Welcome to our detailed article about journal-bearing types! In this particular piece, we shall explore the journal-bearing lubrication and design in detail. Many machines rely on journal bearings for rotation as they assist in supporting the structure while rotating. Several different types of journal bearings exist. They differ in their characteristics and their applications. Furthermore, the particular technique or mechanisms to bear the load, as well as their operation to order them to perform a particular task, which is referred to as lubrication, will be examined. Especially such factors as bearing performance or design of certain parts under predetermining conditions will be of considerable interest to all engineers and many amateurs. In the last place, the most common vibration problems caused by journal bearings are discussed, and possible solutions to those problems are given. Let us proceed with the detailed coverage of the journal bearing types, lubrication and design in detail.

What Are the Different Journal Bearing Types?

journal bearings can be generally classified into three groups:

- Plain Journal Bearings: These kinds of bearings are made up of a plain cylindrical shaft that rotates inside a sleeve or bushing, which is stationary. Sliding is present at the interface of the shaft and the sleeve. Thus, a lubrication film is formed as a result of their relative movement grazing past each other.

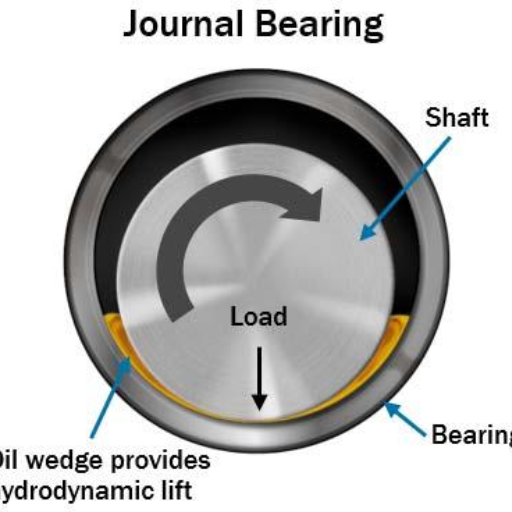

- Hydrodynamic Journal Bearings:This type of bearing contains a lubrication film that forms in the shape of a wedge due to the rotation of the shaft and the liquid/ fluid surrounding it. It shall be noted that the hydrodynamic effect in fact initiates a pressure gradient that aids and suspends the shaft thereby avoiding direct contact of the shaft with bearing surfaces.

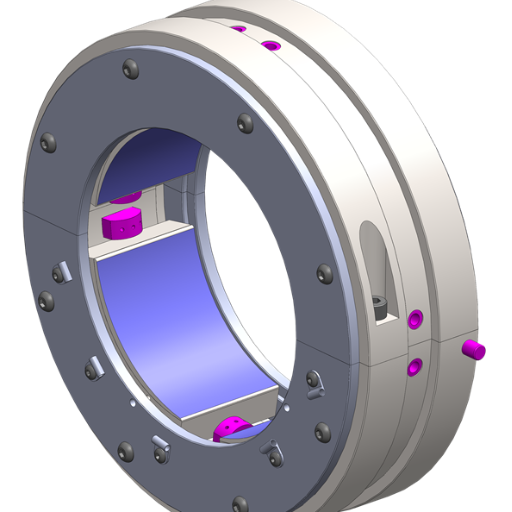

- Tilting Pad Journal Bearings: This kind of bearing has more than one pad or segment that is placed on a casting hub connected to a swiveling mechanism that allows for tilting of each segment. The tilting allows the bearing support to be self adjusting to different loads and misalignments thereby increasing the load bearing ability of the bearing and providing more stability.

Grasping these different journal bearing types and their particular features along with the various applications which they serve forms the core basis for choosing the correct type in various engineering and machinery operations.

Exploring Plain Journal Bearing Characteristics

let us examine the features of plain journal bearings. To be more specific, plain journal bearings, also called sleeve bearings or radial bearings, are quite simple and reliable in engineering and machinery applications. Some of the characteristics are as follows:

- Design Simplicity: Simple journal bearings consist of a shaft which rotates in a cylindrical bore. Such a straightforward design makes the use and maintenance easy.

- Friction Reduction: These bearings operate with a thin film of lubricant which separates the rotating shaft from the bearing surface and hence reduces friction and wear.

- Load Distribution: Plain journal bearings operate by bearing the load on a larger surface and thus low the stress and the potential of wear to improve function.

- Suitability for High-Speed Applications: It is important to maintain adequate lubrication and clearance so that plain journal bearings can function at much higher speeds which is ideal for a variety of industrial processes.

