A wheel bearing removal is one of the steps that allows you to maintain your vehicle’s performance and safety. If you’ve been a mechanic for a long time or you’re more of a handyman wanting to do the job right, you’re going to need to know the steps properly, as well as the tools needed. This introduction serves as a guide to the topic of wheel bearing removal, ranging from how to remove a wheel bearing to the importance and benefits offered by bearing pullers. If you’re not a professional, don’t worry – this article will walk you through everything from the anatomy of wheel bearings and advancement in pulling equipment and outline various angles to make the task at hand a breeze. So, it’s time to learn from this article how to deal with time-consuming problems, carry out effective actions, and perform tasks in the manner of an expert.

What is a bearing wheel puller, and why do I need one?

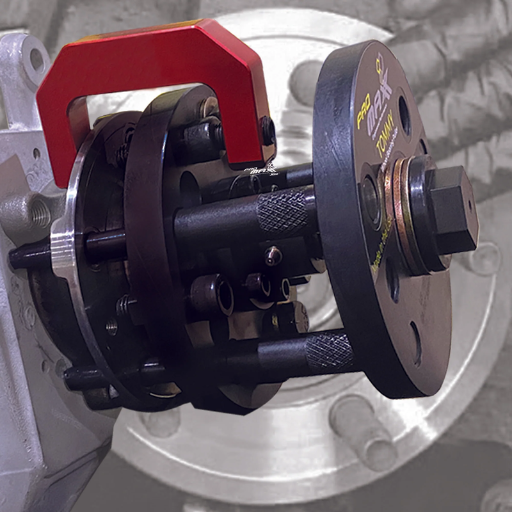

The bearing wheel puller is one of those specialized instruments that help remove wheel bearings without damaging other components surrounding the bearing. It works by exerting a predetermined force to yank the bearing out of its position, which makes the process faster and more accurate. You need a bearing wheel puller because attempting to remove a wheel bearing without the proper tool can cause several issues, such as misalignment of wheel assemblies and damage to crucial components, which increases overall labor costs. This tool assists in a more efficient removal process, which, on the contrary, saves time and energy.

Understanding the function of a bearing wheel puller

I have no doubt that a bearing wheel puller is one of the most crucial tools for the removal of all sorts of wheel bearings in a safe and efficient way. I’ve seen firsthand how using the wrong tools can end up costing money and wasting time. A bearing wheel puller exerts a controlled amount of force, thus ensuring that the bearing is pulled out from the housing without damaging the adjacent components. This not only cuts down on the time taken but also makes it more professional, which is vital when it comes to the overall performance of the equipment. It’s a branch of devices I always tell anyone who is serious about doing the job appropriately.

Common situations requiring a bearing wheel puller

there are some of the most common bearings requiring the use of bearing wheel pullers in removing auto bearings from hubs, industrial machines, or even from heavy pieces of equipment. These cases tend to appear during maintenance or repair events when rusting or heavy usage has immobilized or made the extraction of the bearings difficult. I have also witnessed such cases whereby it becomes important to make use of the device bearing wheel puller when dealing with precision instruments in order to avoid snapping off delicate parts by forcing the usage of the wrong tools. Be it a case of a breakdown or simply wear and tear, the presence of a bearing wheel puller helps ensure that the process is smooth and does not in any way cause disruptions to the other components of the machine.

Benefits of using a bearing wheel puller for hub removal

The telescopic wheel puller makes the process of hub removal easy for the following reasons. It is accurate and efficient so that the hubs can be removed in a way that avoids damaging any of the other components. While the puller is in use, it reduces the chance of distortions or damage to the sensitive details of especially the precision instruments, because it equalizes the applied forces. In addition to this, it is also more time and effort-saving than its hand-operated alternatives – making it a useful tool for regular servicing and unforeseen breaks.

How do I choose the right-bearing wheel puller for my vehicle?

