This is a complete guide on how to replace a wheel bearing, and here’s all that needs to be covered for the important maintenance task to be completed. From comprehending the significance and working of wheel bearings to recognizing the symptoms that indicate a malfunctioning bearing and encompassing the ramifications that arise from procrastinating a much-needed bearing replacement will be discussed in this article. Remember, bearing replacement is something every car owner can perform, regardless of whether you are an expert or a novice. So, without further ado, welcome to our tutorial. Rest assured, after going through this guide, you will possess the confidence needed to carry out a wheel bearing replacement while also ensuring that your car functions properly.

What is a Wheel Bearing, and Why is it Important?

A wheel or axle kind of vehicle assembly has a variety of parts, one of them being a wheel bearing. In other words, a wheel bearing is defined as a set or collection of steel balls or rollers that is kept in between two metal rings, with one of them being fixed and the other being able to turn. The purpose of a wheel bearing is to enable smoother axial rotatory movements between the wheel and the axle. As a wheel gets heavy and used through many driving conditions, its ability to rotate decreases, but the presence of a wheel bearing allows minimal rotation friction to exist, enabling the wheel to turn easily.

As mentioned earlier, the wheel bearing exists to provide support to enable the vehicle to rotate, enhancing the movement of the wheels. Being an important part of a vehicle, if functioning properly, a wheel bearing will encourage the vehicle to turn with ease, steer resoundingly, respond well on the road, and perform optimally alongside other components of the vehicle. However, There could be a scenario where a wheel bearing is not taken care of and maintained properly. In such cases, a person would face many problems, including more wear and tear on tires, overheating the wheels, wheels being torn apart, and loss of control.

In the context of a wheel bearing, knowing the components and its mechanism of functioning is important for a car owner as it gives them the ability to identify where the problem is coming from and resolve it so that proper functionality of the vehicle is met.

Understanding the Function of a Wheel Bearing

First, the wheel bearing plays an important role in vehicle support by allowing the wheels to rotate. It consists of a grouping of steel balls or rollers that are encased within a metal ring known as a race which is positioned in the wheel hub assembly. The wheel bearing also reduces the friction between the rotational axle interface and the wheel enabling for proper free spin of wheels. In turn, this maintains the equilibrium between the wheels with respect to the vehicle and ensures control and a smooth driving experience for the driver. Additionally, having wheel bearings enables any undue stress on the tires and suspension system to be alleviated by equal distribution of the load across the wheels.

Signs of a Bad Wheel Bearing

let’s look at some key indicators that the wheel bearing may be at fault. Identifying these signs is essential to ensure that corrective actions to limit damage are taken at an appropriate time. Here are some of the most accurate signs that indicate that the status of your wheel bearing may deteriorate:

- Unusual Noise: If your wheel-bearing is bad/loose one of the most apparent indications is a constant grinding or rumbling noise emitted from the wheel which is affected, This noise tends to get louder with an increase in speed and bun some changing while turning.

- Uneven Tire Wear: A worn wheel bearing can cause the tire to have uneven tire wear which will usually show on one side of the tire till the other. Make sure to inspect your tire thoroughly because if your wheel bearing is worn out the side of the tread will be bald or have deep cut on it.

- Steering Instability: Wheel bearings that have started to fail can cause the vehicle to have steering problems, which can make it feel loose or steer towards one side, making it hard to keep the vehicle going straight when trying to drive.

- Excessive Vibration: The wear and tear of the wheel bearing cause a vibration that us noticeable on the steering wheel and the cars interior. This vibration might get worse as the speed increases.

- ABS or Traction Control Light:sometimes a wheel bearing might get damaged and as a result the Abs or the traction control are triggered and your dashboard then shows a warning light.

After reviewing this information, if you notice any of the above symptoms, it is essential that you get in touch with a certified mechanic so that there can be a proper inspection done on the wheel bearing to ensure that you are safe on the road. A faulty wheel bearing should always be replaced on time as this best prevents any needless damage to other components while enhancing the efficiency as well as reliability of the vehicle.

Consequences of a Failing Wheel Bearing

- Increased Friction and Heat: With the deterioration of the wheel bearing, the friction that develops between the wheel hub and bearing increases which leads to overheating. This culminates in bearing heat which is likely to cause the bearing to hot and possibly even seize, thereby inhibiting the operation of the wheel.