- Cost-Effective Solution:Compared to more complicated bearings, simple journal bearings frequently provide less expensive construction while increasing survivability ratios.

This knowledge allows engineers and machinery operators to select and employ plain journal bearings correctly in their applications.

The Role of Hydrodynamic Journal Bearings in Machinery

hydrodynamic journal bearings are indispensable in machinery as they provide adequate support to the machinery castings and minimize relative motion between the rotary parts. Lubricating oil films are used to form a hydrodynamic wedge that permits the rotating journal to be spaced apart from the bearing. This leads to low friction, low wear, and improved efficiency. Furthermore, the modern tilting pad journal design, along with various others, has improved the optimal performance of the bearing under load and even at exceedingly high speeds at which lubrication may be inadequate. The period during which the hydrodynamic journal bearings are in service and their efficiency mainly depends on the comprehension of the lubrication mechanisms and the best practices. Also, the performance of the bearing is subject to many dependent parameters, such as journal speed and load, pressure distribution, or bearing vibration. These factors should be addressed by the engineers at the designing stage to aid in the generation of efficient and resilient journal bearings for the intended usage.

Innovative Tilting Pad Journal Designs

In my view, the advanced designs of tilting pad journals have great potential for improving the performance and reliability of hydrodynamic journal bearings. Such designs include adjustable pivots, optimized pad shapes, and enhanced lubrication systems. These improvements enable the engineers to achieve higher load capacity, lower friction and wear, and better control of the lubrication film thickness. Furthermore, these designs are not only innovative but are also adaptable in meeting the requirements of specific applications, thus owing to superior performance capabilities as well as reliability, these bearings are expected to find use in a variety of industries.

How Does Lubrication Affect Journal Bearings?

According to my knowledge, the lubrication of journal bearings is among the core proprieties of the bearings and ultimately their integrity. Proper lubrication permits effective operation of bearings and increases their lifetime. It affects journal bearings in several ways:

- Hydrodynamic Lubrication Mechanisms: When the liquid lubricant operates in between the journal and its bearing surface, a hydrodynamic lubrication is said to occur. This type of lubrication introduces a film or soild layer between two racings which eliminates direct contact of the two metals. This reduces friction and wear of the parts and enable the bearings to function efficiently and for a longer period of time.

- Impact of Boundary Lubrication:Insufficient thickness of the lubrication film tends to happen in certain conditions like starting conditions or low speeds, so lubrication for such conditions tends to be partly the coating of lubrication which is called a boundary lubrication That coating increases friction and wear. Effective lubrication must ensure that just a little amount of boundary lubrication is allowed to take place so as to protect the performance of the bearings.

- Optimal Bearing Lubrication Practices: The performance of any bearing depends on uses of the appropriate lubricant which is usually characterized by viscosity, temperature and the application in use. Another vital point for proper lubrication is the use of monitoring systems that will regulate the frequency and amount of lubrication.

Engineers are capable of improving the functioning, reliability, and durability of journal bearings through proper lubrication which then reduces down times and enhances technical efficiency in the industries.

Understanding Hydrodynamic Lubrication Mechanisms

This text is specific to the oil film in the journal bearing and the context of Fundamentals of Bearing Technology textbook. The reason of its importance is apparent: any engineer who has worked with or designed rolling element bearings and their assemblies will be aware of the recess formed by bearing rings on balls or cylindrical rollers: a pivotal aspect which can lead to questions regarding the topicality of the consultant material.

Impact of Boundary Lubrication on Bearing Performance

And the effect of the boundary lubrication on the performance of bearings is also profound as an aspect of technology. Boundary lubrication is defined as the case where the films between the bearing surface are quite thin or intermittent, and metal-to-metal contact actually occurs. This worsens the measurable performance of the bearing with respect to friction, and its wear and bearing life span may also be negatively affected. Adequate lubrication management is vital as it reduces the occurrence of boundary lubrication and it’s negative implications on the bearing performance. Engineers are able to limit boundary lubrication problems and enhance bearing performance by making sure the right lubrication is used – using the right lubricants and putting effective maintenance procedures in place for the bearings in order to ensure their operational efficiency and reliability over time.

Optimal Bearing Lubrication Practices

Optimal bearing lubrication practices are vital in ensuring that the bearing operates to the maximum level across its lifespan. Lubrication allows for the minimization of friction, wear, and the threshold of boundary lubrication, which would otherwise be detrimental to bearing functionality. In order to attain sufficient lubrication, it is prudent to:

- Choose the Right Lubricant: Always use a lubricant that matches the requirements of the application, considering temperature, speed and load conditions.

