A car’s wheel bearings might be small devices, but they are very important in enabling smooth and safe movement. They allow the wheels to turn with little resistance while bearing the weight of the vehicle. However, if a wheel bearing has become damaged or deteriorated, it can create severe mechanical problems along with safety concerns. The objective of this article is to explain wheel bearing troubles in detail, tell readers what signs can indicate wheel bearing trouble, and determine whether it is safe to drive under such circumstances. You will learn to recognize risks and find solutions that will enhance your knowledge about vehicle maintenance and enable you to avoid hassles during your rides.

What are the Signs of a Bad Wheel Bearing?

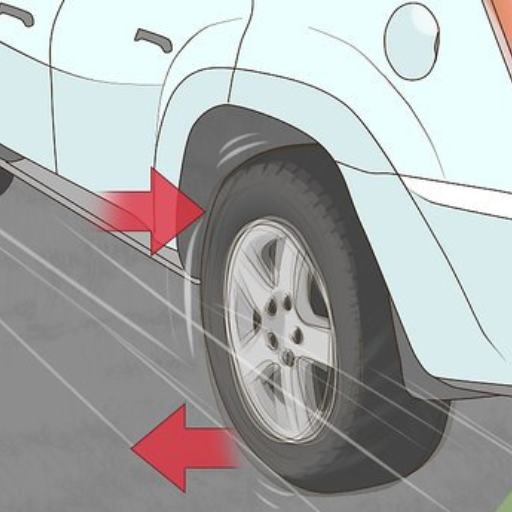

A hint that the vehicle has a defunct wheel bearing is if there are any growling, grinding, or humming noises with the wheel structure, which are amplified during a high-speed drive or while turning. Such a malfunction also results in vibrations in the steering wheel as well as uneven wear and tear on the tires. Moreover, if the wheel is loose and wobbly or the vehicle is forced to tend to one of its sides, then it also points to the wheel bearing being worn. Regaining correct functionality becomes extremely vital to ensure that you and your depends do not incur any harm by extension or that the vehicle does not sustain crucial damage.

Common Symptoms of a Failing Wheel Bearing

In general, problems with wheel bearings tend to present themselves with multiple signs of distress, including strange sounds such as humming or a growl, vibrations in the steering wheel, uneven wear on the tires, or the vehicle dragging to one side. This is also very important for safety and to prevent costly repairs. Should you notice any of these signs, it is prudent to have the vehicle looked at by an expert promptly.

How Bearing Noise Indicates Problems

one of the most useful indicators of malfunctioning needs on the wheel bearing is the noise produced by the bearing, which in most cases might sound innocuous. When bearings wear out, they sometimes produce certain noises such as humming, growling, or even grinding, depending on the magnitude of the problem.” Those sounds occur as the components of the bearing are not smoothly rotating as they should be done due to some physical damage or lack of some lubricant. In my opinion, if you notice that the bearings start to produce even louder noises as the vehicle rotates faster or in an opposing direction, that definitely means the bearings are becoming unsafe and require changes. If one deliberately chooses to neglect these incessant noises, one may be risking themselves to even greater disadvantages and tensions while also putting their lives in the danger of road collisions.

Detecting Vibration and Hum When Driving

While operating a vehicle, the sensation of vibration and/or hum quite possibly highlights an issue with the wheel bearing or mechanical side, combined with other components. Based on my past encounters, I will illustrate a detailed rationale for how I approach these sensations in greater detail.

- Speed-Specific Vibrations: If the vibration becomes more noticeable when you accelerate, then chances are it has something to do with either your wheel bearings or tire balance. Damaged bearings will lead to an imbalanced rotation, resulting in a cordless noise or vibration that only intensifies with increased speed.

- Turning Sensitivity: If there is an increase in the vibration or noise when you steer the vehicle in one direction; more specifically, it worsens when you steer to the left, it is highly likely that the bearing on the opposite side has an issue. For example, If the problem has an increased sensitivity during a left turn, then it implies the right-wheel bearings need a fix.

- Test Surface Sensitivity: Varying the surfaces while driving (like from smooth asphalt to beset pavement) can help figure out if the cause of the vibration is internal or external. If the hum is present on every surface driven, then this hints at a mechanical issue that needs to be resolved.

- Tire and Suspension Inspection: Sometimes, the shaking of the car can be because of the tires or the suspension, which is an error in itself. The bearings may have been fine, but still jumping to conclusions shouldn’t be done without checking for abnormal tire wear, alignment, or suspension damage.