- Unstable Wheel and Steering: If any of the wheel bearings fail partially or completely, the affected wheel may either touch the ground or lose its alignment. This will cause disruption to the steering capability alongside the handle of the vehicle, thus, increasing chances of an accident to the passengers.

- Uneven Tire Wear: A failing wheel bearing can cause the affected wheel to tilt or lean, resulting in uneven tire wear. As a result of that premature damage to the tires will occur and on top of that consumers will be forced to replace the tires at increasingly earlier times.

- Increased Risk of Wheel Separation: If someone ends up incapacitating a wheel bearing, the end result is losing control that will eventually result in the wheel completely tearing away from the vehicle. This experience is an exceedingly life threatening one, as the control will be lost, and thus putting the exposed individual to the risk of colliding with another object, thus increasing the probability of going into an accident.

In order to avoid any further harm to your equipment as well as to maintain your own safety, it is important to pay attention to any indicators which may show that the wheel bearing could potentially be damaged. Any repairs such as frequent checking, maintenance as well as replacement of the worn out or damaged wheel bearings are extremely important routines with regard to the overall performance of the vehicle as well as its reliability.

How to Replace a Wheel Bearing: A Step-by-Step Guide

I will respond in a nutshell to the issue above, “How to Replace a Wheel Bearing: A Step-by-Step Guide.” It is fairly easy to replace the wheel bearing, and it is also one of the most important maintenance activities for the safety and performance of the vehicle. In case you are not sure about the process, follow these steps for undertaking a proper wheel bearing replacement:

- Prepare the Tools: Tools and equipment such as a jack, jack stands, a lug wrench, a socket set, a torque wrench, and a new wheel bearing assembly could be sourced.

- Elevate the Vehicle: A jack should be used to raise the car and make use of jack stands to secure it in place.

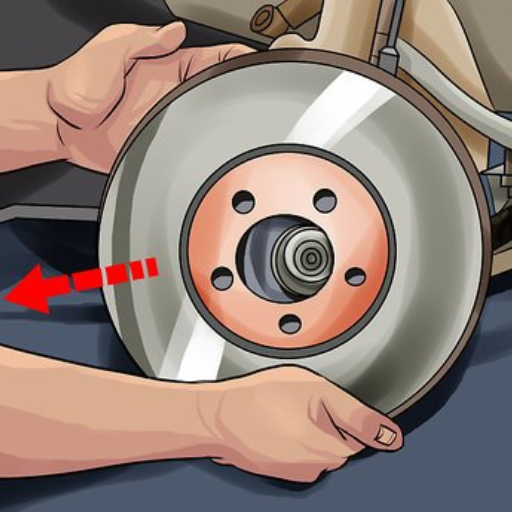

- Remove the Wheel: The next course of action is to take off the wheel by loosening the lug nuts ot using the lug wrench and putting the wheel aside.

- Access the Wheel Bearing:Identify and trace the wheel bearing unit which is located just behind the brake disc. The next step is to displace the brake caliper and disc to be able to access the wheel bearing unit.

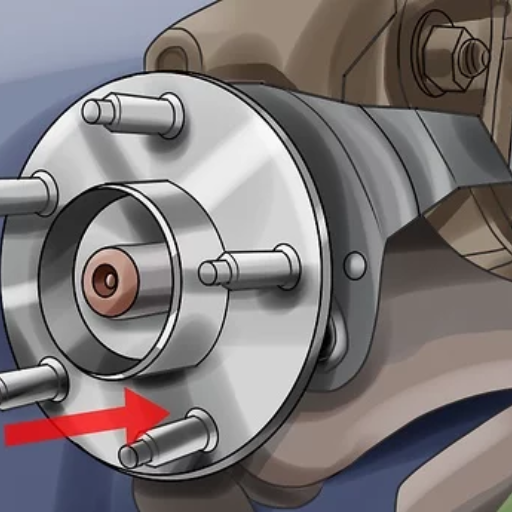

- Remove the Old Wheel Bearing: The demolition of the wheel bearing assembly should be performed with a socket set to unbolt it. The old bearing will be delicately pried off the axle hub next.

