Every car owner needs to be aware of the expenses involved in necessary car repairs if they wish to maintain their vehicle in good condition. Changing a damaged wheel bearing is one such thing that needs vehicle repair. Wheel bearings are a wheel’s member that enables the rotational movement of the wheels while at the same time bearing the weight of the vehicle. Wear and tear of wheel bearings over time can cause a failing wheel bearing and can manifest itself in ways such as strange sounds, uneven tire wear, or steering difficulties. This article explains the essential moderating aspects, such as the cost of replacing wheel bearings for a particular car, labor costs, and the grade of parts required for bearings replacement. Once the factors are known, readers will have an improved sense of how to get ready for the work as well as what to anticipate from it.

What is a wheel bearing, and why is it important?

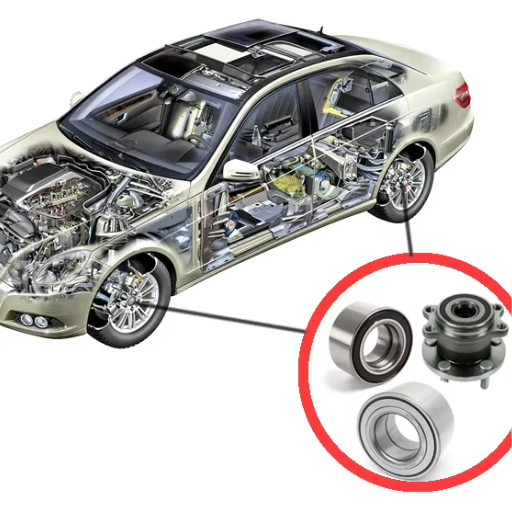

A wheel bearing is one of the many parts of the car wheel structure which allows the wheel to roll with as little friction as possible. It is made of a large number of steel balls or rollers tightly enclosed in a metal ring, which allows for the smooth movement and even distribution of loads around the axis. Its importance lies at the very center of ensuring proper functionality of the wheel, stabilizing the vehicle’s position, and enabling safe manipulation of the vehicle. A bad wheel bearing is able to affect all these points, it is a risk to safety, and requires instant fixing.

How do wheel bearings work, and why are they essential?

A wheel bearing is a component of the car wheel system that facilitates rolling movement with minimal friction. It consists of an intricate network comprising numerous steel balls or rollers encased in a metallic ring that allows for free movement and load dispersion around the central axis. Its concept is critical and localized to the core in relation to the performance of the car wheel system. It is critical to keep the vehicle steady and allow the driver to handle the vehicle safely. Its defects alter all those spheres. Hence, it is a safety hazard and requires immediate attention.

Now, let’s deepen the analysis with detailed parameters:

- Load Support: The lots bearing load includes the car weight, its passengers, and everything inside the automobile it is used for. These loads are distributed judiciously so that the wheel assembly remains intact.

- Friction Reduction: The balls or rollers that you find inside the automotive wheel bearing help to reduce the amount of friction whenever the wheel rolls. This also helps in smooth movement and overheating issues as well as energy saving.

- Stability and Alignment: An effective wheel bearing will ensure that the wheel of the vehicle turns only at one axis and in one direction, which reduces every unwanted movement, and thus, the tires get less uneven wear.

- Durability Under Rotational Pressure: A wheel bearing is constructed of carbide or hardened steel that is of good quality and thus can bear plenty of weight more easily than lower-quality steel.

- Safety: A fracture of a bearing can result in the wobbling of wheels, strange sounds, and, in worst cases, altogether separation of the wheel from the vehicle, and this poses a safety concern. For this reason, proper service and wearing it out on time is quite essential.

Understanding these parameters emphasizes the need to maintain your wheel bearings as well as their importance in achieving seamless, quick, and safe driving telematics. One should always care for them to minimize expensive refurbishments and maintain the operating performance of his vehicle.

