Always having been a central point of the world economy, railways constitute one of the major means of transport and transit of people and goods. Yet another element that is crucial for reliability and efficiency but is rarely paid attention to is railway wheel bearings. These, in turn, are fundamental for the continuity of the rotating parts of rolling stock, making the movement of train passage over enormous lengths of distance more or less an everyday affair. Though the task is daunting, there is so much that could be said about the basic structure, design, function, and construction of railway wheel bearings accompanied by maintenance problems, general engineering of maintenance of these fittings, and performance aspects. With the help of such understanding, one can see more clearly the contribution of such components towards the reliability and durability of modern-day rail transportation operations.

What are railway wheel bearings, and how do they work?

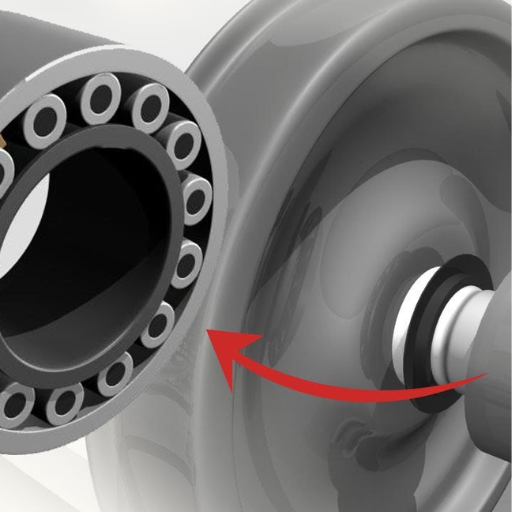

Railway wheel bearings are vital parts of the design of the rotation mechanism of a train wheel, and they support a heavy load. It is those bearings that reduce the friction between the wheelset and the axle in order to provide a more efficient transfer of energy and dependability of operation. Roller or ball-type bearing has been developed that employs the separation of moving parts and load applied thereon in such a manner that motion is caused and never hindered. Advanced materials, thoughtful design, and construction features make railway wheel bearings able to withstand high forces, temperature change as well as adverse environmental factors that guarantee the effective and safe operation of the trains.

Types of railway wheel bearings: Tapered roller vs. cylindrical roller

Tapered roller and cylindrical roller bearings have vastly different features, which are both vital in the rail industry. Of all the types of bearings available, tapered roller bearings are the most capable to withstand harsh environments as they support the highest amount of axial and radial loads. This is a result of their conical shape, which greatly increases the force capacity of a roller bearing. Due to this geometry, it’s possible to have a wear-free component that enhances reliability in high-speed deployments. In the case of cylindrical roller bearings, they are quite proficient in applications where heavy radial loading is required, however, when axial loading is extremely minimal, they are not the best option available. These rollers have a simple design that allows for low friction usage and low upkeep which improves efficiency as a whole. The ultimate choice lies in the working conditions of the rail system.

The role of railway wheel bearings in reducing friction

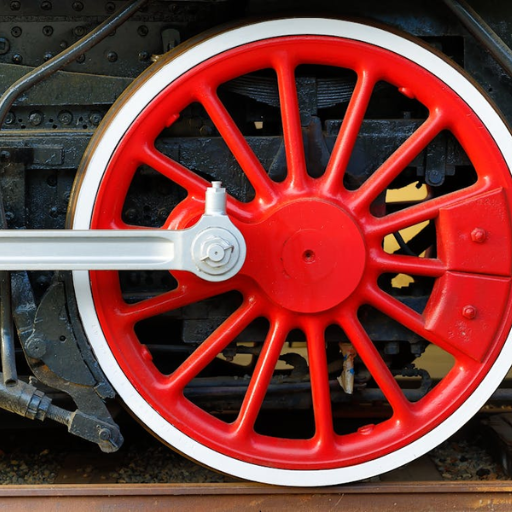

The railway wheel assembly consists of a wheel, axle, housing, and bearing. All of them are important assemblies to procure the smooth functioning of the railway engine or wagon. Without a smooth functioning, the locomotive or wagon is useless. In order to operate railway vehicles through main lines and other fit tracks, it is essential that the wheels rotate smoothly and bearings assist in that. Keeping railways running is the general aim, and bearing types used on rolling stock do not only reduce friction but also wear due to energy being consumed, which improves fuel efficiency and minimizes loss of energy. Their mounting arrangement and their design are impacted by operating conditions, so they are also of high precision.

