As much as it sounds complicated the engines actually operate on a single complex system with every single component being crucial to its performance, when it comes to the engine, the main and rod bearings play a critical role. These two parts allow the operation of moving parts; in other words, they are essential for the proper operation of the engine. Even though these two components might look similar to each other, they simply are not as they are located differently, serve different functions, and possess a different set of characteristics, all of which greatly influence engine efficiency and durability. This article is aimed at differentiating between the main crankshaft bearing and the rod crankshaft bearing in detail, their contributions, efficiency and importance will also be discussed. Regardless of whether you are a car industry expert or an average user, once you are made aware of these components, the engine construction and maintenance will be much easier to comprehend.

What is a Bearing?

Bearing is a key element of machinery that is built to reduce friction between contacting parts and enable movement either in a rotating or linear axis. With the help of smooth surfaces and load support, bearings increase the effectiveness of machines, decrease their use, and have the ability to extend the life of combined elements of engines or other machinery.

Function and Importance offerings

Bearings help keep many machines smooth and functional, and knowing this is pivotal in the field, as I’ve come to notice in my career, their primary purpose can be defined as reducing friction. This is important as it allows for energy efficiency and a seamless motion. They are crucial for any moving component as they sustain the torque and weight that is applied when the item is in motion. Failure to meet this requirement would result in rapid machine breakdown, malfunction, or overheating, which would be quite expensive in terms of cost and loss. Largely, the significance of bearings is derived from their capacity to reduce mechinal tension and evenly spread out the applied force.

Common Issues with Bearings and How to Spot Them

One of the most common problems with bearings that I have seen all too often is improper lubrication. Due to the lack of lubrication, the bearing generates a lot of friction which results in overheating then excess wear to the component. Another major issue is contamination – dirt or debris can get lodged into the bearing, altering its efficiency and producing wear. Misalignment is another relevant problem, even small differences from the correct orientation apply unnecessary force on the bearing compromising its performance and durability. To minimize the effects, I have always suggested looking out for unusual sounds, vibrations, or raised temperatures. Nevertheless, I deem it necessary to prevent these issues by regular inspections and maintenance so these symptoms don’t lead to bigger problems.

Maintaining ProperBearing Clearance

Proper bearing clearance is quite key for the longevity and functioning of the equipment. It is crucial to ensure that the manufacturer’s specifications are followed, as improper clearance can result in overheating and excessive wear, which may result in equipment malfunction. Equipment operating parameters such as temperature and load should be monitored, and during periodic maintenance, the operator should also check for wear. Calipers, touch gages, and dial indicators are widely used checking tools for measuring and adjusting clearance. If the above-mentioned measures are followed, most of the premature bearing problems will be avoided, and the equipment will operate smoothly and efficiently.

Exploring the Role of Bearings in an Engine

Bearings are quite important in an engine as they lessen friction between its moving parts, providing rotation while bearing substantial weight. They assist in improving an engine’s working and durability by reducing damage to parts, enhancing the transfer of energy, and maintaining component alignment. Notably, without bearings, the excessive friction and stresses would cause rapid deterioration and failure of the engine unit parts, which emphasizes their significance in dependable engine operation.

How Bearings Work with, and Complement Engine Functions

bearings are able to perform the task of interacting intelligently with engine components by taking care of and controlling the forces and movement of an operative engine. Here’s how they achieve this vital task across different parameters:

- Load Management

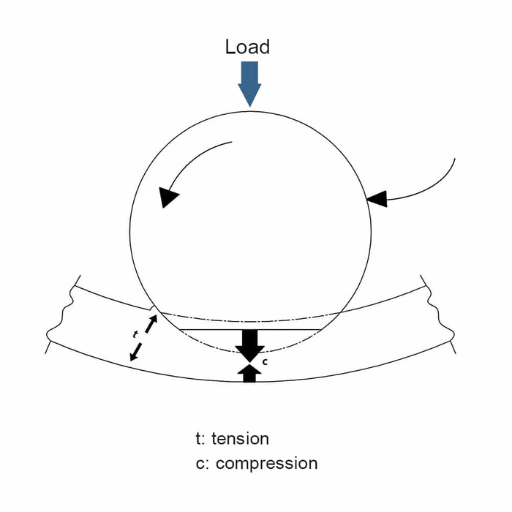

Bearings are able to support both radial loads – which can be described as loads with forces acting perpendicular to the shaft – as well as axial loads, which operate with parallel forces. This assures that the load distribution is done uniformly across all components which greatly contributes towards the reliability of the engine in the long run.