Common signs of a worn wheel bearing

The signs of a worn wheel bearing need to be identified as they impact the safety and the functioning of the vehicle. The following are the most common warning signs that indicate that your wheel bearing could require servicing:

- Unusual noises such as humming, growling, or grinding

When it comes to the weird sounds of voices in a moving vehicle, there are specific reasons behind them, especially for humming or grinding sounds growing louder at miles per hour. That can occur as a consequence of the metal touching metal due to excessive wear caused by the spinning of the vehicle’s tire, which results in a shift in the weight of the vehicle, causing the grinding noise. These interesting noises do alter as the angle of the turn changes along with the Bearing that gets affected, for instance, between metal rusting and corrosion having a suitable temperature.

- Wheel wobble or vibrations

The wobbling of wheels can be one of the destabilizing factors. And that enhances the chances of the steering wheel vibrating, especially at high speeds. When this circumstance becomes a serious concern, it is preferable to address it right away before further damage may cause the steering column, as well as the engine prop shaft and the drive shaft, responsible for transferring a few units to turn the tires, disturbing the steering wheel.

- Uneven or abnormal tire wear

A possibly needed tire wheel depends on the outer covering of the Wheel and reflects from the wheel, and that depends on the wheel of the tire casing, and that also depends on how tightly or properly the wheel is attached or set on the steer or the shaft of the tire. And if that happens, then screwing or loosening any of the components may give rise to differences in the check pattern of the tires replacing irregular wear.

- ABS system failure or warning light activation

Contemporary car models incorporate wheel hubs with ABS sensors. If the bearing is damaged, it may affect your sensor’s ability to track wheel speed, which could potentially allow your ABS alert to light up on the dashboard.

- Excessive play in the wheel hub

At maintenance or examination the loose wheel also was able to notice wobbling motion with a high lateral or vertical oscillation during a rocking motion hand. This amount of wobble usually going to confirm severe wear.

- Heat near the wheel hub

Excessive friction around a bearing that is on its last legs can lead to insufficient lubrication around the bearing, or cause the area around the hub to become too hot to comfortably touch, it is an indication that the bearing is fast wearing out. For better understanding, it is better to explain that point more clearly.

If you see any of these indications, it is time for you to get your wheel bearings checked and replaced if required. Letting the signs go unnoticed or ignored may result in extended damage to the hub assembly and axle, as well as other interrelated systems. Maintenance of such components at regular gaps and identifying the problem early are essential for the entire system to provide a comfortable and safe drive.

How a damaged wheel bearing affects driving safety

The wheel bearing affects the power and control of the vehicle. Most importantly, it impacts safety by giving out a tensile or compressive strength to the vehicle. When a wheel bearing goes bad, it causes slight instability to the steering of the vehicle that, as a result, causes uneven wearing on the tires with higher traction when turning or the ability to make faster cornering while under pressure. Not addressing a problem with the wheel bearings/tightening can also be dangerous, as in worst-case scenarios, if the bearing isn’t functioning, the wheel may not only get stuck, but it may also come off completely. The overall message is that it does not take too long to fix wheel-bearing issues.

How do you determine if your wheel bearing needs replacement?

the sounds of grinding or rattling while on the road can be one of the signs that the wheel bearing is worn out. One way to check if it is off is to take a turn and accelerate. The sounds would only get louder; sometimes, the tires begin to shake or wear off unevenly. What a surprise, right? Not really; That means it is potentially time to replace the wheel bearing along with inspecting whether the vehicle drives straight or swerves towards one side. If you suspect anything is wrong, it’s rare the problem solves itself. Get it checked out to avoid any further bottleneck.

Symptoms of a bad wheel bearing

the initial signs of a malfunctioning wheel bearing are not that easy to notice. However, they have become more defined with time. I have noticed customers driving their cars claim that there are sorts of humming or grinding sounds that amplify when making turns or going faster. In addition, with the sound, the driver may also start feeling that the steering is vibrating, especially as the problem gets worse. An abnormal loss of tread on the tire also suggests that the wheel bearing is about to wear out too which is why i suggest my clients to keep an eye out on their cars steering to see which direction the car goes when on its own. If we spot those early signs, not only do we guarantee safety, but we save on repairs that could be costly later.

