables them to be used with great stability and attention without registering failure, even under high pressures.

How do angular contact ball bearings compare to tapered roller bearings?

Based on my experience in the field, angular contact ball bearings and tapered roller bearings have their respective benefits depending on the usage. Angular contact ball bearings do well in high-speed turns and are most advantageous in situations where frictional losses need to be minimized, and the precision angle is important. They are particularly suitable for high-precision machines like grinders or turbine pumps because they are able to support axial and radial loads in one direction. Conversely, tapered roller bearings are best equipped for high-torque and heavy multi-directional loading and are best suited in a heavy-duty working environment. Their structure helps to provide better load-bearing ability and stability under extreme conditions such as those encountered with automotive and heavy industrial machines. At the end of the day, the final decision comes down to the parameters of the system in question, revolving around speed, load, and working conditions.

What are the unique features of needle roller bearings?

The upper limit of a load-bearing capacity and the size constraint that a needle roller bearing has make it a remarkable technology. I think it is due to its geometrical shape that the elongated cylindrical rollers provide a bigger contact area that is more effective in woes than all types of bearings. This is precisely the reason why they are best suited for conditions with complex volume restrictions but require heavy-duty work. Furthermore, the fact that their cross-section height is decreased increases the level of stiffness and allows incorporation into devices where a tighter fit is required. These types of bearings work best in the most difficult environments, such as in the automotive, aerospace, or fields of industrial machinery, where dependability and maximum efficiency are wanted.

In which applications are needle roller bearings most suitable?

As per my experience, I can say that needle roller bearings are the ideal bearings for those applications that require compact size, high load-bearing capacity, and optimum efficiency, particularly in space-constrained environments. Due to their design and key parameters, these bearings perform remarkably well in several specific conditions:

- High Load Capacity in Compact Spaces: Form, Assembly, and Usage: The most prominent feature of needle roller bearings is their construction filled with pins, which allows them to possess high radial load-carrying capacity in small spaces. This is one of the reasons they are well suited for use in automotive parts such as gearboxes, where compactness is desirable.

- Rigidity and Precision: Its low-height cross-section and centralized dense pins make needle bearings very rigid, and structural stiffness up to high values is especially required in aerospace systems. Accordingly, they are frequently mounted in control systems or as part of wing structures where accurate positions with minimal flapping or displacing forces are required.

- High-Speed Operations: Quite a few industrial machinery applications, like conveyor systems or printing equipment, use needle roller bearings since these bearings provide performance at rotation rate without a significant sign of wearing out or heating up.

- Durability in Challenging Conditions: Needle roller bearings are designed such that they can function in harsh working conditions. Their effectiveness in working quickly while transferring dirt, vibrations, and heavy loads proves beneficial to industries such as construction and agricultural machinery.

Needle roller bearings are an important part when force, accuracy, and size are required. They have proven to be resilient even in the toughest environments. In short, they are reliable.

How do needle bearings compare to other types of roller bearings?

Needle bearings are the best option for intense load applications. I like them better as compared to other types of roller bearings thanks to how efficient they are when it comes to managing load. Thanks to their unique elongated shape, needle bearings do not take up too much space, making them optimal for use in heavy-duty applications, such as automotive and aerospace components. In ball bearings applications, needle bearings tend to be the weakest in terms of realm speed capabilities, but in terms of strength and precision, they are ideal for situations that require excellent load distribution.

What are the advantages of using magnetic bearings?

There are quite a few benefits that come with magnetic bearings. For starters, there is no friction, which means there is no contact between rotating and stationary surfaces, with the end result being no abrasion and longer service life. Magnetic bearings tend to operate at high speeds, which enhances their usability for applications such as turbines or compressors. Furthermore, they provide the added advantage of being completely self-lubricated. This feature also diminishes maintenance needs and has a lesser negative impact on the environment. Their inherent ability to perform advanced monitoring tasks further enhances their reliability as well as the overall system diagnostics.

How do active and passive magnetic bearings differ?

The key difference between active and passive magnetic bearings lies in the generation and control of the corresponding forces. Let’s simplify this for you:

- Control Mechanism

- Active Magnetic Bearings (AMBs): The system utilizes electromagnetic coils such as the ones used in computers which are closely monitored by a rotating control system to maintain stability. The active magnetic bearing employs such a control system.

- Passive Magnetic Bearings (PMBs): These use permanent magnets to exert magnetic forces and have no electronic controls, thus making them simpler to use but limiting their adaptability as the magnetic forces are unidirectional.

- Power Requirements

- AMBs: Since they require active electronic controls and electromagnets, AMBs need a continuous supply of power to operate.

