Turbochargers are integral parts of today`s engine systems, allowing for greater performance improvements as well as enhanced efficiency and extra power. At the core of every turbocharger lies a vital yet often overlooked element—its bearing system. The specific choice of bearing system in turbochargers, whether axial or ball bearing, has been shown to impact both turbocharger performance and life. This article tries to distinguish between the two bearing types, focusing on their operational principle, lubrication, and influence on turbocharger performance. This breakdown will provide ease of understanding and reasonings on which bearing has the upper hand in terms of lubrication; however, if you are looking for an explanation of turbo technology, it will suffice to say that this article is about the optimization of your turbocharger.

What are journal bearings, and how do they work?

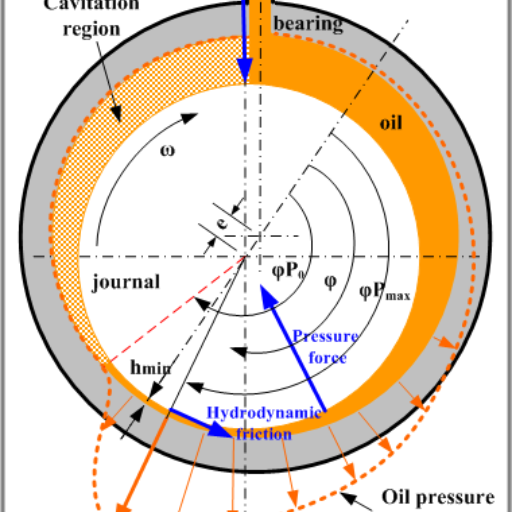

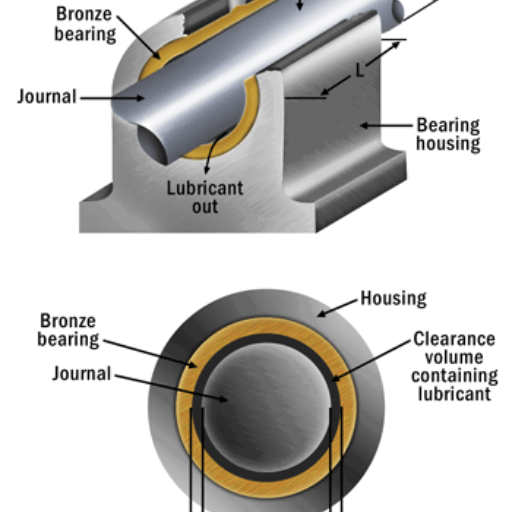

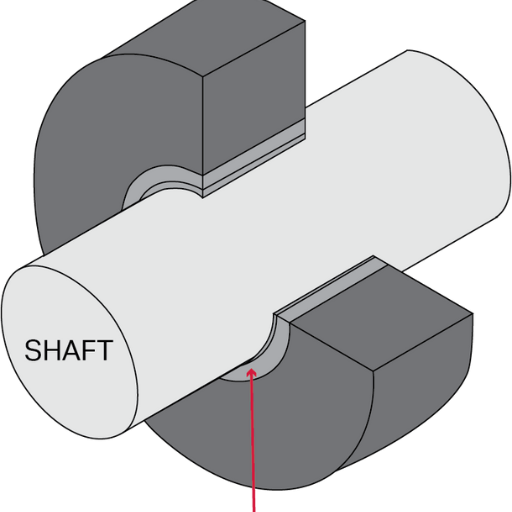

A journal bearing is a type of bearing where a lubricating film supports a rotating shaft. This rotating shaft is situated within bearing housings. The relative movement of the shaft and bearing creates sufficient pressure to prevent the rubbing of metal surfaces. Bearing types and structures that use enhanced fluid flow are also referred to as journal bearings. These are sometimes referred to as fluid or oil bearings,s and they are useful when dealing with reduced levels of friction and wear in high-speed rotating equipment.