Key components of a railway wheel bearing unit

I can, with assurance, say that the constituent elements of a railway wheel-bearing unit have been carefully crafted to serve the purpose intended and are built to last. Generally speaking, such units have an outer and inner ring that envelops the bearing assembly, rolling elements that include cylindrical or tapered rollers for load perception, and a cage that contains the rollers. Besides, sealing elements complete all the structures since their purpose is to keep contaminants such as dirt, moisture, and other particles from accessing the bearing and lubrication systems, which produce friction and heat during operation and maintain operation to be of low level. Overall, they operate synergistically to provide dependable performance, even in the most severe rail environment.

Why are railway wheel bearings crucial for train performance?

Wheeleary bearings_quietly dominate a vast array of deep-seated tasks. To begin with, wheel bearings_being one of the major critical components in the axle_wheel interface of the trains, the bearings allow for the wheel and axle to spin freely with low friction. That, in return, enables the wheels and axles to work more efficiently and smoothly. It is worth noting that wheel bearings do not only allow the wheels of the critical lift units to rotate with minimum friction; the bearings are able to handle enormous weight, increasing the lifespan of important parts while at the same time providing safety by ensuring stability at high-speed ranges(well over 120 km/h). Furthermore, the strength and toughness of the bearings to tolerate extreme conditions is relative to how reliable and excellent the trains will be hence making them critical for ideal train propulsion operation.

Impact on speed and load capacity

my evaluation of the influence of railway wheel bearings on the speed and lifting capabilities of rolling stock seems to me to be absolutely correct….” These details are made in a way that they can support a lot of weight but allow very little resistance in weight to be turned, thus allowing the train to go faster without sacrificing safety. Trains go fast these days because the wheel bearings minimize friction and effectively distribute the load’s stress. So this means that the wheel bearings are able to accomplish the task of allowing the train to pull an even heavier load or even with a larger number of people in it. Their design is crucial to accommodate the need for advanced rail systems in this day and age, which is speed, capacity, and reliability.

Contribution to overall railway system efficiency

La importancia de los rodamientos de rueda para el funcionamiento eficiente de los sistemas ferroviarios es innegable ya que soportan el desgaste que se deriva de la operación de trenes, permiten ahorro de inversiones en energía y disminuyen la frecuencia con que el tren es requerido reparación. Su diseño permite la reducción de cargas y por ende el ahorro de combustible, además incrementa la vida útil de los elementos del tren. Estos beneficios significan no solo reducción de los costos de sistema sino also amenable and efficient service of the railways.

Handling radial and axial loads in railway applications

I can say with assurance that radial and axial load management is one such aspect that in fact affects the performance and reliability of railway systems. Radial and axial loads, which are perpendicular and parallel to the axis of rotation, respectively, not only need to be dealt with but also need to be dealt with with precise engineering solutions if the stability and life of the system are to be ensured. Bearings are more or less actuated to cater to these forces because they enable even distribution of the stresses to minimize wear and tear and mechanical breakdown. The proper type of bearing for their purpose, as well as the right methods of installation and servicing, greatly reduces the risk and improves the efficiency of rail operations.

How do railway wheel bearings enhance safety and reliability?

Cup and cone bearings are very functional for safety and reliability in train operations. As I have witnessed, these parts are built up to withstand all the stresses and the dynamic loads that occur as the train moves, and their working performance determines the efficiency of the rail systems as a whole. So let us see how they enhance safety and reliability:

- Load Distribution: The wheels of the train are outfitted with particular bearing surfaces in which weight is evenly distributed throughout each of its wheels. This interferes with the stress peculiar to the axle or wheel components, thus avoiding the mechanical fault that may lead to the derailment of the vehicle.

- Minimized Friction: High-quality bearings allow for the reduction of friction in parts that are in motion. This not only enables efficient operations of the trains but also avoids cases of overheating occasioned by unnecessary friction which is a big threat to factors of safety.