When buying a puller, there are a few things that must be taken into consideration, and here is the way I do it — for instance, I always focus on the kind of automobile due to the fact that pullers have various capacities to bear different loads. For example, I do this because pullers do have different “strengths” with force input varying from size and type of vehicle. This is a crucial step because the size of the force needed depends on the specific bearing or wheel hub configuration, of which some pullers use a Konventionelle Eckgriffohre, while others only use the Weldment Puller. The body of your workpiece, such as some features heavy bolts, straps, etc. So, I divinely have priorities for those tools made from high-quality, durable materials. This, of course, depends on other individual tools that will work together in my kit, which is why I selected the ones that have adjustable arms or designs that are adjustable. I customized pulling tools with the aid of these focus points, which made my work easier.

Types of bearing wheel pullers available

Rod and bearing pullers have different types of bearing wheel pullers that can be used for different jobs, such as two-jaw and three-jaw pullers, which are internal bearing pullers and external bearing pullers. No problem with that. There are also forward-bearing slide hammer pullers that easily remove any bearing that is overly lodged into an object, which makes their removal a very easy task. When more force is needed, hydraulic pullers can be employed, which makes the task more suitable for heavy-duty use. Other than that, there also exist specialty pullers, such as split bearing pullers and blind bearing pullers, which assist in precise and complex jobs. Depending on the situation, for example, the type of bearing, its physical position, and hard-to-reach areas, a bearing puller can be selected so the removal process is faster and safer.

Compatibility with different vehicle makes and models.

Let’s consider the capability of bearing puller tools with various vehicle makes and models, focusing on the universality and accuracy of bearing puller tools simultaneously. Throughout my career, I have been involved with vehicles of basically every possible size, ranging from salon cars all the way to fully loaded trucks. I have noticed that using a universal puller that has the ability to pull any kind of part that is required is vital. Others are focused on particular brands or models. By contrast, many quality tools are designed to meet the various specifications of many manufacturers. In my case, the ability to invest in tools equipped with adjustable components or interchangeable attachments has proven to be of tremendous assistance. This really allows me to fulfill virtually almost any vehicle’s needs with great confidence that I will manage to do it effectively and accurately.

Key features to look for in a quality bearing wheel puller

When it comes to the customization of the bearing wheel pullers, there are common features that always come up that I would like to mention that are paramount in the effectiveness, strength, and versatility of the tool. Hence, the main parameters one should consider:

- Adjustability

An effective bearing wheel puller should comprise arms that can be adjusted according to the size or the configuration that is required. This is important as it enables different apparatus to be used in different vehicles without the need for several tools.

- Durable Materials

As far as the significance of the puller is concerned, its durability is of huge concern as well. The pullers should be constructed of various high-strength steels or alloys that will not bend even when they are under pressure. Strong pullers not only have a long lifespan, but they also promote safe usage.

- Interchangeable Attachments

One more thing that revolutionized tool performances is those having interchangeable attachments or heads. It enables one to change the components depending on the details of the work one wants to do, which enables a puller to perform various functions.

- Ease of Operation

One major aspect that ensures the smooth functioning of different attachments as well as increases precision is ergonomic designs with easy grip handles or intuitive setups. You expect a tool that does not make the task needlessly complicated, thereby causing division.

- Corrosion Resistance

As these tools are generally immersed in grease and dirt and moistened as well, it is important to select a puller that is coated so as to improve its corrosion-resistant properties, which would come in handy when engaging it on a long-term basis.

- Tight Jaw Grip

The jaws need to have a perfect grip so that the bearing or the wheel which is under detachment does not slip over thus resulting in a mess while the detachment is actually taking place.

- Compatibility

Finally, ensure that the puller will work with many types of vehicles. After all, if the wrench supplier has a universal wrench that conforms to recognized sizes, time and money will be saved in the future.

I understand the augmentation of emphasis on these characteristics to be an indication that my tools have always been reliable and appropriate for the task at hand, be it routine maintenance work or more complicated. Such an investment in a good puller such as this one is not one you will regret.

What’s the step-by-step process for using a bearing wheel puller?