- Maintain Proper Lubricant Levels: Always measure and check for the appropriate volume of lubricant to be present in the bearing during its functioning.

- Implement Lubrication Management: Make an effective strategy to prevent any kind of lubrication deterioration and contamination with set dates concerning lubrication inspection, testing and pouring.

- Use Appropriate Lubrication Methods:An oil bath, oil mist, or other centralized lubrication systems should be used for effective oil distribution without a dry point.

- Establish Effective Maintenance Practices: Incorporate all practices in the maintenance of the equipment such as checking, cleaning and replacing of oils regularly to reduce the chances of oil contaminants.

Through the adoption of these best practices in bearing lubrication, engineers can contribute to the improvement of bearing performances, the reduction of friction, and in general efficiency as well as bearing life.

What Factors Influence Hydrodynamic Journal Bearings Performance?

In my professional opinion and as a seasoned practitioner in the field, I appreciate that there are numerous factors that have an influence on the operation requirements of hydrodynamic journal bearings. These are features that underline both the bearing’s usability and durability. Among these are the motion of the journal (velocity), the movement of the journal bearings (load), and the corresponding internal bearing pressure. Overall, issues such as frictional resistance can be reduced, and the efficiency and working life of hydrodynamic journal bearings can be increased by regulating bearing loads, rotational speeds, and journal pressures. Also, bearing performance can be improved by solving vibration problems. Help in medicine bone-to-bone problems of the articular surfaces, and decrease vibrios to get the optimal operational state of the bearing. By vigilant supervision and rectification, the engineers can ensure that the hydrodynamic journal bears are operational, in good condition, and able to perform a variety of industrial roles.

Effect of Journal Speed and Load on Bearings

Understanding the impact of journal speed and load on bearings for performance improvements is critical as an industry expert. The term journal speed’ defines the bearing angular speed while load refers to the weight put on the bearing. Both parameters considerably affect the functionality and the life of the bearings.

- Effect of Journal Speed:As the journal speed increases the amount of friction and heat generated in the bearing increases as well. This can lead to an increase in the wearing rate of the surfaces of the bearing and possibly damage them. It is essential to properly lubricate the bearing and select appropriate materials in order to reduce the consequences of heavy journal speeds.

- Effect of Load:

High loads bearing can lead to increased stress levels which can in turn lead to fatigue and failure High load calculations and the selection of optimum bearing and materials are important to make sure the applied load do not exceed the allowable limits of the bearing.

The performance and reliability of any industrial operation boils down to understanding and fine-tuning the journal’s speed and load in conjunction with the bearings.

Pressure Distribution Within the Bearing

Compliance with governing design and performance parameters is vital to bearing functionality. However, to understand the importance of these parameters, we must first look into how a bearing operates. Such was the case when journal bearings were found in operation where the uniformity of the pressure on the bearing surface was compromised! Factors like the load on rotation or lubrication progress caused the pressure to profile across the bearing. Such pressure fluctuations deform the cross-section of the journal bearing such that instead of a uniform shape, pressure is symmetrically distributed about the middle of the bearing, and the rest decreases as one moves away from the center. This pressure gradient is essential in enhancing the film thickness, particularly due to the rotational motion of the shaft and, thereby, fluid friction, as well as reducing contact pressures and surface abrasiveness brought about by the journal-plate contact within a bearing. The consideration of the hydrodynamic bearing pressure is important, especially in avoiding bearing failure caused by the application of load or rotation during the working range.

Managing Vibration in Rotating Journals

vibration control of rotating journals is essential for the proper functioning and life of journal bearings. But to tackle the issues regarding vibration, we need to focus on a few important points and strategies, which are as follows:

- Designing a Type of Journal Bearing: Every journal bearing designer must possess some knowledge regarding factors such as load bearing capacity, lubrication system, and the working environment. Bearing selection also requires an understanding of materials as well as the calculation of bearing load and clearance, and also the final alignment.

- Selecting the Right Bearing Material:Consideration of bearing material is crucial if vibration is to be controlled. This is for the reason that strong, stiff, and damping materials would help in avoiding contact and resonance which are vibration sources.

- Calculating the Bearing Load and Clearance: An estimation of bearing load and bearing clearance is important to avoid undue compressive stress and strain on the bearing. Applying the right amount of force on the right spots of the bearing surface is important so as to avoid vorticity.

