The timely replacement of wheel bearings will assist in retaining good steering and control over the vehicle. It is imperative that the bearings are replaced at the right time, as they tend to wear out and go bad with time. Bearings have a direct effect on how smooth the movement is and are critical to the smooth functioning of the automobile. This blog outlines factors that affect the life cycle of wheel bearings, how to identify if they’re good or failing, and finally, effective measures to ensure their longevity. After reading this guide, whether you are an avid vehicle enthusiast or just someone who wants to take good care of their vehicle, you will surely understand how to keep the front wheel bearings in perfect condition.

How Do You Know If a Wheel Bearing Is Going Bad?

A faulty wheel bearing produces some unmistakable symptoms which should alert you to the problem. There are abnormal sounds like grinding, humming, or growling while cornering and accelerating. All these sounds indicate some damaged or worn-out bearings. If you notice vibrations on the steering wheel or uneven tire wear, these could also be signs of a bearing problem. As a rule, in a visual inspection, any excessive movement or play on the wheel or hub assembly points to a failed wheel bearing. Taking care of these symptoms in a timely manner is important so as to not cause any damage to the vehicle.

Signs and Symptoms of a bad wheel bearing

the general symptoms that show that a wheel bearing is failing are unusual noises and driving disturbances. I tend to recommend paying special attention to various whining, howling, or grinding sounds, as these usually point toward damaged bearings. Uneven tire wear or vibrations in the steering wheel are also concerning items that need addressing promptly. I have observed that excessive free play in a wheel or hub assembly during inspections is one of the major indicators of bearing failure. Early treatment of these indicators not only extends the vehicle’s longevity but also enhances your safety while driving.

Does a bad wheel bearing Affect the Steering Wheel?

Absolutely, a worn wheel bearing affects the steering axis, and it’s something I’ve dealt with quite frequently. Here’s how this happens, as worded with key points:

- Vibrations Transmitted to the Steering Wheel

Bearing damage tends to cause a Wobbly Wheel, which leads to friction, which leads to extra pressure and rotation distortion on the wheel, adding clipping to the vibration. Above all, if one observes clippings at high speeds on the wireless steering wigglers that assist the break, then that signifies the need for bearing.

- Pulling or Wandering

When a Bearing fails, it tends to pull one side more, which can cause the wheel bearing to fall off, centering the rotation of the wheel bearing. This would result in the tire bearing the rotational motion only on one side, which would push the other side more, rotating it off balance. As expected, trying to drive in this state would poke holes in the controlling part of the car and damage other components in the vehicle over time.

- Steering Play and Responsiveness

Unwanted wear in the assembly of the steering wheel tends to add tension to the Wheel Hop, which can also be controlled through the cover. This can be noticed through loss of tensile responsiveness or steering wheel wobbliness. This poses a risk and is dangerous primarily at the time of emergency braking and extensive maneuvers since these types of sequences require rigid and constant steering.

- Noise and Its Impact

Failing bearings may cause unusual sounds, for example, grinding or bear growling; they are not limited to the background only. Such sounds may cause non-standard feedback in the steering, with some sounds remaining that only sometimes make it possible to be quiet.

When you react to these problems quickly, not only will you avoid some serious issues with other aspects of your car, but you’ll also make the driving experience much more pleasant and safe.

Can a bad wheel bearing Cause a Clicking Sound?

Yes, I have come across a clicking sound because of a defective wheel bearing, but I consider it normal because the more common sounds are grinding or humming. There is a crucial thing to remember: a clicking sound tends to occur in instances where the bearing is significantly older or damaged, thus creating irregularities as the wheel turns. From my experience, I have noticed this sound more while making tight turns or when the vehicle was under a different load. If you experience clicking and have suspicions that the suspect is the wheel bearing, then it should be checked immediately to avoid further problems.

How Long Do Wheel Bearings Last on Average?

Usually, wheel bearings can be expected to serve a range between 85,000-100,000 miles, but it varies depending on the driving habits and condition of the car. In my experience, frequent use of rough roads, water exposure, contaminations, and poor lubrication can greatly reduce their lifespan. It is always recommended that they keep track of their status during routine maintenance and replace them as soon as wear is detected to ensure safety and performance.