- Friction Reduction

Reducing friction across moving parts is one of the significant functions that account for bearings. They install lubricants that not only increase the motion across the surface smoother but also reduce direct contact even further. This technique is remarkably helpful as it overcomes friction, thus increasing the energy efficiency of an engine.

- Alignment Support

When it comes to rotating elements such as camshafts or crankshafts, bearings make sure that they are aligned correctly, allowing proper functioning of the engine. This preserves wear of the engine as well as potential faults in the system as every component will be ironed out when the engine system is aligned properly.

- Energy Transfer

Bearings enhance performance in engines by allowing energy to be transferred with ease and components to rotate without restriction, resulting in savings that normally would have been lost due to friction or alignment issues. This improves the overall efficiency of the engine system, which in turn increases the amount of energy or power the engine produces.

- Longevity of Components

Bearings effectively reduce the wear and tear against their resistance, prolonging the life of essential and critical engine components. This, in turn, minimizes the amount of downtime caused by repairs or diagnosis while simultaneously reducing the cost of repairs.

All these factors, when considered together, help in ensuring that not only do bearings provide support to the efficient functioning of an engine but also assist, improve, and increase the overall economy and life of the engine. In their absence, the engine would stop working in a short space of time due to mechanical overload, which explains its importance.

Signs of Wear and Tear

In my work, I believe that one of the most important aspects of sustaining the functionality of an engine and avoiding any damage is recognizing the signs of bearing wear. Some evidence that could be viewed includes loud vibrations or scrubbing noises, heat accumulation or overheating of the bearings, and bearings housing MSS. Moreover, physical indications like surface wear, pitting, rust, or cracks are characteristic of a bearing that is reaching its working time limit. Awareness of these aspects makes it possible to fix the problem before it causes any further disorders, such that the engine remains in good working condition. Great attention and care are taken into routine and periodic servicing to detect them earlier.

Techniques to Ensure Proper Installation

In order for bearings to work efficiently and have a long life, the bearings themselves need to be installed correctly. Begin by cleaning the housing and any components in the vicinity to minimize the risk of contamination. Use only appropriate tools—do not use hammers or implements which may cause damage. Confirm that alignment is correct before installing because alignment is essential in avoiding damage. Lubricate the bearing with oil or grease in the right amount and type as required. Lastly, do not deviate from what the manufacturer recommends while using thermal or hydraulic installations for some tasks. If you follow these principles, the chances of having operational problems are greatly minimized.

How Do Bearings Affect Engine Performance?

Based on the evaluation of the data collected during the industrial survey, I can claim without any doubt that the bearings significantly influence the performance of the engine by facilitating smooth operation to lower friction and assist in rotating elements. The effective use of bearings not only increases productivity but also extends the engine’s use time. To begin with, listed below are the parameters that illustrate the ways in which bearings affect the performance of the engine:

- Friction Reduction: In order to reduce friction between the moving components of the machine, bearings are put in place, resulting in improved fuel efficiency and lesser heat generation.

- Load Distribution: Just like the loads, bearings also ensure that the weights are balanced out on the engine and does not overly stress out a few components, this reduces wear and maintains the balance of the engine through multiple different conditions.

- Rotational Accuracy: The bearings in an engine allow for the crankshafts and camroph accessories to align properly and rotate without any issues. This aligns the components accurately, hence ensuring there is stability in the functioning of the engine, which also helps avoid vibrations.

- Durability and Longevity: Bearings reduce the amount of force transmitted to the metal, allowing metals to not have to sore through a contact point and soak up force instead. This extends the lifetime of other crucial engine components that are in the engine bearing.

- Heat Management: When properly lubricated, bearings aid in heat dissipation generated during engine operation. This helps prevent overheating and keeps the machine within its set temperature limits.

Each of these parameters makes it possible to operate the engine at a high rate. Any depletion in the state of health of the bearings, whether through the correct misalignment, contamination, or low lubrication, can cause many performance issues, loss of serviceability, and many expensive repairs. That is why routine checks are very important together with adhering to the instructions of the manufacturer.

The Impact of on Performance

The smooth operation of the engine is greatly facilitated by the use of bearings, which ensure minimal friction and wear of critical engine components. If the bearings are in good working condition, the engine can be efficient and develop its maximum power while needing only minimal maintenance. On the other hand, damaged or worn-out bearings can result in excessive vibrations, excessive heat generation, and eventually total engine destruction, all of which adversely affect performance. Hence, preventive measures such as maintenance of the bearings and routine engine checks are crucial to ensuring engine longevity and overall effectiveness.

