We are very happy to launch this complete guide on how to change a wheel bearing! The information that will be presented below will elaborate step by step on the process, the most important considerations, as well as essential tips to serve you for a successful outcome for the wheel bearing change. Even if you are an experienced DIY expert or a fresher with little technical expertise, all the knowledge within this guide ought to be enough for you to complete the task at hand with assurance. From the necessity of using wheel bearings to the equipment installation and step-by-step procedure, we have covered everything. Let’s take a look and prepare ourselves for the process of wheel bearing replacement!

What is a wheel bearing, and why is it important?

Considering the expertise in the automotive industry, it is prudent to start by answering the following questions: What is a wheel bearing, and why is it important?

A wheel bearing is the principal element that makes the rotation of a wheel assembly frictionless and seamless. It is fixed within the metal ring, known as the bearing race, which is composed of a set of steel balls or rollers that assist in reducing friction and bearing the weight of the automobile. As a part of the hub assembly, the wheel bearing not only allows the rotation of the wheel but also carries the weight of the whole automobile.

Many people underestimate the significance of a wheel bearing. In any vehicle, it serves the crucial function of ensuring that the wheels operate safely and efficiently by decreasing the contact between the moving components and their contact surfaces, thereby prolonging the lifespan of the active parts and improving their functions. With a good bearing, vehicle handling, response to steering, and the ride’s overall quality is improved. Ignoring a bad wheel bearing can cause disturbing consequences, which include loss of safety and a greater chance of being in an accident, as well as severe damage to other parts of the wheel and an almost complete failure of the rest of the wheel assembly.

To put it in a nutshell, a wheel bearing is an important component of a car that ensures the car wheels are safe and operate smoothly. It facilitates complete rotation effortlessly, minimizes friction, and helps to bear the vehicle weight which together enhance the driving experience.

Understanding the function of a wheel bearing

I appreciate the significance of a wheel bearing in the proper and efficient movement of the vehicle’s wheels. There are many vital aspects provided by the wheel bearing that ensure comfort and security while operating a car.

First of all, a wheel bearing provides effortless wheel rotation, which helps to lower friction and ease movement of the vehicle. It bears the weight of the vehicle and assists in evenly distributing off the weight of the load across the wheel assembly. This not only improves the overall function of the vehicle but also makes the ride more comfortable for the driver and passengers.

A good wheel bearing that has ideal bears load also keeps a proper wheel alignment and aids in the prevention of any possible misalignment that might cause some handling difficulties or irregular tire wear. It assists in securing the wheel to the vehicle and therefore reduces chances of accidents or loss of the wheel.

In short, looking at the easier and complex aspects of a wheel bearing helps in looking after the safety and functioning of the vehicle. If there is a good condition of all the wheel bearings in the automobile, the driver can be free from all sorts of worries since the chances of accidents as well as numerous damages can be disregarded.

Signs of a failing wheel bearing

I can point to clear indicators of a wheel bearing that is failing:

- Unusual Noises: One of the most clear indicators which point out the problem of a malfunctioning wheel bearing is a loud noise coming from a specified affected wheel. This noise can take the form of a scraping or grinding sound or a thudding and roaring noise, more so at high speeds.

- Uneven Tire Wear: A malfunctioning wheel bearing may lead to tires that wear out unevenly. If you find that the tire tread wear has occurred more on one tire and it is showing more damage than the other tires, there is a defect on the wheel bearing.

- Steering Instability: A malfunctioning wheel bearing can also influence steering and thus cause difficulties in maneuvering and turning of the vehicle. With such a failure, you may feel slop in the steering or that the car is pulling to one side during your motion.

- Excessive Vibration:A malfunctioning wheel bearing may also translate to higher amounts of vibration on the steering wheel or on the floor of the car. This vibration shakes the vehicle more as it accelerates or decelerates.

In case you spot any of the above circumstances, it is highly recommended that you get your wheel bearings checked and replaced where necessary. A malfunctioning wheel bearing should never be taken lightly as it may have serious implications on both the vehicle performance and safety.