It is important to take care of these problems as soon as they appear. Ignoring them, however, may result in severe mechanical errors. In addition, vehicle control may be compromised. Refrain from diagnosing the problem yourself and always consult a specialist.

How Long Can You Drive on a Bad Wheel Bearing?

The type of damage a bad wheel bearing can inflict on your vehicle will ultimately determine how long it can last without getting changed. However, it is highly unadvisable to keep driving a vehicle once it starts to show symptoms of wear, that is. Ignoring a bad wheel bearing can easily cause damage to the axle, driving hub, or other integral parts of your car. Apart from these damages, a detached wheel is also a risk, and that is a safety hazard while driving. Therefore, it is recommended that you avoid incurring further wheel bearing repair costs by doing timely maintenance on the bearing and your vehicle in general.

Risks of Driving with a Failing Wheel Bearing

In what can be termed as gross negligence, the industry driving risks of a deteriorating wheel bearing are paramount. Allow me to elaborate. Here is what you may be faced with if this issue is neglected:

- Loss of Vehicle Control: the most frightening risk accompanying a motion vehicle is a complete wheel detachment while the vehicle is in motion, while these scenarios are quite rare in occurrence needless to state the consequences could be deadly.

- Damaged Hub and Axle Assembly: Grinding and growling are unorthodox sounds that carry the risk of suggesting a failing bearing; not only are they one of the first indicators of potential bearing loss, but they also make the ride uncomfortable, as these vibrations could cause the breaking down of different parts, which further raise the repair and maintenance costs.

- Brake System Problems: A failing wheel bearing could potentially worsen the overall conditions of the brake system as it places undue stress on the whole assembly, the ineffectiveness of the brakes then results in increased stopping distances which could potentially be quite dangerous and reduce the overall control of the vehicle during emergencies.

- Noise and Vibrations: Failing wheel bearings apply undue friction, which, if left unchecked, could lead to a chain reaction of a variety of other problems. Loss of intra-axle lubrication could also lead to overheating of the still-connected parts or other wear-related issues.

- Complete Wheel Detachment: A loss of the wheel itself or uneven tire wear due to a breakdown in wheel bearings causes a vehicle to be uncontrollable, especially during higher speeds, which could pose dire and unwanted threats.

There are a number of risks associated with these signs, so I advise addressing the problem as soon as you notice any of them. I suggest having your car checked by a specialist without delay.

What Happens if a Wheel Bearing Fails While Driving?

Driving without a malfunctioning wheel bearing can be catastrophic. As you progress, there can be significant noise, feedback, and vibrations, which make the vehicle more and more difficult to manage, which can lead to issues where a wheel completely locks up or even, at times, comes off the car entirely. When these issues take place, they can result in the driver, as well as other people on the road, being at risk. This is why the first signs of issues with the wheel bearing need attention and professional inspection.

Why It’s Dangerous to Drive on a Bad Wheel Bearing

The safety of driving on a faulty wheel bearing is risky as it affects the overall vehicle control system and exposes a wheel to greater failure chances which in turn may result in unforeseen unfortunate instances or accidents. It poses a danger, not just to the driver but also to the other people on the road. The problem is of crucial importance and so it must be dealt with quickly to avert grave mechanical defects and danger.

Is it Safe to Drive on Bad Wheel Bearings?

I would strongly recommend never using a vehicle that has bad wheel bearings. Speaking from my knowledge in the automotive industry, I understand how the issue can be bypassed, and this often leads to local disasters where the wheel droops or even comes off while on the road. From a practical perspective, yes, the car might be able to be used under the afflicted circumstance, but the stress and instability brought onto the other systems make fixing the situation a harder and more expensive task, not to mention putting your safety at risk. If a vehicle has a bad wheel bearing, I would say getting it checked and fixed should be on the priority list because it surely is no joke.

Potential Consequences of Ignoring the Issue

To disregard such a problem would be dangerous not just for the car’s occupants but also for other road users, it would allow the unfortunate event of losing a wheel bearing during automatic vehicle operation where the consequences would be tire wear, wheels falling off or issues with the vehicle steering. Prompt resolution of this issue would avoid putting one’s life at risk.

When to Seek Help from a Mechanic

If you hear grinding, humming, or growling noises from your wheels if you feel that the steering response is somehow sluggish, seek an auto mechanic. Additionally, the vibration of the steering wheel, as well as the uneven wearing of tires, is a strong indication of some wheel bearing problems. Do not wait—taking care to remedy these concerns will reduce the risk of further damage and make your car safe to drive.

How do you tell which wheel bearing is bad?