Optimizing for Efficiency

Based on what I have witnessed throughout my career, fostering efficiency starts off with a routine check and maintenance of all engine parts with a special focus on the bearings. I have also observed that the application of good materials and appropriate lubrication minimizes wear and enhances performance over the years. Also, keeping track of the early indicators of wear, like odd sounds or vibrations, helps in solving the problem before it becomes too big. It is a preventive strategy that not only boosts performance but also improves the working life of the engine and thus increases reliability.

Choosing Between Fixed and Fluid Bearings

Shopping for some bearings? Are you feeling spoilt for choices while picking between fixed and fluid bearings? When it comes to selecting between fixed bearings and fluid bearings, the deciding factor will always be what the application requires. Each type has its own set of benefits and drawbacks, and comprehension of the related parameters is critical in determining the most appropriate selection. Here’s what the various factors are:

- Load Capacity:

The most consistent and dependable load-carrying structure or bearing types in construction applications are fixed bearings; the ability to withstand huge static and dynamic loads is also higher than those. If the application requires heavy machinery installation or a large amount of structural weight, then fixed bearings are the most developed supporting elements for the job. In terms of applications that need composite structures with lightweight and minimal friction components, fluid bearings appear to be the most optimum.

- Speed and Performance:

In the case of fluid bearings, operation speeds are better as a result of lesser friction. Rotational systems such as turbines that operate at high speed will operate with better performance due to a thin film of oil or lubricant that is responsible for heat steaming and thus aids fluid rotation; on the contrary, fixed bearings will be great for applications that require medium slower speeds with more precise control.

- Durability and Maintenance:

With regard to application robustness, fixed bearings are usually built to have more durability; this is major because components used in the making of fixed bearings are stronger than those of fluid bearings and also due to the fact that fixed bearings do not require as much lubricant as fluid bearings do, fixed bearings also have less maintenance. High maintenance requirements are imposed by fluid bearings since they are reliant on a lubrication that is constantly provided and environmental conditions.

- Environmental Conditions:

If you’re using fixed bearings, they are effective even in conditions of extreme temperature fluctuation, contaminants, and liquids, but when in the presence of rigid obstacles, the precision fluid bearings are pulled out; however, the viscosity and efficiency of the lubricants resume the performance of fluid bearings allowing them to operate at an average temperature.

- Cost Efficiency:

The simplest design is usually true for fixed bearings, which is why they are cheaper, whereas the lubrication system used in screens fluid bearings adds more cost in both the initial and operational phases. But, considering the lesser abrasion and better-most performance of these fluid bearings, it may be worthwhile to make such an investment for a couple of extremely accurate applications.

Here are some factors to keep in mind when selecting a component. This helps in choosing a bearing type that is adequate for anticipated productivity and lifetime requirements. It is essential to appreciate that each decision made with respect to the selection in question contributes in some way or another to an overall optimum mix of expenditure, service, and performance.

How to Address Bearings

For a more effective approach to bearing problems, the emphasis should be on the selection, installation, and maintenance. To start with, bearing type should be selected in relation to the application where load, speed, and the environment are taken into consideration. When installing bearings, damage and contamination are prevented through the use of suitable tools and equipment. Regular checking and lubrication are very important in extending the life of the bearing and avoiding failure. These elements can help enhance bearing performance, which translates into minimized downtimes and reduced costs.

Identifying Symptoms Early

It is highly advisable to identify issues with bearing at an early stage as it helps to avoid expensive risks. Unusual noise making, excessive vibration possible heating of the operating temperature, and visible wear or damage are some of the indicators to look out for. These symptoms can be spotted early by conducting frequent condition monitoring, whereby vibration analysis or the use of temperature sensors can come in handy. By taking care of these warning signs in time, one can avoid further deterioration and maintain the health of the system.