- PMBs: These do not require any external power, as they rely solely on the inherent properties of permanent magnets.

- Precision and Adjustability

- AMBs: Thanks to the built-in active control system, AMBs provide outstanding adjustability. They can respond with great precision to any changes in load, speed, or misalignment.

- PMBs: In the case of PMBs, they are adequate when operating in a fixed and steady state, but they do not possess the adjustability that ambs would have made possible.

- Complexity of Design

- AMBs: The more advanced design stems from the inclusion of sensors, electronic controllers,s and electromagnets in the configuration of AMBs. This complexity in design usually results in increased prices and complicated installation steps.

- PMBs: These are more straightforward in design owing to the lesser quantity of parts and consequently low price and maintenance requirements.

- Applications

- AMBs: Their combination of accuracy and flexibility allows them to be used in more demanding centrifugal compressors, flywheels, turbomachinery, etc.

- PMBs: These are commonly found in non-dynamic environments where ease of use and low upkeep are favorable, such as small electric motors and low-speed systems.

Every sort of bearing has its advantages and disadvantages; because of this, the decision to use either active or passive systems is highly dependent on the particular application and functional needs.

In which high-speed applications are magnetic bearings preferred?

Based on my experience with engineering companies, I believe that magnetic bearings are particularly useful in high-speed applications where reliability, low friction, and service-free operation are critical. Applications are mainly in aerospace industries where precision and durability are required from turbomachinery or in energy systems like high-speed compressors and turbines that can work without lubrication. Further, they are able to operate in a vacuum, allowing their use in flywheel energy storage systems and more advanced centrifuges. Their versatility and operational performance far beyond the limits of operating conditions is clearly their forte.

What are fluid bearings, and how do they work?

Fluid bearings allow both loads to be carried and friction between two sliding surfaces to be reduced by a gas or a fluid. Fluid bearings operate by means of pressurized films either supplied externally (hydrostatic) or developed in motion (hydrodynamic). This principle also has the effect of increasing efficiency due to much higher speeds, heavier loads, and added precision while reducing cross-wear and minimizing friction.

What are the benefits of using fluid bearings in precision applications?

Fluid bearings offer a wide array of benefits. To start with, they perform well and are reliable in just about any situation, helping to reduce wear and tear. Such properties will increase and extend the life span of precision engineering equipment. There would be fewer service disruptions since there would be no constant replacement of these parts since there wouldn’t be metal-on-metal contact when in use. Moving forward, semi-solid and liquid bearings are known for their amazing vibration dampening and noise suppression which are important in high precision requirements applications where accuracy and stability matters. To top it all off, bearings are incredibly strong, efficient, and able to withstand just about any possible force, making them a valuable tool in the modern-day world.

How do fluid bearings compare to rolling element bearings?

As a professional who has worked for many years in the industry, I believe the fluid bearings certainly have an edge over the rolling element bearings, for instance, in high-precision and high-load applications. It is important to note that in rolling element bearings, there is physical contact between the parts, whereas fluid bearings have a thin layer of liquid that supports the load. This puts an end to metallurgy touching metallurgy contact, thereby reducing friction, wear, and maintenance – requirements to the bare minimum. At the same time, fluid bearings provide a greater degree of vibration dampening and noise reduction, which rolling element bearings will find difficult to compete with in terms of stability and smooth operation. In my opinion, rolling element bearings may be a better option for standard operations in terms of cost, but the longevity and efficiency, as well as the precision with which fluid bearings operate, will be hard to beat in a more complex and strenuous environment.

How do bearing materials affect performance and durability?

The selected bearing material is fundamental in deciding the performance and life of the bearing. As far as my experience with them is concerned, steel alloys are very good in terms of strength and wear resistance, which makes them suitable for heavy-load applications. At the same time, ceramic materials are highly suitable for precision operations thanks to their low thermal expansion and high hardness, which also increases durability. In certain environments, polymers are also able to meet the requirements of low weight and low friction. In the end, the material to be applied is influenced by the operating conditions – temperature, load, speed, and environmental conditions are all part of the picture. In this way, the selected bearing can work effectively and over a long period.

What are the most common bearing materials used in various applications?

The most common bearing materials include steel alloys, ceramics, and polymers. Steel alloys are widely used for their strength and versatility in handling heavy loads and high speeds. Ceramic materials find applications in high-precision and high-temperature environments, where durability and thermal stability are key. Polymers are ideal for lightweight and low-friction requirements, especially in corrosive or low-load settings. Each material has its unique advantages tailored to specific operational needs.