Consequences of ignoring a faulty wheel bearing

The International Rond point des voitures et Automobiles Declarants REG., it is totally unacceptable to overlook a damaged wheel bearing as that will affect the working as well the safety of the automobile. A wheel bearing that is failing and is never attended to may result in:

- Increased Risk of Accidents: Faulty wheel bearings mean the stability and control of the vehicle will be affected especially when making turns or when driving at high speeds and since the driver cannot guarantee responsiveness from the affected wheel, this increases risk of accidents.

- Uneven Tire Wear:A bad wheel bearing would also affect how the tires conect An improper alignment of the wheel causes wear on tires, leading to high and uneven deterioration of the tire tread that shortens the tire lifespan and the performance of the tires.

- Damage to Other Vehicle Components: A faulty wheel bearing not only gets stresses from movement patterns but also causes its associated parts to bend and break a lot more. This could also increase damages to more critical components such as Fahrenheit and steering over time, resulting in costly repairs.

- Costly Repairs:There are further surrounding components of vehicles such as hubs which would further go wrong and make things especially difficult when repairs are being carried out and things tend to get worse when a wheel bearing collapses which end up leading to high costs of repair.

Any notice of a failing wheel bearing has to be rectified immediately so as not to compromise on both the safety and the functionality of the car. Actively working on this and getting help can reduce the effects of such a problem and ensure that the car remains functional and serves the owner for a long time.

How do you prepare for a wheel bearing replacement?

Being part of this industry, it is wise to know what you are getting into firsthand before blanking out on a wheel-bearing replacement. Here are the fundamental steps with the aim to ensure a smooth and successful process of replacement:

- Gathering necessary tools and materials:Before commencing, it may be prudent to collect all of the tools and materials needed for the replacement – in this case a jack, jack stands, lug wrench, socket set and horsefly, new assembly of wheels bearing, and specific tools defined in the car’s repair manual if the same does not come with the product itself.

- Ensuring safety and proper setup: It is paramount to, first and foremost, maintain safety. Always remember to maneuver the vehicle and park it in a level place and activate the parking brake. To avoid any chance of such movement, always keep wheel chocks in place. Make sure to practice safety measures such as wearing protective gloves and eyewear at all times.

- Important considerations before you replace the wheel: Follow the procedures carefully and take precautions as per the driver’s manual for vehicle repair. This may be the disconnection of the battery, some unscrewing, or the following correct torque. Do not forget to read the especially written instructions to allow you to achieve a successful replacement.

You can enhance the process of an upcoming wheel bearing replacement and get the desirable results by adhering to these basic steps. Remember to examine the service manual of your vehicle and seek the help of professionals when necessary.

Gathering necessary tools and materials

I’m now going to explain the various tools and materials needed for replacing a wheel bearing in a succinct manner.

All replacement jobs require preparation in terms of having the right tools. Hence, it makes perfect sense to gather all your essentials before the commencement of the wheel bearing replacement process:

- Socket Set: Depending on the requirements of the vehicle’s socket drive, screw, and nut replacement will require a versatile socket set that incorporates different sizes of sockets.

- Torque Wrench:For any bolts or nuts that require fastening this type of tool guarantees that the tightening specifications required by the manufacturer are thoroughly observed.

- Breaker Bar: A breaker bar will be useful in providing additional effort required in loosening the screws and bolts in place.

- Pliers: Components that are clipped in place by retaining clips may require the use of pliers to easily remove them.

- Hammer: Sometimes stubborn parts may need to be lightly hammered to get them out. Hammering can prove to be useful in such cases.

- Wheel Bearing Grease: The application of new grease on the replaced wheel bearing would also ensure the smooth running and durability of the new bearing.

- Axle Nut Socket: If you have an automobile, you may require an axle nut socket for taking the axle out from the automobile.

- Safety Equipment: Managing safety hazards is very essential while swapping the tires, therefore wear gloves, safety goggles and appropriate clothes for the procedure.

Having these tools and materials ready before beginning the wheel bearing replacement ensures that you will be able to complete the work confidently and get the best outcome.

Ensuring safety and proper setup

offering solutions to issues comes with the prerequisite that safety protocols are observed and that an efficient operating procedure is followed. Prior to commencing the replacement, one should appreciate the procedures involved in the process and the tools that they are able to employ. Let’s go through a brief outline answering the above questions and help you with high proficiency and smooth work when replacing the wheel bearing.