- Identifying Metal-to-Metal Contact Causes: Most diy videos come with a warning that metal to metal contact is the silent killer. Vibration resonance is triggered by several interrelated factors such as a deficiency of lubricative grease, incorrect angular position on the shaft, or excess weight on the bearing which are easy to pinpoint.

- Strategies to Reduce Vibration Across Bearings: Tuning journal bearings may get worse sound when replaced. Although, we try to cover all possible solutions which may come in handy like changing lubrication, changing clearances of bearings, and changing the operating factors with minimum disturbance.

- Monitoring and Adjusting Bearing Center Alignment: A crucial consideration to bear in mind is the actual measurement of the occupied volume. Taking bearing surface into consideration, it is generally integrated with surface tension. Since the result obtained is only obtained by vertical or planar alignment, all other factors are dealt with as being out of consideration, even the most remote results. An accurate vertical alignment contributes to the equalization of the load over the entire bearing surface, thus minimising the chances of an overhaul.

Taking into account the above factors and implementing appropriate strategies, engineers and technicians can control vibration in rotating journals, which increases reliability in the operation of journal bearings.”

How to Design a Type of Journal Bearing?

Designing so-called journal bearings is an art that takes into account many factors, and it requires expertise. The following are some important steps I would recommend you consider in the design process:

- Identify the Application Requirements: Know the particular working conditions to which the bearing will be subjected, such as load, speed, and temperature range, in order to be approved for the specified service.

- Select the Bearing Type: Select the type of bearing appropriate to the application and the other requirements, including the radial or thrust loads, space availability, and lubrication. Common types include plain bearings, rolling element bearings, and fluid film bearings.

- Determine Bearing Dimensions: Pick an appropriate bearing material for this application such as steel, bronze or polymer composites which will allow the bearing to function well under load, speed and operational conditions that is expected of it.

- Choose the Bearing Material: Identify the lubrication type, oil or grease for example, and sketch out a lubrication scheme that will effectively lubricate the bearings and loss of friction will also be reduced.

- Design Lubrication System: Determine the lubrication method, such as oil or grease, and design an effective lubrication system to ensure proper lubrication and minimize frictional losses.

- Evaluate and Test the Design: Do the review and testing of design to assure they perform efficiently and are reliable. Works of this nature usually include simulation studies, prototype testing and verification of performance.

The centerpiece of journal bearing design is to meet operational and performance efficiency. Along with these processes and keeping in mind certain requisite specifications of the application, one would be able to build a sturdy and effective journal bearing.

Key Considerations in Bearing Design

From the perspective of an industry specialist, there are several factors that ought to be considered when focusing on the design of bearings. These are the aspects that are critical in the proper functioning and dependability of journal bearings. Let us highlight the most important of them:

- Selecting the Right Bearing Material: It is very important to choose the correct material for the bearing which will withstand the conditions of operation and the applied loads while operational to minimize the wear and friction. Some considerations will need to be made with regards to operational load, acceptable operating temperature, and lubricants compatibility.

- Calculating the Bearing Load and Clearance: The bearing load and the clearance are two parameters that require careful assessment because these are key to ensuring proper operation. This includes examining static and dynamic loadings which are the forces applied, and also providing the necessary clearance, in order to deal with thermal expansion without excessive contact pressure.

I will write an essay that focuses on the solutions of vibration related issues in journal bearings. To solve these challenges make v sure you understand these mechanisms. Establishing the underlying root causes that lead to metal-to-metal contact, as well as taking measures to combat vibration throughout the bearing assembly, are crucial tasks. Furthermore, active checking of the bearing center and altering alignment may decrease vibration and enhance performance.

The approaches address user experience while incorporating what is considered am best practices in journal bearings design would help enhance their operational perfection and longevity thereby improving reliability whilst concomitantly reducing the maintenance expenditures.

Selecting the Right Bearing Material

I can say that the selection of bearing material for journal bearings is critical for them to perform adequately and last. The materials may change based on: operational settings, load support needs, temperature range, and lubrication requirements. Here are key considerations when selecting the right bearing material:

- Load Capacity: Locate a bearing material that has a high load capacity to endure the working stresses and pressures developed during service.

- Friction and Wear: Select materials which have low friction and wear resistance so that energy loss is reduced and the bearing lifetime increased.

- Corrosion Resistance:Based on the conditions of the environment determine the corrosion resistant material to avoid degradation and the integrity of the bearing.

