Ball bearings are crucial parts of most machines and systems as they enable smooth and effective motion. They are small devices, but they are very useful as they lessen the relative movement between different machine components, thus ensuring the correct operation of the machine over a long period. They include rotating components such as automotive engines, industrial machines, and even common items such as bicycles. This article sets out to explain in detail how ball bearings operate, their different uses, and how to properly install them into other components. In case you are an engineer, a field technician or just interested in the subject, this article will help you understand how ball bearings work and why they are so important in contemporary mechanics.

What are the different types of bearings?

There are different types of bearings depending on the specific applications and the loading requirements. Some of the more common types are ball bearings (which take both radial and axial loads), roller bearings, which are best suited for heavy radial forces, and tapered roller bearings, which are efficient in absorbing a combination of radial and thrust forces. Furthermore, because of their thin shape, needle bearings can be accommodated even in very small places, whereas thrust bearings are used in circumstances where only axial loads are used. Other specialized types include spherical bearings, which allow some degree of misalignment, and magnetic bearings, which operate without friction. All types have specific functions and as such help to enhance great functionality in various industries.

Understanding ball bearings vs. roller bearings

I approach the topic of ball bearings and roller bearings from a practical standpoint in order to understand their core differences. Ball bearings and roller bearings are used to limit the friction of two moving parts, although they function best in various scenarios according to their configurations. This is how I see it:

- Load Handling

Ball bearings work well in applications where there is primarily radial load (force applied to the shaft perpendicularly) and also light and moderate force. The round shape of the spheres enables them to turn easily and minimizes friction. However, a ball bearing can accommodate a limited amount of axial load (force applied parallel to the shaft) but in comparison to roller bearings, much more inefficiently.

Conversely, the roller bearing is the one unassisted by the ball that can take the most excessive loads, whether they be axial or radial. These cylindrical shaped cages have a greater area that supports the load enabling the moment to be distributed over a larger area. This enables the use of such parts in construction express machinery or conveyor systems, which would have otherwise been difficult due to excessive loads in the industry.

- Speed

Ball bearings are designed for high-speed applications as they are smooth in shape which causes minimal friction when they are rotating at a high speed making them optimal to use for fans motors and turbines. Roller bearings on the other hand due to the large contact area have greater internal friction which makes them perform better in low to medium speed situations.

- Precision

If smoothness and accuracy are must-haves then ball bearings are the answer. Their structure limits vibration and enables accurate rotation which makes them ideal for anything from medicine to space. In contrast, roller bearings are tough and sturdy, but they are not, by their very nature, very precise, and are more functional in heavy-duty rugged places.

- Durability and Life Span

It’s safe to say that roller bearings are superior to ball movement if we consider the particular mounting area. We’re saying this because with that large contact area, that bearing type generally has a much longer lifespan when wear and tear comes in due to heavier weights and stress being placed on it. Though capable of high versatility, Ball bearings which are also a type of bearing may become worn out easily when subjected to high pressure in constant intervals.

For choosing between these two types of bearings my focus is always on these parameters—load sensing type, speed requirements, precision requirements, and durability requirements. Each application has its own specific operational characteristics that allow for the selection of the best type of bearing to enhance its performance and avoid early wear.

Exploring plain bearings and their applications

plain bearings are one of the most useful types of bearings in instances where mechanics need to be basic, reliable, and low-cost. These bearings roll without rolling elements and bear with sliding motion which makes these bearings useful in places where the need for maintenance is less or lubrication can be partial. I’ve oftentimes encountered them within the car, building and heavy engineering industries, thanks to their ruggedness and capacity of withstanding high loads and brutal shocks. However, it is important to take the material used and the working environment into account, excessive friction or high temperatures can alter the output. Since the material of the bearing and its configuration is suited to the application, I have come across plain bearings as one of the lasting and effective means.

Specialized bearings: Thrust and angular contact bearings

Thrust bearings are made to bear axial load hence they provide a great advantage where the load may be acting along the shaft such as in turbines, automotive gears, and many more. In contrast, angular contact bearings are suitable for bearing combined loads i.e. radial and axial loads in applications such as precision machinery and high-speed spindles. These specialized bearings guarantee reliability and efficiency in high-demanding applications through correct specification in relation to the load direction and the intended purpose.

