Greetings and welcome to our detailed handout named ‘Discovering the Phenomenon that is Roller Bearings and Their Usage’! In this fascinating article, we will take a look at the rather complicated world of roller bearings, focusing on their classification, operational processes, and even how they are used in various fields of technology. Barrel or roller bearings are critical parts for good and optimal movement by bearing and minimizing friction between the vast number of mechanical devices. Ranging from industrial machinery to automotive applications, roller bearings are essential in terms of performance enhancement, reliability, and durability. The aim of this blog is to demystify the functional principles of roller bearings and to review the range of roller applications that make them one of the most popular and used bearings. Let’s go!

What Are Roller Bearings and How Do They Work?

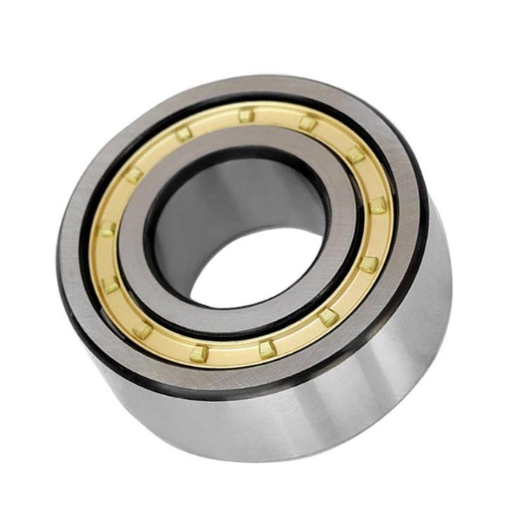

Due to their design as mechanical elements aimed at reducing friction and thus enabling smooth motion in an effortless and efficient manner, roller bearings are considered industry specialists. They are composed of an inner ring, an outer ring structure, and rolling elements that are placed between the two rings. These rolling elements may be composed of cylindrical, tapered, spherical, or needle-shaped rollers, which enable the bearing to sustain both radial and axial loads. The combination of the inner and the outer rings forms a raceway where the rolling elements are situated and spin while bearing the load. This innovative configuration enables great weight-thrust tolerance and excellent working precision in roller bearings. From industrial machinery applications to automotive components, roller bearings facilitate the motion of parts, increase efficiency, save on energy loss as well as extend the possible use of mechanical systems.

Understanding the Rolling Element

I start off by noting that a rolling element is an important component of roller bearings in terms of the functions and benefits it provides. The rolling element is the part of a rotary bearing that aids in reducing friction to enable smoother motion. It usually appears as cylindrical, hockey stick, spherical, or needle-shaped elements depending on the type of roller bearing in use. These rolling elements are specially configured to bear the axial loads between the inner and the outer rings so that the bearing can be loaded adequately but also allow for reasonably accurate movement of the parts over a large period of time. This nearly means that roller bearings help to improve performance, reduce waste of energy, and increase the life of mechanical systems in lots of industries, such as industrial plants and car parts. Okay, now let’s go further and study the composition and structure of inner and outer rings and the working mechanisms of roller bearings.

The Inner and Outer Ring Structure

My expertise permits me to provide a brief analysis of the inner and outer ring structure of roller bearings from a first-hand perspective. Inner and outer rings have to be highlighted in roller bearings as they are responsible for supporting and allowing the bearing to be loaded successfully and efficiently. Usually, the inner ring is bolted to the shaft which moves while the outer ring is in a fixed position. Taken together, both parts create a cylindrical space within which the shaft rotates while keeping the rollers in place. With this configuration, appropriate load transfer is achieved with less friction, making the mechanical systems more effective. The application of roller bearings may be witnessed in a wide range of industries as they reduce friction and allow for smoother functioning of the equipment and other parts of different machinery and vehicles, leading to their longer useful life.

How Roller Bearings Provide Support

You may note that, with regard to various mechanical systems, roller bearings offer crucial aid. Roller bearings are elements intended to make use of and transmit a load through the rotation of a shaft or an axle, thus reducing friction. Roller bearings contain a set of cylindrical, tapered, spherical, or needle-shaped rollers that are arranged in a circular pattern, with the rolls maintained in position relative to one another. This particular structural arrangement provides more efficient load bearing, minimizes wear and tear, and improves the performance of mechanical systems in general. Aiding the functioning of industrial machines, automotive parts, or high-speed devices, roller bearings afford support, reduce friction, and improve the reliability and service life of a variety of key parts.