To replace a wheel bearing, follow these important steps:

Remove the wheel and axle, nut. Use a lug wrench to first loosen the wheel. I recommend checking with your car manual since every car has a specific socket size that is required when removing the axle nut. Moving forward, this procedure will expose the hub and axle-bearing components.

Remove the brake caliper and rotor. It would be nice at this point if you would adhere to the vehicle specifications since some braking systems tend to be complex. In such cases a proficiency in using a brake caliper piston tool or rotor removal tools would be advisable.

Remove the old hub and bearing assembly, the step entails unbolting the brake rotor from the vehicle and would open up the hub and bearing assembly. Depending on how the steering knuckle or spindle was fixed, the unassembly should be done slowly so as to prevent causing any damage to the components positioned around that area.

Install the new bearing and reassemble the components. Lubricants tend to be necessary at the points where the components are mounted so applying a little anti-seize lubricant to the areas where the wheel bearing is to be fitted is prudent as well as complying with any instructions given by the manufacturer. Now it is time to reinstall the previous components, these include the brake rotor, caliper and any other component that was removed.

If you follow these steps and use the basic equipment like a ballbearing puller, struts, sockets, and screwdrivers, you will be able to replace a wheel bearing and get your car back to its original condition. Also, do not forget to use some safety equipment like gloves, goggles, and appropriate clothes for the specific task at hand.

With consideration to safety measures of the user and the process involved in the replacement, step by step this process becomes self explanatory and allows one to carry out the procedure of wheel bearing replacement easily and effectively.

Important considerations before you replace the wheel

I have in mind the following considerations before undertaking the task of wheel bearing replacement:

- Inspect for Signs of Wheel Bearing Failure: Now before we even get to the replacement, allow me to point out what signs of a wheel bearing fault looks like. Unusual sounds (especially grinding and humming), vibration in the wheel and improper wear of the tires are signs to look out for. It is important to recognize that these issues will help in proving that the problem indeed stems from a faulty wheel bearing.

- Observe Safety Precautions: Make it a goal to wear appropriate protective equipment like gloves, safety glass and appropriate clothing that will enhance your general safety. In addition, you should put your car at a flat surface and pull the parking brake to stop any unwarranted movement.

- Prepare the Necessary Tools and Parts: Have all the gear ready and in hand, it would consist a battery powered wrench, a breaker bar, a number of sockets and screw drivers and other tools including a cotter pin puller. Besides, secure the right assembly as a replacement that fits the wheel bearing of the car you have.

- Refer to Manufacturer’s Instructions: Every car comes with a manufacturer’s outline, vehicle guide and a restoration textbook which can be accessed on the internet to provide detailed authority and torque values. Following the specified policies makes sure that all the processes go as planned and the change is a success.

Taking these factors into consideration, you will be ready to confidently approach the wheel bearing replacement process, thus ensuring that your vehicle works efficiently and safely.

What are the steps to replace a wheel bearing?

Bearing in mind the salient points, one can assume that a wheel bearing replacement strategy consists necessarily of several sequential techniques that fall below the threshold of perfect replacement. To this end, the following figures are intended to illustrate the critical stages of the entire bearing replacement operation:

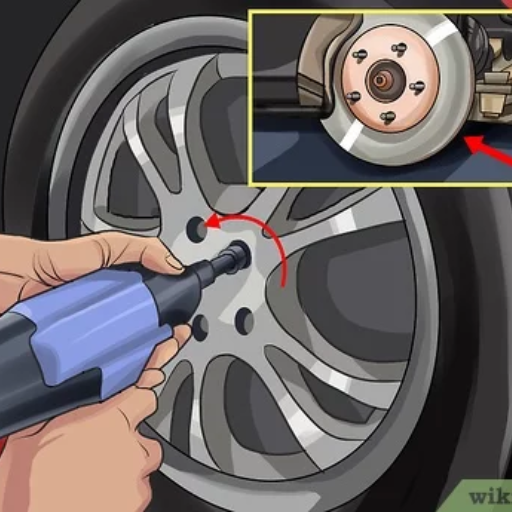

- Removing the Wheel and Axle Nut: Start off by raising the vehicle and removing the wheel and tire off the vehicle. Then with the use of the correct tools, detach the nut that secures the axle.