A physically broken wheel bearing is replaced based on the diagnosis done such as test driving or sound observation. Usually, a failing wheel bearing will always make a deafening noise while moving, which usually occurs when turning in the direction of the supposed broken bearing, such as when you steer the left wheel side of the car, and if the sound becomes louder, it indicates that the right side bearing is damaged. Further to add, if one places a wrench and turns each wheel, a broken bearing will create some friction and looseness. For further accuracy, consulting a professional mechanic is always recommended.

Diagnosing Front Wheel Bearings vs. Rear Wheel Bearings

There are some major differences between front wheel bearings and rear wheel bearings, which will assist in accurately defining the specific issue. The explanation is presented below.

- Location of Noise or Vibration

Most of the time, vibrations and noise generated by the front wheel bearings are felt by the steering system. Any unusual sound, which could be a growl, a click, or even high pitch while driving, which becomes more when you lean on it during a turn, would suggest that an inspection of the front bearings is necessary. With regard to the rear wheel bearings, I can say that the driver might not directly experience the vibrations or noises but will be able to hear them from the rear part of the vehicle.

- Impact on Steering Control

It is logical to think that if a front bearing is faulty, this may lead to disorientation in the vehicle while steering as it is directly connected to the steering system. For example, the driver may begin to feel the steering being somewhat loose or the vehicle may appear to be steering with lesser precision than before, all of these symptoms imply wear in the ball bearings. In contrast to this, the steering mechanism during the beginning of the turn has not been affected much by rear wheel bearings, and when the steering is operated normally, noise and vibration are felt, and the problem could be present behind the steering wheel.

- Testing Methodology

A common method for diagnosing a faulty wheel bearing involves lifting the vehicle and spinning each wheel. For front wheel bearings, ensure you’re also checking for excessive play in the steering components since the problem might be more apparent due to their connection to the wheels. Rear wheel bearings, however, should be checked for irregular resistance or grinding noise while spinning the wheel freely.

- Load and Turning Tests

It’s also important to remember that while performance evaluations are being conducted, the test drivers are also rotating the vehicle, and this action can aid in discerning the type of wheel bearing problem the vehicle has, front or rear. The turning of the steering wheel puts more strain on the front bearings; hence, if one side is damaged (if turning left and the damaged side in question is the right side), noise is amplified. Turning the vehicle around tends to cause a sound that is more constant than a rotating vehicle which is the reason why more attention is required when accelerating or decelerating, this sound has less variation unlike the noise from the rear which is consistent while steering.

- Visual Inspection

Apart from being dependent on the manufacturer, the vehicle’s design also plays a role. For example, in front-driven cars, the front wheel bearings are more likely to be integrated into the hub and, consequently, suffer severe wear. They are also more visually appealing because of the grease leakage; some damaged ones are simpler in terms of structure and less susceptible to wear and tear.

- Driving Dynamics

Once again, it is the bearings at the front wheels that influence the vertical stability of the vehicle and the accuracy of the steering efforts. The rear wheel bearings are also cited as a source of noise. However, their main deterioration takes the form of road awash and loss of tire texture.

Reflecting on these parameters individually, it is possible to make a more confident diagnosis of whether the problem is with the front or the rear wheel bearings. But in either case, always conduct a thorough examination or get a mechanic to do it to ensure what you’ve diagnosed is correct.

Professional Methods for Identifying a Bad Bearing

determining a defective bearing is a practice based on solid skill and acuity. A good way to begin is by performing a detailed sound examination- if a growling or humming sound alters with the speed of the vehicle, then it is an area of concern. Subsequently, I advise safely raising the car and wobbling the wheel to see if there is wheel play; too much movement of the wheel usually indicates a damaged bearing. Finally, look at the tires; they should not have wear and heat around the wheel hub which in itself is justification of a problem with the bearing. These treatment methods do not only help save a great deal of time but guarantee the correct diagnosis, and thus, repair works are applied accurately and in the right time.

How to Replace a Wheel Bearing?