If the following steps are adhered to, the use of a bearing wheel puller becomes rather easy. In this first step, I ensure that I make adequate use of a jack and “jack stands” so that the vehicle I would be working on is raised and in a position where it cannot move accidentally. For the next step, I locate the wheel or hub assembly that needs to have the bearing removed and take off any other components that may include the wheel or brake rotor so as to make the removal of the bearing easier. In the next step, I carefully place the bearing wheel puller so that it is level with the bearing or hub and tighten it to provide a firm hold. I then turn the puller’s central screw and start applying pressure on the puller, making rotating movements to slowly pull the bearing out without damaging any of the parts around it. Once the bearing is out, I look for wear or debris in the area before I place the new bearing inside. Overall, a calm and precise approach is what allows an outcome that is not only neat but also effective in all aspects.

Preparing your vehicle for bearing removal

In order to remove the bearing, the vehicle should be raised and supported manually using a jack and jack stands. Remove the wheel and undo the brake caliper, brake rotor, and axle nut, as they may stand in the way of access to the bearing. Wipe the area around the bearing to prevent contamination and check all parts for wear and tear. These preparatory steps make the bearing removal process easier and safer.

Proper technique for attaching and operating the puller

To guarantee that the puller is attached and operated correctly, I always perform the task in a step-by-step manner,and here is how I do it:

- Select the Right Puller for the Job: Firstly, it is vital to select the type of puller that corresponds with the type and size of the bearing to be worked on. Failure to use the appropriate size can lead to damage to the bearing and or the adjacent parts as well.

- Properly Align the Puller Arms or Jaws: It is my duty to locate its arms or its jaws carefully such that if they do grip any component or bearing you wish to remove they are held securely in place. Place: with regards to alignment, wherever it is important, if incorrectly placed, then that can lead to slippage and then the said component can be damaged or worse is a hazard. These points must be uniformly distributed around the circumference.

- Secure the Puller’s Center Screw in Place: Then adjust the center screw of puter such that it sits correctly onto the shaft’s center access. This would ensure that the force applied is symmetrical, thereby ensuring minimum pressure is put on other parts.

- Slow and Steady Operation: I begin tightening the compound puller screw, and during this process, I make certain that careful and gradual force is applied. Too fast or too unevenly increases the chances of the parts getting damaged. When screwing in one part it does not alter the screw puller alignment, I also supervise the puller alignment so that no discrepancy occurs during the process.

- Lubricate if Necessary: For particularly stubborn components or bearings, I might use a small amount of lubricant on the threads of the puller or the shaft to reduce friction during operation. This makes the removal process smoother and prevents unnecessary strain on the tools.

- Check for Obstacles or Resistance: Finally, I pay attention to any unusual resistance or obstruction. If the bearing seems stuck, I stop and inspect for other issues, like corrosion or dirt buildup, which might need to be addressed before proceeding.

This minimizes the possibility of damage or mistakes while ensuring the puller works without any problem. Adopting a more detail-oriented stance towards this activity enhances worker safety and greatly increases the chances that the task will be accomplished correctly.

Tips for dealing with stubborn wheel bearing hubs

I usually treat resistance with wheel bearing hubs by ensuring everything is well-lubricated. For starters, everything penetrates oil that has been put on the hub to help ease rust. In addition, heating surrounding areas tends to loosen the steel grip on the hub, which makes it easier to remove. I will then utilize a heavy-duty puller to assist with the right force so as to prevent damage. This practice typically yields the best practices. Otherwise, it is always about taking the time to wait for the right opportunity.

Are there any specific tools or accessories I need with my bearing wheel puller?

there are certain tools and accessories that I consider indispensable when a bearing wheel puller is being used. First, a good set of wrenches or sockets would be necessary to ensure that there is proper fitting and working of these tools. Additionally, I recommend having some penetrating oil as well since it helps loosen the bearings with some adhesion and thus prevents any damage. In addition, having a good mallet or hammer can prove to be useful when you want to gently tap some components. Last but not least, a torque wrench is very important to ensure that every component is duly and appropriately tightened when the equipment is reassembled. With these tools present, work can be quicker and results better.