- Durability: The most popular kinds of bearings are fashioned from materials and coatings that are resistant to wear and tear, corrosion, and extreme temperature. Such durability implies that the operational life span is increased alongside the periods between maintenance interventions, reducing the downtime rate and thus improving the train operation reliability.

- Shock Absorption: When a train moves, during its operations there are vibration and impacts it receives. There are bearings that are fitted, which are primarily created to absorb and dampen such forces so that severe impacts on other vital parts of the trains are avoided.

- Real-Time Monitoring: Some modern bearings are fitted with temperature, vibration, and other characteristic indicators or sensors. These sensors would give real-time information, which, when properly interpreted, would give a basis for making decisions on predictive maintenance of the bearings, thus precluding any breakdown of the machine.

Addressing these key parameters enables the railway wheel bearings to render great safety and reliability to train operations. For advanced engineering, preservation measures stress that they are the cornerstones for the durability of rail systems.

Ensuring smooth operation at high speeds

The ability to maintain high speeds comes down to meticulous design, routine upkeep, and excellent monitoring. The use of materials of the highest standards, aerodynamic shaping of the wheels, and receiving real-time data from sensors enhance performance and stability. The risk of failures is minimized through the use of predictive maintenance, thus allowing the trains to function efficiently and safely even in harsh environments.

Extending service life and maintenance intervals

It has been my observation that increasing and extending service intervals of equipment in the field invariably begins with the use of quality and high-performance parts. Employing newer material technologies, such as wear-resistant alloys, composite materials, etc, aims to reduce the number of revisions. In addition, the utilization of intelligent maintenance schedules through forecasting techniques can help reduce excessive maintenance and uncontrolled standstills by detecting problems before they arise. The major point is a shift from a reactionary stance to a proactive one—with maintenance for insurance—preventative measures to monitor, evaluate, and take action to address increasing trends of smaller quarrels that have the potential of developing into larger concerns. The end result is not only better equipment life but also improved reliability of the system in general.

Adapting to various operating conditions

Adjusting to new operating conditions is simply a matter of knowing the required parameters and changing them accordingly. Based on my experience, there are a number of key factors we need to look into:

- Temperature Variations – Systems are frequently subjected to extreme temperature alterations due to either the environment or usage requirements. For this purpose, we choose materials that can withstand such thermal expansion and contraction while ensuring that they still function and do not lose their integrity.

- Load and Stress Levels – Depending on the configuration, different loads and stresses can operate on the system. From a system design perspective, I make components capable of withstanding maximum loads without causing excessive stress, hence achieving their objectives. This addresses the prediction of stress points through simulations and the design of the solution for such conditions.

- Environmental Exposure -As time passes, humidity, dust, chemical, or altitude exposure can result in wear out of the system components. To reduce such environmental implications, protective layers, sealants, or stronger materials such as some composites are needed.

- Dynamic Operations -In systems that operate by switching between different modes (fast breakthrough walking with long rest phases), we make use of heavy configurations. To ensure easy switching between modes, optimizations such as adaptive control mechanisms and proper software are enough.

Through monitoring these parameters and their relationships and making necessary adjustments accordingly, systems can be conditioned to function even in an unstable environment. It’s a never-ending process, and developing such solutions relative to the given task still remains crucial for the achievement of performance purposes.

What are the different types of bearings used in railway wheels?

I can explain that there are two main types of bearings that are used in the wheels of railway vehicles: roller bearings and plain bearings. Surely, the most widespread of these is the roller bearings, especially the tapered ones, because of their strength, ability to carry high loads, and functionality in resisting friction. These types of bearings can easily handle both thrust and radial loads which makes them suitable for heavy rail applications. In contrast, plain bearings (journal bearings) are less used nowadays but have been utilized in the past train designs. Despite the fact that they are rather basic in design, plain bearings require more maintenance and lubrication to function properly. Innovation has moved on, and roller bearings are emphasized because of their effectiveness and maintenance-free operation.