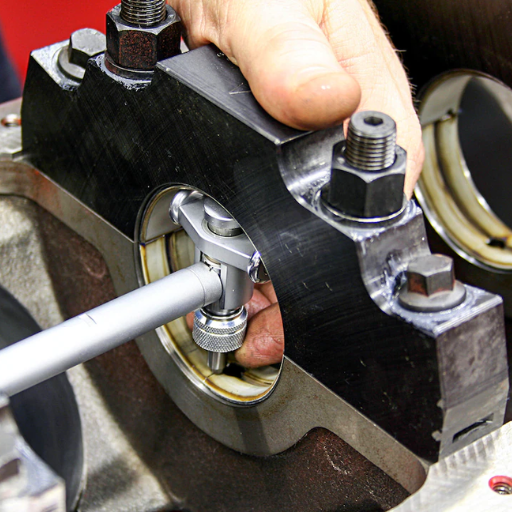

Steps to Replace Damaged Bearings

The process of replacing damaged bearings should be carried out step by step in a way that guarantees safety and performance efficiency. To begin, switch off the source of power on the equipment to avoid injuries. Take note of the order of assembly for future reinstallation as you gently remove the components surrounding the faulty bearing so as to reach it. Use appropriate tools, such as bearing pullers, so that removal of the damaged bearing may not harm other parts of the equipment. Make sure to thoroughly clean the housing and shaft to remove any debris or contamination. To make sure that the bearing is correctly aligned, use even pressure when installing the new bearing. Lastly, put together the components, lubricate the bearing as per the suggestions, and check that the equipment is working as it should. Manufacturer guidelines have to be followed, and accuracy must be the key throughout the process.

Preventative Measures to Avoid

In my experience as an industry professional, the most effective way to minimize the incidence of bearing failures is to combine the best practices of maintenance and proper handling methods. A few examples of attitudinal problems are exceeding equipment limits, skipping lubricant applications, or not using the right lubricant at all. I always stress the necessity of so among the rest of the safely characterized materials and stockpiling tools overshadowing bearing devaluation sign and non-intention of use tools to the basic functional requirement as losing tools with no intention of use is a time when free overhead is cheap. Using clean tools for handling bearings and maintenance of proper environmental conditions for their storage can greatly enhance their life. In the end, routine preventative maintenance aids in enhancing the consistency and reliability of performance.

ComparingBearings: Which is More Prone to Issues?

Looking at bearings, both ball bearings and roller types appear to have their respective problems. Generally, due to their structure, ball bearings are more likely to suffer from problems of misalignment, which can cause unbalanced wear or even fateful occurrences. In contrast, roller bearings are more prone to contamination or insufficient lubrication because of the larger contact area of the rolling elements with the races. However, in my view, the solution to these issues is to know the requirements of the application and select the right bearing with due handling as well as maintenance.

Understanding the Differences and Their Vulnerabilities

Let’s systematically break this down so we understand the differences and weaknesses between ball bearings and roller bearings, starting with:

- Misalignment

Bearings would misalign in cases where there is a missed or error occurrence in the orientation of two or more shafts that leads to uneven movement during rotation at the center of the ball bearing, which is the focal point. Misalignment among forces in the bearings can manipulate a specific area, creating immense stress on it, which, with time, could result in wear and cracks. This precariousness is suitable for ball bearings, which can be used in terms where there are no or fewer chances of misalignment of alignment control. To lay off the risks, enforce a strictly followed maintenance and proper installation.

- Load Handling

Point bondage with the surface renders the potential of the roller bearings to be ineffectively utilized as they are designed to work specifically on the line contact surface. Point contact means that roller bearings have tangential contact, a tangential line that is the point best suited to nutation and refers to the rotating direction of an object with a fixed axis. It wouldn’t be wrong to point out that point contact means low strike and heavy loads tangentially. Point contact, despite having a challenge in maintenance, also has great durability. Regular sustained lubrication schedules and consistency in using the relevant lubricant types can ease point contact and prevent it from being a hassle.

- Contamination

Considering that roller bearings function more efficiently due to the metal sleeve overlap to seal rotations, which would otherwise require precise lubrication but do increase the risk of misalignment. Particle debris overcoming the races could dent and fracture the rotors, but this could have negative effects on the turbulence of the rotators. High-grade lubrication systems in case of rotation with aligned seals could drastically improve the life span of product rotation.

- Speed Capabilities

The structure of ball bearings allows them to function better than roller bearings at higher speeds because of less friction from point contact. At very high angular velocities, roller bearings might have problems because their increased contact area generates heat which increases their lubrication requirements. When choosing a bearing, consider the required speeds and load conditions to find an appropriate compromise.

- Heat Management

Both bearings might experience adverse effects due to temperature variations, but roller bearings, in general, tend to heat up more because of their larger working surface area. The proper chilling mechanism or usage of heat-resistant materials can help perform roller bearings in high-temperature conditions.