How to inspect wheel bearings at home

It’s easy to assess wheal bearings at home with a careful approach. My first suggestion is that the vehicle should be lifted using a jack and further assisted with a jack stand. Never rely on the jack only; it is not safe. Once the wheels are lifted, place your hands at the top and bottom of the tire and try moving it back and forth. This is a test with excessive play indicating a potential looseness. After this, grab the wheel and spin it while listening for any grinding, scratching, or even a squealing sound that could be the courtesy of a damaged bearing. We are actually being offered a quick approach. Just grab the tire and use the same principle, from a more suitable angle, take off the wheel and the brake assembly so we could look directly onto the hub. Are there any signs of rust, erosion, or mechanical damage that could take place in the area close to the bearing? If you consider this, then you could save money and visit the mechanic only when absolutely necessary.

When to consult a mechanic

A mechanic should be consulted as soon as grinding noises persist, wheel play becomes excessive, and any visible bearing damage or wheels spin roughly after self-inspection is performed. This problem often needs special tools and professional help in order to fully fix the issues. Do not wait any longer because driving while having defective bearings can be quite dangerous.

What is the average cost of replacing a wheel bearing?

Replacing the wheel bearing can cost differently depending on various aspects, and from my side, let me put that in the correct sequence:

- Type of Vehicle – The bearing replacement cost will greatly depend on the vehicle’s make and model. Such cars, such as an imported car or a luxury car, will be good examples of cars, as they will require specific parts and manpower, which will raise the cost directly. However, average mechanics that replace wheel bearings for most cars typically charge from $150-$300, depending on the car per wheel.

- Labor Costs – As mentioned before, the replacement of a wheel bearing mainly includes replacement of wheel hub which in some cases the brakes need to be replaced, due to this manpower cost becomes critical. Most such rates vary but, on average, range from about $100 to $200.

- Parts Costs – In such cases, the cost of the replacement bearing will also vary due to the difference. For instance, the price of a single ball bearing starts from about $50-$100, but in a hub assembly, the ball bearing prices go around $200-$400.

- Additional Repairs – In case the bearing suffers damage, it can lead to related components attached to it also getting damaged, and in some cases, such as the wheel hub or axle replacements, might be essential, which will be an additional price charge.

On the lower end, drivers can pay around $250, with the higher end of the replacement cost per wheel being about $500. Since prices will vary according to your geographical location, car type, and the condition of already installed parts, it is advisable to contact your mechanic for an accurate quote.

Factors affecting wheel bearing replacement cost

There are multiple reasons for concern while replacing the wheel bearing of the vehicle. Such as what the cost would become considering the car model and the make as well. This is due to the fact that luxury or specialized vehicles require expensive parts. The level of damage can also be a reason for cost alterations, especially for the repairs required in the wheel hub or the axle. Moreover, there are also differences when it comes to the payment to be made for the services of the shop or the location. In particular, the remuneration available for the mechanics also matters a lot. And finally, the cost can have double implications based on the kind of spare parts used, be it the OEM or others that were fitted into the car.

Cost to replace a wheel bearing in different car models.s

The car’s brand influences the estimates a lot when it comes to bearing wheel replacement. A general vehicle will cost anywhere between $200 to $400 per wheel bearing. On the other hand, exotic cars range anywhere between $500-$1,000. Perfectly put, This is because the parts tend to be expensive, as well as the designs and the assembly. However, in order to get accurate expectations according to your vehicle model and your region, a professional mechanic needs to be consulted.

How much should you expect to pay for labor?

Depending on your location and the specific make and model of your car, the complexity of its design, and the labor costs associated with changing a wheel bearing, it costs between $100 and $250 per wheel. More basic designs are faster to work on, while high-end or niche automobiles tend to be more time-consuming and cost more in terms of labor.

Can you replace a wheel bearing yourself?

Yes, replacing a wheel bearing by oneself is possible, but one must be an expert as well as have enough time to carry out the task with the right tools. But this is a very involved and very difficult process that also requires tools like a bearing puller or bearing press. If you do not have such experience, it would be best to avoid even trying out this repair as it could end up worsening the problem or, worse, bringing about safety concerns. Unless you are skilled enough and have the right tools from your arsenal, it is advisable to leave the replacement in the hands of a skilled professional mechanic.