How do ball bearings work to reduce friction?

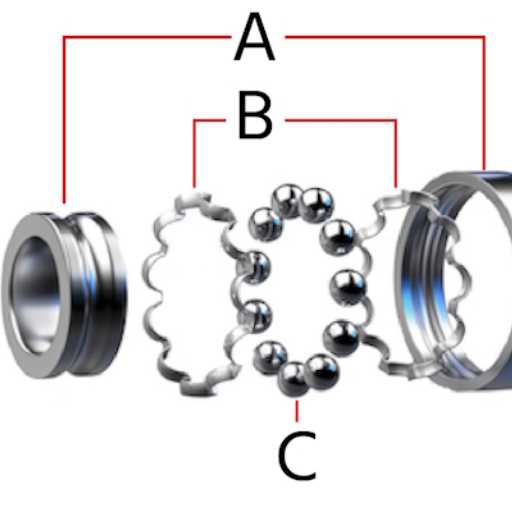

Ball bearings consist of spherical balls sitting in-between surfaces located across the inner and outer races. The in-built functionality here is that when the ball turns, it rolls when one of the surfaces moves instead of sliding, thereby reducing the amount of friction and overall wear and tear. This rolling, in my personal industrial experience, greatly reduces energy loss and improves the efficiency of the functioning of any machine. Moreover, their remarkable materials and manufacturing improve the performance of these bearings, as well as their durability at different loads and speeds.

The role of inner and outer races in ball bearings

In ball bearings, the inner and outer races are indispensable elements as they assist the movements that allow the ball bearings to perform efficiently. The inner race is attached to the shaft portion that rotates, whereas the outer race is secured within the casing. Together, both form a path for the balls to roll, increasing the revolution and mass transfer and providing the distribution of loads. This design also ensures the stability, durability, and efficiency of the bearings under different applications.

Deep groove ball bearings: Design and functionality

because these bearings can accommodate radial and axial loads effectively, they are suitable for various applications. To explain how they work, deep groove ball bearings are a combination of rolling and turning motions.

The design of a deep groove ball bearing comprises a number of parameters, including the following:

- Raceway Geometry: The parameter of curvature for the raceways in these bearings bears the same spherical contour as that of the rolling balls. For this reason, rolling is smooth with no interruptions, thus relieving stress and enabling high speeds.

- Ball Bearing Size and Material: The balls themselves must maintain exact dimensions and they are mostly produced using steel or ceramics, depending on the design. This also contributes to strength and being abrasion resistant.

- Inner and Outer Races: These are manufactured with exact tolerances with substantial grooves which allow the balls to be captured under combined radial and axial loads. This design feature is inherent with this category of bearings in exception to other types of bearings.

- Seals or Shields: Seals or shields are used for a majority of deep groove ball bearings to offer protection from dirt, dust, and other foreign materials. Therefore, their life span is enhanced, and functioning in relatively hard environments does not cause failure easily.

- Lubrication: Lubrication is one of the factors which has to be done Aberration. Grease or oil lubrication bearings lessen friction, limit heat generation, and sustain an order of efficiency for a long time.

Thanks to this design, deep groove ball bearings are suitable for use in electric motors, automobiles, heavy machines, and even household appliances. The deep groove ball bearings are remarkably efficient, which makes them a critical element revolving around countless systems.

Self-aligning ball bearings for enhanced performance

Self-aligning ball bearings offer outstanding performance in regard to any application where misalignment or shaft deflection is a key factor. In my professional opinion, these bearings are revolutionary as their design is such that the inner ring is able to turn freely and independently in the outer ring. This self-aligning capability can flex angular misalignments; hence, the stress on the components is reduced, and the life of the machinery is enhanced. Self-aligning ball bearings provide smooth operation and greater reliability in severe working conditions, be it in industrial equipment, agricultural machinery, or even textile applications.

What are the key considerations for bearing mounting?

For improved bearing optimum performance and increased longevity, correct bearing mounting practices should be followed. Some of the measures include cleaning and examination of the shaft and housing so as to avoid damage or contamination, the use of an appropriate mounting method (cold, thermal, or hydraulic), and checking for direct allowance to prevent undue pressure or wear. Plus, applying the specified lubrication and tinkering levels further reduces the likelihood of breakdown.