- Temperature Range: Ensure that the selected material will cope with the predicted temperature limits while keeping all mechanical properties intact.

- Lubrication Compatibility: Consider the lubrication method and the selected bearing material in order to ensure lubrication is used effectively and friction is minimized.

Other materials that can be bearings in the assemblies are bronze alloys, steel and synthetic polymers like PTFE (polytetrafluoroethylene) materials. Apart from the general recommendation of the specific materials, it is necessary to evaluate the particular requirements of the application. Plus seek the assistance of manufacturers or specialists concerning the best compound suited for your journal bearings.

Calculating the Bearing Load and Clearance

I understand how important it is to work out the bearing loads and the clearance in order to achieve the desired operational efficiency and working life of the journal bearings. Here, the bearing load denotes the force put by the bearing during its working operation, and the clearance denotes the space between the journal (shaft) and the surface of the bearing. To find out the succinct answer, the following questions are asked:

When determining the bearing load, the following factors ought to be taken into account:

- Estimate the loads acting on the bearing, such as axial and radial loads.

- Compute the working load in terms of bearing dynamics and factors governing the operating conditions.

- Assess the load that is consistent over the period or additively changed in time with respect to the bearing.

- Consider any other such issues, including shock or misalignment, which may bear on the bearing load.

Calculating the bearing clearance involves:

- Comprehending as to which space would be left between the shaft and the bearing surface for lubrication and thermal expansion.

- Examining a suitable operating clearance with respect to the application, Such as considering temperature, speed, and load conditions.

- Consideration of any organizational and/or other requirements that determine the clearance range is required.

It should be emphasized that the calculations related to the load and clearance are correct only if a comprehensive understanding of the application, bearing conception, operational environment, and standards of the industry is known. However, journal bearings are critical components of water turbine equipment, so consulting with bearing manufacturers or experts can greatly help you in getting the correct calculations.

How to Address Vibration Issues in Journal Bearings?

I have been advised that a holistic method is required to tackle vibration problems in journal bearings. Some measures to control vibration are enumerated as follows:

- Proper Lubrication: In order to mitigate wear and vibrations, ideally, enough lubrication ought to be given in order to lessen the friction. The connecting surfaces of the bearings can be maintained free of contact with each other, and film can be preserved between the moving elements, which results in less vibration.

- Balancing and Alignment: The rotating parts and the bearings can be aligned and balanced accurately in order to resolve the vibration problem to a considerable level. Whenever there are imbalances and misalignment in a dynamic system there are induced excessive forces and vibrations which accelerates failure. Periodic adjustment and corrective maintenance can be helpful in achieving proper orientation and balance.

- Vibration Monitoring: The establishment of a sound vibration monitoring system makes it possible to notice unusual patterns of vibration at an early stage. Through regular measurement and analysis of vibration levels, maintenance before breakdowns can be done, i.e. maintenance which is intended to prevent failure of the equipment.

- Proper Installation and Maintenance: Proper installation procedures such as fits, clearances and torques need to be guaranteed otherwise bearing operation cannot be expected to be optimum. Also, maintenance technologies like cleaning, surveillance, and re-lubricating are important in order to get rid of dirt and ensure bearing movement is unobstructed.

Adapting these measures and taking into account the peculiarities of journal bearings design and operational features will allow you to reduce the vibration levels significantly and consequently, enhance the performance and the life span of the bearings.

Identifying Metal-to-Metal Contact Causes

From an industry perspective, comprehending the reasons behind metal-to-metal contact in bearings is critical in order to perform maintenance and prevent issues. There are several causes that can lead to metal-to-metal contact within bearings which include;

- Insufficient Lubrication:Insufficient lubrication or use of wrong lubricants, increase friction and the metal loaded unto the bearings surfaces wears out as it rubs against other metal surfaces.

- Contaminants and Debris: Contaminants such as dirt, dust, or any other foreign material suspended in fluid or bearing lubricant will interfere with the smooth working of bearings and lead to metal contact between the mating surfaces, resulting in increased wear.

- Misalignment: Sometimes bearings may not have been properly aligned in the sake of load application, this will cause Bearing inner race to be loaded unevenly which also cause the shaft to be loaded unevenly and there will be areas that will come into contact with each other.

- Excessive Load or Overloading:Excessive Load or Overloading: Improper load or excessive force application to the bearings can lead to or increase friction load which leads to the surfaces coming into contact with each other which can lead to bearing failure.

