Thank you for clicking, and welcome to our guide on the costs of replacing wheel bearings. In this article, we will cover what a wheel bearing is, the role it performs in the whole vehicle, the signs that a wheel bearing is bad, and how to tell if one is, in fact, in need of replacement. A look nascent research on the expected replacement cost of a wheel bearing searches for an answer to the question – how is replacement cost estimated? We will also take you through the work involved in replacing a wheel bearing, including what tools you need and what procedure to follow. All in all, this article provides a clear description of the dos and don’ts regarding wheel bearings and how long they last as well as how much they are expected to cost. So, without much waiting, let’s begin and find out how much a wheel bearing replacement will set you back.

What is a Wheel Bearing, and Why is it Important?

I will try to answer in one sentence the following questions – What is a Wheel Bearing and Its Importance?

A wheel bearing, which is an engineering term that describes an apparatus splined to the hub of a wheel, is considered to be a significant part of the wheel assembly of a vehicle, as it’s the part that rotates with the wheel whilst preventing friction, which allows for rotation of the wheel to be done effortlessly. It consists of a set of steel balls or rollers and a metal ring revolving around it, called the bearing race. They are situated in the wheel hub assembly. One of the key roles of a wheel bearing is its ability to bear the load of a weight that is glued into the mass of a vehicle while at the same time transferring forces from the ground onto the wheel for optimum performance and controlled operating conditions.

There are several reasons why wheel bearings need to be installed in a vehicle. First of all, they help the wheels of the vehicle to rotate well which enhances the general drive quality of the vehicle. They reduce friction and, in turn, make the wheel spin on its own, which would then allow the vehicle to be more fuel-economical. Also, wheel bearings assist in loading the weight of the car evenly through its multiple tires and improve car stability and steering performance. If the wheel bearing doesn’t perform as expected, it possibly results in the car experiencing an increase in vibrations while driving, the tires wearing out excessively, and the steering control being compromised, all of which pose a threat while using the vehicle.

In conclusion, wheel bearings are an integral part of the performance, safety, and durability of your vehicle. The importance they hold must be appreciated and maintenance of wheel bearings forms part of this appreciation for an ideal driving experience.

Understanding the Wheel Bearing Functionality

The smooth and frictionless rotation of the wheels of your vehicle is accomplished by the wheel bearings which are critical parts of the wheel assembly. They consist of a set of small balls or rollers made of steel kept inside a metal ring called a race. The most important of the several functions of wheel bearings is to assist in the rotation of the wheels with low friction when weight rests on the vehicle and it moves.

Bearings, which support the wheels, are blasted with stress and load while driving, and they are also relatively prone to wear and tear. Wheel bearings are crucial as without them, great performance from the vehicle, along with safe driving, will not be guaranteed. Wheel bearings work using scientific principles to generate their effects, where reducing the friction on the wheels facilitates a rotation on them free of immense heat building up, which then minimizes the vibrations and leads to even tire wear on the wheels. To top it off, with the proper care of the wheel bearings, the control of the vehicle and its handling will be again augmented, providing a safe and smooth drive.

With the help of proper care and maintenance of the wheel bearings, the bearings can easily be identified as wearing out through a periodic inspection. The bearings should be replaced if they are either worn out or damaged, as they will become a threat to safety and lead to very expensive repairs. Now that you know how wheel bearings work and their importance, hopefully, you will not take them for granted and will take care of them so all your journeys will go smoothly.

Common Symptoms of a Bad Wheel Bearing

I will give you a brief answer as an authority in the field: What are the most common signs of a worn-out wheel bearing?

- Unusual Noises: A proposer uses the term whirring to describe a persistent rumbling or growling characteristic sound that usually elevates or mulitdesnascthroughout the car during acceleration or whether the car is returned to the one it’s moving towards.

- Vibrations: Under circumstances when the containing of one or more wheel is insufficient one or more wheel bearing start to shake leading to some amount of shake of the steering wheel or the entire car for starters when there is no sufficient or low acceleration and increase with increase speed.

- Uneven Tire Wear: It fgeneral knowledge that wheels tend to roll smoothly at straight roads with some wear on the outside edges, or tend to wear down when there is some or heavy contact on one side of the wheel they’ll start to wear unevenly from one side, this is due to a bad wheel bearing.