What Are the Different Types of Roller Bearings?

let’s explore the different types of roller bearings that are widely used in various mechanical systems. These bearings are essential for providing reliable support, reducing friction, and extending the lifespan of critical components. Here are the main types of roller bearings:

Cylindrical Roller Bearings

Cylindrical roller bearings are able to bear certain area restrictions as they have relatively greater radial load bearing capacity. Incorporating them into designs is no problem as they have shock resistant rollers arranged in the shape of a cylinder and are able to support single directional axial loads.

Taper Roller Bearings

Taper roller bearings are made such that they support both the radial and axial loads. They include having inner and outer ring raceways that are in a conical shape thus facilitating the transfer of great amounts of radial and also axial loads. Taper roller bearings find use in car industry and also in large machines.

Spherical roller bearings can be used to support heavy radial loads and a considerable amount of misalignment. They consist of barrel shaped rollers and are able to handle both radial and axial loads. Applications which are likely to suffer shaft deflections or misalignment usually employ spherical roller bearings.

Needle roller bearings belong to the family of small-sized bearings which are space saving and also provide a high load-bearing capacity despite their small cross-sectional area. They possess long, thin rollers which are best suited for narrow axial spaces and heavy radial load situations. Needle roller bearings find their application in automobile transmission assemblies and industrial machinery.

These different types of roller bearings cover a wide application range and are widely used in industrial machinery, automotive, and high-speed application sectors. Choosing the right type of roller bearing, the engineer or designer will guarantee to achieve reduced friction, proper load management, and higher efficiency of the mechanical assemblies.

Cylindrical Roller Bearings

Numerous industries employ cylindrical roller bearings, which are classified as rolling element bearings. These bearings not only have a considerable radial load-carrying capability but can also manage reasonably mild axial loads as well. Their very design consists of cylindrical rollers that are maintained in alignment by the inner and outer raceways, which in turn enhances effective load transfer while minimizing friction. In the automotive sector, cylindrical roller bearings are frequently employed in transmission units, industrial machinery as well as high-speed systems. Thanks to their versatility, durability, and heavy load handling capacity, they have become essential parts of the proper functioning of mechanical systems.

Exploring Taper Roller Bearings

Since you are familiar with the industry’s jargon, let us now turn our attention to taper roller bearings. These special bearings are capable of taking radial and axial loads simultaneously and,thus, are most suitable for applications where heavy thrust loads require support. Taper roller bearings are composed of conical inner and outer races, with tapered rollers, which are guided by the races. This configuration optimizes the distribution of the bearing load and minimizes friction, thus improving the efficiency and durability of the bearing. Tapered roller bearings are a type of bearing that is often used in vehicle transmissions, industrial machinery, and equipment that functions at high speeds. The importance of tapered roller bearings in operating mechanical systems’ smooth functioning cannot be overlooked. Their versatility, robustness, and ability to sustain heavy loads make them essential not only in certain specialized industries but all dynamic industries.

Spherical Roller Bearings

As a professional in the sector, allow us to appreciate the field of spherical bearings in detail. Due to their outstanding structure & construction, spherical roller bearings are of great help in systems that have to endure high levels of rotation and oscillation since they’re able to withstand a large amount of misalignment along with heavy radial and axial loads. The comprehensive design of spherical roller bearings provides some of the advantages that are suitable for the many different applications in which they are used. They are extensively fitted in automotive transmission, industrial applications, and high-speed devices for the purpose of smooth as well as efficient performance of mechanical systems. The heavy weight-carrying capacity, load-bearing efficiency, and friction-reduction characteristics of spherical roller bearings enhance their performance and longevity. They are also extremely durable, making them an important part of many moving industries.

Insights into Needle Roller Bearings

Interacting with clients that go beyond international borders in regard to reaping the benefits of needle roller bearings, I have always been impressed by their versatile capabilities and remarkable functionality in various applications. These custom-made bearings have their distinct advantages, which make them a requirement across various sectors. It is my pleasure to offer you a warm welcome to the tempting world of needle roller bearings and understand the role they play in the modern world market.

Industries that operate in automotive, industrial machinery, and high-speed equipment heavily rely on needle roller bearings as they are important parts of the machine that give it the desired motion. Bearings of this kind are well suited for industries that require a compact structure and precise control with the capability of withstanding heavy loads. The commendable performance characteristics and work in especially adverse operating conditions of the needle roller bearing arise from their ability to carry loads, support loads, and friction.

