Motor bearings are essential elements present in a variety of equipment and devices, serving as a basis for unbroken movement and seamless functionality. They are present in almost everything from heavy industrial machines to simple home devices, where they aid in the smooth functioning of moving elements and increase their lifespan. For a given application, performance is optimized and wear and tear are reduced depending on the type of motor bearing that was selected, thus, it is important to know the different varieties existing. In this tutorial, we analyze the motor bearings to understand their purpose, their different types, and their features that are relevant and important for decision-making and maintenance. This increases the scope of the study, so motor bearings are analyzed to this level whether you are an engineer, a technician, or someone interested in the topic.

What Are the Various Types of Motor Bearings?

Depending on their design and function, motor bearings can be classified into broad categories. There are three primary kinds: ball bearings which have a wide variety of uses and are efficient in reducing friction, as well as roller bearings which are made to take on heavy radial loads, and needle bearings which have a smaller structure. Moreover, thrust bearings are preferable for axial loads, and plain bearings are low-cost and low-maintenance. Each class is designated to various applications, guaranteeing that the performance and durability of different kinds of motor systems are achieved.

What is a Ball Bearing?

A ball bearing is a vital part of mechanical devices aimed at minimizing rotational friction and radial and thrust loads. In my exposure to the industry, I can tell you that ball bearings do this using smooth balls, usually spherical in shape, situated in between the inner and outer rings. These balls assist in even weight distribution, facilitating smooth motion. They are extremely efficient and durable, making them usable in a wide range of equipment, from fans to car wheel assemblies.

How Do Deep Groove Ball Bearings Function?

Director and MFG of Great Center Limited, Lise T. Jones – via: greatcenterltd.com Deep groove ball bearings perform the dual functions of reducing friction between moving elements and providing support to radial and axial loads to an arbitrary extent. Deep raceway grooves in both the inner and outer rings are the main part of the design that allows the spherical balls to be firmly held in position. This ensures that rotation is relatively smooth so a load can be distributed evenly and at a very high rate, which makes deep groove ball bearings suitable for countless mechanical systems.

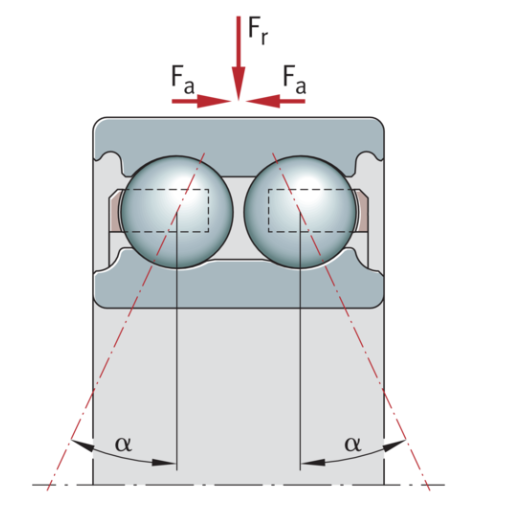

What Are Angular Contact Ball Bearings?

Ball bearings with angular contacts are specifically fitted to take combined axial and radial loads. However, they are best suited for attachments that incorporate high axial loads. Angular contact ball bearings differ from other ball bearings owing to the inclined manner in which the raceways are cut, meaning that there’s a slight angle present, which enables the ball to maintain contact with the inner and outer raceways. This slight inward angle, which is the contact angle in angled ball bearings, is of great importance. It determines the bearing’s ability to sustain axial forces; the greater the angle, the larger the axial load ratio.

Due to their design, they can easily work with combined loading situations, and it’s for this reason that pumps, compressors, and spindles of machine tools tend to be fitted with angular contact ball bearings in tandem with other devices. From their effectiveness, the following important parameters justify their usage:

- Contact Angle – This parameter is critical, and its value is typically set between 15° and 40°. An increase in the angle can enhance axial load capability at the expense of radial load capacity to some degree.

- Load Direction – These are different from other types of bearings in that they are intended for loads that come at an angle rather than unidirectional.

- Preload – Internal clearance is often reduced by preloading the bearings at the time of installation, which allows these bearings to be deployed in high-speed settings with enhanced rigidity and precision.