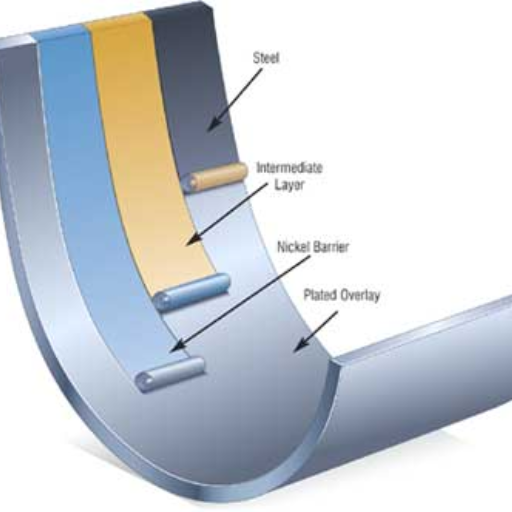

Understanding the basic structure of journal bearings

Journal bearings are fairly simple but brilliant in their basic design, in my opinion, having been in the field for some time. A journal bearing is basically made up of two components only: the bearing house and the journal, which rotates inside the bearing, which happens to be a part of the shaft. Things like lubricants are also vital, but here, the lubricant essentially forms the hydrodynamic film that separates the bearing and shaft surfaces so they do not touch one another. Such a solution reduces friction, allows uniform loading of different surface,s and ensures smooth functioning of various components in different states. For many years, I’ve been working with such functional elements, and I can say that although their structure is quite simple, their role is crucial in high-performance units.

How hydrodynamic lubrication supports rotating shafts

I have witnessed LUBRICATION IMPORTANCE and hydrodynamic lubrication, in particular, which assists in rotating shafts countless times in my work experience. Here’s how it works in simple terms. As a rotating shaft begins to turn, the lubricant situated around it is also moved, causing a pressure increase, which eventually forms a thin film. This film assists the shaft in suspension, thus ensuring no direct contact is made with the bearing surfaces. Such a mechanism is in play; otherwise, friction and abrasions would wear out both the shaft and the bearing in due time.

Since there will be no great disparities among compressibility, shear strength, and viscosity, let us list the most important parameters to analyze the way hydrodynamic lubrication assists shafts in rotation:

- Rotational Speed – Lubricants are extremely dependent on the shaft speed since this speed affects how quickly the lubricant comes into action. A good hydrodynamic film strengthens with an increase in the speed of the devices, but there is an optimum speed since too high of a value rather leads to overheating instead.

- Viscosity of the Lubricant – With respect to the multilayer model, we consider the thickness of the lubricating film, which will in turn allow us to analyze the protective capability of the wetting layer. Internally, a greater viscosity can deliver better support for lower speeds, while low viscosity support provides high speed.

- Load on the Shaft – The magnitude and distribution of impact and resultant forces affect the hydrodynamic film’s modulus of thickness and pressure. All lubrication processes need to be designed for the basic load to ensure adequate formation of the required lubrication film.

- Surface Roughness – Good lubrication practices are dependent on the smoothness of the tangible surfaces in the shaft and bearing. Increased roughness of surfaces can disrupt the film, thereby leading to an increase in friction and wear.

- Bearing Geometry -An equally relevant degree to which the bearing design geometry impacts the performance is the effective flow and pressure of the lubricant.

As a consequence of accurately controlling these parameters, hydrodynamic lubrication not only enhances the supporting of rotating shafts but also their operational efficiency and durability. It’s compelling physics and engineering that enable the high performance of even the most sophisticated machinery.

Types of Journal Bearings and Their Applications

Journal bearings form an integral part of many mechanical mechanisms and apparatus, which are specially designed to bear and position rotating shafts under load application. It allows the loaded shaft to revolve freely ensuring that an optimum speed is maintained to prevent overheating. They come in various types, each fit for different operating and environmental conditions. Here are the main types of journal bearings and their applications, along with the parameters relevant to their usage:

- Plain Journal Bearings

Plain journal bearings are the simplest type and rely entirely on a thin film of lubricating fluid to separate the shaft and the bearing surface. They are commonly found in compressors, turbines, and high-speed machinery.

- Key Parameters: Load capacity, surface roughness, lubricant viscosity, and shaft speed. These factors determine the bearing’s ability to maintain a continuous lubricating film and prevent metal-to-metal contact.

- Sleeve Bearings

Plain bearings, which are also called sleeve bearings, are cylindrical in shape and completely enclose a rotating shaft. They are great for electric motors and fans as they are able to work quite well under moderate speeds and loads.