During my work, I remember that needle roller bearings have a special regard for their small size, due to their spaceturneo, they are able to bear great radial loads. This means that they are best used in applications with limited space, or when low components are required. Furthermore, needle roller bearings are also highly rigid and can operate at high speeds, thus expect to function in harsh conditions.

It is necessary for industrial professionals as well as engineers to know the uses and the beneficial features of the needle roller bearing. The subsequent sections will suggest the improvement of the load transfer and the durability of the rolling bearings with special focus on the industrial and automotive applications and how to select the most suited type of roller bearing while the purpose alsoaplicationspecific. Let’s start this journey and discover together the world of needle roller bearings.

How Are Roller Bearings Used in Various Industries?

My professional background compels me to frequently respond to questions related to the use of roller bearings in a variety of industries. The reason roller bearings are used in such a variety of applications across many industries is their adaptability and dependability. A few key sectors that depend on roller bearings are:

- Automotive Industry: Roller bearings are installed in an automotive application which includes wheel hubs, transmissions, engines, and suspension systems. They help in providing smooth and rotational movements and aid in increasing the functioning of the vehicle machinery.

- Industrial Machinery: Roller bearings are widely Applied in Industrial Machines like conveyor systems, pumps, gearboxes, and other rotating equipment. They aid in space management through controlling motion mechanisms, absorption of weight, and allowing for streamlined functioning in extreme circumstances.

- Aerospace and Aviation: Roller bearings find application in aircraft engines, landing gear systems, and control surfaces within the aerospace sector. Thanks to their design, roller bearings are capable of high rotations per minute, are bearing great loads, and tolerating very low and very high temperatures.

- Power Generation: In power generation, roller bearings are found to be applicable to turbines, generators, and wind turbines. They assist in minimal resistance while providing support in order for energy to be generated efficiently.

- Medical and Healthcare: In the medical field, roller bearings are installed in surgical instruments, scanners, and pumps. They enable precise movement,t which reduces sound and vibration everywhere. They are also made with satiny, clean, and sterile surfaces.

- Heavy Machinery and Construction: Rollers bearings serve a critical purpose in heavy machinery as well as construction and industrial equipment such as cranes, excavators, and loaders. They assist in carrying substantial weights and lend strength and endurance in harsh conditions.

Other aspects such as load capacity, operating speed, temperature, range, the presence of a lubricating substance as well as the environmental conditions should be taken into consideration when rolling bearings are to be employed on various industries. The maintenance and fitting of rolling bearings should also be done well to ensure that they function perfectly and last for long in that particular scope of operation.

Industrial Applications of Roller Bearings

The reliance on roller bearings is significant in several industries and is well understood by seasoned professionals in the industry. Heavy machinery and construction equipment, among them cranes, excavators, and loaders, use roller bearings to easily subject themselves to high pressures while remaining operable in a rough atmosphere. Such bearings provide superior solutions where large masses, accuracy, and dependability are required. Manufacturing, mining, agriculture, and transport, among other industries, use roller bearings where effectiveness, performance, and durability are of great importance. They are quite beneficial in maintaining smooth and efficient operations under harsh and demanding industrial environments.

Automotive Applications of Roller Bearings

Being in this industry, I have personally noticed how important is the use of roller bearings in automotive applications. These bearings are found in widespread use in diverse automotive components such as wheels, transmission, engine, and suspension systems. Their strong construction and features are perfect for surviving the tough conditions and loads that are common in the automotive sector.

In automobile wheels, the use of roller bearings contributes to the ease in rotation of the wheels enabling the vehicle to move. They are of low friction and possess a high load-bearing capacity which ensures effective use of power from the engine to the wheels. Furthermore, roller bearings assist in lowering fuel consumption and ensure the vehicle’s drive train lasts longer by decreasing wear and tear.

In the case of transmissions, roller bearings assist in enhancing effective shifts between gears while at the same time ensuring minimal noise and vibration. They offer a unity of effort and effective service by working as a considerable member in the power transmission line of the vehicle. Moreover, the use of roller bearings is also seen in engine components like camshafts and crankshafts where they enable the components to rotate while ensuring proper orientation is achieved.

Additionally, roller bearings are employed in suspension systems, where they increase the system’s stability, strength, and comfort. These bearings are crucial in shock and vibration damping in order to deliver smooth and controlled motions. Their capacity to withstand heavy weights and handle strenuous road conditions makes them essential in bolstering the effectiveness and robustness of the suspension systems in cars.