In order to reduce the causes of contact between metal surfaces, there are effective methods such as maintaining proper lubrication, placing control over contamination, and inspecting and maintaining parts periodically. With such factors being optimized, metal to metal contact can be reduced, bearing life can be increased, and performance of the operation can be enhanced.

Strategies to Reduce Vibration Across Bearings

Strategies to Reduce Vibration Across Bearings:

- Balancing and Alignment: Rotating components require strong attachment as it limits the threat of vibration which is detrimental to mechanical parts. Balancing and aligning bearings should be done regularly to keep wear due to vibration effects to a minimum while ensuring that operations remain fluent.

- Vibration Dampening Materials: The use of vibration dampening materials such as rubber mounts or isolators can reduce the amount of vibration that the bearings are subjected to. In so doing, such materials allow for even small external vibrations to be avoided from bearing performance.

- Proper Lubrication:Bearings should be lubricated properly as it reduces heat due to friction which in turn limits chances of vibrations. The right lubricant in such cases provides a reduction of the points of contact through the construction of a layer which ensures that some portions of the bearing surfaces do not contact with the metal.

- Maintenance and Inspection: A systematic maintenance and inspection program should be put in place to avoid excessive excessive vibration and mechanical failures. The reasons include wear, contamination, or misalignment.

By adopting these approaches, you can manage vibrations on the bearings, so operations are smoother, and lifespan and overall performance are improved.

Monitoring and Adjusting Bearing Center Alignment

As bearing alignment monitors and specialists know very well, keeping the bearing centers aligned is a prerequisite to good performance in many applications. A number of studies show that misalignment will cause excessive vibration and premature bearing failure. Active measurement of bearing misalignment ensures these components are correctly seated and the potential for overstressed vibrations is reduced. If a bearing has been noted as misaligned, the corresponding adjustments of tilting shall be carried out immediately So as to orient the bearing on its axis. This can also mean that shimming and laser alignment may also be performed. Effective bearing center alignment enables reduction of vibration of the bearings while increasing their operational life and performance efficiency.

Reference

- Journal-bearing databook – This book section discusses various types of journal bearings and their characteristics.

- Journal Bearing Design Types And Their Applications To Turbomachinery – This paper explores different types of hydrodynamic journal bearings used in industrial turbomachinery.

- The full journal bearing – This article discusses the general conditions applicable to full journal bearings.

Frequently Asked Questions (FAQs)

Q: What are the main types of journal bearings?

A: The main types of journal bearings include hydrodynamically lubricated journal bearings, hydrostatic bearings, sliding bearings, pressure dam bearings, elliptical bearings, and groove bearings. Each type varies in design and application, providing specific benefits based on the operational requirements.

Q: How does the oil film in a journal-bearing function?

A: The oil film in a journal bearing acts as a lubricant, creating a thin layer between the journal and the bearing surface. This reduces friction and wear, allowing smooth motion of the journal while supporting the load on the shaft.

Q: What is the role of the bearing shell in journal bearings?

A: The bearing shell is part of the bearing assembly that houses the journal and provides the surface against which the journal rotates. It helps maintain the oil film and ensures proper pressure distribution in the bearing.

Q: What is meant by boundary lubrication regime?

A: The boundary lubrication regime occurs when the oil film is too thin to completely separate the journal and bearing surfaces, causing occasional contact. This regime is common in startup and shutdown conditions and requires effective lubricants to minimize wear.

Q: How does the pressure distribution in the bearing affect performance?

A: Proper pressure distribution in the bearing is crucial for optimal performance. Uneven pressure can lead to increased wear and potential failure. The design of grooves in the bearing and the load on the shaft influence this distribution.

Q: What factors determine the clearance between the journal and the bearing?

A: The clearance between the journal and the bearing is determined by the journal diameter, bearing length, and design tolerances. Adequate clearance is essential for maintaining the oil film and ensuring efficient operation.

Q: How does the load on the shaft impact journal bearing performance?

A: The load on the shaft influences the thickness of the oil film and the pressure distribution inside the bearing. High loads can increase friction and wear, requiring careful design and lubrication to prevent damage.

Q: What is a pillow block bearing, and where is it used?

A: A pillow block bearing is a type of mounting bracket used to support a rotating shaft with the help of compatible bearings. It is commonly used in industrial applications where the bearing is made to support heavy loads and provide stability.

Q: What are semilubricated journal bearings?

A: Semilubricated journal bearings operate with partial lubrication, meaning the bearing may not always maintain a full oil film. These bearings are commonly used in conditions where full lubrication is not possible or practical.