- Key Parameters: Depth of clearance between the shaft and the sleeve, the mating materials’ compatibility, and the thermal conductivity to control wear and heat.

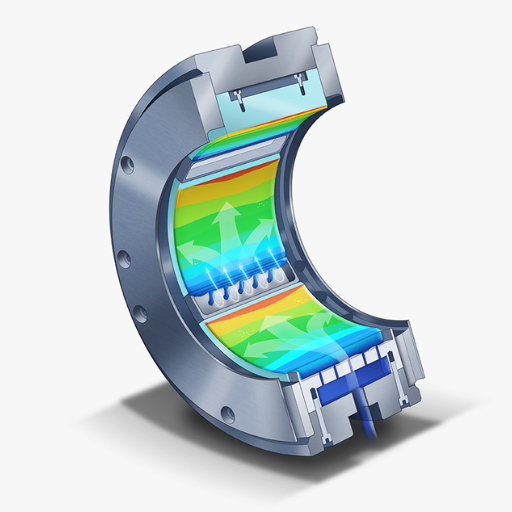

- Hydrodynamic Journal Bearings

These bearings utilize hydrodynamic lubrication and generate a pressurized fluid film during functioning to support heavy loads. Their application includes gas turbines, marine engines, industrial pumps, etc.

- Key Parameters: Lubricant film thickness, thermal stability, rotation speed of the shaft, load seeking, and bearing configuration.

There is a strategy in the selection of the right kind of journal bearing and looking into these parameters so that the engineers can have dependability and sufficiency and performance of their systems as required by operational needs.

What are the main advantages of using journal bearings?

I have been involved in this industry long enough to know that some of the benefits of using journal bearings are: ease of use; they are tough and very efficient. These bearings operate at low loads of friction when properly lubricated, enabling them to work well at high rotating speeds and under great loads. Furthermore, due to their sturdy construction and ability to distribute the load evenly around the bearing surface, they have a long life. Their reliability is further increased by their ability to withstand other conditions in the industry, such as heat or intense shaking. All in all, it is undoubted that journal bearings are a perfect option for the systems set to work steadily and maintain their functionality over a prolonged period of time.

Superior performance in high-speed applications

In high-speed tasks, classes of machined bushes known as journal bearings are claimably superior due to their efficacy in reducing dynamic frictions. Their configurations play an important role in sliding at higher rotor speeds by minimizing wear and energy losses. Moreover, the internal self-lubricating properties or external lubrication systems included in the journal bearings improve their effectiveness, thus increasing the overall efficiency of high-speed machines.

Excellent load-bearing capacity for radial loads

Based on my experience, I know that journal bearings are the best devices for supporting radial loads. Their heavy construction practically ensures that forces acting on them are coordinated, which means that under severe loads, there is less likelihood of mechanical failure. Thus, they are ideal for situations where support and performance are critical.

Reduced friction and wear in rotational motion

The thin film of lubricant helps the sliding surfaces to be separated from each other, leading to rotation in the process of utilizing journal bearings. Because of the reduced contact, extreme heat and wear of the material are avoided, which in turn leads to increased life and performance.

How do journal bearings compare to ball bearings in turbos?

In my turbo experience, both journal and ball bearings have their pros and cons, depending on the particular requirement of the system. First of all, I कहना Journal bearings are trouble-free, therefore, they are simple and cost-effective. A sufficient supply of oil is needed to sustain the hydrodynamic film, thus, these bearings are perfect when operated on high speeds for prolong time since they suffer from minimal frictional wear. However, ball bearings are better as they have additional components and rolling elements, which can lessen the rotational friction more than journal bearings and increase the responsiveness of the turbo, thus decreasing the spool time. However, I understand ball bearings are best in extreme performance or racing applications, but they are pricey and require more careful attention. I guess the final decision has to be made between bore and ball bearings based on factors related to Powell River flux profile application, available cash, economy, and performance.