Essential components of a comprehensive wheel bearing removal kit

In regards to a wheel bearing, an appropriate wheel bearing removal kit should consist of a hub puller or hub removal tool that will ensure safe extraction of old bearings, as well as a hammer for those extra hard-to-remove bearings and a bearing press or installer kit for reinstalling the particular component, ensuring that it is done properly. One penetrating oil, a torque wrench, and a heavy rubber mallet are added to the kit, making it precise and assisting the efficiency required in the process of removing the hub. Wheel bearing maintenance will become more reliable and free of damage with the aforementioned set of tools.

The role of slide hammers and gear pullers in bearing removal

slide hammers and gear pullers are essential implements for removing bearings. The slide hammer applies the required force when a bearing is stubborn or stuck to the components attached. On the other hand, gear pullers provide controlled accuracy in the extraction of bearings located in small or awkward areas. The combination of these tools also lessens the number of steps taken to accomplish the job, adding speed and accuracy in the removal processes, thus making them critical in enhancing efficiency and proper management of the removal task.

Importance of using the right grease for wheel bearings

Since the correct lubrication is applied, friction is lessened, overheating during use is avoided, and wheel bearings can work in the right conditions. The specific grease used in wheel expansive bearings is designed to endure high loads, exposure to varying temperatures, and contamination; thus, the bearings are expected to last longer and perform optimally. Otherwise, failure to lubricate will cause excessive wear, driving risk, and expensive repairs.

What are the advantages of a Tommy wheel-bearing puller?

On my part, the standout item has got to be the Tommy wheel bearing puller in terms of its effectiveness and consistency. Its sturdy construction enables the removal of even the most stubborn wheel bearings while avoiding damage to adjacent areas. The tool is easy to use, thus saving time and energy needed for maintenance jobs. Also, its strength ensures it withstands regular usage in tough environments which makes it worthwhile for both professional mechanics and DIY enthusiasts.

Unique features of Tommy wheel bearing pullers

The distinguishing feature of Tommy creates the wheel bearing pullers, their unique design makes them effective and user friendly and Maintenance free as well. These consist of good engineering that does not capture the components of the pullers, they are able to provide intense workloads, and they give a great turning force, which is time-saving. This level of strength, dependability, and simplicity of use in pullers makes them the best in the industry in bearing withdrawing jobs.

Compatibility with Ford and Subaru models

Tommy wheel bearing pullers work perfectly with Ford and Subaru models. The wheel bearing pullers are designed to fit a variety of models from both manufacturers, which makes the bearing removal task much easier. Whether it is a Subaru vehicle like the Outback or an older model of the Ford F-150, those pullers work precisely, allowing any job to be done efficiently.

Performance benefits of using a Tommy wheel bearing puller

the advantages that arise from the utilization of a Tommy wheel-bearing puller are indeed unparalleled performance-wise. Now, here is how I can break down the features that you ought to expect from this tool:

- Precision Fit – The Tommy wheel bearing puller is designed in such a manner that it not only engages the bearing appropriately but also prevents any damage to the neighboring parts. Such level of precision is very important when servicing sensitive areas in Ford and Subaru vehicles.

- Ease of Use – This tool’s ergonomic shape and how it works make it perfect for anyone, whether you are a novice or a professional. This allows for the removal of bearings in a simple manner and in a short time, thus saving time and effort.

- Durability and Strength -The Tommy wheel bearing puller is constructed from superior materials, which makes it last in hardcore applications. This toughness means that it can perform well even when used multiple times on hard jobs.

- Compatibility -There is no need to worry about changing tools or using other means to work on other vehicles since it is designed to fit as many models as possible. Thus, it is an ideal choice as you work on a normal car or a heavy-duty truck.

- Efficiency – It reduces the chances of errors during the removal of the part and avoids additional wear and tear on the vehicle by applying pressure evenly. Such effectiveness not only provides the right kind of service but also reduces expenditure in the long run.

By solving the central issues of usability, compatibility, and durability, the Tommy wheel bearing puller truly exceeds the competition. It’s a tool I trust because it makes a sophisticated process easy while always returning brilliant results.