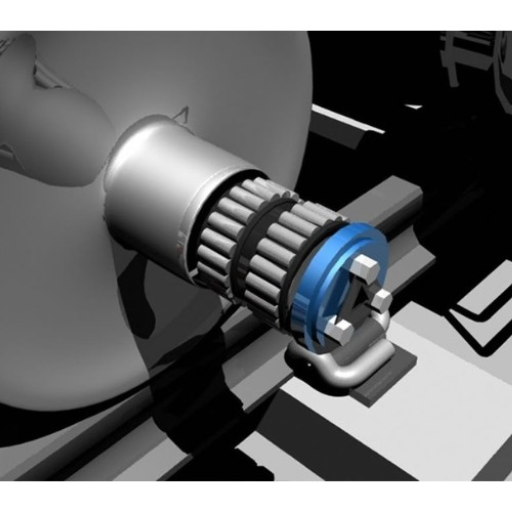

Double-row tapered roller bearings for heavy-duty applications.

Double row tapered roller bearings are specially designed for high axial and radial load carrying capacities important in heavy duty applications. Apart from that, their incorporation is meant to help them achieve an aspect that is very important in the manufacturing process or in the process of production, which is the ability to withstand and operate in extreme conditions. This property is essential for the railways, construction, and mining industries. These bearings are able to be delivered because of the way they are designed, where the radial load is able to be distributed effectively across two rows of rollers, thus enhancing service life while maintaining high precision and stability under heavy pressure.

Cylindrical roller bearings for high-speed trains

I have experienced how design innovation has enabled high-speed train cylindrical roller bearings to satisfy key operating requirements. These high-speed train bushes are expected to withstand the harsh centrifugal forces, rotary motion, and thermal expansion that result from the rotary motion of the unit. Thus, they operate effectively and self-sufficiently. This is a breakthrough because reducing friction and temperature will reduce depot maintenance work and expenses. As I’ve seen, their optimized design improves overall energy efficiency and the safety and stability of the passengers on the train during high-speed train travel.

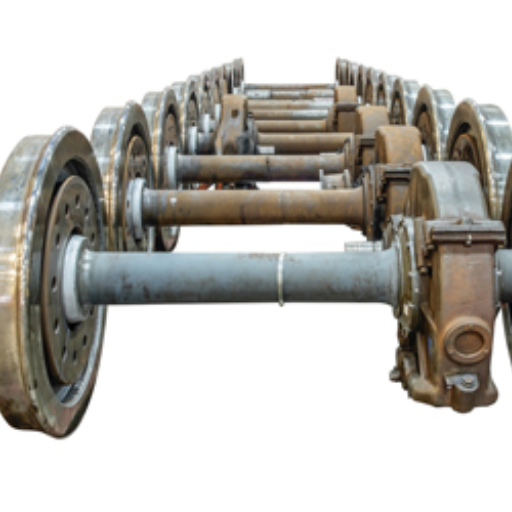

Spherical roller bearings for freight cars

Spherical roller bearings are essential in freight cars as these vehicles are exposed to heavy loads and rough tracks on a daily basis. From my field experience, they are simply unique as their configuration supports significant radial and axial loads whilst providing for a long life even in extreme conditions. Such a level of survivability leads to a reduced number of replacements and maintenance schedules, which is crucial for minimizing equipment idle time in freight activities. Furthermore, their self-aligning feature is also beneficial, especially during operations, whereby shaft misalignments, most often encountered in freight systems, are self-compensated.

How do you choose the right railway wheel bearing for your application?

Focusing on the appropriate railway wheel bearing for your application requires that you consider load capacity, operating speed as well as the environment. Evaluate the bearing’s capability to withstand radial and axial loads together with the temperature and humidity under which it is expected to work. In addition, check that the shaft design and alignment tolerances are suitable for the bearing. To achieve the best results, talk to manufacturers to recommend the right bearing type that corresponds with your needs.

Factors to consider: Speed, load, and environmental conditions

Based on my experience in the industry, choosing the best railway wheel bearing comes down to three critical factors – speed, load, and environmental conditions. In high-speed applications, a bearing with greater accuracy and resistance to heat is needed, whereas in heavier applications, materials and designs that can withstand heavy stress are required. Environmental conditions such as high temperatures or high humidity levels determine the presence of appropriate sealing and corrosion-resistant bearings. By taking these factors into consideration alongside the requirements of your application, you are more certain of the bearing’s reliability and performance in the long run.