- Removing the Brake Caliper and Rotor: The next thing you need to do is detach the brake’s caliper as well as the rotor. Most of the time this requires unfastening the bolts of the caliper, removing the brake pads, and then the rotor from the hub.

- Extracting the Old Hub and Bearing Assembly: Now that the brakes have been removed, the next step is to remove the old hub and bearing assembly. Depending on the type of car you are in, this may necessitate the removal of other parts like the ABS ring or hub.

- Installing the New Bearing and Reassembling Components: The last step would be removing the old hub and the bearing assembly and placing the new bearing inside the hub, which most of the time requires proper placement so that the bearing fits perfectly. Lastly reassemble the required parts starting from the rotor, the brake caliper, and finish off with the axle nut.

Seek guidance from the manufacturer’s guidelines, review manuals, or Search online to get their insight on the specific requirements and the torque specifications. The steps provided in this outline are broadly aimed at accomplishing the defined tasks to ensure the successful replacement of the wheel bearing.

How to remove the wheel and axle nut

From the position of an industrial professional, the most critical stage for the spin bearing change is unscrewing the wheel axle nut. In this regard, let us briefly summarize the operative balance:

- Loosen the lug nuts:If you are only working on one side of the vehicle and do not need to lift it, it is recommended to first lift the vehicle securely on the jack before loosening degree wheels nuts. This will help in better unfastening the weld nuts when the vehicle is lifted off the ground.

- Lift the vehicle: Use a jack to raise your vehicle and firmly place it on jack stands. Check that the vehicle is at rest.

- Remove the wheel:Remove the slack and the nuts from the studs and use force to work the wheel off of the hub and set it aside. Keep the wheel safe in a secured area.

- Remove the axle nut: Find the axle nut at the wheel’s central area of the hub. Apply a reasonably sized socket and breaker bar to the nut in order to work it forced off. For instance, Sometimes a nut needs to be wound up quite a bit and therefore a resizable tool is necessary to wind it up.

The next steps will guide you on how to remove the wheel and axle nut thus enabling you to move on to other parts that require disassembling and changing of the wheel bearing. Make sure that you refer to the vehicle manufacturer’s specifications, or the repair manual, to obtain the specific details and torque settings for a proper replacement of the wheel bearing.

Steps to remove the brake caliper and rotor

I provide below clear and precise answers for the steps required in the disassembly of the brake caliper and rotor:

Firstly, park the vehicle on a flat surface and engage the wheel lock.

Preliminary step: loosen the lug nuts of the wheel, which are to be replaced but are not removed fully.

Make use of a jack in order to elevate the vehicle and insert the correct safety jack stands.

Remove the nuts and detach the wheel.

Search for the brake caliper which is secured by a pair of bolts or pinned into place.

Using the proper socket or wrench, remove the bolts or pins and gently pull the caliper away from the rotor. The caliper should be suspended by wire or bungee cord to avoid stressing the brake hose.

Once the caliper has been detached, the brake rotor is removed either by pulling it away from the wheel studs or by removing the retaining cotter screw where applicable.

In this manner, the brake caliper and rotor will be removed effectively, enabling the procedures in the other steps of the wheel bearing replacement procedure to be understood. Remember, when in doubt, always contact the specifications provided by your vehicle’s manufacturer or their repair manual.

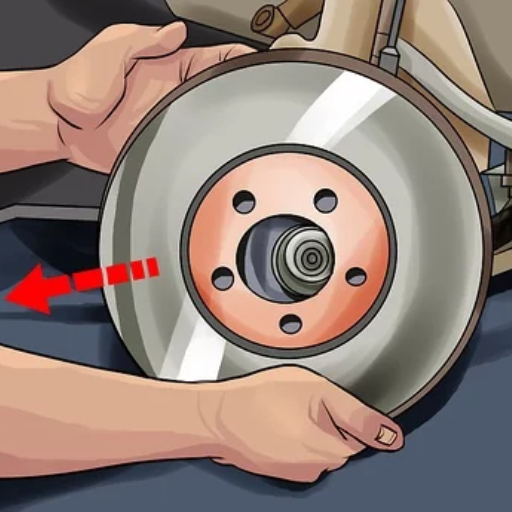

How to extract the old hub and bearing assembly

In your line of work, there are definite procedures to be followed so as to avoid pitfalls whenever removing the old hub and bearing assembly. As a start, the same subprocess as that indicated in the previous section, the brake caliper and brake rotor need to be detached before the components in question are removed. When these components are removed, removing the old hub and bearing assembly is done as follows:

- Remove the hub nut: The hub nut is the central bolt of the whole assembly, loosen and remove it with the appropriate size socket and breaker bar.