Differences in bearing design and operation

A journal bearing will use an oil film for lubrication, which is very thin but provides strength and ease, especially under load. On the other hand, ball bearings have rolling elements that reduce friction, allowing faster spool times and greater efficiency. While journal bearings are cheap and strong, ball bearings are expensive and require a greater level of maintenance, but they provide high accuracy and performance. It depends on the application and the aim of the operation.

Comparing lubrication methods: oil vs grease

A journal bearing will use an oil film for lubrication, which is very thin but provides strength and ease, especially under load. On the other hand, ball bearings have rolling elements that reduce friction, allowing faster spool times and greater efficiency. While journal bearings are cheap and strong, ball bearings are expensive and require a greater level of maintenance, but they provide high accuracy and performance. It depends on the application and the aim of the operation.

Impact on turbo performance and longevity

Using either oil or grease affects turbo performance and lifespan. Efficient lubrication minimizes the chances of wear, friction, and maximum airflow effectiveness. In turbochargers which operate at high speeds, oil is the lubricant most preferred as it travels and distributes heat well. However, great care must be taken to avoid any contamination of the oil. Turbo systems usually do not use grease because it is unable to withstand high temperatures and fast rotational speeds. All in all, considering the right type of lubricant oil and taking care of it are both necessary in order to maximize the performance and lifespan of a turbo.

What are the common applications of journal bearings?

Journal bearings are arguably the most common pattern of bearings in the engineering world due to their availability in high load capacity and rotating motion. As far as I am concerned, they are found in turbines, industrial compressors, and electric motors where they support great deals radial load. Also, they are of great importance in automotive applications, such as ultramodern engines, where the crankshafts and camshafts are mounted on them to facilitate their working with low friction. Being simple and rugged, and capable of operating under adverse conditions, they are suitable and widely used in drive systems and heavy equipment.

Use in automotive and industrial turbines.

In automotive and industrial turbines, ball bearings are very important components as they reduce friction, enhance energy efficiency, and facilitate high-speed rotation even with large loads being applied. In the case of the turbines, these bearings assist in adequate rotation of the shaft while reducing wear and tear under very high temperature and pressure conditions. This consistency and accuracy make ball bearings an ideal subject of attention if one’s aim is to utilize the turbines to their fullest potential.

Applications in various mechanical systems

Being a professional in the ball bearing manufacturing and supply industry, I can tell you that ball bearings are simply universal components since they serve the dual function of minimizing friction and enabling rotation in any of the mechanical systems. I would like to explain this to you in the most simplistic manner by showing you some key applications and relevant parameters that justify their importance:

- Automotive Systems

Automotive systems include various regions of wheel hubs, transmissions, engine parts, and, most notably, ball bearings. Their role here is primarily to transmit radial and axial loads in a proficient manner while enabling smooth and stable motions. Their performance in such challenging environments is largely dependent on the load-carrying capacity, rotational speed, and operating temperature.

- Industrial Machinery

From belt systems to electric motors, industrial machinery ball bearings serve an important role as far as the strength and working efficiency of various machines is concerned. These systems are subjected to many hours of work and substantial loads, so the materials used to construct the bearing (stainless steel and ceramic), lubrication, and wear and tear must be taken into account.

- Aerospace Systems

When working with aeronautical engines or navigation systems, there is a need for ball bearings that can operate in harsh environments, and those are very difficult to find. In such instances, it is necessary to keep shareholders’ interests intact, including weight, vibration, and temperature configuration.

- Medical Devices

Ball bearings are equally essential in robotic surgical units or imaging devices, which can be regarded as cutting-edge medical technology. These types of devices hardly make noise and are very precise; there is a very high focus on their motion, and most importantly, they are accurate.

- Home Appliances

People have become dependent on using Ball bearings in home appliances, such as off motors for washing machines, vacuum cleaners, and fans, in order for these devices to function in silence. The amount of time and money spent maintaining these consumer bearing systems is a benchmark for them, durability is also a factor.

In all use cases, the selection of the appropriate ball bearing is a matter of understanding these particular parameters and relating them to the requirements set forth by the mechanical system. By taking care of these aspects, ball bearings lead to an improvement in performance as well as cost efficiency in terms of extensive lifetime reliability.

How is lubrication managed in journal bearings?