Press fit vs. slip fit: Choosing the right mounting method

the choice between slip fit and press fit unquestionably depends on intended usage and operational conditions. A press fit is also known as an interference fit, and in some cases, it causes slight deformation, which enhances the joint during assembly. This is perfect in situations where stability and strength are of the essence but excessive force should be avoided to not damage components. On the other hand, a slip or a clearance fit makes any assembly or disassembly easier, resulting in a better degree of freedom and less resistance to movement. In situations where load stability and long-term dependability are crucial, I usually recommend a press fit, but for systems that require frequent adjustments or relining, then a slip fit is ideal. Last but not least, the solution arrived at has to comply with the functional specifications and tolerances of the system.

Proper alignment techniques for optimal bearing performance

Proper alignment is absolutely crucial, especially when it comes to bearing performance and so it is one of the key factors I tell everyone who is about to work with precision machinery or equipment. On the other hand, misalignment may result in unfavorably bearing loads, increasing vibration as well as damaging the bearings within a short time span, which isn’t a good thing! This is how I approach the determination of the proper alignment in a simple, coherent manner:

- Shaft Alignment – Shafts must be ensured to be properly aligned at all times. This means the shafts are not at an angle to each other (angular alignment), and the shafts must run parallel along their length (parallel alignment). For best accuracy and consistency, a laser alignment tool is recommended.

- Tolerance Check – It is one of the practices of engineering to take into account that all assembly, especially the bearing, has specific limits of tolerances with regards to contact alignment. It is important to consider what a manufacturer states as alignment tolerances and ensure that they are always observed. This step is very important to ensure that stress points are not induced in the bearing.

- Soft Foot Adjustment – Before finalizing the alignment, one should check for ‘Soft Foot,’ which is the case when one machine foot does not fully rest against the base. If this is not done, such displacement could induce distortion of the alignment at the final stage where when bolts are tightened. Incorporate feeler gauges or shims in order to make use of all feet level.

- Axial Positioning –One must always ensure that the bearing that one is using is fitting to the shaft properly & doesn’t have any kind of circular movement towards the direction of the shaft. Since it is said time is money, the cost of replacing every bearing would be. Therefore, it is best to replace it with a firmly fitted bearing.

- Dynamic Load Testing – On the other hand, once alignment has been achieved, I prefer to operate the system and, using an analyzer, measure the occurrence of abnormal vibrations, which in most cases will point towards some form of misalignment. Vibration analyzers are great for that.

With early intervention on these factors, it can be concluded that longer bearing life, smoother running, less energy loss, and lower maintenance expenditures will be the end result. Incorporating these alignment methods makes maintenance a lot easier and guarantees that the equipment performs in the best possible way.

Mounting bearings on shafts: Best practices and common pitfalls

In the context of fitting bearings onto shafts, I have witnessed how crucial proper practices are in ensuring the success and longevity of equipment. Precision Far and above, my first recommendation is always clean, as in the shaft (or the bearing). Again, any particle debris dirt that can cause rough wear or contamination must be eliminated. Tools are also of critical relevance; for example, applying a bearing heater to create an even temperature expansion eliminates the risk of destruction when installing the component.

One common mistake I have seen is over-relying on force or using some tools that could disfigure either the bearing or the shaft. Furthermore, the interference fit will be compromised due to the failure to confirm that the shaft has acceptable limits of size and roundness. Always adhere to manufacturers’ specifications of interference fits and never forget to check alignment after installation. While these steps may take a little extra time at the beginning they prevent you from having costly problems later on.

How do roller bearings differ from ball bearings?

The main differences between roller bearings and ball bearings are in their construction and the amount of load that these bearings can handle. A roller bearing consists of cylindrical, tapered, or needle-shaped rolling elements, which means they can accommodate larger radial loads as well as a combination of radial and axial loads. A ball bearing, on the other hand, has a rolling element in the shape of a sphere or a ball, which means they are more appropriate for applications that are light in weight and require high speed with low friction. The use of the two depends on the application’s requirements of load, speed, and accuracy.