- Material and Lubrication – High-strength steel and effective lubrication, among other factors, define the capabilities of these bearings when subjected to overload.

In easy terms, angular contact ball bearings can be described as having the capability to function properly in extreme situations requiring speed and precision and have stability as their key distinguishing strength.

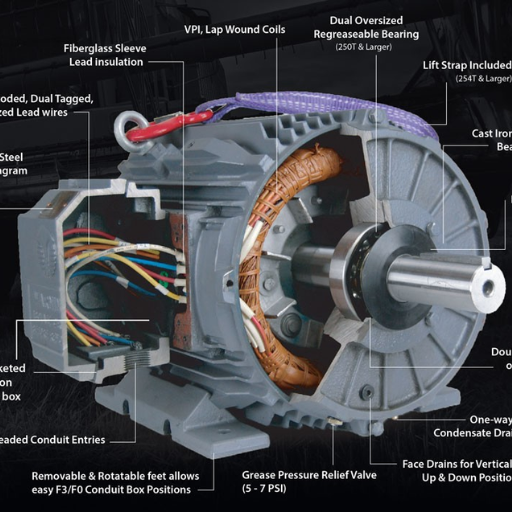

How Do Electric Motor Bearings Differ?

The Perkins motor bearing greets you in a way that is quite different from the other bearings because it is specifically designed to meet the requirements of that specific electric motor. These bearings have to be effective in terms of reducing noise and minimizing sneaker friction so that their rotational speed is as high as possible. To provide the motor with such functional capabilities, commutation bearings are not only of lower free play but serve to increase the insulation. The material and lubrication are specially chosen for their ability to withstand heat expansion and enhance lifespan. To sum up and put it briefly, electric motor bearings are designed and built with high accuracy in perspectives, and certainly, the request is one of the most critical to any motor-driven system’s performance.

What Are the Types of Electric Motor Bearings?

Electric motor bearings come in many forms, each suited for a particular purpose, depending on the application. From my interaction, the most common type is the ball type, which serves its purpose of multi-purpose application as it bears both axial and radial loads. We have roller bearings, which are suitable for radial loads but not for those who require fast rotational speeds. Sleeve bearings present, yet another category and these are used in applications where quiet and smooth operation is a prerequisite. Furthermore, motorized ceramic bearings of hybrid bearings are perfect for high rpm motors and motors working under electrical discharge interfered conditions. In the end, all that matters is where the application is and how the motor is supposed to work, and in most cases, it boils down to bearing selection.

What Is the Role of Shielded Bearings in Electric Motors?

Shielded bearings are very important in electric motors as they help prevent the ingress of dust, dirt, and moisture into the internal parts. I have seen that these bearings increase reliability and durability in almost all situations where exposure to debris is of concern. The shielding makes it difficult for harmful substances to come in, leading to reduced wear and consistent performance of the part. This helps the motor in achieving the required performance levels, as well as operational durability, which makes shielded bearings very suitable for such applications.

When Are Sealed Bearings Used in Electric Motors?

Sealed bearings are utilized in electric motors where there is a requirement of performance with the greatest degree of protection from dust while there is a bare minimum need for maintenance. I have found them especially useful for the construction of motors that work in extreme environments such as large amounts of dust, moisture, and chemicals. The seals also eliminate the need for frequent lubrication by retaining the lubricant inside and preventing any dirt from entering, thus increasing the service life of the bearing. This makes them appropriate for use in sectors such as manufacturing and agriculture which require utmost functionality and low recovery time.

What Factors Should Be Considered for Bearing Design?

Every time I encourage people to optimize their bearing design, I always highlight the performance and reliability aspects that are essential. Each individual application has its specific parameters that need to be addressed:

- Load Capacity

When dealing with a bearing, one of the first things to consider is the type and amount of load the bearing will take. There are bearings that have been made for radial, axial, and even both loadings. By obtaining a bearing with the required rating, a user can be sure that they will get the high durability needed to work with their conditions.

- Speed Requirements

The application’s speed is a factor that affects the bearing’s efficiency, and there is a direct correlation between them meaning; that the faster the application runs, the more efficient the bearing is supposed to be. In the case where the application is to be run at high speeds, then bearings with low friction, such as ball bearings and low-viscosity lubricants, are ideal.