The key aspect of journal bearing design is to maintain bearing lubrication at optimal levels so that the bearing can perform with high efficiency and has a long life, which is augmented by proper selection and maintenance of the lubricant. In my observations, journal bearings require oil to be able to provide hydrodynamic lubrication and avoid metal-to-metal contact. This greatly helps decrease wear and friction. The lubrication oil should be selected in accordance with the operational parameters, such as the load, the velocity, and oil temperature. Proper supervision and change are important. Also, the functional features of the bearing, such as grooves and ports to canalize the lubricant, allow for the bearing protection to be provided in stable conditions while powered on.

Understanding hydrodynamic and boundary lubrication

A full film of lubricant forms a barrier between the moving parts of a machine, therefore preventing direct contact between the spaces under hydrodynamic lubrication, which occurs at high speeds. At boundary lubrication regimes where a full film does not exist between the moving parts, such as at start-up, shut down, or during high load situations, the friction and wear of individual components may increase. In these cases, friction can be temporarily reduced using antiwear additives that create a protective layer between moving parts. Both boundary and hydrodynamic conditions are very critical; hence, for effective performance of bearings under varying operating conditions, it is essential to understand their application.

Importance of proper oil viscosity and film thickness

Through my work in the industry, it is quite clear that holding the right oil viscosity and film thickness is vital for the proper functioning of the machinery and its lifespan. The viscosity of lubricants defines the oil’s effectiveness in penetrating and forming a protecting layer, whilst oil films more than metal contact on any surface. When viscosity is lowered too much, a lack of oil film leads to increased friction and wear on the components. However, both resistance to flow may be too high, which means that the thin film is adversely affecting the lubrication and, in turn, wasting energy. Therefore, to achieve performance dependability and cost-effectiveness, having the right measures pertaining to the intended application is a must.

Maintaining optimal bearing clearance for lubrication

By satisfying the lubrication requirement and accounting for all other operational conditions, an optimal bearing clearance is set. Inadequate clearance can block the required amount of lubricants from flowing in, which can result in excessive friction and increased operating temperatures, while too much slack could end up destabilizing the film and ingressing foreign materials. The optimal clearance should be compatible with the respective bearing type, load, bearing speed, and thermal expansion so that lubrication is satisfactory, wear is minimum, and efficiency is high. Regular checking and supervision of the process during its execution phase are important for the accomplishment of this important task.

What are the potential challenges with journal bearings?

One of the leading problems with journal bearings is ensuring that the supply of lubricant and the heat generated are on the same level. In my professional opinion, high temperature enables metal-to-metal contact, which results in mechanical failure due to wear and tear. Moreover, particles or moisture pollution of the lubricant is a severe risk as it can lead to film breakdown and promote destruction. Abrasive conditions resulting from misalignment are another important concern as they may lead to slight variation of load across the bearing, leading to distortion of certain portions. Such parameters as speed, load and temperature are relevant in relation to the solution of the problem and should be monitored to avert major breakdowns that would be more costly.

Managing contamination and wear in the bearing housing

To help address issues related to contamination and the extent of deterioration of bearing housing, a set of custom proactive measures, as well as regular servicing practices, should be introduced. First, seals of good quality should be installed, which could stop the penetration of dirt, water, and other objects. Moreover, the filter units should be installed to cleanse the lubricant and changed within the suggested time limits so that it does not lose its quality. During the maintenance of the equipment, the bearing housings should be checked periodically for excessive wear and misalignment, and corrective measures should be undertaken to avert worsening the situation. By employing these precautions, the reliability and service life of the bearings will be substantially improved.

Optimizing bearing life in high-speed applications

In my view, the first thing that one has to consider in order to optimize the bearing life in high-speed applications is to choose an appropriate bearing type and material that can withstand the corresponding loading conditions. Several with respect to proper installation have to be considered in order to prevent abnormal stresses and vibrations that, in turn, increase the rate of deterioration, such as ensuring the averagely moderate alignment. I’ve also found that this problem can be solved by petroleum products specifically developed for high-speed applications as they reduce friction and heat. Regular trend analysis is a must; I suggest using such a system for temperature and vibration, which captures the fluctuations over time. It is right to say that by adopting these practices and developing a proactive maintenance approach one is able to enhance the operational life of the bearings even for the most adverse high-speed applications.