Comparing OEM and aftermarket bearing options

What’s best, OEM (Original Equipment Manufacturer) or aftermarket bearings? To put it simply, it depends on what you need. OEM bearings are basically as good as the original equipment they are made to be used with, as they are designed to match it perfectly. However, aftermarket bearings can be more affordable and come in a wider variety of options, but finding one that meets your standards can be difficult, as the quality across them varies greatly. Where the application is critical, OEM bearings are generally to be preferred while in less critical applications or where project budgets are a constraint, aftermarket bearing may be sufficient.

What are the maintenance requirements for railway wheel bearings?

In Australia, I have an adequate understanding of the industry and what the requirements are for sustaining railway wheel bearings in order for there to be adequate safety, reliability, and longevity. Inspections must be routine, which will look into wear, corrosion, and overheating, which in turn may signify misalignment or poor lubrication. Grease type and amount are vital constituents in lubrication management since excessive friction or failure may occur otherwise. Furthermore, adequate cleaning and reconditioning of parts have a generally positive effect on performance. New technologies like condition monitoring systems have also been proven particularly useful in the early detection of failure and in enabling scheduled maintenance to be carried out in advance. Implementing a regular maintenance policy not only reduces artificial downtime but also increases the working life of the bearings.

Lubrication practices for optimal performance

In regard to lubrication performance, always choose a lubricant compatible with the working conditions such as temperature, load, and speed. Keep adequate lubrication intervals throughout the lubrication cycle of the equipment, and ensure that over-greasing is avoided because it will generate excess heat and pressure. Regularly take lubricant condition readings with oil analysis to ascertain contamination or emulsion degradation. Automatic lubrication systems, where applicable, should be implemented to reduce the risk of human error as well. With all these practices in place, the equipment’s reliability and bearing life would be substantially improved.

Inspection and replacement schedules

forming an effective timetable for inspection and maintenance works best to achieve optimal machinery performance. I suggest that routine inspections be carried out so as to be able to note any early signs of wear, such as noise or vibration or visual observation of any damage. As for the replacements, following the manufacturer’s instructions should be enough, but remember that the environment and severity of the use of the machine have to be taken into account as well. Rebearing the equipment before it breaks down is helpful in avoiding long periods of activity loss and unanticipated breakdowns. From my own experience, I also stress keeping thorough records of all inspections and replacements to monitor changes and aid future decisions. This approach guarantees that equipment operates as expected over time efficiently and effectively and, therefore, is relatively less prone to breakdowns.

Where can I find reliable suppliers of railway wheel bearings?

Compliance with the right certificates of quality. First, focus on manufacturers such as Timken or SKF, as they are leaders in the market and have extensive track records. Also, ask around the industry or any trade associations and directories on railway equipment to find reliable contacts. Member directories of ThomasNet or GlobalSpec are good alternatives as well. Specialists are often the best option as they are well-known in the industry, and so are the ones with customer support representatives who are easily approachable.

Leading manufacturers in the railway-bearing industry

Only industry veterans who have remained active throughout the decades can support say that Collins and Timken do not surrender the lead whenever SKF, or even American companies, is concerned. From my experience, they are largely able to deliver sound, tailored solutions that conform to the rather harsh requirements of the railroad industry. These companies concentrate on high-level engineering and unique materials and thus their bearings are always strong and good in effectiveness and serve a growing number of railway operators across the globe.

Considerations when selecting a railway-bearing supplier

In choosing a railway-bearing supplier, factors like product quality, accepted experience in the industry, and ability to provide depth of technical support should be given priority. Determine the supplier’s certifications, their experience history in railways, and their ability to deliver appropriate solutions for specific needs. Besides, it is essential for the long-term performance of the center to have a reliable supply chain and after-sales support.

Reference

- An investigation of rail bearing reliability under real conditions of use – This study examines roller bearings used in railway ore transportation wagons, focusing on failure distribution.