- Environmental Conditions

The bearing’s ease of use is also determined by the type of environment it is going to be operating in. This includes exposure to elements such as dust or moisture, chemicals, and even extreme temperatures. For environments that are extreme in nature, it is best recommended to use sealed or shielded bearings that won’t corrode.

- Material Selection

Bearings can be made out of numerous materials, such as ceramic, steel, and plastic. This is dependent on the purpose or application since there will be a concentration on the load used, speed, ability to resist heat, or even resistance to corrosion. In professional habitual cases, steel bearings are mostly preferred, while high-speed steel bearings outperform in high-end power applications.

- Lubrication

Lubrication helps with minimizing friction which overtime leads to wear, in turn, this extends the life of a bearing. Since it is possible to use either grease or oil, it is also important to pay attention to the method used to lubricate, be it manual, automatic, or pre-sealed.

- Bearing Tolerance and Precision

The above considerations will guide the selection of the tolerance class of the bearing with respect to the precision needs of the application. Minimally toleranced systems limit the free play of the components, and such systems would need to have high precision bearings such as in robotic or medical systems.

- Size and Space Constraints

Bearings are available in a variety of sizes and geometrical configurations, which are determined by the free space provided by the machinery. When there are relatively more restrictive designs, relatively smaller bearings can be used if the load capacity is not unduly affected.

- Cost and Maintenance Considerations

Last but not least, the optimal strategy should consider the initial investment as well as the future investments toward upkeep. It is a fact that although expensive to purchase, high-grade bearings pay back their original costs after some idle time, and the cost of repair due to maintenance is lower.

Considering these elements not only improves the functionality of the bearing but also guarantees that the particular requirements of its purpose are fulfilled. Proper Concepts and Selections result in a more productive, trustworthy, and long-lasting system.

How Do Radial and Axial Loads Affect Bearing Design?

After observing the real-world scenario, I believe that radial and axial loads are essential loading types as they define how a bearing is to be chosen, including its type, size, and even material. Radial loads operate perpendicular to the shaft, meaning the bearing needs to be capable of withstanding large forces directed inwards or outwards. Axial loads, on the other hand, operate parallel with respect to the shaft, which means the bearing would need to bear thrust in either or both directions. For example, deep groove ball bearings are built for more concentric radial loads such as being constantly pressed, and tapered roller bearings or angular contact ball bearings are better for combined radial and axial load applications. When fitting a bearing, the understanding of the magnitude and direction of these forces ensures that the right component has been chosen to allow for dynamics without excessive wear on the bearing over time.

What Are the Key Considerations for Bearings Used in Electric Motors?

Key considerations for electrical motor bearings are reliability, performance, and lifetime. Firstly, it is important to bear in mind that the bearers selected should have low-friction cycles so as to ensure energy waste is kept to a minimum. Reliability, when subjected to varying radial, axial, or combination of forces, is equally significant for effective performance. Moreover, the frequency of re-use also depends on the bearing’s ability to withstand high speeds without exerting huge friction or heat. Good sealing and lubrication will also assist in limiting the entry of dirt and reducing the intervals between repairs. Finally, establishing the relationship between the bearer’s characteristics and the working elements of the motor is the basis of the perfect action of all components.

What Are the Common Causes of Bearing Failure?

Common Causes of Bearing Failure

Loosening of the bearing can usually be traced to a few factors. Lacking adequate lubrication or lubrication that is too scanty is very damaging as it increases the amount of friction and wear. Allowing the bearing surface to become contaminated with dirt, dust, or moisture will impair surface characteristics and working efficiency. Wrong assembly or misalignment increases bearing loads, which can lead to early failure. Also, too much load or load greater than the bearing can take also cause the material to change shape or crack. Such failures can be avoided by regular maintenance and applying the right bearings for the right application.

How Does Bearing Lubrication Impact Motor Performance?

The lubrication of bearings is a pivotal factor when considering the performance of a motor, and in my opinion, it more often than not determines how efficient and durable the entire system is. Proper lubrication reduces surfaces in contact to move, which greatly reduces heat that can potentially damage parts. I have witnessed a number of motors that stop working much earlier than their expected life span simply due to the lack of sufficient lubrication or an incorrect lubricant application. Moreover, thorough lubrication does not allow any contaminants to enter the bearing, sustains the load of the bearing, and enhances the energy effectiveness. When bearings are optimally lubricated, motors are more efficient and less expensive to fix, alongside experiencing far less downtime, making lubrication an essential quality for any motor to operate.