- Detach the brake disc: If the brake disc is not floating and has to be removed, you will have to remove the retaining screws with an appropriate screwdriver set, and now just slide the brake disc off the hub.

- Separate the hub from the knuckle: Sometimes the hub can get pressed into the knuckle, in that case use a suitable hub puller tool or a hydraulic press along with or instead to provide an equal force to separate it without hurting the knuckle.

- Remove the old bearing: The old bearing could be press fit into the hub and to remove that a bearing puller tool or a hammer with a drift punch that is suitable to that inner race will aid in taking out the old bearing from the hub without damaging the hub or other parts.

By following these steps, you can remove the old hub and bearing assembly in a safe manner which will in turn help during the replacement processes. Again, be more careful and look at the manufacturer instructions or repair manual of the vehicle, as these instructions may vary from make and model.

What tools do you need for a wheel bearing replacement?

In your case, work on the vehicle bearing replacement requires precision tightening which can be accomplished using a torque wrench and a breaker bar, selected proper sockets and screwdrivers for necessary components assembly and disassembly and extra devices such as cotter pin removers. While undertaking this task, these tools will help you replace your wheel bearing quickly thereby ensuring the vehicle’s reliability and performance.

Using a torque wrench and breaker bar

If you are a professional replacement of wheel bearings, I believe that you have the right tools for work. A wrench or barrel will ensure that specific components are tightened appropriately because these tools are very important for the operation and maintenance of the vehicle. With a torque wrench, you are able to provide the proper amount of force while tightening the fasteners; this means that there is no need to worry about over- or under-tightening the component. With life, there has to be challenge, and that is why because some bolts and nuts would rather refuse to move, a breaker bar is provided to give the person replacing the wheel bearing a better grip on those bolts or nuts. With the right tools, just completely rest your nerves, and you can take out the wheel bearing safely and with perfect accuracy.

Essential Sockets and Screwdrivers

clients always seek information on the tools required for a successful wheel bearing replacement. Furthermore, having said that, a torque wrench and a breaker bar are not sufficient, having a complete set of essential sockets and screw drivers is a must also. Such tools will enable you to securely and efficiently remove and replace components while conducting the replacement procedure of the wheel bearing. Some of the tools that one must include in their toolkit are:

- Sockets: One Never Knows One’s Needs, that is, the basic should include both metric and standard sockets in a variety of sizes and types so as to be capable to remove and tighten bolts and nuts. Always also carry deep and shallow sockets depending on the would-be access point.

- Screwdrivers: Different Fitting Tools that may include screwdrivers or other types will be paramount in removing and or installing screws or any other fastening devices, thus, a collection of flat-headed screw drivers and Phillips will be essential.

Essentially, the thoroughness of complimenting sockets and screwdrivers guarantees that the replacement of the wheel bearings will be both versatile and accurate.

Is replacing a wheel bearing a DIY project?

Even though some car aficionados may be capable of performing a wheel bearing replacement on their own, in most cases, this is a complicated and intricate task. There is no question that it requires an in-depth knowledge of mechanics as well as the proper tools. It involves pulling apart and putting together intricate parts, tightening to the right torque, and putting everything together in alignment. For individuals who are not confident in their mechanical skills, it is safer to seek the help of a skilled mechanic.

Skills required to replace a wheel bearing

Knowledge of car systems, experience in taking apart and putting together wheel parts, using tools efficiently and remembering the torque specifications are important for replacing a wheel bearing. Without these skills, the task cannot be raised including security issues.

When to consult a professional mechanic

If, however, you do not possess the required skill set, experience or the tools needed, it is recommended that you reach out to a professional mechanic for a wheel bearing replacement. Also, if you feelin confident at any point during the process or cannot pinpoint the cause of the wheel bearing malfunction, these professionals are trained to ensure that the entire task is performed accurately and in an efficient way.

Is replacing a wheel bearing a DIY project?