To sum up, roller bearings are used in various applications within the automotive sector, which enhances the efficiency, performance, and life span of automobiles. They provide the ability to manage large forces including load and control motion even in extreme conditions obtaining work in the automotive field.

Use in High-Speed Applications

To begin with, roller bearings are widely employed in a variety of high-speed applications on account of their efficiency and reliability. In essence, the benefits derived from the use of roller bearings in high-speed applications can be summarized as follows:

- Enhanced Speed Capability: The construction of roller bearings has the ability to withstand high-speed rotational velocities, which enhances the cut-through friction and thus allows for quicker movements. It is suitable for applications where fast is the most important.

- Efficient Load Management: Roller bearings are able to withstand tangential and axial loads evenly over the rolling element which inturn is helpful in creating an evenly distributed load across them. Such evenly distributed load assists in shielding against over stress and wear thereby enhancing the life expectancy of the components under high load and rapid rotation speed conditions.

- Superior Durability: Due to the tough structure combined with suitable materials and manufacturing precision of roller bearings enables them to be reliable. They are able to endure high speeds and output energy while put through excessive wear, fatigue and temperature.

In conclusion, it can be said that roller bearings can be employed in situations that require the bearing to have high speed. This is because they allow for high-speed operations, they assist in distributing the weight, and they are extremely durable. If you wish for your high-speed devices to operate effectively and have a long service life, you need to select the right type of roller bearing for your requirements, handle lubrication appropriately, and perform regular maintenance.

What Are the Advantages of Using Roller Bearings?

roller bearings provide an array of advantages depending on the application. Some of the most prominent advantages of roller bearings are discussed below:

- Enhanced Speed Capability: The construction of roller bearings is such that they can operate at greater speeds which makes them useful for areas that require rotation at high angles. Minimal heat wastage and low friction characteristic allow for hassle free operations at greater speeds ensuring maximum performance.

- Efficient Load Management: Roller bearings are quite efficient when it comes to accommodating larger loads while ensuring that there is a load that is uniformly spread across the surfaces of the bearing. The design and geometry are such that they can carry a decent load thus reducing the load applied on the machines hence improving the system.

- Superior Durability: One of the key characteristics of roller bearings is their ability to withstand harsh environments and to outlast most components in that environment. They are able to endure harsh conditions, such as operations at high speeds, because of the nature of the materials used and how the bearings are made. They also have a lot of resistance to erosion, fatigue, and even temperature, which allows them to work in difficult operating conditions.

Exploiting these facts, it can be argued that roller bearings increase efficiency and reliability and provide longer service life in high-speed systems. The choice of the appropriate type of roller bearing in line with the specific requirement and the necessary maintenance or proper lubrication further enhances their applicability and guarantees problem-free operation.

Benefits of Roller Bearings in Load Management

the drawbacks of load-bearing roller bearings are outweighed by the advantages. Let me put it concisely as to why roller bearings are essential in load-bearing operations:

- High Load Capacity: Flat and cylindrical surfaces are in contact in roller bearings. These bearings possess an ability to support heavy machines and equipment. They possess the ability to carry any heavy load thus are able to support machinery. With their unique roller designs the load in these machines is spread over a larger distance reducing stress and wear of the machine.

- Reduced Friction and Energy Loss: Designed to operate under minimal losses of energy and friction, roller bearings present true load management. This feature alone allows gears and other mechanical components to turn with ease, as friction caused during contact is reduced through the rolling movement of its internal components. Not only does this save energy, it improves the efficiency of the machine by increasing its life.

- Superior Rotational Speed: The bearings are expected to have superior performance when put in a high speed application due to their stable structure, and smooth rolling action. Such applications are crucial as they encompass rapid movement and rotation thus needing fast and precise components which the bearings are able to provide. In layman terms, bearings will not fail at excessive spinning.

- Reliable Performance and Longevity: In simple terms, roller bearings last a long time. Tthe components of these bearings are specifically constructed with advanced materials aimed at providing outstanding protection against friction, thermal exposure, and other forms of damage and fatigue, while accurate manufacturing tolerances guarantee optimized performance. This enables reliability in high speed systems even when working under extreme environments.

For that reason, roller bearings are load-carrying elements that guarantee optimal performance of the machines and equipment.