Cylindrical roller bearings: Applications and advantages

Thanks to the unique configuration and structural features, the cylindrical roller bearings are auxiliary assembly components with a broad scope and numerous advantages. From my experience in the field, I can tell you that these bearings are designed for applications where a significant amount of radial load and the life of the bearing is essential. Now, to break this down for you, I’m going to address the pivotal parameters that contribute to the effectiveness of cylindrical roller bearings:

- High Radial Load Capacity: Due to the lines of contact that exist between the rollers and the raceways, these bearings can endure very high radial loads and are, therefore, well suited for application in gearboxes, electric motors, and industrial machinery. Such kinds of bearings are known as cylindrical roller bearings.

- Suitability for High Speeds: They provide high performance when subjected to high speeds, but only if proper lubrication is provided. This capability is important to industries like the automotive and aerospace industries,s where performance is critical when there is movement.

- Axial Load Support Options: Although cylindrical roller bearings (with flanges, for instance) are primarily used to support radial loads, they are also capable of withstanding light axial loads, hence providing versatility in certain applications.

- Separation of Inner and Outer Rings: Because Cylindrical roller bearings are separable, their installation and maintenance requirements are considerably easy. It is a huge benefit for big machines, where the need to reduce downtime is paramount.

- Reduced Friction: Due to their design, there is lower friction between the rolling elements and the raceway. This is advisable as it reduces the energy consumption of the bearings and increases their longevity when used in proper conditions.

Such benefits make cylindrical roller bearings suitable for construction, heavy-duty equipment, and wind turbines, amongst many other machinery. Each application has its own range of parameters that have to be thoroughly considered in order to reach the maximum performance and lifetime of the bearing system.

Tapered roller bearings: Managing axial and radial loads

Tapered roller bearings are crucial in technologies that require the combination of both axial and radial loads. Based on my work with this type of bearing, I have found them particularly effective in applications where the load is applied in multiple directions- for example, in automobile axles or gearboxes. Their geometry, consisting of tapered inner and outer ring raceways, enables them to be more stable and accurate at increased load levels. The most important factor in improving their performance and life expectancy, particularly in demanding situations, is alignment and lubrication. Using the correct tapered roller bearing for the job will guarantee dependability and efficiency in a number of industries.

Needle bearings: Compact solutions for high-load applications

Baring In” shell needle bearings are recognized as specialized bearings since they have long cylindrical rollers with thin cross-sectional areas, making the most compact bearings with quite a high load-carrying capacity. They bear a design that allows the maximum contact surface area to be occupied, which aids in load dispersal in tight confines. They are perfect needle bearings that perform well under high radial loads, especially when space is a constraint, such as in automotive gearboxes or aerospace systems. In order for it to function and withstand harsh conditions for a long time, it needs to be lubricated and properly maintained.

What factors influence bearing selection for specific applications?

Choosing the right bearings for certain uses always leads me to think of a number of aspects that may unnerve so many others in regard to increased performance and durability. As bearings are developed to accommodate certain types and sizes, both axial and radial loads that are to be applied during operation are simply fundamental. Recalling the operational speeds of the bearing during functioning, introducing the installation of the lubes, and determining the material used also sways the final outcome. Various features, such as the temperature of the environment, humidity, and presence of contaminants, are essential in determining whether sealed or unsealed bearings should be employed. Space consideration is often a chief factor, whilst the ease of installation and the required maintenance should ‟t be neglected. At the end of the day, blending these considerations would come in handy in enhancing the effectiveness, consistency and efficiency of the application on the whole.

Considering load types: Radial vs. axial forces

There are some basic concepts that should be clarified regarding radial and axial components. In rotation systems, radial components are those acting in a direction perpendicular to the axis of rotation, and axial components are those running parallel to the axis of rotation. For instance, deep groove ball bearings are able to withstand radial loads placed onto the axle perpendicular to the barking surface. Axially loaded bearings, such as thrust bearings and angular contact bearings, are made for axial loads. If the application involves the application of both axial and radial forces, then a tapered roller bearing that incorporates both features would be most suitable and provide the highest reliability. The force factor that differentiates one bearing from the other ultimately determines the applicability of the bearing type.