I can say with assurance that the question of whether replacing a wheel bearing is a DIY job has a precise answer. Even though some gearheads and seasoned DIY enthusiasts may wish to take on that job, it is worth mentioning that replacing a wheel bearing can be a complex process with the need for expert knowledge and tools. Hence, it is advisable to have the wheel bearing replacement done by a qualified mechanic so that the replacement is done correctly and professionally. Such an endeavor would remove the risks and complications that might occur.

Skills Required to Replace a Wheel Bearing

Changing a wheel bearing is a relatively complicated task, so it requires a certain level of knowledge and skills. Below are the major skills and knowledge required in wheel bearing replacement:

- Mechanical Aptitude: Wheel bearing replacement cannot be completely understood without sufficient knowledge of the vehicle’s mechanical working and parts.

- Diagnostic Skills: It is equally important to have competence in diagnosing faulty wheel bearings, approaching the problem in the right defined steps which include dealing with unusual noise, wheel vibration, or numerous tire wears.

- Technical Knowledge:It is essential to know and understand the cross-referenced vehicle bearing system and the standard degree of the procedures used during disassembly and later during the installation phase. This also encompasses the torquing requirements, places of fit, and tools required for the process.

- Safety Awareness: Working on heavy vehicle parts requires a mind towards safety first. Understanding how to follow safety steps like jack stands, lockout/tag out, and wearing safety equipment is vitally important.

- Specialized Tools: Wheel bearing replacement is often associated with certain tools, including bearing pullers, presses, torque wrenches, and many more. But correct use of such tools is of critical importance to ensure smooth efficient and safer replacement of wheel bearings.

Although skilled DIYers may be able to carry out the replacement of a wheel bearing, the best course of action is to take the vehicle to a professional mechanic since wheel bearings are precision parts. Their knowledge and specialized equipment will make sure that the replacement process will have the least amount of risks and complications, if any at all.

When to consult a professional mechanic

It is vital to understand when to contact a professional for the replacement of wheel bearings, which is part of the duties of an industry expert. There are specific sets of tasks that a skilled professional is better suited for, even though seasoned do-it-yourselfers are able to perform these tasks. The following are some scenarios where help from professionals should be solicited:

- Lack of Experience:In the cases where automotive repairs knowledge is not available, it is wise to get assistance from a pro. Replacing a wheel bearing entails several steps and the use of specialized tools and an expert will ensure that it is done correctly.

- Complex Repairs:Most people in such a case will want to seek support from a professional as in such cases where an ABS sensor which might be integrated in the wheel bearings might have become faulty, making the repair a little complicated. They have the skills that assist in such cases while ensuring that there are fewer complications during the repairing sessions.

- Warranty Considerations:To ensure that certain warranties are not breached, one might need to get the bearing done by an authorized specialist if their vehicle is still under warranty. This, however, does depend on a person’s warranty terms and conditions and such issues should be cleared up prior to any DIY attempts.

- Safety Concerns: At all times, keep in mind that while working on automotive elements, safety is very important. General safety practices, presence of proper tools or personal safety may seem like not enough justification in a person’s opinion for engaging a professional but it’s the right thing to do so. The qualified person has sufficient knowledge to prevent any unwanted injuries to both himself or your car by adopting the required measures.

With an insight into this, it makes it easier to decide whether one can go ahead with the wheel bearing replacement themselves or hire a trained mechanic.

What are the costs associated with wheel bearing replacement?

allow us to turn our attention to the expenses involved with replacing a wheel bearing. A cross-section of the wheel bearing replacement process indicates that typically, the total expenditure will comprise the cost of parts as well as labor. They’re all the more providing a summary to orient you with the budgeting:

- Cost of Parts: New Hub and Bearing Assembly:

- The total cost of the parts needed for a wheel bearing replacement can differ from one make and model to another as well as from brand to brand and quality to quality. The average cost of newer wheels hub bearing assembly is from one hundred to five hundred dollars per wheel or this includes both parts.

- Labor Costs and Time Estimates:

- The labor costs for a wheel bearing replacement will also vary, and it will depend on the primary labor rates of the repair shop or mechanic that you decide to visit. In general, the man-hour required for a wheel bearing replacement ranges from 1 to 2 hours per wheel. Labor costs are considered fixed, but they always depend on the scope and complexity of work and the location of a certified mechanic.