- Looseness in the Wheel: When a wheel goes loose on bearings and stays or just wouldn’t move around, causing a cavity without adding pressure towards this wheel and without applying enough acceleration, this excess play around the wheel could tend to move it out of its scope provoking the bearing or bearing needs to replace.

- ABS Warning Light: Increase inappropriately high or accurate ‘snags’ in wheel are provocated or found if a wheel crack or wears and tear – damaged, this could increase the chances of detaching master sensor and turning ‘ABS’ on.

Always consult with an automobile steering, suspension, and/or wheel alignment technician if you encounter any of these signs. If you wait too long, more extensive work may be needed to ensure that your vehicle’s future use does not put your safety at risk.

How a Worn Wheel Bearing Affects Your Vehicle

A bearing’s wear has various consequences, I must comprehend the influence the wear has on the performance and safety of the vehicle. The following are the adverse effects on the vehicle due to a worn wheel bearing:

- Noise and Vibration: The general observation when a wheel bearing is worn can be a low humming or grinding sound,d which can be more pronounced while the car is in motion or during a turn. This noise will only get worse as the bearing continues to wear out. You may also develop vibrations in the steering column of the car or the floor of the car which is again an indication of having a faulty wheel bearing.

- Uneven Tire Wear: A worn out bearing may result in tires wearing out unevenly due to the force exercised on them while the vehicle is in motion, al the wheels may not rotate uniformly according to the desired axis. Speed wobbles can also be observed, where certain portions of a particular tire would engage more contact with the road which leads to faster deterioration of one side of the tire and consequently leads to uneven tread wear.

- Handling and Steering Issues: It can also be observed that if a wheel bearing has been worn out the stability of your vehicle and the handling has ultimately been compromised as well. Steering and driving becomes quite tedious, and maintaining the car on the desired defense or offensive position while driving becomes very hard. This problem, if unchecked, can lead to severe problems of taking the required angle in dolphins of corners or sharp bends.

- Increased Friction and Heat: Internals rubbing against each other is a sign that a wheel bearing is wearing out and results in friction which leads to heat generation this could lead to the bearing being damaged or it bearing to have abnormal wear which over time would result in the wheel bearing needing to be replaced otherwise it would completely fail.

To maintain the vehicle in an optimal operational condition, any warning signs pointing to a worn out wheel bearing should be attended to without delay. Routine checks and maintenance can identify and remedy issues related to the wheel bearing in its nascent stages enabling you to have smooth and safe rides.

How to Know if You Need a Wheel Bearing Replacement

The working life of a wheel bearing is rather long, but how does one industry expert know when to replace it? Then watch for these few indicators:

- Unusual Noise: If you happen to hear a noise from the wheels that seems to be a buzz, rumble, or growl when driving fast, it can signify a bad wheel bearing.

- Uneven Tire Wear: An unusual round shape or the probing of the edges of the tires will also signify that there can be damage to the wheel bearing.

- Steering Instability: If turning the steering wheel of your vehicle has become a hassle and requires a higher amount of effort,t which is abnormal, then your car might have a damaged wheel bearing that is causing the wheel to lose balance.

- Wheel Vibration: If accelerating or braking causes your steering wheel to rattle or when the rattle mixes with vehicle vibrations, the wheel bearing may be faulty.

- ABS Malfunction: The third reason could be an illuminating ABS light in your car or an anti-lock function may not be working, all of these symptoms can show a wheel bearing grievance.

In the event that either of these signs manifests, it would be appropriate to have your wheel bearings assessed and if there is suspicion of any damage, replaced. Remember, on time detection and regular management can take care of the problem and allow you to enjoy safe and comfortable driving.

Signs That Your Wheel Bearing Needs Replacement

I would like us to focus on the indicators that suggest the replacement of your wheel bearing. Being able to detect these signs early on can assist in reducing the extent of damage and, more importantly, promote safe driving. Here are a few warning signs to look out for:

- Unusual Noises: A clear indicator that the wheel bearing is faulty is when you hear strange sounds such as grinding, humming, or growling, particularly when the vehicle is moving.

- Uneven Tire Wear: Insufficient wheel bearing adjustment or a damaged one will often result in wheels and tires being out of alignment. If your tires start to wear unevenly or unusually fast, this can also indicate a damaged wheel bearing.

- Steering Instability: If wheel bearings have significant wear then they may cause steering looseness or instabilities when the car is moving. You may also now have a hard time keeping your vehicle in a straight line while crusing, and even experiencing some form of vibration or too much floppiness in your steering wheel.