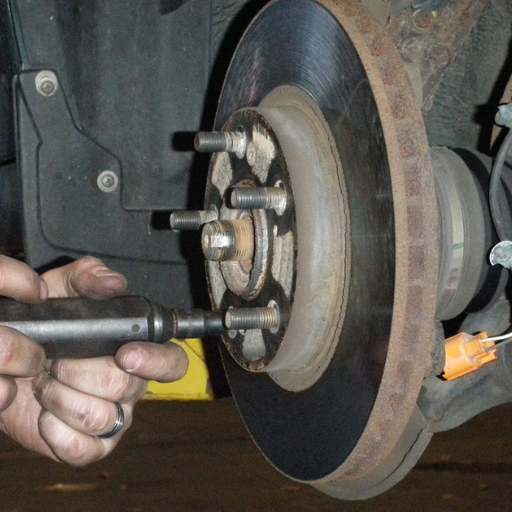

In the first step, stratify the vehicle on levelers in order to have unimpeded access to the hub assembly by removing the wheel. Next, carefully remove the brake components, including the ever-so-delicate calipers first, followed by the rotors and, if needed, the axle nut as well. Bear in mind that the removal of the said components is only done to gain easier access to the puller or hub press. Also, A warning: while removing the bearing, use a puller or press that is specifically suited to remove the said component; otherwise, the hub assembly will be damaged. Apply a mix of special grease and Loctite or similar fast bonding agents to the new bearing and replace the previous one. Settle the bearings in their respective places, the two tiny steel bearings that are visible should be placed in the shoulder window, there should be a fine latch out there that will prevent ejection of the bearings from the shoulder window to enable the locknut to be easily mounted without any dragging. Fit the wheel safely, lower the vehicle, and check if the new set is correctly aligned. Thoroughly do the required checks, including going for a test run after securing all the components. In essence, while all these tools are available, the entire process should be completed by professionals well-versed in the mechanics to ensure optimal safety and effectiveness.

Steps for Wheel Bearing Replacement

Wheel bearings are critical components of any vehicle, and if yours have started to fail, worry not! Unfortunately, replacing a wheel bearing can be rather challenging. However, the appropriate mindset and methodology will make the entire process much more comprehensible. Just how would I commence this assignment? Let us delve into the specifics:

- Gather Your Tools and Safety Equipment

Before starting off, ensure that you have all the necessary tools like a jack, lug wrench, socket set, torque wrench, and a bearing press/puller. Do not forget the safety equipment, such as gloves and safety goggles, so as to remain safe during the operation.

- Secure the Vehicle

Ensure the car is parked on a flat surface and the parking brake is applied. Chocks on wheels can help to secure the vehicle in place so that it is not able to roll while you are working on it.

- Loosen the Lug Nuts

With the vehicle still on the ground, use the lug wrench on the wheel lug nuts. Ensure they are slightly loose. This will allow for quick and easy removal of the wheel once it is raised.

- Lift the Vehicle

Make use of a jack by placing it close to the wheel that is going to be worked on. Make sure to place jack stands on the car after lifting it up, this will minimize the chances of injury as you are not solely dependant on the jack anymore.

- Remove the Wheel

Carefully set the wheel aside so that it won’t be damaged after you’ve unbolted it by loosening the lug nuts.

- Access the Wheel Hub Assembly

To get at the wheel hub Assembly, the brake caliper and rotor may have to be removed first. Unbolt the caliper using a socket set and then hang it with a piece of wire. Remember not to let it hang by the brake line.

- Detach the Wheel Hub

The first thing that has to be done is to locate the wheel bearing assembly, which is quite important as it is a part of the hub. There may be a need to remove components, which depends on the kind of vehicle you’re operating on. For instance an axle nut or tie rod might need removal, in such a case referring to the manufacturer’s specifications will be extremely helpful.

- Remove the Old Bearing

If the bearing is not a bolt type, then a bearing puller or press will have to be used in order to disassemble it from the hub assembly. One needs to be very careful as the component can be destroyed when removed improperly.

If you follow these procedures carefully, you will be able to change a wheel bearing accurately and efficiently. Be sure to look up your vehicle’s service manual for detailed guidance, and for more difficult or strange steps, don’t be afraid to ask for expert help.

Tools Required for Hub Assembly Repair

Here is a short list of the tools I always recommend when establishing and repairing a hub unit. To begin with, typically a full set of hand tools including: a selection of rods, a socket set, wrenches and screwdrivers with assortments of heads. Also, a torque wrench will very help with the fastening of screws against the specified torque requirements. Do not forget a breaker bar, the big one to use with unbreakable bolts. A jack lift and duckboards are a must for securing the car during some work. An additional aide, loosening parts like a mallet or hammer is equally helpful, a hub puller however saves a lot of time and effort. Finally, keep some rust penetrant and cleaning supplies available for preparation and cleaning of surfaces. Generally speaking, the better the tools you have when doing repairs, the better the outcome of the repair.

When to Consider a Professional Mechanic for Replacement

There are a number of cases in which it is best to engage an expert mechanic for hub assembly replacement. Even though a great number of auto enthusiasts do ordinary maintenance and repairs, there are times when do-it-yourself goes beyond the limits due to the fact that it requires specialized skills, tools, and experience. So, what are the most important elements to take into account?