How do I maintain my bearing wheel puller for long-lasting performance?

To keep my bearing wheel puller in excellent functional order for years to come, I simply abide by a few technical rules. First, I have quite a routine after I finish using the tool. I love cleaning things, so I make sure to remove grease, dirt, or anything that might damage the tool over time. I rub a clean cloth while scrubbing the implement and, if necessary, use mild soap. Secondly, all components should be examined for damage or excessive wear, and I immediately attempt to remedy some of the concerns without delaying their resolution if any are detected. Thirdly, the moving parts of the puller caster end’s lubrication are also important since it helps to protect the screw and other components from rust and other problems. Fourthly, every implement should be stored in a safe and dry environment out of extreme moisture and heat. All such actions will ensure that my wheel puller will last for a long and always be in a brand new form, waiting for the next task.

Cleaning and storage best practices

cleaning and proper storage of the tool is essential for its durability and foremost usage. To keep the equipment in good order and guarantee its quality, make it a point to wipe off any dirt, check for any damage, make sure moving parts are oiled, and put the equipment away in a climate-controlled room. By doing this, you help ensure the reliable performance of the equipment and prolong its life.

Identifying signs of wear and when to replace components.

When performing the assessment for various signs of wear, I visually examine the tool for any visible damages such as cracks, dents, deformations of the frame and other components as well as other factors. Since instruments, in general, have moving parts, I look for internal wear signs, such as unusual resistance or looseness in any of the moving parts. If I detect destroyed threads, bearings that show signs of usage, or increased operational spans that lead to decreased accuracy, then it means that those specific parts need to be replaced; otherwise, they will not be able to function. In addition to this, I also listen out for abnormal sounds such as silencing squeaks or noises which are usually produced when something grinds together that requires attention by a specialist or just simply has to be replaced. Including such usual checks on my schedule in a proactive manner helps me in ensuring that the tools I use do not malfunction ensuring safety and reliability during use in different jobs.

What safety precautions should I take when using a bearing wheel puller?

Safety measures should be of utmost concern, as they guarantee that no injuries nor damage to the equipment occur whenever a bearing wheel puller is being operated. Steps for safety should begin by putting on suitable personal protective clothing, such as gloves and safety glasses, so as to protect oneself from flying objects and sharp corners. Make sure that the puller is fitted in the right way and that the bearing is perfectly matched with it in order to avoid any unexpected dislocations or failure of the tools. Always turn the tool with a steady control to make sure that excessive force that might crack the component or puller is not applied. Finally, make sure that the joint or the structure has not been displaced before attempting to apply force and make sure the puller is not in any way worn out or damaged before using it.

Personal protective equipment recommendations

there are some specialized items that qualify as personal protective equipment (PPE) that include at least a single pair of safety glasses that protect your eyes against flying debris or metal fragments that could cause serious damage during work. I also involve myself in the usage of strong gloves that I ensure are well-fitted in order to protect my hands as well as ensure a firm grip on the tools and sharp edges. Provided that the task is located in a certain site that has high noise levels, I may also employ passive hearing protection like ear plugs or earmuffs to guard against hearing loss. Besides, strong closed-toe shoes are also important as they protect my feet from injury in the event that any tools or components are dropped on them. In support of this, taking such measures assists in ensuring safety and effectiveness while operating with a bearing wheel puller.

Common mistakes to avoid during the bearing removal process

An operator applying too much force without checking puller alignment, risking damage to both the bearing and components, is one of the more prevalent errors to be done. Another frequent error is the failure to decon the site before commencing work, which invites dirt interference or uneven pressure applied while being removed. It is also worth noticing that not lubricating specific elements causes greater friction and complicates the removal process. In other instances, if the puller used is not of the right type and size, the chances of effective removal are reduced as well as increased chances of an accident. When doing such a removal, make sure you prepare well, as this will increase the efficiency and safety of the removal process.