- ABS Warning Light: Your car may have a wheel bearing failure if the abs warning light illuminates on your dash board. This is important because the ABS system relies on an accurate measurement of wheel speeds which will be faulty if a bearing is damaged.

If any of the signs mentioned above are observed, it is recommended that the wheel bearings be checked and likely corrected. Remember that inspection at an early stage, followed by necessary, timely servicing, can go a long way in making sure that driving is safe and free of problems.

How to Inspect Wheel Bearings for Wear

In order to maintain peak performance and safety of vehicles, regular inspection of wheel bearings for wear is an indispensable step in maintenance. There are several basic procedures that may help you in this case:

- Listen for Unusual Noises: Noise can be a critical diagnostic in any setup behind the wheel. Abnormal sounds like grinding, humming, or rumbling can signal faulty wheel bearings.

- Check for Wheel Play: Put the vehicle on a jack and proceed to hold one of the tires from its top and bottom sections, which are the 12 and the 6 o’clock positions, respectfully. Then try and shake the tire to feel how loose it is feeling or if there is too much play in the wheel. A loose feeling or excessive play could indicate a failing wheel bearing.

- Test for Wheel Roughness: Hand rotation of each steer tire allows a roughness or sheer to be felt. Rotations should be consistent with a natural feel, lack of roughness or ruggedness indicates a bearing has been damaged.

- Inspect for Wheel Movement: Using the same method as above, ensure to grab the bottom and top sections of the vehicles tire and attempt to shake it horizontally. A little shake is normal but if there is too much shake or the feeling is rather loose it could mean the wheel bearing is worn out.

Ongoing examination of your wheel bearings can allow one to notice any early defects and avoid in hereafter further damage. If you identify any physical signs of abuse or wear on your bearings, they should be removed from the wheels. Thus, the bearings must be checked by a skilled mechanic and replaced when it is obvious that they are not ready anymore for the road.

Identifying a Failing Wheel Bearing

identifying a failing wheel bearing is crucial in securing the safety and the operability of the vehicle. Here are some key signs to look out for that indicate a failing wheel bearing:

- Unusual Noise: The first signs of failing and worn wheel bearings would often be growling, humming or grinding noise emerging from the aggravated side of the wheel. This noise might get louder when the car is accelerating or when the vehicle is making turns.

- Vibration or Shaking: A defective wheel bearing might cause violent vibration and shaking in the car including the steering wheel, this would result to less smooth and comfortable driving of the car.

- Uneven Tire Wear: Certain aspects such as wearing tires, if the tread of the tires wears unevenly or wears on one side relatively faster as vet observed change with time it may be bent as one tire has worn unevenly as its bearing has defects then it leads to broken bearings on the car in most cases.

- Loose or Wobbly Wheel: Bad or defective bearings on a wheel can lead to excessive movement or loose bearings on the wheel. If shaking the wheel countrywide leads to a side shake, then there have to be abnormal signs indicating the bearings are getting worn off.

In the case that you witness any of these indicators, then you need to contact a qualified mechanic who will inspect and replace the wheel bearings if necessary – Taking care of wheel bearings issues in an efficient manner should prevent escalation of issues in wheel bearings which in return will make you feel secure on the road.

Understanding the Cost to Replace a Wheel Bearing

let’s go ahead and determine the cost to replace a wheel bearing. First of all, the average cost of replacement of a wheel bearing will depend on multiple factors such as the car’s make and model, the geographical location of the repair shop as well as the type of issue related to the wheel bearing. As regards this, here’s a general summary:

Factors Influencing the Cost of a Wheel Bearing:

- Thanks to invoicing, price consistency is easy across locations. Graded prices reflect some bearing prices at certain stores, but do note that customers could get discounted bearing prices due to negotiation.

- However my cost analysis model which uses multiple data points can objectively quantify varying ratios of such variables in the equation and allows me to estimate the rare bearing charging sales with its equivalents as the average clocking margin replacement charge ratio or for several jobs.

- In ye olde market, higher quality is more expensive per bearing, that is how global market functions, for example a 6803 bearing could be priced at $1 within China.

Average Wheel Bearing Replacement Cost:

In most cases, the prices encompassing the cost of the labor and parts in the replacement of a wheel bearing vary between $150 and $400. However, it is crucial to emphasize that these figures are merely approximations and can change depending on the circumstances mentioned earlier.