- Lack of Specialized Tools

Parts of the hub assembly, such as bearings and really rusted parts, may involve specialized tasks like pressing in or out and this additionally calls for access to high-end equipment. Given that these may not be available, a professional mechanic is equipped with all the necessary tools to complete the task well and in a safe manner.

- Complex Vehicle Systems

The hub assembly is one of the main components in a vehicle, and it is where a lot of critical systems such as ABS sensors, Traction Control, and advanced drivetrains are integrated in a lot of vehicles these days. Any improper handling or installation of the hub could damage or impede the function of these costly systems hence reason why these installations are best left for professionals who are qualified to do this and have the experience to follow the manufacturers’ requirements.

- Severe Rust or Corrosion

It’s common to have rust and corrosion of the hub assembly and other parts if you reside in areas with salty climates or regions that have very cold weather. On the flip side, a professional mechanic has experience in working on corroded or rusted bolts and other parts and could help you determine if other servicing is also required.

- Time and Experience Constraints

Hub assembly repair is relatively more time-consuming if you have never attempted it before. Should you feel unsure about your skills or your profession in hand is time-consuming, it would be wise to leave the job to a contract worker. This will minimize trial and error and the subsequent annoyance.

- Safety Concerns

It goes without saying that no vehicle should be undervalued in terms of safety. This is because if a hub assembly is not fitted correctly, it can lead to extreme situations such as uneven tire wear, unsafe handling of the vehicle, or even a wheel coming off. A qualified professional guarantees this by making sure the task is completed in one go and all safety measures are adhered to.

Keeping these aspects in mind allows one to decide appropriately whether to carry out the repair on their own or get professional help for it. Keep in mind that it is always good to keep the focus on safety and the latter half of the vehicle’s reliability.

Reference

- Holts Auto: Can I Drive with a Bad Wheel Bearing?

- Mechanics Stack Exchange: How dangerous is it to drive on country roads with a potentially failing wheel bearing?

- SKF Vehicle Aftermarket: 4 Symptoms & Signs of a Bad Wheel Bearing

Frequently Asked Questions (FAQs)

Q: Can you drive with a bad wheel bearing?

A: Driving with a bad wheel bearing can cause a dangerous situation, as it may lead to a loose wheel, increased wheel wobble, and even wheel bearing failure. It is advised to get the bearing checked and replaced as soon as possible.

Q: What happens if a wheel bearing goes bad?

A: If a wheel bearing goes bad, it can cause the wheel to wobble, make noise, and eventually lead to a complete wheel bearing failure. This can result in the loss of control over the vehicle, making it unsafe to drive.

Q: How long can I drive with a bad wheel bearing making noise?

A: It is not recommended to continue driving with a bad wheel bearing making noise. The longer you keep driving, the higher the risk of causing further damage or experiencing wheel bearing failure.

Q: What wheel bearing noise indicates a problem?

A: Common wheel bearing noise includes grinding, humming, or rumbling sounds coming from the tire and wheel area. If you hear such noises, it’s crucial to have the bearings inspected promptly.

Q: How often should wheel bearings be replaced?

A: Wheel bearings last anywhere from 85,000 to 100,000 miles under normal driving conditions. However, regular inspections can help detect any issues early, especially if the vehicle is used in harsh conditions.

Q: Can a bad wheel bearing cause the wheel to fall off?

A: Yes, in extreme cases, a bad wheel bearing can cause the wheel to become loose and potentially fall off, leading to a dangerous situation. Immediate attention is required if there is any play in the wheel or signs of damage.

Q: What are the signs of wheel bearing failure?

A: Signs of wheel bearing failure include unusual noises, vibrations, a loose wheel, or uneven tire wear. If you experience any of these symptoms, it is important to have the vehicle inspected by a professional.

Q: Can a bad wheel bearing cause damage to other components?

A: Yes, a bad wheel bearing can cause damage to other components, such as the tire and wheel, drive axle, and even the worn suspension. Addressing the issue early can prevent costly repairs.

Q: What is the cost of a wheel bearing replacement?

A: The cost of a wheel bearing replacement can vary depending on the vehicle’s make and model. On average, it can range from $150 to $500, including parts and labor.

Q: Is it dangerous to drive with a bad rear wheel bearing?

A: Yes, driving with a bad rear wheel bearing is dangerous, as it can lead to a loss of control and potentially a dangerous situation. It is essential to address any signs of a damaged bearing promptly to ensure safety.