Why Roller Bearings Offer Durability

While working with roller bearings, it will be noticed that these are quite strong in their construction and have a specific design philosophy. The pointers below summarize the reasons why roller bearings are considered to perform well and for an extended duration:

- Load Distribution: Roller bearings are well known for their load being spread over a wider surface area, which decreases the degree of stress and contact surfaces and minimizes the wear of the parts. Dewearing is amongst best practices that enhances load distribution which in turn, improves chances of averting early onset dysfunction and increasing the duration the part can function.

- Enhanced Load Capacity: Other categories of bearings possess a reduced load bearing strength as opposed to roller bearings. Thanks to the strength of the design of the rollers, greater weight can be applied with no performance detriment to the roller.

- Resistance to Friction and Wear: Friction and wear from the rolling elements and the raceways are properly managed in roller bearings. The major rolling motion aids in minimizing frictional forces, thus resulting in lesser wear and tear and an enhancement in the usable life of the bearing.

- High-Quality Materials and Manufacturing: Roller bearings enjoy long life due to the materials that are used in their construction and the processes that are employed to manufacture them. Careful detail, such as roller bearing manufacturing, enables bearings to function under difficult working environments which involve temperature, shock, vibration and other forms of contamination without losing durability.

Thanks to the efficient load distribution capabilities, greater load carrying capacity, friction and wear resistance, and also the use of reliable materials and manufacturing technology, roller bearings offer the required durability to be dependable and perform effectively for a long time in so many different types of applications.

How to Choose the Right Type of Roller Bearing for Your Needs?

Choosing the right type of roller bearing for your needs requires careful consideration of various factors, as you see for yourself that this is an evolving industry. To help you with this, I will offer a short answer.

- Understand Your Application Requirements: The first step in this process is to assess the requirements of your application in detail. For instance load capacity, speed, temperature and environment will determine the type of roller bearing which best suits your application.

- Evaluate the Operating Conditions:Find out the operating conditions under which the roller bearing is to be used. Such aspects as axial and radial loads, shock and vibration and dirt or moisture must be considered. This evaluation will assist you to determine the most effective bearing design and materials suitable for your application.

- Consider Bearing Precision and Tolerance: In some cases, depending on your application needs, you may be forced to decide whether to use standard roll bearings or precision roller bearings. Precision bearings are used in applications that require narrow tolerances and higher accuracy, thus enhancing smooth operations of the machine.

- Consult with Bearing Manufacturers and Suppliers: One of the best ways to select the best roller bearing for your application is to contact reputable manufacturers or suppliers of bearings. They will provide you with their bearings while aiming at a correct match with the application as per their experience and knowledge of the industries and applications.

With an insight into your application specifications, the study of the environment, an evaluation of the desired accuracy and tolerance, and engaging an expert’s opinion, the time has come to make a sensible choice and select a type of roller bearing whose performance and reliability is exactly suited to your requirements.

Understanding Application Requirements

knowledge of the application specifics is your top priority in gaining the appropriate roller bearings. Here are a few questions you could raise:

- Load Capacity: You need to ask yourself: what is the net expected load that the bearing would be called to support? Determining the load capacity requirement would aid at defining the size and the type of roller bearing that could sustain the loads applied.

- Speed and Operating Conditions: What are the features of the application in terms of speed, temperature, and other environmental conditions? Given the fact that different types of roller bearings have their own operational conditions in which they are designed and built to suit, it becomes imperative to select the right type that performs as needed under the given conditions.

- Precision and Tolerance: Quite how accurate and round the bearing needs to be for the application in question. According to the accuracy and smoothing requirements, you may consider using standard or precision roller bearings. More specifically, precision ones have very narrow tolerances and tight fits thus ensuring high accuracy which is needed for applications where there is demanding need for precision and smooth operation of devices etc.

- Consult with Bearing Manufacturers and Suppliers: Make sure to consult good bearing manufacturers or suppliers who will be able to assist and support you in making the right decision in selecting the appropriate roller bearing that suits your application better. They can support you with valuable information based on their experience and understanding of particular industries and applications.

Choosing the right type of roller bearing for your application is vital. It’s all about thoroughly understanding your application requirements, evaluating the operational conditions, taking into account precision and tolerance, an,d of course, seeking expert advice. And in the end, such an approach will ensure that the roller bearing you select will perform optimally and reliably as per your requirements.