Speed requirements: Choosing bearings for high-speed operations

While I am discussing the subject of bearings, I would like to highlight the critical role of choosing the high-speed types for working in any kind of high-speed action. The operating conditions that any high-speed application is expected to operate in are a hot and very tough one. If the wrong type is used, it can compromise the bearing in use. One has to focus on bearing materials, lubrication, and precision tolerances. A case in point would be the multi-purpose ceramic hybrid bearings, which are an ideal fit for a majority of the high-speed scenarios due to their lightweight, low friction, and superior thermal resistance. Moreover, wear and efficiency loss should be reduced through suitable lubrication – for the temperature and speed at which the application operates. My rule is always to choose bearings with higher speed rating bearings and verify with the manufacturer’s specifications to meet the requirements suitable for the application. It is this accurately targeted approach that guarantees the reliability and durability of the bearings even when exposed to harsh operating conditions.

Environmental factors affecting bearing choice and performance

Bearings are often continuously exposed to environmental factors and conditions that will assist or increase their performance. These conditions may include sub-zero temperatures and exposure to moisture, dust, and other corrosive materials that could affect the bearing’s operating life and operational Efficiency. For instance, high humidity or wet environments could require the use of corrosion resistant materials like stainless steel or ceramics. Likewise, extremely high temperatures may require the use of high-temperature lubricants and thermally stable designs. Always comprehensively assess the operating environment to ensure that bearings are able to withstand the appointed tasks, advance bearing efficiency, and also reduce the risk of failure.

How can bearing life be extended through proper maintenance?

I shall answer that in prose form. In my humble opinion, getting proper maintenance resources to prolong the lifecycle of bearings is entirely about considering important components in an organized and, at the same time, dispersed manner so that wear and tear occur very little or not at all while their operational reliability is ensured. In this case, it does not help to put together press-on nails and hope that they will perform well. Here’s a detailed breakdown of the critical parameters:

- Regular Lubrication: One cannot emphasize enough the importance of bearing lubrication. Not only do lubricants help in the reduction of friction, but they also reduce heat and protect the surface of the bearings from destructive contaminants. Always comply with the manufacturer’s recommendations regarding the type of lubricant—grease or oil—that meets the environmental specifications. Additionally, always adhere to the lubrication schedule prescribed by the manufacturer.

- Proper Installation: Installation practices are also critical. If proper alignment is not carried out, or the fittings used are incorrect, the bearing is bound to fail due to uneven forces. When installing bearings, always use the right tools and correct methods and check that the bearing is not loaded in excess by confirming that it is properly aligned.

- Contamination Control: Sand, dirt, grease, moisture, and any trenching resource may prove disastrous for the bearings. Install containment methods like repair systems, periodic cleaning, the setup of a clean working environment, and other advanced techniques to protect your bearings.

- Load and Speed Monitoring: Bearings are designed to run within specific limits; not carrying loads beyond their rated capacity or rotating at speeds greater than intended will ultimately quicken their demise. Operating outside the set load and speed conditions will only serve to do harm. If indeed necessary, use load restraints.

- Temperature Management: Bearing overheat is a common concern that must always be avoided. One must always monitor operational temperature and the dissipation of heat along with temperature-specific materials if required. Doing this will help ensure the bearing stays in an optimal state.

- Inspection and Early Detection of Wear: Regularly checking bearings for wear, noise ,or vibration provides you the option to fix small problems before they become larger. Vibration analysis or thermal images can be used for detecting sounds which can help in the early diagnosis of any issue.

With great attention paid to these parameters and when these are embedded into a proper maintenance schedule, the life of the bearings can be increased substantially. With proactive maintenance, not only are expensive interruptions avoided, but the health of equipment is preserved over time.

Lubrication best practices for various bearing types

In the case of bearing lubrication, I always start by thinking about the specifics of each bearing type. For rolling element bearings, I make sure to use the right grease or oil depending on the load, the speed, and the environment. For plain bearings, I believe that maintaining an oil film to separate metal-to-metal contact is essential. I always recommend using the right type of lubricant with the right viscosity and additives for the given application – high temperatures, heavy loads, etc. Furthermore, I follow a strict relubrication schedule, which avoids both over- and under-lubrication, which helps to improve bearing operation and life.