- Install the New Wheel Bearing: Grease thinly on the axle hub and complete cleaning it to make the fitting smooth. Place the new wheel bearing assembly on the hub and secure it in the right position by fastening the bolts.

- Reassemble the Brake Components: All brake components in their damaged state should be removed and the brake disc and caliper should replace them and make sure that the necessary alignment followed the torque instructions pertaining to the manufacturer during securing.

- Replace the Wheel: The final procedure left to undertake is re-attach the hub which was loosening the wheel and re-attached the nut at the tip using the wrench.

- Lower the Vehicle: Walk walking a jack to support the lifting mechanism of the car body, take away the jack stands and gently reduce the car from the jack stands with the support of the jack until the jack stands are completely removed.

If these instructions are strictly complied with, one can be petrol confident of replacing a wheel bearing without hampering the working or safety of the vehicle. Nonetheless, It is better to seek advice from an expert if there is doubt in carrying out the procedure or if one is not confident with it.

Tools Required to Remove the Wheel

In order to remove a wheel for the wheel bearing replacement, the following tools are needed to accomplish that:

- Lug Wrench: A lug wrench forms an important tool used for loosening or tightening the lug nuts fitted on the wheel axle.

- Jack: A jack is required to raise the car in order for the operator to gain access to the wheel.

- Jack Stands: Jack stands are means used to support the vehicle in case it has been raised.

- Wheel Chocks: To restrict the motion of the car during the removal of the wheel, a wheel chock is used.

- Socket Set: A socket set that contains the appropriate measurements is necessary for removing the wheel lug nuts.

- Torque Wrench: Torque wrenches are instruments that are used to ensure that lug nuts are fitted to the manufacturers specified strength.

- Penetrating Oil: Some penetrating oil may be useful for undoing rusted or frozen lug nuts.

The presence of the tools mentioned above ensures a smooth and efficient process of removing the wheel for the purpose of replacing wheel bearings.

Step-by-Step Process to Replace the Wheel Bearing

Considering your expertise in this field, let us now begin with the step-by-step guide on how to replace a wheel bearing. Once these instructions are followed, the process will be simple and straightforward:

- Prepare the Vehicle: When preparing the equipment, turn it off and park it in neutral gear while maintaining the shift lever in a safe position, set the brake firmly as given by the manufacturer and to ensure that an extra layer of security has been added, place wheel blocks behind the tires.

- Loosen the Lug Nuts: Prior to attempting to change the wheel or tire on this vehicle, rest assured that the tire will always be secured to prevent movement upwards and out of the sump, which can easily be increased using truck hydraulic lifts.

- Lift the Vehicle: Remove the vehicle in a secure manner using a car jack then carefully place jack stands on it. To maintain the vehicle’s safety and security, do not exceed the lifting range.

- Remove the Wheel: Dismantle the lug nuts and remove the targeted wheel, setting it aside in a specific location far from others.

- Access the Wheel Bearing: In some cars for instance, it may be essential to switch out the brake disc and the caliper in order to replace the wheel bearing properly . In the manual insert of the car, the instructions have been written clearly.

- Remove the Old Wheel Bearing: After the components above are complete, bear pullers and other appropriate tools will be utilized to remove and replace all the old bearings. Ensure that the new races and bearings have been oriented exactly how the old ones did.

- Install the New Wheel Bearing: Prior to placing the new wheel bearing, wipe the hub assembly with a clean cloth. Apply a little amount of grease on the inner race of the bearing and using a bearing installation alternative, push it into place.

- Reassemble the Components: Replace all other parts which were detached while gaining access into the wheel bearing like the brake rotor and caliper. Using a torque wrench to ensure proper tightening of all fasteners, which looks as per the manufacturer recommendations.

- Mount the Wheel: Re-attach the wheel back to the hub assembly and manually fasten the lug nuts onto the wheel. Using a torque wrench, fasten all lug nuts in crisscross or star patterns after lowering the vehicle back onto the ground.

- Test the New Wheel Bearing: Drive the vehicle while focusing on the new wheel bearing, ensuring that it is operating in perfect condition. Take note of any odd sounds or vibrations; also monitor how the vehicle moves and how it breaks.