Factors Influencing the life of wheel bearings

- Driving Conditions

the condition of the roads in which you operate your vehicle is of utmost importance. Driving on rough trails can accelerate bearing damage because there is high vibration and more shock. And, in wet or snowy weather conditions, water or road salt can get inside the bearing assembly, leading to corrosion and contamination, which is also not ideal. So, any of these environmental factors are detrimental to the bearings, which is why, in such situations, it’s necessary to always check the bearings for damage and other symptoms.

- Quality of the Bearings

Equipping your automotive components with quality bearings is critical for their efficient functioning. It is safe to say that reputable bearing manufacturers do put their knowledge and expertise into producing high-end, durable bearings that can take a beating. Focusing on the core of the business is essential to avoid wastage of precious resources. Investing in high-quality parts will save you time and effort significantly as they won’t wear out as quickly.

- Maintenance Practices

Using appropriate lubricants is crucial to keeping the components and boosting their lifespan. Heat buildup and eventual Failsafe components can be caused by friction from inadequate or poor quality grease. Clean, inspect, and lubricate the bearings with the recommended grease during maintenance. Avoiding this step will considerably reduce their life.

- Driving Habits

When you over stress the wheel bearings with sudden load changes like slamming the brakes or sharp turns All of this In my years on a similar job i have witnessed so many cases where they have been subject to overuse and abusing causes the premature failure of the bearings. If you drive steadily instead of aggressively, not only is it better for your other automotive components, but it will improve the longevity of the bearings, too.

When you pay attention to these aspects, the lifespan and effectiveness of your wheel bearings will be because the features have changed. It’s all about properly maintaining your vehicle to avoid the more expensive line of repairs and just keeping everything in optimum working order.

Can Driving Conditions Cause premature failure?

Indeed, operating conditions have a significant impact on a constant velocity bearing’s short service life. Based on my experience, driving through deep water, exposure to excessive road salt, or driving on rough terrain, etc., can shorten the constant velocity bearing’s lifespan. All of these extreme conditions introduce water, dirt, and debris in the bearings that, over time, will erode the lubrication, and corrosion or mechanical damage will occur. As a precaution, never wash your wheels and canvass after using it in depth water tanks or salt ponds (during the salt extraction process in dry areas), and make sure to examine your car for odd sounds or shakes after salt exposure. A little bit of preventive work goes a long way in extending your wheel bearing lifespan.

Do sealed bearings Last Longer?

Yes, sealed bearings have a longer lifespan in most applications as they are manufactured to be intrusive and do not allow dirt to come in contact with lubrication. In my case, a seal allows the grease to be kept in the bearing while keeping out water, dirt, and other particles that can compromise the performance of the bearing. However, it should also be said that longevity can also be attributed to the quality of the bearing and the conditions under which it is to be operated. Sealed bearings are quite easy to maintain, but for maximum longevity, so long as they are within specifications, you may not wish to expose them to extremes.

What Are the Warning Signs That a Wheel Bearing Replacement Is Needed?

Noises such as grinding and humming might also be an indication that the wheel bearing needs replacing; if you notice these noises coming from the wheels, coupled with excessive tire wear and vibration in the steering wheel, then it is an indication that a wheel bearing needs replacement. Other indicators would be difficulty handling the vehicle while steering, especially around corners, or the wheels being loose. If you have these problems, then it is best to have them fixed quickly in order to not end up damaging the vehicle further.

Symptoms of Worn-Out wheel bearings

Faded wheel bearings frequently make grinding or growling sounds, especially when the automobile is rolling. The drivers may also complain of feeling the vibration in the steering wheel or tapering in the tires. Another typical symptom is a loose motion of the wheels or impaired handling of the vehicle during turns. Also, ensure that these pointers are addressed in time so as to avoid any major accidents or mechanical failures in the vehicle.

How to Identify a grind or hum Noise

identifying a grinding noise or a humming noise in your vehicle requires both sound analysis and the driving conditions in which it happens. Here’s a how-to guide that will help you:

- Driving Speed

When changing speed, listen carefully. When vehicles move, they make this noise, which is usually a hum or rumble, but that could get relatively louder or quieter as the speed of the motor vehicle changes. This could be a telltale sign of bearing or drivetrain-related issues.

- Turning the Steering Wheel

While steering, watch and listen. If the noise is intensified when steering, it could mean that one of the wheel bearings is bad. For example, when turning left, if the noise increases, it could be the right side bearing.