Implementing a preventive maintenance schedule for bearings

Bearings should be subjected to a preventive maintenance timetable whereby inspection, cleaning, and lubrication are carried out in order to enhance the performance and lifespan of the bearings. First, determine the operational parameters, such as the applied load, the speed, and the temperature levels, for optimal maintenance interval frequencies. The timing of periodic inspections is required to check for obvious signs such as worn parts, vibrations, and noise and have them corrected to avoid unnecessary wear and tear. Condition monitoring mechanisms, vibration analysis, and thermal imaging are very good tools for predicting failures. By employing standard reporting and performance metrics for every maintenance performed, you enhance the prevention of threats and increase the reliability of the equipment.

Reference

- A Guide to Precision Ball Bearings – This article discusses the functions, structures, and types of ball bearings used in various applications.

- Materials for Ball and Roller Bearings – This source provides information on the common materials used in rolling element bearings.

- SKF Deep Groove Ball Bearings – The SKF bearing catalog offers a wide range of designs, variants, and sizes of deep groove ball bearings.

Frequently Asked Questions (FAQs)

Q: What are rolling element bearings, and how do they work?

A: Rolling element bearings, including ball bearings, are mechanical components that reduce friction between moving parts. They consist of an inner and outer race with rolling elements (such as balls or rollers) between them. These bearings work by allowing the rolling elements to rotate smoothly within the races, facilitating linear motion or rotation while minimizing friction and wear.

Q: How do you properly mount a bearing on a shaft?

A: To mount a bearing on a shaft, follow these steps: 1) Clean the shaft and bearing surfaces. 2) Apply a thin layer of oil to the shaft. 3) Align the bearing with the shaft. 4) Use a bearing press or arbor press to apply even pressure to the inner race. 5) Ensure the bearing is fully seated against the shaft shoulder. 6) Secure the bearing with appropriate retaining devices, such as lock nuts or circlips. Always refer to manufacturer guidelines for specific mounting instructions.

Q: What’s the difference between ball bearings and spherical roller bearings?

A: Ball bearings use spherical balls as rolling elements, while spherical roller bearings use cylindrical rollers with a slight barrel shape. Ball bearings are generally better suited for high-speed applications and can handle both radial and thrust loads. Spherical roller bearings can accommodate higher loads and misalignment but typically operate at lower speeds. Both types are widely used in various industrial applications.

Q: How do radial load bearings differ from thrust load bearings?

A: Radial load bearings are designed to support loads perpendicular to the shaft axis, such as the weight of a rotating shaft. Thrust load bearings, on the other hand, are engineered to handle axial forces parallel to the shaft. Some bearings, like angular contact ball bearings, can handle both radial and thrust loads. The choice between these types depends on the specific application and the direction of the forces applied to the bearing.

Q: What are the advantages of using flanged bearings?

A: Flanged bearings offer several advantages: 1) Easier installation and alignment due to the integrated flange. 2) Improved load distribution and stability. 3) Reduced need for additional mounting hardware. 4) Better sealing capabilities to protect against contamination. 5) Simplified maintenance and replacement. Flanged bearings are particularly useful in applications where space is limited or where precise positioning is critical.

Q: How do you know if ball bearings need replacement?

A: Signs that ball bearings may need replacement include: 1) Unusual noise or vibration during operation. 2) Increased heat generation. 3) Reduced rotational smoothness or “rough” feel. 4) Visible damage or wear on the bearing races or balls. 5) Excessive play or looseness in the bearing. 6) Decreased performance or efficiency of the machine. Regular inspections and monitoring of bearing conditions can help prevent unexpected failures and downtime.

Q: What are the main differences between separable and non-separable bearings?

A: Separable bearings, also known as split bearings, can be disassembled into two halves, allowing for easier installation and maintenance without removing the shaft. Non-separable bearings are manufactured as a single unit and cannot be taken apart. Separable bearings are often used in applications where shaft removal is difficult or impossible, while non-separable bearings generally offer higher load capacity and are more common in standard applications.

Q: How do sleeve bearings compare to ball bearings?

A: Sleeve bearings, also called plain bearings, use a smooth surface to support the rotating shaft, while ball bearings use rolling elements. Sleeve bearings are simpler, less expensive, and can operate more quietly than ball bearings. However, ball bearings generally offer lower friction, higher load capacity, and better performance at high speeds. The choice between sleeve and ball bearings depends on factors such as load, speed, cost, and maintenance requirements of the specific application.