So long as you stick to the suggested processes and use the correct equipment, you can perform this task without any worries.

Testing the New Wheel Bearing Installation

However, keeping the focus on the Bearing Test, it is important to ascertain that it is working well, as this is critical for the effective usage of your vehicle. Here are a few points worth remembering:

- Listen for Unusual Noises: While taking the car for a drive, focus on sounds that may not be normal around the wheel area. Things like screeching, humming, or grinding sounds may be signs that the new wheel bearing has an issue.

- Monitor Vehicle Handling:During the test drive, monitor how you feel the performance of the vehicle. If there’s some shaking, pulling in the steering too much or engine seem hard to turn, it could mean that there is an issue in the installation of the wheel bearing or it missed the mark entirely.

- Check for Smooth Braking: The brake system should be checked for efficiency and efficacy in operations. Otherwise, if you notice that brakes do not seem to be working smoothly and are instead feeling jerks and slight pushes during braking, chances are there is a problem with the wheel bearing.

In this way, by carefully observing the action during the test drive, it is possible to accurately test the operational qualities of a new wheel bearing and eliminate existing problems. It should be noted that mounting and testing the components is of utmost importance for the dependable operation of the vehicle and the safety of the driver.

How to Identify a Bad Wheel Bearing?

the process of identifying a bad wheel bearing begins with observing certain warnings. Make sure to be on the lookout for the signs as illustrated below, which typically point to a failure of your wheel bearing:

- Unusual Noises: One of the symptoms of a wheel bearing being bad is the presence of abnormal sounds such as humming, grinding, or growling while the vehicle is driven. These can happen more often when the vehicle steers or changes lanes.

- Vibrations:Failing to smooth out a wheel bearing will induce forceful contact that can be felt through the vehicle, steering wheel, floorboard and seats. The feelings of whooshing may feel more prevalent at higher rates of speed.

- Uneven Tire Wear: When there is a tapering of tires for some wheels while others are normal, it indicates that one or more wheel bearings have gone bad. Some of the characteristics of abnormal bearing include bald patches or uneven tread patterns. This happens when the wheel bearing is malfunctioning and causes uneven weight distribution.

- Steering Instability: A vehicle with a worn out wheel bearing will have a struggle with maintaining its steering. The vehicle will steer to one side of the driver due to acceleration and the bearing going wrong.

- ABS Light Activation: A vehicle with a bad wheel bearing that is screeching or has irregularities in its form can struggle with turning the ABS signal on and off. This is initiated when the wheel speed sensor picks up irregularities from the wheel bearing.

Should you suffer from any of the mentioned issues, it would be prudent to get your wheel bearings checked and changed if required. Neglecting the indications of an irregular wheel bearing can cause great damage and become a danger while driving on the roads.

Common Symptoms of a Bad Wheel Bearing

let’s get straight to the point regarding the issue of symptomatic wheel bearings. The degradation and potential failure of a wheel bearing are often exhibited through several distinct indicators. Such indicators include:

- Unusual Noise: Its relentless gritty sound that increases the speed of the vehicle noise is one of the most rudimentary signs that the wheel bearing is on its last legs. This is largely known to be a deep grinding sound caused by metal rubbing with force against other metals.

- Vibration in the Steering Wheel: Vibration of the steering wheel is an effect caused by a malfunctioning wheel bearing, the effect is felt more so on the wheel during the higher speeds, the effect then distorts into mild vibrations. Again, as the car ages the vibration increases.

- Uneven Tire Wear: When the wheel bearing is down, ofteh the wheel balnace which is found out of such throws out of weight is affected. The needed drywall is for the car: wood furring separations or spacing’s that holds up the wheel angle and greatly sanctions the tire from uneven wear so that the bearing doesn’t boost excessive cut tires along with cupping.

- ABS Light Activation: There goes am ABS light during the malfunction of the wheel bearing, and the wheel bearing has gone bad only one road sensor is left then the steering shaft still has irregularity and is eyeing the cutoff.

In such a case, we recommend servicing your wheel bearings and replacing them when necessary. Worn out wheel bearings pose a threat on the road and to ignore the signs of a bad bearing can cause even more damage.