Why Replacement Costs Vary by Make and Model:

Since various models require different designs and parts availability, the price changes. In case some cars need more complicated joining or special instruments, all that may also be tallied up to the price.

Be on the lookout for the upcoming parts of the article, where we are going to detail the procedures undertaken during the replacement of a wheel bearing, criterions for the equipment required for wheel bearing replacement, and expected durability of the front wheel bearings.

Factors Influencing the Cost of a Wheel Bearing

there are many elements that affect what you will pay when you decide to have a wheel bearing replaced. These factors include:

- Make and Model of the Vehicle: The cost may differ from vehicle to vehicle due to the differences in the design and the complexity of parts and their assembly.

- Labor Costs: Variation might also be experienced, owing to the nature of the mechanic doing the replacement – his capabilities and efforts.

- Quality of the Replacement Parts: The cost can also be influenced by the quality of the replacement parts used. Low-quality parts may be cheap but can affect overall stability and performance.

- Extent of Damage: If the wheel bearing has for instance interfered with the hub assembly or even the brake mechanism, the overall cost of the repair skyrockets.

A number of such factors have to be considered when estimating a wheel bearing replacement cost. For more, follow the description of the average wheel bearing replacement cost and the elements determining differences in costs among a range of vehicle makes and models.

Average Wheel Bearing Replacement Cost

I have noticed that wheel bearing replacement is quite widespread, especially among semi truck owners as an industry expert and businessmen. The average cost doesn’t exceed 600 dollars per wheel, while the bare minimum starts at around 150 dollars, with parts, and labor included. The end price may depend on the vehicle, the garage, or the reconstruction of even other categories. Above all, we have taken into consideration a universal estimation, hence cost may vary.

In terms of wheel bearing replacement, costs can differ owing to a number of elements, such as:

- Vehicle Make and Model: The automobile’s construction and engineering characteristics will influence how easy is to replace parts and how much it will cost.

- Quality of Parts: Lowering costs can range from parts that have different brands or different specifications. Therein, whereas low quality products may be cheap in cost, they may not be effective.

- The extent of Damage: Due to a damaged bearing, if the other displaced components include the hub assembly or any other parts of the brake system, then the cost for the replacement of parts will also increase through such methods.

Walk through these points before planning the cost of changing a wheel bearing. Keep watching for more information about typical costs associated with wheel bearing replacement as well as the factors that cause variation in costs depending upon vehicles make and model.

Why Replacement Costs Vary by Make and Model

According to industry expert analysis, the differences in wheel bearing replacement prices from various manufacturers are influenced by the following Read More: In WBM’s Interesting Universe, You Will Find

- Quality and Design of Wheel Bearings: There are various levels of design and bearings, and as such, different manufacturers produce varying bearing designs. This also explains why some vehicles might require replacement of wheel bearing for a more expensive specialized to certain models.

- Availability and Accessibility of Parts:Cost also tends to vary with availability and accessibility of wheel bearing parts such as the addative and substrate on an operational basis. There is always an expectation that particular brands, types, and models will at some point be harder to replace in the service, thus increasing expected service costs and time.

- Complexity of the Wheel Bearing Assembly: Wheel bearing assembly for different vehicles shows a considerable variation regarding the degree of complexity. There are other vehicles that have more complex systems which may include the need to have other parts removed to replace the wheel bearing and the replacement becomes more complicated hence more expensive.

- Dealer vs. Independent Repair Shop: The selection of whether a dealer will be replaced or an independent repair shop would do the replacement almost suggests the cost to be paid. This is because working with a dealer means that Original Equipment Manufacturer parts have to be used meaning high labor costs. This will ultimately raise repair and replacement expenses when compared to independent repair shops.

Consulting with a qualified mechanic or automotive specialist for an approximate quote for your make and model is also necessary, as such factors can explain the differences in wheel bearing replacement costs.

How is a Wheel Bearing Replacement Done?

I know that replacing a wheel bearing involves many important steps that guarantee that an ideal wheel bearing replacement is accomplished. Here is a brief summary of the general procedure:

- Preparation: Firstly, lift the car and secure it on jack stands. Detach the wheel and the brake caliper, which is immediately next followed by the removal of the brake rotor or the drum depending on which one is present.

- Access the Bearing: For some vehicles, it may be required to remove some other parts for instance the axle nut or the hub assembly for easy reach of the wheel bearing.