- Comparing DIY versus Professional Service:

- In such circumstances, you will or will not incur labor expenses, but you may have to take into account the time and effort needed to accomplish the work as well as possibly possessing special tools. Professional service covers all the pain angles and the replacement is done the right way and in the right time. As always, professional labor prices will differ based on the shop or mechanic you choose.

It should be undertaken that the provided estimates for the cost do not necessarily constitute the definitive cost of replacement and may change depending on factors. For an accurate estimate that is tailored to the kind of vehicle or area, a reliable repair shop prior to commencement is to be consulted. They will be in position to explain in details, how much it will cost to have the wheel bearings changed.

Cost of parts: new hub and bearing assembly

we can go ahead and move on to the parts and costs associated with wheel bearing replacement. The parts’ prices, however, will depend on several reasons, such as the car you are driving, quality, and the place you are buying them from. As a rule of thumb, a new hub and bearing assembly can set a person back in the range of $100 to $300. One should always remember that these prices are just estimates, and there may be other costs. To obtain precise quoting specific to your vehicle, their services retain a qualified mechanic or some sort of workshop.

For now, we shall also consider the labor and the time required to carry out a wheel bearing replacement. The cost of labor is certainly going to change in this case depending on where one is located, the mechanic’s experience and the shop one selects. About time estimation, however, it is estimated that one could carry out a wheel bearing replacement within 1-3 hours. These are, however, different estimates, but neither is the situation that cuts across all of them.

In the next sections, we look at both DIY and professional service options for a wheel bearing replacement. If you decide to do the work yourself, you stand to make certain savings in regard to labor costs. Even so, the cost in terms of time, effort and special tools needed for the job has to be weighed. Alternatively, if a service is hired, you are assured that the replacement is going to be done properly and that peace of mind is guaranteed. However, the charges for professional work will differ depending on the particular shop or mechanic that you decide to work with.

Of importance to note is that the information given here is used as a general guide for the costs of wheel bearing replacement and may not be the actual figures for your case. To get a more precise approximation suited for your vehicle and region, it is best to get in touch with a local mechanic or auto repair service. They will assist in explaining what items come into play and their respective costs involved in a wheel bearing replacement.

Labor costs and time estimates

let us give you a brief clarity on the issue regarding labor costs and the time needed for the work on replacing the wheel bearings. Labor rates may bear variations due to various factors, such as the kind of vehicle being worked on, the location of the workshop, and the specialist’s experience. In most cases, a wheel bearing replacement would cost not less than $150 and not more than $300 per wheel as labor. Do bear in mind this is a rough estimate, and the true cost could differ.

Professional estimates have noted that a proficient mechanic with experience in replacing wheel bearings should be able to carry the work out within a period of one to two hours for each wheel. It’s important, though, for mechanics to remember this is an average number, and there are a number of factors that will change this, including but not limited to the condition of the wheel bearing that is being replaced and extra issues that make the task more complex than it was expected to be.

Sometimes, the decision may be between doing it on your own and hiring a professional. In such a scenario, don’t only think about the costs but also things like your skill and knowledge on the subject, the availability of tools, and the difficulty level of the workaround. Even though doing the entire replacement by oneself can save some money that is paid out to a worker, one has to be fully aware of the amount of time that the process will consume, the force it will require, and the fact that some tools are necessary. When hiring a professional, one is sure that the replacement will be done right and on time, so one doesn’t have to worry.

In this case the cost of service is provided just for the purpose of getting an idea and will differ from actual figures and time taken. If you require a more precise estimation related to your case, it is recommended to contact a garage or a workshop that specializes in this matter. They will be in a position to tell you the entire expenses eye for wheel bearing replacement for your car as well as the area you are located.

Comparing DIY versus professional service

In terms of the industry perspective, and taking into account the professional approach and DIY approach in replacing wheel bearings, there are several aspects to focus on.

1. Level of Experience and Expertise:

- DIY Approach:People with the right skills, tools and experience may try and replace the wheel bearings on their own.

- Professional Service: In this service, the replacement is in the hands of professionals who have the know-how and skill to perform the various repairs. They have the special tools and the diagnostic hardware and technical help which goes with it.