How a Bad Wheel Bearing Affects Your Vehicle

A worn wheel bearing may seem unimportant in the eyes of a vehicle owner, but from an industry perspective, it may cause severe effects on both the safety and the performance of the vehicle. A bad wheel bearing can cause multiple problems, which usually would severely affect the drivability of the car. Here are a few ways in which a wheel bearing might affect a vehicle:

- Noise and Vibration: A faulty wheel bearing will most likely make a grinding, humming, or rumbling noise that comes from the side of the wheel, and these are perhaps the most discernible signs of a failed wheel bearing. Loss or damage to the bearing component will eventually result in binding and excessive loss, which will, in turn, yield these sounds. Also, vibrations can sometimes be felt through the steering wheel or floor of the car, especially when moving at high speeds.

- Uneven Tire Wear: The smooth movement of the wheel can be changed as a result of having defected wheel bearing, which in turn results in the uneven wearing of the tires. More specifically, if you observe that your tires are coming off too early or nonsymmetrically, then it could point to the damage of the wheel bearing.

- Steering Instability: Damage to the wheel bearing may reduce the overall performance of the ABS (Anti-lock Braking System), and this will lower the working efficiency of the system. Such a condition is very dangerous on the road as it increases the distance within which the vehicle can brake.

- Reduced Braking Efficiency: The improper installation of a wheel bearing induces uneven distribution of weight, resulting in wheel misalignment, better known as steering misalignment. Such misalignment has dire consequences; it interferes with the car’s handling abilities, causatively lowers the responsiveness, and increases the rate of tire deterioration.

Examination of wheel bearings is essential if you observe some of the following signs: the wheel bearing seal is leaking grease, your steering is feeling loose, a grinding noise is noted when turning corners, your car tends to rotate forcefully to one side when braked, the wheel rotates freely with little friction when spinning it by hand. If any of these signs bear witnessing changes occur to a bad wheel bearing then you should seek a replacement of the wheel bearings if necessary. Burning a B warning sign of a bad wheel bearing can, with time and negligence, lead to more damage as well as becoming a safety hazard on the road.

What is the Cost to Replace a Wheel Bearing?

the cost of replacing a wheel bearing is very varied in terms of factors. To replace a single wheel bearing, the average range is $150-400, including parts and labor. But it must be emphasized that the exact price depends on the model of the car, the type of wheel bearing, and the area that you are in.

Some of the factors that can bring a change in the cost:

- Whether the wheel bearing is located in the front or rear end of the vehicle

- The amount of detailed work required for the wheel bearing assemblage

- The make and the replacement part’s standards

- Your car model specifics

To get precise quotes for a specific vehicle and scenario, it’s recommended to speak with a licensed mechanic or an automotive service center. They are able to evaluate the state of the wheel bearing, offer a more comprehensive cost estimate and replacement options that will suit them best.

Self-fixing and replacing them can look to be inexpensive, but one should think of many good reasons for getting a professional replacement. Professional technicians have the skill and necessary tools to allow the bearing to be fitted correctly and in a safe manner, which also limits the likely possibility of inflicting further damage or safety issues. In addition, many service centers offer a warranty on the coverage of parts and labor, which makes the customers more assured and secure in the long run.

Purchasing a new wheel bearing not only contributes to the safety and functionality of your vehicle but is also cost-effective in the future. Better noise handling and reduction of vibrations, alongside improving the comfort of the drive, can all be achieved by getting a new wheel bearing. Responding to issues regarding a wheel bearing and replacing them with quality substitutes in a timely manner will also aid in the longevity of the suspension system of the vehicle.

In the event that you experience strange sounds emanating from your car’s wheel bearing, vibrations, or wobbling when steering the car, then it is highly recommended that you get your wheel bearings checked and replaced if required. Problems with wheel bearings should not be ignored, as they can cause additional damages which can pose hazards while on the road. Make sure to put the health of your car first. For appropriate diagnosis and actions, get in contact with an automotive expert of your choice.