When to seek professional help for wheel bearing removal

Anyhow, I believe that wheel bearings can be removed without being cut off for the sake of argument. However, if one notices signs of severe corrosion or excessive wear on the components or if cutting the bearing off is rather difficult, it would be better to leave this job to a professional. And here’s a very simple reality. Even if you are fully capable of doing the task technically, if you do not possess the right tools or feel unsure about the precise application of alignment and force, the job takes longer than it should. Without the right tools, it is wise to leave such tasks to professionals with right set of tools. Otherwise, it would be ideal to prepare yourself properly for this task. Not only one’s safety but also the integrity of car parts is at stake. It wouldn’t be unreasonable to estimate that a four-wheel drive could end up costing the owner a staggering 300,000 to 400,000 in basic repairs if it is poorly taken care of in terms of its essentials. Usually, self-sufficiency is overestimated.

Reference

- How to Change Wheel Bearings: 12 Steps (with Pictures) – wikiHow

- DIY Guide: How to Replace Your Car’s Wheel Bearings – Goodhood

- How to replace a Wheel Bearing – NSK

Frequently Asked Questions (FAQs)

Q: What is a wheel-bearing hub puller, and why is it important?

A: A wheel-bearing hub puller is a specialized tool designed to remove wheel bearings from vehicle hubs. It’s crucial for automotive maintenance as it allows for the safe and efficient removal of bearings without damaging the wheel hub or surrounding components. This tool is especially useful for select Ford and Subaru models, among others.

Q: How does a wheel bearing removal tool kit typically work?

A: A wheel bearing removal tool kit usually consists of various components, including a puller, adapters, and a Tommy rail. The puller attaches to the wheel hub, while the adapters ensure a proper fit for different bearing sizes. The tommy rail provides leverage to extract the bearing. This combination allows for ultimate performance with the Tommy wheel bearing hub puller, making it possible to remove a wheel bearing in a matter of minutes.

Q: What are the benefits of using a Subaru wheel-bearing hub puller?

A: A Subaru wheel-bearing hub puller is specifically designed for Subaru vehicles, ensuring a perfect fit and optimal performance. It reduces the risk of damaging the wheel hub or axle during the bearing removal process. This specialized tool works seamlessly with Tommy wheel bearing pullers, providing efficient and safe bearing extraction for Subaru models.

Q: Can you explain the difference between a wheel-bearing puller hub removal tool and a gear puller kit?

A: While both tools are used for extraction purposes, a wheel bearing puller hub removal tool is specifically designed for removing wheel bearings from hubs. On the other hand, a gear puller kit is more versatile and can be used to remove various components, such as gears, pulleys, and bearings from shafts. The wheel-bearing puller is optimized for automotive use, whereas a gear puller set may have broader applications across different mechanical systems.

Q: What should be included in a comprehensive wheel-bearing removal tool kit?

A: A comprehensive wheel bearing removal tool kit should include a bearing puller extractor, various-sized adapters, a Tommy rail for leverage, and possibly a slide hammer. Some kits, like the bearing puller 12-piece set, may also include additional tools for different vehicle makes and models. For ultimate versatility, look for a kit that works with Tommy wheel bearing pullers and covers both Ford and Subaru models.

Q: How do I properly maintain my wheel bearing after removal and replacement?

A: After removing and replacing a wheel bearing, proper maintenance is crucial. Use a high-quality wheel bearing grease, preferably a lithium extreme pressure anti-wear grease, to lubricate the bearing. Ensure the bearing is correctly seated and torqued to manufacturer specifications. Regularly inspect for signs of wear or noise and replace as needed to maintain optimal performance and safety.

Q: Are there any specific considerations when removing bearings from the front wheel versus the rear axle?

A: Yes, there are differences to consider. Front-wheel bearings often integrate with the hub assembly and may require a specific front-wheel bearing removal tool. Rear axle bearings might be pressed into the housing and could need additional tools like a slide hammer. Always consult your vehicle’s service manual and use the appropriate tools, such as a ProMaxx extractor or Tommy Subaru wheel bearing hub puller, depending on your specific make and model.