- Road Surface and Conditions

Apply the noise on different surfaces and conditions. The smoothness of the road aids in the detection of the rotational grind or continuous grinding; however, noisy or rough roads tend to conceal these vibrations. If the sound is constant on all surfaces, then it should be worth the trouble.

- Location of the Noise

Try to locate the sound-making source vertically and horizontally in the axis of the vehicle: front, rear, left, or right side of the vehicle. This can help you isolate the troublesome wheel or component.

- Visual and Physical Checks

If need be, use a jack/lift to safely place the vehicle off the ground and, by hand, rotate the wheels. A defective bearing can be suspected when the wheel’s rotatable base ends or feels rough. Again, excessive play should be assessed by rocking the wheel back and forth.

Every single one of these parameters is important in order to come up with a proper diagnosis. I always try to recommend a visit to a professional as soon as you notice abnormal sounds, be it humming or grinding, besides the road or tire noise, as it could mitigate risks of expensive repairs and safety concerns.

How to change a wheel bearing Safely?

If performed correctly, not only does the wheel bearing have a long lifespan, but it is also protected from outside elements or excessive dirt and liquid if properly maintained. Changing the wheel bearing requires skill, experience, and the right tools, and it is important to follow guidelines properly. Sounds easy enough, right? Well – take a step back. To start with, ensuring that the vehicle is parked on a flat area, engage the parking brake and chock the wheel closest to the bearing you are maintaining, this helps to provide added stability. Using a T50 socket, break free the lug nuts but do not take them off completely. Using the proper vehicle jack, lift the rear end of the desired side of the vehicle and connect strong jack stands for added support. Remove the caliper and take off the rotor, which allows you to push the hub assembly. Depending on the make of the vehicle, the removal process may differ slightly. Try to remove the axle nut and some of the retaining bolts before attaching the steering components. Using a bearing puller, remove the old bearing, place the new one onto the hub assembly and use a torque wrench to secure it onto the desired location. Connect everything back into the correct position, ensuring each component is tightly secured and won’t loosen during use on the road. Remember to keep a strict check on the performance of the vehicle, and start off slow and gradually increase in speed; this ensures smooth usage without any vibrations caused between the wheel and the hub.

Tools Required for Wheel Bearing Replacement

- Lug wrench

- Bearing puller or press

- Pry bar

- Screwdrivers

- Torque wrench

- Breaker bar

- Jack and Jack stands

- Hammer or mallet

- Safety gloves and eye protection

-

Socket and ratchet set

Step-by-Step Guide to replacing wheel bearings

- Raise and Secure the Vehicle

Before commencing work on the vehicle, first, lift the car, but be sure to do it properly and tightly using a combination of a jack and jack stands.

- Remove the Wheel and Brake Components

Bring the wheel down with a lug wrench; start unscrewing the lug nuts. Take apart the wheel, break mass space and its rotor, also, remove the braking system components if they are blocking the single hub.

- Detach the Hub Assembly

If the vehicle you are working on has an axle, make sure to remove the axle nut. Otherwise, proceed to the next step. After that, unfasten the bolts that hold the hub in place. Depending on the make and model of the vehicle, you might need to disconnect additional parts, so be careful.

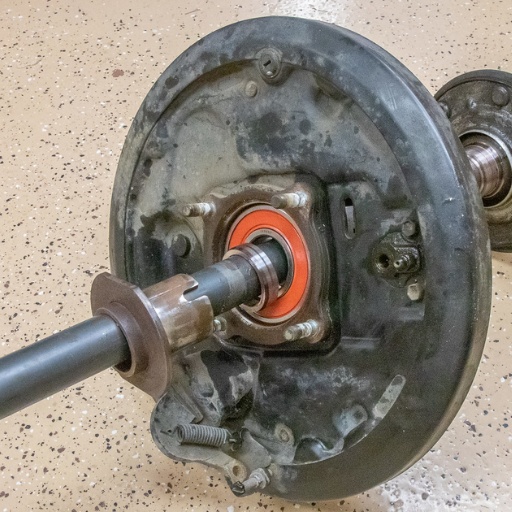

- Extract the Old Bearing

By employing a bearing puller or press, take off the now useless bearing, but make sure that while you do so, all bolts and areas that touch the bearing are unharmed.