2. Time and Effort:

- DIY Approach: Although this is a fairly simple thing to do, replacing the wheel bearing is a process that is bound to take some time for the average individual. It involves following step-by-step directions, having the right tools on hand, and spending a few or maybe even a couple of days finishing the job.

- Professional Service: When you select this option, however, you will conserve not just effort but also time. Because trained mechanics know how the wheel bearing replacement is done, they will do it quickly, reducing the time your vehicle occupies the repair shop.

3. Cost Considerations:

- DIY Approach: If you want to make some savings in terms of labor costs and perform the replacement on your own, that is also an option. In doing so, however, one is also required to consider the outlay of special tools, other parts or materials which may be required, and the potential dangers of mistakes which can lead to additional damage and costs.

- Professional Service: Yes since a professional service will involve some cost in terms of labor, many people still prefer this option due to the additional advantages like warranty of parts and labor, assurance that the job will be done once and in the proper manner and the added convenience of leaving the repair to the professionals.

In the end, the choice is all yours regarding whether to do it yourself or hire professionals. However, consider your level of skill, your availability of the right tools, the intricacy of the repair, and your own convenience. We all just need to assess these particulars and take the one that fits out best out of all the options available to us.

Reference

- How to Change Wheel Bearings: 12 Steps (with Pictures) – WikiHow

- DIY Guide: How to Replace Your Car’s Wheel Bearings – Goodhood

- How to replace a Wheel Bearing – NSK

Frequently Asked Questions (FAQs)

Q: What are the signs that you need to replace a wheel bearing?

A: Common signs that you need to replace a wheel bearing include unusual noises such as humming or grinding coming from the wheel area, uneven tire wear, and vibrations while driving. If you notice any of these symptoms, it may be time to inspect your front or rear wheel bearings.

Q: Can replacing a wheel bearing be a DIY project?

A: Yes, replacing a wheel bearing can be a DIY project if you have the necessary tools and mechanical skills. However, it’s important to follow a comprehensive guide and take all safety precautions, as working on vehicles involves tasks like removing the wheel and handling the bearing hub assembly.

Q: What tools are needed to change a wheel bearing?

A: To change a wheel bearing, you will need a jack to lift the wheel, a lug wrench, a socket set, a torque wrench, and possibly a bearing puller. You may also need specific tools to address the control arm, tie rod, and ball joint, depending on your vehicle’s design.

Q: How do you replace front wheel bearings?

A: To replace front wheel bearings, you need to remove the wheel, disconnect the brake caliper and rotor, and then remove the bearing hub. After removing the outer bearing, you can replace the hub with new bearings and reassemble the wheel components in reverse order. Always refer to your vehicle’s manual for specific instructions.

Q: What is the process to remove the bearing hub assembly?

A: To remove the bearing hub assembly, first lift the wheel and secure the vehicle. Remove the wheel, brake caliper, and rotor. Then, detach any bolts or clips holding the bearing hub assembly in place. Once removed, you can replace the hub and bearings as needed.

Q: What precautions should be taken when working on the front wheel bearing?

A: Ensure the vehicle is securely supported before lifting the wheel. Use proper safety gear and tools, and be cautious when handling heavy components like the strut and control arm. Follow all instructions carefully and consider factors beyond the control of your expertise, as mentioned in guidelines like those from ChrisFix, to avoid any hazards.

Q: How do you check for bad wheel bearings in a rear wheel drive vehicle?

A: To check for bad wheel bearings in a rear wheel drive vehicle, listen for unusual noises while driving, check for play by rocking the wheel back and forth, and inspect for uneven tire wear. If any issues are detected, you may need to replace the rear wheel bearings.

Q: What should you do after replacing a wheel bearing?

A: After replacing a wheel bearing, ensure all components are securely reassembled. Lower the car safely, double-check torque specifications on bolts and nuts, and test drive the vehicle to ensure the problem is resolved. If any issues persist, consult a professional for further auto repair assistance.

Q: Why is it important to replace the dust cap after changing a wheel bearing?

A: Replacing the dust cap is important because it protects the new bearing from dirt, debris, and moisture, which can cause premature wear and damage. Ensure the dust cap is properly seated after reassembling the wheel to maintain the longevity of the new bearing.