Factors Influencing Roller Bearing Selection

In my capacity as an industry expert, it is clear that there is a range of crucial aspects that should influence a choice of a specific roller bearing for the respective application. These factors will help guarantee the best performance and reliability. Here are the most important techniques to use:

- Load Capacity: When selecting a bearing, one must first consider the extent and direction of the force it will be subjected to, especially when in use. A roller bearing which is selected should match the load requirements in order to avoid premature failure and working efficiently.

- Speed and Temperature: The speed of rotation and the temperature of the application must be noted. The extremes in both parameters mentioned can adversely affect the performance or useful life of the bearing. Use a roller bearing with appropriate thermal and rotating features to perform at peak efficiency.

- Environment and Contamination: Assess the operating environment for potential contaminants such as dust, water, chemicals, or significant moisture content. Appropriate stepping bearing seals or shields would prevent entry of such contaminants augmenting the dependability of the bearing and its life.

- Space Constraints: Space allocated for the bearing in the application must be taken into account round roller bearing has an ergonomic design but is restricted by vertical length. It must be ensured that all parts of the selected roller bearing’s form, dimensions and working angles fit in the designated space without disrupting other parts.

- Maintenance and Lubrication: Assess the maintenance schedule and lubrication means available for the roller bearing. Some bearings may need to be attended to on a schedule while others do not need such service. Also, from the inception, lubrication to the bearing is important in order to reduce friction and avoid the bearing’s damage. Go for a bearing that fits in with your maintenance and lubrication plans.’

The application’s requirements can be met best if these factors are taken into account while choosing a suitable roller bearing. A good performance, as well as reliability and longevity of the equipment are ensured. Make sure to talk with bearing manufacturers or suppliers for guidance specific to your needs.

Reference

- TRITAN Bearings: Your Trusted Source for Quality Roller Bearings – A comprehensive guide on choosing the right roller bearings.

- Roller Bearing Types: Engineering Reliability and Efficiency – An informative article on different types of roller bearings and their engineering applications.

- Investigation of the Possible Applications for Microtextured Surfaces in Bearings – A scholarly article discussing innovative applications for roller bearings.

Frequently Asked Questions (FAQs)

Q: What are roller bearings, and how do they function?

A: Roller bearings are mechanical components used to reduce friction between moving parts, allowing for smooth rotation or linear movement. They work by using cylindrical, spherical, or tapered rollers within the bearing, which helps distribute loads evenly and reduces wear and tear.

Q: What are the main types of roller bearings?

A: Roller bearings come in various types, including cylindrical bearings, spherical bearings, tapered roller bearings, and needle roller bearings. Each type is designed for specific applications and industries, depending on load capacity and speed requirements.

Q: How do ball bearings differ from roller bearings?

A: Ball bearings use spherical balls to maintain the separation between bearing races, while roller bearings use cylindrical or tapered rollers. Ball bearings are ideal for applications with lower load capacities and higher speeds, whereas roller bearings can support heavier loads and are used in a wide range of applications.

Q: What are roller thrust bearings,s and where are they used?

A: Roller thrust bearings are designed to handle axial loads or loads parallel to the axis of rotation. They are used in a wide range of applications where high axial load capacity is needed, such as automotive transmissions and industrial machinery.

Q: What are cylindrical roller thrust bearings?

A: Cylindrical roller thrust bearings are a type of roller thrust bearing that uses cylindrical rollers to support axial loads. These bearings are suitable for applications requiring high load capacity and are also used in heavy machinery and gearboxes.

Q: How do needle roller thrust bearings work?

A: Needle roller thrust bearings use long, thin cylindrical rollers to handle axial loads. This design allows them to support high load capacities while maintaining a low profile, making them ideal for applications where space is limited.

Q: In what applications are roller bearings commonly used?

A: Roller bearings are used in a wide range of applications, including automotive axles, industrial machinery, conveyor systems, and aerospace components. Their ability to handle both radial and thrust loads makes them versatile for different applications.

Q: What factors should be considered when selecting roller bearings for a specific application?

A: When selecting roller bearings, consider factors such as load capacity, speed, temperature, environment, and space constraints. The selection of roller bearings should match the specific needs of the application to ensure optimal performance and longevity.

Q: Are tapered roller bearings similar to other roller bearings?

A: Tapered roller bearings are similar to other roller bearings in that they use rollers to reduce friction. However, they are uniquely designed with conical rollers and races, allowing them to handle both radial and thrust loads, making them ideal for applications like vehicle wheel hubs.