Tools required for DIY wheel bearing replacement

If you’re planning on replacing your wheel bearing yourself, all you need is a wheel wrench, jack and jack stands, socket set, torque wrench, bearing puller or press, hammer, and punch. You should also wear gloves and goggles for safety to create a safer area to work in. It is also advisable to carry a service manual for the specific vehicle model you own as it guides you throughout the process.

Step-by-step guide to replacing the bearing

Replacing a wheel bearing is a multi-step process that involves sufficient detail, concentration, and specific tools. Here’s a how-to guide carefully tailored to help you carry out the replacement procedure without any hassle:

- Prepare your workspace

To begin, pick a solid and flat area to work in; it’s also advisable to go for a garage with reinforced flooring. After that, make sure the vehicle doesn’t roll once the work begins by engaging the emergency brake. To do that, put wheel chocks behind the vehicle’s wheels. Lastly, ensure you gather all the necessary tools as well as protective equipment.

- Loosen the lug nuts

Depending on which side the faulty bearing is located on, use a lug wrench to loosen the corresponding nut. Do note you don’t want to take the lug nut off completely, as that may end up making the solvent unstable.

- Lift the vehicle

Normally, you’d want to use a mechanical jack to lift the incomplete vehicle, but since this is a more specialized process, it’s more advisable to start using an impact wrench, and after fully replacing the bearing, the jack can be used.

- Remove the wheel

Take the previously loosened lug nuts off by unscrewing them in a clockwise direction, and after doing so, remove the wheel to uncover the brake assembly.

- Detach the brake components.

Push the brake caliper and rotor out; you might require a socket set to remove the caliper bolts. Use a wrench to unscrew the bolts and ensure the brake caliper is restrained using a bungee cord or wire to prevent any excess strain put on the brake line.

- Access the wheel hub assembly.

First, a torque wrench is used to strip down extra equipment that might be required by the vehicle. Commence by loosening the axle bolt and torque it accordingly. Strictly follow this step and make sure that the force you’re using is correct.

- Remove the old wheel bearing.

To remove the wheel bearing from the hub assembly, you would need to use a wheel bearing press tool. If you see that the bearing isn’t moving, get your hand and punch it, and then use it to rotate the hub. Remember to use minor force as a strategy for surrounding components. Some examples of Fuel Oil are Gasoline, Kerosene, and Aviation Fuel.

- Install the new wheel bearing.g

Again, use a bearing press tool to press the new bearing into the hub. Remember to properly check if the bearing fits in as well and is secured.

- Reassemble the components

Reattach all other components, such as the calipers, the axle nut, and the brake rotor, and make sure that all of them are tightly secured. Also, ensure to go through the service manual for further specifications on twisting. None of the components of the part disconnect from each other. So start off gently unscrewing all the bolts.

- Reattach the wheel

After reassembling the vehicle, I recommend taking it for a test drive. In the process, ensure to search for abnormal noises and check if the vehicle works seamlessly. Remember, if you do come across any issues in the process, be sure to reset it or even take the assistance of the professionals.

After seeing a wheel bearing repair up close it may seem like quite the daunting and complicated task, however, doing the following wheel bearing replacement steps would surely ensure straightforward repair. Safety first, as always, so make sure you use the correct tools and follow the specified torque settings in the manual.

Risks of replacement

If you decide to do a DIY replacement of a wheel bearing, you might want to think again if you don’t have any sort of experience. A bearing can easily wear out, and if you were to install it incorrectly, this may lead to wheel misalignment, which can damage the vehicle outright when it reaches a certain speed. Doing any repairs without the correct equipment and tools only increases the likelihood of you injuring yourself and damaging components. If mechanical repairs are new to you, then it’s best to leave it to the professionals who have the experience that is required.

How does the hub style impact the cost of replacement?

The style of the hub has quite a bearing on the wheel’s design and build process. Most modern-day vehicles come with a bearing integrated hub assembly, which makes the repair process quite easy, although the integrated bearings and hubs tend to be more costly. You have to take everything apart and press the old bearing out or in when replacing a standard serviceable bearing. This is much more of an intensive task. While the parts themselves may be less expensive, the extra labor cost could increase the cost of the entire job. In conclusion, the hub style to a large extent determines the repair process in terms of how complicated, and costly it will be.