Factors Influencing the Cost to Replace a Wheel Bearing

Due to a pretty wide range of factors, the expenses for getting a wheel bearing replaced can differ considerably. I am a professional in this area, so here are some of the pointers that would assist you in comprehending the key elements that affect the pricing:

- Vehicle Make and Model: Different vehicles have different designs of the wheel bearings which might in turn complicate the cost and replaceability. A luxury or a specialized vehicle will demand certain parts or specialized labour and thus will cost more.

- Wheel Bearing Type: Differentiation can also happen due to types of wheel bearings, some have ball bearings whilst others have roller bearings. The cost of a bearing is beholden to the cost of a vehicle as for roller bearings are harnessed at a greater cost than ball bearings.

- Quality of Replacement Parts: Another factor that affects the price of a new wheel bearing is the quality of replacement parts. Careful investment in high-quality components that may be expensive upfront usually provides better service down the line.

- Labor Costs: hourly rates for a certain shop for a repair, the intensity of the repair and also the time needed to replace and reach the wheel bearing affect the labor cost in a rotor bearing replacement. Same labor in different places differ not just in price but the entire shop.

- Additional Repairs: Often, large costs are associated with replacements due to additional repairs that need to be done. For instance, replacing or servicing the wheel hub assembly will ultimately lead to an increase in costs.

- Warranty Coverage: In case your vehicle is still under warranty, then the costs associated with the replacement of a faulty wheel bearing might be part of the coverage, hence out-of-pocket expenses might be negligible or non-existent.

To determine the cost of replacing a wheel bearing, it is wise to seek the assistance of a reliable automotive expert. Such a specialist can provide estimates based on a specific vehicle and other such relevant factors, thus making it more comprehensive for the client.

Comparing DIY and Professional Replacement Costs

let’s turn our attention to the comparison of the costs involved in the replacement of wheel bearings by DIY (Do It Yourself) and the replacement undertaken by professionals. The price of replacing such components is never consistent because it’s dependent on one or more of the following: the model and make of the vehicle, the nature of the wheel bearing, and the services rendered. In order to understand these aspects better, here is a short guide:

DIY Replacement:

- If one were to undertake dock building on coal islands on a do-it-yourself basis, there would be potential for labor savings because there would be no time and no payment for labor incurred.

- However, it is crucial to understand that the replacement of a wheel bearing requires certain tools and mechanics skills.

-

If they command such skills and have the equipment on hand, then there is a do-it-yourself replacement option which may be open to them. Be mindful, though, of how a restatement may be done because it could be dangerous if restatement is performed incorrectly — further damage could be a consequence.

Professional Replacement:

- The task of replacing the wheel bearings is done only by trained professionals with sufficient experience, this is assured by professional replacement.

- Professional replacement also warrants a correct replacement as necessary tools and equipment will be available.

-

Although professional services are charged for some labor, they highly guarantee convenience and a better skill set.

In the end, it’s up to each individual because it all comes down to their level of comfort, mechanical abilities and tools at hand whether to replace it themselves or have a professional see to it. Just remember, taking care of your wheel bearings is vital for your security as well as the performance of your car. Until you are very sure about what you are doing, please talk to a professional about your unique case before taking any action.

Long-term Benefits of Investing in a New Wheel Bearing

I know that there are various advantages that accrue with the installation of a new wheel bearing, especially in terms of the safety and functioning of your automobile in the long run. Here’s why it’s worth considering:

- Enhanced Safety: Repairs or replacements of worn-out bearings will contribute to sustaining the ability of the vehicle’s mechanics to perform optimally, prolonging their ability to maintain good longitudinal and lateral control of the vehicle while improving its dynamism – The drastic reduction in responsibilities and functions taken up by replacing bearings reduces the number of faults around the vehicle hence accidents will be at minimal levels.

- Improved Fuel Efficiency: A good wheel bearing will eliminate all unnecessary wear and tear and, wobblyt bearing caused by irrational forces and low forces hence converting most of the rotation in to energy wastage during movement, a wobbly force multiplies energy wastage contributing to increased fuel costs, new bearings will restore the ride quality and reduce fuel costs and wastage in the end.

- Extended Tire Lifespan: Another benefit of replacing a faulty wheel bearing around the vehicle is the ability for tires to be machined within the required tolerances; a worn-out wheel bearing would struggle to rotate the wheel assemblies at the required angle and position, causing the resultant force to be unevenly distributed resulting in premature tire change as some of the tires would not be able to perform their operation cycle thus operating at a much higher alteration level and degrading at an exponential rate.