Reference

- Journal Bearing vs. Ball Bearing Performance – This source discusses the oil flow and lubrication requirements of ball-bearing designs.

- Ball Bearing Vs. Journal Bearing….Differences – This forum post provides insights into the differences in oil flow and lubrication between the two bearing types.

- Turbocharger Bearings – This article explains the two main types of turbocharger bearings: hydrodynamic journal bearing systems and ball bearing systems.

Frequently Asked Questions (FAQs)

Q: What is the main difference between a journal bearing and a ball bearing in turbo applications?

A: The main difference between a journal bearing and a ball bearing in turbo applications lies in their design and lubrication methods. Journal bearings rely on a hydrodynamic fluid film for smooth rotation, while ball bearings use rolling elements. Journal-bearing turbos typically use oil lubrication, whereas ball-bearing turbos can use either oil or grease lubrication, depending on the specific design and application.

Q: How does oil lubrication work in journal-bearing turbos?

A: In journal-bearing turbos, oil is supplied to create a hydrodynamic fluid film between the rotating journal and the bearing shell. This oil film separates the surfaces, reducing friction and wear. The rotational speed of the journal helps to draw the oil into the bearing clearance, forming a wedge-shaped film that supports the load and allows for smooth rotation. The oil also helps to dissipate heat generated during bearing operation.

Q: What are the advantages of using journal bearings in turbochargers?

A: Journal bearings offer several advantages in turbocharger applications. They are simpler in design and construction, making them more cost-effective. Journal bearings can handle higher loads and provide better-damping characteristics, which can help reduce noise and vibration. They also have a longer lifespan in high-speed applications and can operate at higher temperatures compared to ball bearings. Additionally, journal bearings are commonly used in various automotive and industrial turbocharger applications due to their reliability and performance.

Q: How do ball-bearing turbos differ from journal-bearing turbos in terms of lubrication?

A: Ball-bearing turbos differ from journal-bearing turbos in their lubrication requirements and methods. While journal bearings rely solely on oil lubrication, ball bearings can use either oil or grease lubrication. Ball bearings require less oil flow for lubrication, which can result in reduced oil consumption and faster spool-up times. Grease-lubricated ball bearings can offer simplified lubrication systems in some applications, potentially reducing complexity and maintenance requirements.

Q: What are the lubrication regimes in journal bearings?

A: Journal bearings operate under different lubrication regimes depending on the operating conditions. The two main regimes are boundary and hydrodynamic lubrication. In boundary lubrication, which occurs during start-up or low-speed operation, there is some contact between the journal and bearing surfaces. As speed increases, the bearing transitions to hydrodynamic lubrication, where a full fluid film separates the surfaces, providing low friction and wear. Understanding these regimes is crucial for proper bearing design and operation in turbocharger applications.

Q: How does the speed of rotation affect journal bearing performance in turbos?

A: The rotational speed of the journal significantly impacts bearing performance in turbos. As the speed increases, the oil film becomes more stable and effective at separating the surfaces. Higher speeds generally lead to better load-carrying capacity and reduced friction. However, extremely high speeds can also lead to increased heat generation and oil churning losses. Turbocharger designers must carefully consider the bearing speed to optimize performance while ensuring adequate lubrication and cooling.

Q: Are there any special design features used in journal bearings for turbochargers?

A: Yes, there are special design features used in journal bearings for turbochargers to enhance performance and reliability. These may include grooves in the bearing surface to improve oil distribution, floating bushings to provide additional damping, and carefully engineered clearances to optimize oil film formation. Some advanced designs may also incorporate hybrid bearings that combine elements of journal and rolling element bearings to achieve specific performance characteristics.

Q: Which type of bearing, ball bearing or journal bearing, is better for high-speed turbocharger applications?

A: The choice between ball bearing and journal bearing for high-speed turbocharger applications depends on various factors. Journal bearings are often preferred for very high-speed applications due to their simplicity, reliability, and ability to handle high loads. However, ball bearings can offer advantages in terms of reduced friction and faster response times, especially at lower speeds. The best choice ultimately depends on the specific application requirements, including speed range, load conditions, packaging constraints, and cost considerations