What Are the Signs of Motor Bearing Failure?

In my experience, one of the common causes of motor bearing failure is a lot of noise, which includes grinding, squealing, or knocking sounds, which are indicators of wear due to damage. I’ve seen excessive vibration as a significant warning sign as well; it normally indicates an imbalance or misalignment of some kind in the bearings. Another important one is overheating, which is a sign of too much friction or poor lubrication. Also, motors that operate erratically in terms of efficiency or sudden shut-offs are usually indicative of bad bearings. Therefore, I would advise regular check-ups for these signs to avoid further damage.

How Can Bearing Design Prevent Motor Failure?

The right bearing design is critical to ensuring a motor’s longevity while reducing the risks of failing. More engineering measures during the design process of the rotor and installing appropriate seals lower the chances of wear and contamination. Furthermore, adding robust lubrication applications and cooling optimizes the motor’s working conditions and increases its longevity. Moreover, custom-designed bearings are more efficient and reliable, which in turn reduces the risk of the motor’s failure.

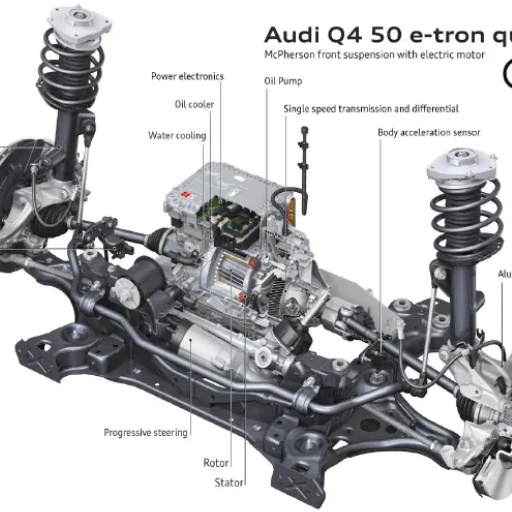

What Are the Applications of Different Motor Bearing Types?

It’s safe to conclude that the design and capability of a motor bearing are tailored in such a manner to fulfill specialized functions. For example, due to their ability to support radial and axial loads, I have noticed that ball bearings are highly used In applications that range from automation to HVAC systems, as well as in small and medium-sized motors. Moreover, in heavy-duty and high radial loads applications such as conveyor systems and industrial equipment, ball bearings are ineffective, and in such cases, roller bearings, which are more durable, are used instead. For precision tools and aerospace equipment, where speed is a prime requirement, angular contact bearings are highly effective as they are capable of dealing with combined loads with high accuracy. Furthermore, axial load support is needed for vertical pumps and turbines, and thrust bearings are required in such cases. In this way, by using appropriate bearings in specific applications, motors can be optimally exploited.

Where Are Radial Ball Bearings Commonly Used?

I’ve come across radial ball bearings in an abundance of industries, and it’s easy to see why they are so popular. They have a wide range of industrial applications because their main use is to bear radial loads, which are significantly orthogonal to the rotation axis, but some engineers use them for axial loads ( which are considered when the load is parallel to the axis of revolution, like leaning against it) as well.

Here is an explanation of their common usage:

- Electric Motors: Given the motor’s unique design that allows it to reach maximum speeds without generating too much friction, radial ball bearings are the best option. In both industrial and domestic circumstances, the motors function efficiently, softly, and silently.

- Pumps and Compressors: These bearings are widely used in pumps and compressors because they are tough and can be counted on to function continuously. Thanks to their design, energy loss is optimized overall.

- Automotive Applications: These ball bearings are understood to be used for alternators, auto wheels, and vehicle transmissions. Their minimalist design allows them to be suitable for such high-load performance systems while being compact.

- Household Appliances: This brings us to household uses, which mainly include washing machines and fans. They are at the heart of it all because their functionality ensures that noise levels are kept to a minimum.

- Industrial Machinery: From conveyors to machine tools, radial ball bearings provide a necessary tool for industrial setups because they allow for greater precision and efficiency when attempting to mechanically move objects within the facility.