- Reduced Maintenance Costs: Costly wheel replacements can be avoided investing in new settings which are at a lower amount than changing the bearings as the end and the beginning cost overlaps, shoulder or spindle sections will not be damaged as the new settings will avoid the costly damage in the process of replacing the bearings and will increase the longevity of the vehicle.

- Enhanced Driving Experience: Driving with a replaced bearing will be a great experience as the wheels will be able rotate at the correct angles without those annoying vibrations transforming the whole ride into a pleasant one without those irritating sounds every few minutes which would distract from the experience..

In conclusion, the costs incurred in acquiring a new wheel bearing are justified over the years as one improves safety, fuel efficiency, tyre wear and tear, maintenance cost and the general experience of driving the vehicle. Hence taking good care of your wheel bearings would mean you get an effective vehicle, and most importantly safe on the roads.

When Should You Replace a Wheel Bearing?

The right moment for replacing a wheel bearing is subject to various considerations . Nonetheless, there are a few general indicators that demonstrate whether one should have a replacement. These are the key points or indicators which might be helpful to check out:

- Unusual Noises: Listen, If the wheels emit any growling, humming, or grinding noise, then you should prepare yourself for a welch’s wheel bearing. The issues could also worsen when taking corners.

- Uneven Tire Wear: Persistent wheel bearings coming under heavy use and wear on the edges and one or more tires would suggest a fault in the wheel bearing. This is due to a pressure imbalance which the wheel bearings cause on the tire leading to diagonal wear on the tires.

- Steering Instability: Basically, if you have failure with a wheel bearing the steering of your vehicle would fail too. If there is play in the steering wheel the diameter of the wheel increases or the steering wanders around, then it’s crucial for you to change the wheel bearing.

- Vibration or Looseness: Lost motion shock in steering or bearings which are torn up, which means there would be vibrations in the bearings and the steering wheel. More combining force can lead to further bearing disintegration which worsens the issues more.

Menționez ca aceste indicii nu sunt la fel pentru fiecare model de lucru sau masina, si in functie de conditiile de mers, pot sa varieze. If you notice any of these signs, or are suspicious about the condition of your wheel bearings, do not hesitate to see a professional mechanic for examination and action. As a reminder, waiting too long to replace a failing wheel bearing is a good way to ruin your vehicle’s performance, safety, and life expectancy.

Understanding the Lifespan of a Wheel Bearing

You must understand that the lifetime of a wheel bearing is crucial in preserving the performance and safety of your car. The actual lifetime may differ according to the rank of the vehicle and general conditions on the road, but the following should be considered as broad guidelines:

- Mileage: As per the statistics, a wheel bearing should be able to survive the rigors put forth for an average of 85,000 to 100,000 miles. However, factors outside the control of manufacturers depict a drastic difference in its lifetime; these include the driving style, the condition of the road and how much load capacity is put into use.

- Maintenance: Lifespan of a wheel bearing can also be extended through regular maintenance which includes lubrication of critical components and routine checks of the bearing. Once wheel bearings reach the end of their life span they should be replaced as quickly as possible so as to not inflict any further damage to the peripheral components of the wheel and its assembly.

- Driving Conditions: Constant driving in tough exterior environments or ever-changing temperature levels or driving in the flooded areas can quicken the depreciation in the quality of the bearings. In such cases more regular checks and even replacement of components might be required.

- Signs of Wear: Worn out bearings can also be detected through the peculiar sounds or difficulty in steering the car or undulation of the wheel. Depending on these somewhat common symptoms it is advisable to take the vehicle in for maintenance in order to replace the bearings if they have suffered any damage.

Monitoring these parameters and dealing with any signs of wear and tear immediately will help in maintaining the adequate functioning of your wheel bearings, thus ensuring a more comfortable and less risky drive.

Indicators It’s Time to Replace a Front Wheel Bearing

I would like to mention a few signs that indicate that a front wheel bearing might need replacement:

- Unusual Noises: If odd noises such as humming, grinding, or squealing sounds arise in the wheel area when turning the vehicle, understand that the wheel bearing is most probably bad and worn down and necessitating a replacement.