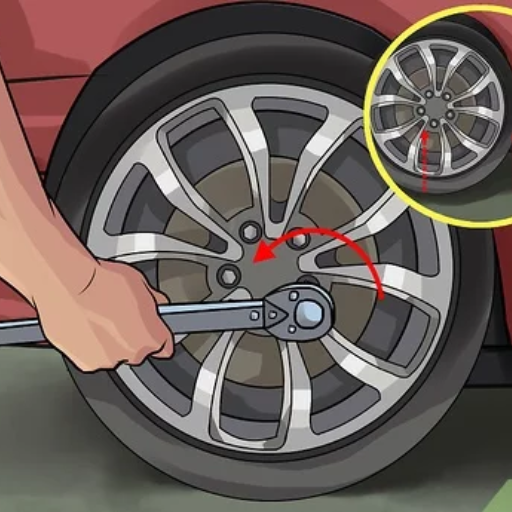

- Remove the Old Bearing: Remove the bearing assembly from the hub using special tools designed such as by either pulling or pressing from the back as needed.

- Clean and Inspect: Make sure that the entire remains of the hub are cleared away completely and that damaged or worn-out areas are assessed. Make sure the hub surface is clean and free of polish.

- Install the New Bearing: Apply grease onto the inside of the wheel bearing gently and then press it into the hub securely where it rotates. In doing so, confirm that it is positioned in the correct position.

- Reassemble: Attach again the rotor or the drum, calipers and any parts that were taken off. Ensure that the respective fasteners are strictly followed to maintain the correct torque specifications.

- Test and Verify: Finally, always make sure that the wheel bearing replacement was accompanied by a test drive so as to enable notice if there are unusual sounds or vibrations during the movement of the bearing.

Steps to Replace a Wheel Bearing

Here’s how you would replace a wheel bearing:

- Raise the Vehicle: Using a jack to raise the specific vehicle from the surface area, the vehicle must be properly secured with jack stands placed underneath it

- Remove the Wheel: To get access to the wheel hub, remove the wheel by unscrewing the lug nuts.

- Detach the Brake Caliper: Depending on the type of the vehicle, detach the brake caliper and move it away without disconnecting the brake line.

- Remove the Brake Rotor or Drum: If it exists, take off the drum or brake disc so that you are able to see the wheel hub assembly.

- Remove the Wheel Bearing: To take the wheel bearing off the hub assembly, use the equally suitable tools but avoid scratching any components nearby.

- Install the New Wheel Bearing: First, clean the hub assembly and then rub lubricant on the new wheel bearing before gently positioning it onto the hub. Time to ensure that it is properly positioned and placed.

- Reassemble: The previously removed parts, including the brake caliper, brake disc, and other peripherals, should be put in the right position. Ensure you use the right torque specification for the fasteners.

- Test and Verify: After bearing replacements are completed, take the vehicle for a fitting that ensures that there is no unusual sound, vibration or anything weird as the wheel bearings are working.

A qualified mechanic and the manufacturer’s instructions should also be sought for exact information about replacing the wheel bearing for your specific vehicle.

Tools Needed for Wheel Bearing Replacement

Because there are procedures for replacing wheel bearings, let us address the questions that tend to always emerge. So, to carry out a wheel bearing replacement, you must have a set of instruments necessary for it to make the task easier. So here are the key instruments that you’ll need:

- Jack and Jack Stands: These are the essential tools for complete safe wheel removals on vehicles.

- Lug Wrench or Socket Set: Wheel nuts or bolts can be taken away and installed using these tools.

- Torque Wrench: A tool used to achieve correct torque specifications whilst fastening tightened fasteners.

- Hub Puller or Wheel Bearing Puller: These are employed in the detachment of the previous wheel bearing from the hub structure.

- Bearing Packer: This will allow you to grease the new wheel bearing prior to installation.

- Press or Bearing Installer: Pressing the new wheel bearing to the hub removes all stressing actions.

- Brake Caliper Tool: If required, provides for the safe removal and replacement of the brake caliper

- Brake Bleeder Kit: This is in case you need to bleed the brake system after the installation of the bearing.

Ensuring that you have the right tools and using them appropriately guarantees a well-fitted replacement for the wheel bearings. Also, do not forget to consult with the manufacturer’s specifications or a competent mechanic with regards to your particular make and model of the vehicle.