- High-speed train wheelset bearing fault diagnosis and prognostics – This research presents a new prognostic model for wheelset bearings, emphasizing reliability and sustainability.

- Reliability and fatigue life evaluation of railway axles – This article evaluates the reliability and fatigue life of railway axles using a system-level reliability method.

Frequently Asked Questions (FAQs)

Q: What are railway wheel bearings, and why are they important?

A: Railway wheel bearings are critical components in railway rolling stock that support the weight of the vehicle and allow the wheels to rotate smoothly. They play a crucial role in ensuring the performance and reliability of trains. These bearings are typically located in the wheel hub and are essential for maintaining proper wheel alignment, reducing friction, and distributing loads evenly across the axle.

Q: What types of bearings are commonly used in railway applications?

A: Several types of bearings are used in the railway industry, including: 1. Ball bearings (such as deep groove ball bearings and angular contact ball bearings) 2. Roller bearings and cylindrical roller bearings 3. Tapered roller bearings 4. Plain bearings 5. Magnetic bearings (in some advanced applications): The choice of bearing type depends on specific railway requirements, load conditions, and operating environments.

Q: How do wheelset bearings contribute to train operation?

A: Wheelset bearings are critical components that support the entire weight of the railway vehicle and allow for smooth rotation of the wheels. They help reduce friction between the axle and the wheel hub, enabling efficient movement of the train. Additionally, these bearings play a vital role in maintaining proper wheel alignment, absorbing radial and axial loads, and ensuring overall stability during train operation.

Q: What are the main differences between ball bearings and roller bearings in railway applications?

A: Ball bearings and roller bearings are both used in railway applications, but they have different characteristics: – Ball bearings: These use spherical balls as rolling elements and are suitable for high-speed operations. They can handle both radial and axial loads but have lower load-carrying capacity compared to roller bearings. – Roller bearings: These use cylindrical, tapered, or spherical rollers and can handle heavier loads. They are often used in applications requiring higher load-carrying capacity but may have speed limitations compared to ball bearings.

Q: How do traction motor bearings differ from wheelset bearings?

A: Traction motor bearings and wheelset bearings serve different purposes in railway vehicles: – Traction motor bearings: These support the rotating shaft of the electric motor that provides propulsion to the train. They need to withstand high speeds and vibrations associated with motor operation. – Wheelset bearings: These support the entire weight of the railway vehicle and allow for smooth rotation of the wheels. They need to handle heavier loads and provide stability during train movement.

Q: What factors are considered in the product description of railway wheel bearings?

A: A product description for railway wheel bearings typically includes: 1. Bearing type (e.g., ball bearing, roller bearing) 2. Size and dimensions 3. Load-carrying capacity (radial and axial) 4. Speed ratings 5. Lubrication requirements 6. Sealing arrangements 7. Material specifications 8. Temperature range 9. Compliance with industry standards 10. Special features (e.g., sensors for condition monitoring)

Q: How do railway wheel bearings contribute to the overall reliability of rolling stock?

A: Railway wheel bearings are the backbone of rolling stock reliability because they: 1. Ensure smooth and efficient wheel rotation 2. Reduce friction and wear on axles and wheels 3. Distribute loads evenly across the axle 4. Maintain proper wheel alignment 5. Absorb shocks and vibrations 6. Contribute to energy efficiency by minimizing rolling resistance 7. Help prevent derailments when properly maintained By performing these functions, wheel bearings significantly enhance the safety, performance, and longevity of railway vehicles.

Q: What maintenance practices are essential for railway wheel bearings?

A: Proper maintenance of railway wheel bearings is crucial for ensuring their longevity and performance. Essential maintenance practices include: 1. Regular inspection and condition monitoring 2. Proper lubrication at specified intervals 3. Checking for signs of wear, damage, or contamination 4. Monitoring operating temperatures 5. Replacing bearings at recommended intervals or when signs of deterioration are detected 6. Ensuring proper installation and alignment during replacement 7. Keeping detailed maintenance records for each wheelset, These practices help prevent unexpected failures and ensure the safe and efficient operation of railway vehicles.