Grasping these weaknesses not only facilitates the selection of a correct bearing for the application but also guarantees performance optimization and an increase in the lifetime. Routine service, proper mounting procedures, along with specific supervision based on the outlined parameters will solve most performance problems satisfactorily.

Comparative Analysis of Ball Bearings and Roller Bearings

In my experience in the field, the decision of whether to use ball bearings or roller bearings usually depends on the requirements of the particular application. Ball bearings are employed in high-speed operation and are suitable for applications that require accuracy with low levels of friction, such as electric motors or aerospace parts. In comparison, roller bearings are more dominant in situations where large amounts of force need to be applied, especially in industrial equipment or automotive aspects.

When advising clients, I always try to stress the importance of a more customized approach in the selection for speed, load, and heat dispersal optimization. Any design of the bearing has its advantages, and these advantages have their limits. Knowing those limits helps achieve the best performance of the component while not overworking the equipment and its maintenance.

Expert Opinions on Durability

I would say durability is the most important feature when choosing a bearing and, in my experience, depends mostly on the working conditions and maintenance performed. Ball bearings are effective and efficient at high speeds, but if the bearings experience excessive load or poor lubrication, these bearings can become worn out. Roller bearings have a larger and stronger structure and provide an overall higher durability when in harsh and heavy-duty environments, but these again still require a constant and consistent amount of maintenance to avoid early breakdowns. Many times I recommend my customers to concentrate on the materials used in the bearings and to lubricate them on a regular basis, this would help both types of bearings to last longer. Durability also depends on how well the operation has been balanced with proactive care.

Reference

- Engine Bearings – Main and Rod – This article from Engine Builder Magazine discusses the design differences and performance aspects of main and rod bearings.

- Difference between rod and main bearing on Reddit – A discussion on Reddit’s MechanicAdvice forum that provides insights from various users about the differences between these bearings.

- Rod bearing and main bearing differences on Toyota Van Tech – A forum thread that explores the differences in size and application of rod and main bearings.

Frequently Asked Questions (FAQs)

Q: What is the primary function of a main bearing in an engine?

A: The main bearing primarily supports the crankshaft, allowing it to rotate within the engine block. It helps maintain the alignment of the crankshaft and absorbs forces generated during engine operation, ensuring smooth rotation and optimal performance.

Q: How does a rod bearing differ from a main bearing?

A: A rod bearing connects the connecting rod to the crankshaft, allowing the transfer of forces from the piston to the crank. In contrast, a main bearing supports the crankshaft itself. Both bearings are essential for smooth engine operation but serve different roles within the engine architecture.

Q: Why is oil pressure important for rod and main bearings?

A: Oil pressure is crucial because it forms a lubricating film between the bearing surfaces and crankshaft journals. This film reduces friction and wear, preventing bearing damage and maintaining engine efficiency. Insufficient oil pressure can lead to bearing failure.

Q: What are the common signs of bearing wear in an engine?

A: Common signs include unusual engine noises such as knocking or rattling, low oil pressure, and metal shavings in the oil. These symptoms may indicate worn-out bearings, necessitating immediate inspection and possible replacement to prevent engine damage.

Q: How do you measure the oil clearance for main and rod bearings?

A: Oil clearance is measured using a plastinate or micrometer to determine the gap between the bearing shell and the crank or rod journal. Proper clearance is critical for adequate oil film formation, ensuring effective lubrication and cooling of the bearing surfaces.

Q: Can coated bearings improve engine performance?

A: Yes, coated bearings can enhance performance by reducing friction and wear. They often provide better resistance to heat and chemical degradation, making them suitable for high-performance engines where extreme conditions are common.

Q: What role does the oil pump play in bearing health?

A: The oil pump circulates oil throughout the engine, maintaining the necessary oil pressure to lubricate bearings and other moving parts. A malfunctioning oil pump can lead to inadequate lubrication, increasing the risk of bearing wear and engine damage.

Q: How do torque specifications affect rod and main bearing installation?

A: Proper torque specifications ensure that bearings are correctly seated and aligned, preventing excessive movement or misalignment. Incorrect torque can lead to uneven wear, reduced bearing life, and potential engine failure.

Q: What is the difference between stock and performance bearings?

A: Stock bearings are designed for standard engines and offer adequate performance for everyday driving conditions. Performance bearings, however, are engineered to withstand higher loads, rpms, and temperatures, making them ideal for racing or high-performance applications.