- Install the New Bearing

Taking the new bearing that you purchased, set it up for pressing in. Do not forget to follow the torque instructions that were in the box, and that will ensure a perfect fit.

- Reassemble the Components

Now, to put everything back together, slot the hub back in, along with the brake system components and, finally, the wheel. One thing to make sure of before the new bearing installation is that all the bolts and nuts used on the hub are perfectly tightened together.

- Lower the Vehicle and Test

Once done with reassembly of the vehicle, execute a test on the wheel spin of the new bearing to confirm that it fits well, if it does proceed to wait for the car to come down and lower the jack that you used at the start.

Can Ignoring a worn-out wheel bearing Cause Further Damage?

Worn-out wheel bearings should not be ignored as they might lead to further serious damage. A worn-out wheel bearing exerts too much pressure on parts around it, such as the hub, axle, and even the suspension system, which can make these parts deteriorate or fail too soon. Furthermore, it poses a threat to road safety by making the wheels more susceptible to potential misalignment, loss of stability, and, in worst-case scenarios, even detaching from the vehicle. Replacing a faulty wheel bearing on time is effective in avoiding expensive repairs as well as safety issues while driving.

Impact on suspension and brake Systems

A damaged wheel bearing can have drastic negative effects on both the suspension and the brakes. A failing bearing only adds strain, which will compound the problems and can lead to uneven tire wear, suspension misalignment, and a reduction in handling ability. Speaking with respect to the brake system, the discarded strength can cause instability, adding up to variable force applications, causing damage to the brake rotor, or accelerated wear of parts. Therefore, one of the wheel bearing issues that need to be resolved on time is the major parts of the brake and suspension systems.

What Happens to the hub and CV joint?

A car’s wheel bearing support points or centralizes the hub and CV joint, which are of great importance when it comes to a car’s performance. Frequent usage of the CV joint can also weaken or cause a high level of strain, which may cause a great deal of wear and tear on the components. Because of these aspects, they are highly crucial and should get the treatment they deserve, early on.

Reference

- 5 Steps to Increase Wheel Bearings Lifespan and Enhance Performance

- How Long Do Wheel Bearings Last? – Bell and Bell

- Symptoms of Bad Wheel Bearings – Wrench

Frequently Asked Questions (FAQs)

Q: How long should a wheel bearing last?

A: A wheel bearing is designed to last approximately 85,000 to 100,000 miles. However, this can vary based on driving conditions, such as encountering potholes or bumpy roads, and maintenance practices.

Q: What are the signs that a wheel bearing needs replacing?

A: Common signs include unusual noises coming from the wheels, a vibration in the steering wheel, uneven tire wear, and a loose feeling in the front end. Ignoring worn-out wheel bearings can lead to further damage.

Q: Can I replace just one wheel bearing, or should I replace all?

A: While you can replace one wheel bearing, it is often recommended to replace both wheel bearings on the same axle to ensure balanced performance and longevity.

Q: What role does a wheel bearing play in a car’s wheels?

A: Wheel bearings are crucial components of a vehicle’s wheels, allowing them to spin smoothly by reducing friction between the drive axle and the brake disc or drums.

Q: How do driving conditions affect the service life of wheel bearings?

A: Driving over potholes or curbs or on bumpy roads can significantly shorten the service life of wheel bearings due to increased stress and potential damage to the bearing set.

Q: What happens if I ignore a worn-out wheel bearing?

A: Ignoring a worn-out wheel bearing can lead to severe consequences, including a complete loss of control of the vehicle, damage to the hub bearing, and potential failure of the car’s wheels.

Q: Are front and rear wheel bearings the same?

A: Front and rear wheel bearings may differ in design and load capacity. Front-wheel bearings often handle more stress due to steering and braking forces.

Q: How are wheel bearings related to the wheel speed sensor?

A: Wheel bearings, which may contain the wheel speed sensor, are located inside the hub. A faulty bearing can affect the sensor’s readings and trigger warning lights on the dashboard.

Q: Should wheel bearings be replaced with tires?

A: While not necessary, it is a good idea to inspect wheel bearings when replacing tires, especially if the tires have lower tread or show uneven wear, indicating potential bearing issues.

Q: Can improper wheel alignment damage the bearing?

A: Yes, poor wheel alignment can lead to uneven tire wear and added stress on the bearings, potentially causing damage over time.