Types of Hub Assemblies

Оnly two kinds of hub assemblies are in use in modern automobiles today: integrated hub assemblies and serviceable hub assemblies. Integrated hub assemblies are the ones where both the wheel bearing and hub come as a single unit and they are cost-effective and easy to replace but incurs high initial cost. Serviceable hub assemblies, on the other hand, have individual components that can be disassembled, repaired, and replaced, but such results in lower purchase costs of parts and higher labor due to the extensive dissembling and assembly needed. Each category comes with a unique set of advantages and disadvantages that depend on the needs of the automobile design, the type of maintenance, or the budget.

Comparing hub bearing and roller bearing

Hub bearings and roller bearings have differing designs and uses, which is the primary distinction between the two. As a result, they are ideal for modern automobiles, given their ease of fitment and integration into a unit that combines the wheel and hub bearing. Alternatively, roller bearings employ cylindrical-shaped rollers to share the load, which are most commonly found in old machinery or heavy-use machinery. Hub bearings are designed with an utmost emphasis on ease of use, hence, are perfect for the vast majority of automobiles while roller bearings are almost indestructible which allow them to work in stressful environments with significant load. The vehicle, its parts, and how these parts are used will affect the decision of which is more suited between the two types of bearings.

Choosing the right hub style for your vehicle

Picking the right hub style for your car is based on understanding how it works and its functions. For the latest passenger vehicles placing emphasis on efficiency and easy maintenance, wheels are usually the best option due to their design and stability. But if your vehicle operates under heavy loads or tough conditions, then for you, humanity roller bearings are the best option. They last the longest and can handle much more stress. Always take into consideration the design of your vehicle along with the conditions in which it operates in order to get the best results and durability out of it.

Reference

- Kelley Blue Book – Provides national average costs and insights into how luxury brands might affect pricing.

- Subaru Outback Forum – Offers real-world examples and quotes from users discussing replacement costs.

- Quora – Discusses retail prices and considerations for DIY replacements.

Frequently Asked Questions (FAQs)

Q: How much does it cost to replace a wheel bearing?

A: The cost to replace a wheel bearing can vary depending on the make and model of your vehicle, the type of bearing, and labor costs. On average, it can cost around $150 to $800 per wheel bearing, including parts and labor.

Q: What are the symptoms of worn wheel bearings?

A: Symptoms of worn wheel bearings include a humming noise, a noisy wheel, vibrations in the steering wheel, uneven tire wear, and the vehicle pulling to one side. If you experience any of these signs, it’s essential to have your wheel bearing inspected.

Q: How much does it cost to replace front wheel bearings?

A: Replacing front wheel bearings typically costs between $300 and $500, but the price can vary depending on the vehicle’s make and model, as well as labor costs. It may be cheaper to replace the rear wheel bearings.

Q: Is it necessary to replace the steering knuckle when replacing a wheel bearing?

A: In most cases, you do not need to replace the steering knuckle when replacing a wheel bearing. However, if the old bearing has caused damage to the steering knuckle, it may require replacement.

Q: Can a noisy wheel indicate a wheel bearing issue?

A: Yes, a noisy wheel, especially one that produces a humming noise or grinding sound, can indicate that a wheel bearing is going bad. It’s crucial to address this issue promptly to avoid further damage.

Q: How long does it take to replace a wheel bearing on your car?

A: Replacing a wheel bearing on your car typically takes about 1 to 2 hours per wheel, depending on the complexity of the vehicle’s design and the condition of the old bearing.

Q: Do I need a wheel alignment after replacing a wheel bearing?

A: It is usually recommended to perform a wheel alignment after replacing a wheel bearing to ensure proper handling and tire wear. Misalignment can occur when the wheel bearing is replaced.

Q: Is it more expensive to replace four-wheel bearings at once?

A: Replacing four-wheel bearings at once can be more costly upfront, but it may save money in the long run by preventing further damage and ensuring consistent performance. The cost of a wheel bearing replacement per wheel may be slightly reduced when done together.

Q: Does car insurance cover the cost of a wheel bearing replacement?

A: Generally, car insurance does not cover the cost of a wheel bearing replacement as it is considered standard maintenance. It’s advisable to check with your insurance provider for specific coverage details.