Understanding the Hub Assembly Process

it is crucial to have insight into the hub assembly process when changing out a wheel bearing. It consists of the wheel bearing, which is necessary to support the smooth rotation of the wheel. When replacing the wheel bearing, the hub assembly has to be taken apart most of the time. To that end, let’s cover the steps of the hub assembly process:

- Wheel Removal: Initiate the process by securely elevating the vehicle and taking off the wheel, making sure that the vehicle is properly stabilized with jack stands.

- Brake Caliper and Rotor Removal: When it is required, take off the brake caliper and rotor in order to have access to the hub unit. Tools and equipment such as a brake caliper tool may be necessary to remove and reinstall the brake caliper.

- Hub Assembly Removal: With the removal of the rotor, the hub assembly becomes visible, which is the final step before removing the brake caliper. Depending on the brand, some vehicles have the hub assembly held in place by bolts, screws, or retaining nuts. Remove these fasteners and carefully unattach the hub assembly from the vehicle.

- Bearing Replacement: After getting rid of the hub assembly, the old wheel bearing can be removed from the wheel hub. Most likely, this will be disassembled with the aid of a bearing puller or press to facilitate the motion of the bearing from its position on the hub assembly.

- Bearing Installation: Practicing to well grease a wheel bearing with a bearing packer is vital before replacing a new bearing to a wheel. Once that is omitted, smooth functioning is out of the question. Ensuring that, to press the new wheel bearing on the respective hub, either a press or bearing installer will work effectively.

- Reassembly: After the new wheel bearing has been placed, wheel bearing remounting is achieved by doing the steps backwards from the removal sequence. This consists of tensioning the hub assembly using fasteners, putting back the brake rotor and caliper in case of their removal, and lastly, putting the wheel back to the vehicle.

Asking a qualified mechanic and consulting the manufacturer’s guidelines of your vehicle are the best options as it ensures that a precise wheel bearing restoration that follows the best practices is carried out and understanding the spare parts, such as the hub assembly helps. Always remember never skip these crucial steps.

How Often Should Wheel Bearings Last?

According to my industry knowledge, the typical lifespan estimation of a wheel bearing is largely dependent on driving conditions, the maintenance of the respective bearing, and the quality of the bearing itself. However, as a general rule of thumb, a front wheel bearing should last roughly between 100,000 miles and 150,000 miles. The number provided is just an approximation and, therefore, requires critical evaluation and, as a pair of modules, inspection and maintenance to practice effective longevity.

Another worrying factor is the life of tire components which will affect the life of a wheel bearing. Poorly adjusted wheel castor angles, imbalance or even bald tires places unnecessary strain on the wheel bearings. Hence a proper castor alignment, regular inspection and maintenance of bald tires will go lengths in increasing the life span of wheel bearings.

To ensure that the lifespan of your wheel bearings is increased, you may undertake the following maintenance activities:

- Based on the manufacturer’s instructions for your particular model, adhere to the suggested service and maintenance schedule for regular inspection and servicing the wheel bearings.

- Confirm that adequate water and heat resistant grease is available and continuously apply it to the wheel bearings in order to achieve better performance.

- Avoid traversing heavy water or extreme off-road conditions that could bury the wheel bearings underwater or be covered with debris.

- Make sure to closely monitor any abnormal sounds, vibration, or excess of play in the wheels, and carry out the necessary repairs promptly as these may indicate issues with the wheel bearings.

These servicing tips should be followed, and the state of the wheel bearings should be kept under surveillance over time in order to enable the wheel bearing assembly to function optimally and for a long period of time.

Expected Lifespan of Front Wheel Bearings

The operational life of front wheel bearings will differ due to different driving situations, measures taken to maintain them, or the bearings’ quality. However, front wheel bearings have a lifespan of an average of 85,000 – 150,000 mph. It has to be pointed out that this is an approximation. Hence, individual experiences may be different. It is important to operate under normal maintenance and subjection to the manufacturer’s rules and guidelines to enhance one of the operations of the bearing, which is its lifespan, as well as ensure the proper performance and safety of the bearings on the road.

How Tire Wear Affects Wheel Bearing Life

comprehending the conventional wear of tires and its contribution to the performance of wheel bearings is fundamental. It has been noted that tire wear is an issue that can shorten wheel bearing life. If the tires are out of alignment, low on pressure, or worn out unevenly, it subjects the wheel bearings to excessive loads. These additional loads can facilitate excessive tear and wear, which may result in the bearings being damaged before their actual end of life. Hence, correct positioning of tires, tire rotation, and tire wear assessment techniques are key measures that are required so as to ensure the optimal life of the wheel bearings. Proper tire being attended to and tire wear problems being dealt with will mean that the wheel bearings will last longer while increasing vehicle performance and also ensuring safety.