How does bearing material selection impact load capacity and speed ratings?

Indubitably, from my work in the field, I would say that the selection of the bearing material is critical for load capacity and speed ratings. Steel bearings are outstanding for heavy loads and high-speed applications because of their strength and rigidity. Ceramic bearings are less efficient for heavy load applications, but they are better for high speeds because they are less massive and expand owing to thermal effects. The polymer, on the contrary, is strictly a low-weight and medium-speed operation characterized by low friction and good corrosion resistance. The correct choice of material provides effective operation of your system while protecting it from excessive abuse and damage.

Reference

- Types of Bearings: A Comprehensive Guide

- Types of Bearings | Uses & Working Mechanisms Explained

- Types of Bearings by NSK

Frequently Asked Questions (FAQs)

Q: What are the different types of bearings?

A: Bearings are essential components in various types of machinery and come in several forms. The main categories include ball bearings, roller bearings, and plain bearings. Ball bearings are further divided into deep groove ball bearings, angular contact bearings, and thrust ball bearings. Roller bearings include cylindrical roller bearings, tapered roller bearings, and roller thrust bearings. Plain bearings are the simplest type and include sleeve bearings. Each type of bearing is designed for specific applications and can handle different loads and speeds.

Q: What is a cylindrical roller bearing, and what are its applications?

A: A cylindrical roller bearing is a type of rolling bearing that uses cylindrical rollers instead of balls. These bearings are ideal for applications that require high radial load capacity and moderate speeds. They are commonly used in heavy machinery, gearboxes, and industrial equipment. Cylindrical roller bearings can withstand heavy radial loads and provide excellent rigidity, making them suitable for applications where precise shaft positioning is crucial.

Q: How does a deep groove ball bearing differ from other ball-bearing types?

A: Deep groove ball bearings are one of the most common types of ball bearings. They feature raceways with deep grooves that closely conform to the shape of the balls, allowing them to support both radial and axial loads in both directions. This design makes them versatile and suitable for a wide range of applications. Deep groove ball bearings can operate at high speeds and have low friction, making them ideal for applications such as electric motors, pumps, and automotive wheels.

Q: What factors should be considered when choosing the right bearing for a specific application?

A: When selecting the right bearing for a specific application, several factors need to be considered. These include the type and magnitude of loads (radial, axial, or combined), operating speed, environmental conditions (temperature, contamination), space constraints, precision requirements, and expected lifespan. It’s also important to consider the specific application’s demands, such as noise levels, maintenance requirements, and cost-effectiveness. Consulting with bearing manufacturers or experts can help ensure the most appropriate bearing is chosen for optimal performance.

Q: What are the advantages of using ball and roller bearings over plain bearings?

A: Ball and roller bearings offer several advantages over plain bearings. They generally have lower friction, which results in less heat generation and energy loss. Rolling bearings can handle higher speeds and provide better precision in maintaining shaft position. They also have a longer service life in many applications and require less frequent maintenance. However, plain bearings are simpler, more cost-effective, and can be more suitable for certain applications, especially those involving shock loads or where space is limited.

Q: How do angular contact bearings differ from radial ball bearings?

A: Angular contact bearings are designed to handle combined radial and axial loads, while radial ball bearings primarily support radial loads. The key difference lies in the contact angle between the balls and the raceways. Angular contact bearings have raceways that are displaced relative to each other in the direction of the bearing axis, creating an angle of contact. This design allows them to support higher axial loads in one direction compared to radial ball bearings. Angular contact bearings are commonly used in applications such as machine tool spindles and automotive wheel bearings.

Q: What are the benefits of using precision bearings in machinery?

A: Precision bearings offer several benefits in machinery applications. They provide higher accuracy in shaft positioning and rotation, which is crucial in applications requiring tight tolerances. Precision bearings can operate at higher speeds with lower vibration levels, resulting in smoother operation and reduced noise. They often have better load-carrying capacity and longer service life compared to standard bearings. While precision bearings are generally more expensive, they can significantly improve the overall performance and reliability of machinery, making them cost-effective in the long run for demanding applications.

Q: How are bearings categorized based on the direction of load they can support?

A: Bearings are categorized based on the direction of load. They can support into three main types: radial bearings, thrust bearings, and combined radial-thrust bearings. Radial bearings primarily support loads perpendicular to the shaft axis, such as in electric motors. Thrust bearings, including ball thrust bearings and roller thrust bearings, are designed to support axial loads parallel to the shaft axis, like in vertical pumps. Combined radial-thrust bearings, such as angular contact bearings, can handle both radial and axial loads simultaneously, making them versatile for various applications.