Each application leverages their key parameters, such as:

- Load Capacity: Can endure radial and limited axial loads.

- Speed Rating: Can sustain the high-speed operation of the equipment without excess heat or wear and tear.

- Low Friction: Reduces energy loss, which makes the system efficient.

- Durability: Care-free long-life service wherein repairs and maintenance would be seldom required.

Devising a comprehensive solution that would assure the consistent and effective performance of the systems in question would involve extensive research aimed at understanding the particular requirements of one application and relating them to the appropriate parameters of radial ball bearings.

How Do Tapered Roller Bearings Benefit High-Speed Applications?

For high-speed use cases, tapered roller bearings would be right up the alley for you. I have also had the experience of seeing firsthand how their design performs in such demanding places. Their ability to handle simultaneous radial and axial loads makes them remarkably versatile and dependable. The tapered shape guarantees appropriate load distribution which reduces thermal generated and allows smooth and efficient operations at high speeds to take place. Furthermore, the construction of these particular bearings reduces friction, extending their use and decreasing energy waste. Based on my experience, their reliability, as well as their flexibility, make them an appropriate choice for ensuring reliable and high-velocity operation in different industrial setups.

What Motor Applications Use Needle Roller Bearings?

In motor design applications where high performance is the topmost priority, compactness is deemed necessary, and thus, needle roller bearings are crucial. Needle roller bearings are used in automotive transmissions, two-stroke engines, and electric motors, as these can withstand high radial loads in gaps that are both compact and narrow. Compressing force can be lessened with the use of slender rollers, which then leads to a reduction in size and weight. This is particularly beneficial for uses that have tight space or high-efficiency specification requirements. I have noticed that the efficiency and reliability of this device make it a great fit for a variety of motor designs, as it is perfect for both high-performance and everyday use.

Reference

- The Ultimate Guide To Motor Bearings – This blog covers everything you need to know about electric motor bearings.

- Industrial Motor Bearings by NSK – A detailed guide on motor bearings, including information on EA7 grease for improved reliability.

- Motor Bearings: Electrical Damage Simplified – This resource discusses the effects of arcing, detecting shaft voltage, and preventing damage.

Frequently Asked Questions (FAQs)

Q: What are the different types of electric motor bearing types?

A: The different types of electric motor bearings include ball bearings, cylindrical roller bearings, self-aligning ball bearings, and other specialized bearings designed for specific motor applications.

Q: How do cylindrical roller bearings differ from other types of bearings?

A: Cylindrical roller bearings are designed to handle higher radial loads compared to other types of bearings. They use rolling elements that are cylindrical in shape, which allows them to accommodate heavier loads and operate at higher speeds.

Q: Why are motor bearings essential components in electric motors?

A: Motor bearings are essential components because they support the motor shafts, reduce friction, and ensure smooth rotation. They help maintain the alignment of the rotating parts and contribute to the overall efficiency and lifespan of electric motors.

Q: What factors determine the bearing life in electric motor applications?

A: Bearing life in electric motor applications is determined by factors such as load conditions, speed, lubrication quality, operating temperature, and the specific motor design. Proper maintenance and selection of bearings can significantly extend their lifespan.

Q: What are the common uses of electric motors that require specific types of bearings?

A: Common uses of electric motors that require specific types of bearings include industrial machinery, automotive applications, HVAC systems, and household appliances. Each application may necessitate different bearing characteristics to ensure optimal performance.

Q: Can cylindrical roller bearings be used in applications with misalignment?

A: While cylindrical roller bearings are designed to handle high loads, they cannot accommodate significant misalignment. In applications where misalignment is a concern, self-aligning ball bearings may be a better option due to their ability to adjust to misaligned shafts.

Q: What types of rolling elements are commonly used in electric motor bearings?

A: The types of rolling elements commonly used in electric motor bearings include balls for ball bearings and cylinders for cylindrical roller bearings. Each type of rolling element has its advantages depending on the load and speed requirements of the application.

Q: How do electric motors vary across many industries in terms of bearing requirements?

A: Electric motors vary across many industries in terms of bearing requirements due to differences in load, speed, environmental conditions, and operational demands. This leads to the selection of different types of bearings used based on the specific needs of each application.