Maintenance Tips to Extend Wheel Bearing Longevity

here are some of the maintenance tips that can help you enhance wheel bearings’ lifespan:

- Regular Inspection: Look out for anything that might indicate damage to the wheel bearings – unusual sounds, abnormal movement, and wobbling wheels. If checked on time, damage can be kept at bay and their life can be maximized.

- Proper Lubrication: The wheel bearings of your vehicle should be lubricated as per the recommendations of the manufacturer. It is very important to lubricate them as it minimizes friction and prevents excessive wear and tear.

- Proper Installation: Change the wheel bearings in case they are worn out and put in place the new ones as per the required installation steps, torque requirements mentioned. Failure to do this can lead to a situation in regard to the wheel bearings.

- Avoid Excessive Loads: Do not use the vehicle more than its rated weight. Using impressive weight will add to pressure being exerted onto thrust bearings which will worsen the lifecycle of thrust bearings.

- Avoid Harsh Driving Conditions: Try not to drive over rough terrains, holes, or the risk of off-roading as you have a possibility of harsh driving conditions because of these factors.

- Regular Maintenance: Follow the routine vehicle service checklist recommended by the manufacturer in case of any vehicle requirement. The pressure put onto the thrust bearings will be lowered if the tires and wheels are properly maintained.

It is advisable to avoid situations that could damage your wheel bearings. Also, you should consult your manual to avoid making any mistakes. Following these suggestions will not only make sure the wheel bearings are being used in the ideal situation but even enhance their lifespan.

Reference

- J.D. Power: Offers detailed cost estimates for replacing wheel bearings, including factors that influence the price.

- Quora: Discusses cost variations based on vehicle type and location, with insights from community members.

- J.D. Power: Another guide from J.D. Power that explores variables affecting wheel bearing replacement costs.

Frequently Asked Questions (FAQs)

Q: How much does it cost to replace wheel bearings?

A: The cost of replacing wheel bearings can vary depending on the make and model of your vehicle and the type of bearing required. On average, you can expect to pay between $150 and $300 for each wheel bearing replacement.

Q: What is the average cost of replacing a front wheel bearing?

A: The average cost of replacing a front wheel bearing typically ranges from $200 to $400, including parts and labor. However, prices may vary based on your vehicle’s make and model.

Q: Do all four wheel bearings need to be replaced at the same time?

A: Not necessarily. Wheel bearings need replacing only when they show signs of wear or failure. It is possible to replace just one wheel bearing if the others are still in good condition.

Q: What are the symptoms of a worn wheel bearing?

A: Common symptoms of a worn wheel bearing include unusual noises like grinding or humming, uneven tire wear, vibrations in the steering wheel, and a loose or shaky steering knuckle. If you notice any of these signs, it’s advisable to have your wheel bearings inspected.

Q: Is it cheaper to replace the bearing yourself?

A: While doing the work yourself might save labor costs, wheel bearing replacements can be complex and require specific tools and expertise. Incorrect installation can lead to further damage, so it’s generally recommended to have a professional handle the replacement.

Q: How long can I expect a new car’s wheel bearing to last?

A: A new car’s wheel bearing can last as long as 85,000 to 100,000 miles with proper maintenance and driving habits. However, this can vary based on the vehicle and driving conditions.

Q: Can a bad wheel bearing lead to other issues?

A: Yes, a bad wheel bearing can lead to additional issues such as damage to suspension components, cv joint, or ball joint. It can also affect the alignment of the vehicle and cause uneven tire wear.

Q: What are the different types of bearings used in vehicles?

A: Vehicles commonly use different styles of bearings, including roller bearings and ball bearings. The type of bearing used can affect the price of a wheel bearing replacement and the vehicle’s overall performance.

Q: How much does it cost to replace a rear wheel bearing?

A: The cost to replace a rear wheel bearing is similar to that of a front wheel bearing replacement, typically ranging from $200 to $400, depending on the vehicle and labor costs.

Q: Can a wheel bearing failure occur suddenly?

A: While wheel bearing failure can sometimes happen suddenly, it often progresses gradually. Regular maintenance and paying attention to symptoms can help detect potential issues early and prevent sudden failures.