- Steering Instability: If while using your vehicle, the steering seems to have loose, slack, and unsteady movement then this could most likely indicate a broken wheel bearing. Potential safety risks might cause problems with regard to controlling the vehicle as a result of the bearing in the wheel becoming worn and loose.

- Wheel Vibration: Oftentimes, bearing vibration occurs when the steering is being turned and sometimes during vehicular movement. Given that there is a visible deterioration of the bearing, the potential need for a replacement would render the vibrations of the steering wheel to become irritable.

- Uneven Tire Wear: Under aging processes, abnormalities in tire wear such as wear on one side of the tire or bald spots can commence due to some form of wheel normal or abnormal bearing forces To take note of the above, such procedures can be highly suggestive of a wheel bearing fault.

In case you notice any of these symptoms, you should consider contacting a mechanic for maintenance services to check and replace the front wheel bearings if necessary. Otherwise, even bigger damage can take place which could not only affect the smoothness but even the safety of the car.Nonetheless, immediate action is more constructive.

Reference

- How to Change Wheel Bearings: 12 Steps (with Pictures) – wikiHow

- What is a car wheel bearing? How do you replace them? – RAC

- DIY Guide: How to Replace Your Car’s Wheel Bearings – Goodhood

Frequently Asked Questions (FAQs)

Q: How much does it cost to replace a wheel bearing?

A: The cost to replace a wheel bearing can vary widely depending on the type of vehicle, whether it’s a front or rear wheel bearing, and where you live. On average, the cost can range from $150 to $800, including labor. Always consider getting a detailed estimate from a trusted auto repair shop.

Q: Can I change a wheel bearing myself?

A: Yes, you can change a wheel bearing yourself if you have the necessary tools, skills, and time. It involves several steps such as removing the wheel, brake caliper, and rotor, and often requires removing the axle nut and the hub bearing assembly. It’s important to follow a reputable guide or video tutorial, such as those by ChrisFix, to ensure accuracy and safety while working on vehicles.

Q: What is a hub-bearing assembly?

A: A hub bearing assembly is an integral part of your vehicle’s wheel assembly. It supports the wheel and tire and allows them to rotate smoothly. It typically includes the bearing itself, the hub, and sometimes the wheel studs. This component is crucial for safe driving, so it’s important to replace it if it becomes worn or damaged.

Q: How do I remove the axle nut?

A: To remove the axle nut, you’ll need a breaker bar and a socket that fits the nut size. Ensure the vehicle is securely lifted before attempting to loosen the nut. It may require significant force to break it free, so use caution and proper technique to avoid injury or damage.

Q: What is the purpose of bearing grease?

A: Bearing grease is used to lubricate the wheel bearing assemblies, reducing friction and wear while preventing rust and corrosion. Proper lubrication is essential for the longevity of the bearings and the safe operation of the vehicle.

Q: How do I replace the dust cap?

A: To replace the dust cap, gently tap it off the hub using a flathead screwdriver or a similar tool, being careful not to damage it. Once the new bearing is installed, align the new dust cap and tap it back into place using a rubber mallet until it’s securely seated.

Q: What are the steps to remove the hub?

A: To remove the hub, first remove the wheel, brake caliper, and rotor. Then, remove the axle nut and any bolts securing the hub to the vehicle. Once these are removed, you can take out the hub assembly. Be sure to follow detailed instructions or a tutorial to ensure each step is completed correctly.

Q: What should I be aware of when learning how to replace a wheel bearing?

A: When learning how to replace a wheel bearing, be aware of the complexity of the task and the need for specific tools. Factors beyond the control of inexperienced individuals, such as the tightness of bolts or the condition of the bearing race, can complicate the process. ChrisFix assumes no liability for property damage or personal injury, so ensure you fully understand the procedure and take all safety precautions.

Q: Are there any risks involved in replacing a wheel bearing?

A: Yes, there are risks involved in replacing a wheel bearing, such as potential property damage or personal injury. Incorrect installation can lead to bearing failure, which might result in accidents. Always ensure you have the required skills, tools, and knowledge before attempting this repair, and consult a professional if unsure.