The bearings from older machines, while being second-hand, may not seem to be essential in machinery and functional systems, but their possibilities ought not to be disregarded. This guide seeks to assist readers with bearing insight and point out how these bearings are quite useful, sustainable, and inexpensive. Whether you’re a seasoned engineer, an entrepreneur in need of affordable options, or simply inquisitive about refurbished machine parts, this article will serve as a guide for you. You will be able to see for yourself why second-hand bearings are a cost-effective, resourceful choice in the industrial world today, starting with how second-hand bearings are repaired and remanufactured and what their myriad uses are.

What are second-hand bearings, and why should I consider them?

Bearings that have been refurbished and inspected carefully in view of the fact that they are pre-used can be used in place of new bearings and even have comparable performance. This not only sustains the lifecycle of materials but also reduces waste, which is cost-effective in the long run because it minimizes lead times. This cost-effectiveness makes them reliable and eco-friendly.

Understanding the concept of second-hand bearings

As far as second-hand bearings are concerned, I am sure that they go a long way in helping companies save costs while at the same time setting their sustainability goals. If procured from suppliers, such bearings are checked and repurposed. In doing so, companies save on operational expenditures while remaining good stewards. It is all about being thoughtful and making decisions that are good for the economy and the environment.

Benefits of choosing second-hand bearings over new ones

Bearings that are purchased or used by someone else have their benefits, such as being priced quite cheaper than anew and are quite environmental friendly, such bearings can be delivered to a customer within shorter periods of time as well. Most second-hand bearings have been refurbished and have had comprehensive quality evaluations, making them work better than some new components and promoting sustainability by reducing waste and conserving resources.

Common applications for second-hand bearings

I can assure you having a capacious, experienced approach, there is vast applicability of second-hand bearings, particularly where trust, economy, and quick availability are concerned. Roast a chicken with its ribs using a slow cooking method; the following are some typical applications segmented by such needs and parameters:

- Industrial Machinery

Used bearings are widely found in industrial machinery such as conveyor systems, pumps, compressors, and heavy-duty gearboxes. Most of these items wear out and, therefore, need parts that are cost-effective and easily accessible to reduce their downtime. Reconditioned bearings can be affordable as they offer great performance as compared to brand-new ones.

- Agricultural Equipment

Farm implements such as tractors, plows, and harvesters are some of those tools that use second-hand bearing blankets quite often. The application of these bearings is their strength, as they can work under harsh environments, which include dirt, moisture, and varying loads. Farmers are the end users of these reconditioned bearings as they are economical and viable, especially when farming on a large scale.

- Mining and Quarrying

When they are not on, mining or quarrying may be one of the most volatile environments; everything is literally covered with dust, and the loads and equipment are constantly vibrating. The components of the equipment, such as crushers, conveyor belts, and loaders, are equipped with bearings, which are among the most used parts in this industry. For best results, refurbished second-hand bearings can be used in this kind of environment.

- Renewable Energy Systems

Certain parts of wind and water turbines, like nacelles and gearboxes, are steadily adopting the use of refurbished bearings. This not only helps in working towards environmental consciousness in the energy sector but also aids in the transition to a circular economy.

- Automotive and Transportation

Used bearings are utilized for vehicle fleet maintenance and repairs in buses, trucks, as well as trains. Unitized and tested properly, these bearings assist in project longevity, which helps lower operating costs.

Every application mentioned here illustrates how secondhand bearings do better in terms of cost, life span, time sensitivity, and green impact. Cleaning and repairing these parts allows us to guarantee that they will not fail in hostile environments and, at the same time, promote eco-friendly policies across many sectors.

How do you find reliable suppliers of used bearings?

The quest for trustworthy suppliers for used bearings devices begins with extensive research and necessary checks. First, I advise giving preference to Suppliers with good refurbishment and quality assurance skills. Also, such Suppliers should openly disclose their quality inspection and testing procedures because this is usually a good indicator of their quality. Also, I have noticed that reliable suppliers who are members of relevant professional associations are usually of higher reliability standards. Personally, I am also inclined to trust referrals and reviews from other colleagues in the industry – such information may help me find reliable partners who manufacture quality products on an ongoing basis.

Key factors to consider when choosing a supplier

In this case, let’s suppose you need to choose a supplier. Focus on continuous quality control, timely delivery of goods, proper communication, reasonable prices, and well-known companies. As always, check the certificates and choose suppliers that complement your business principles and prospective goals.

Online platforms for sourcing second-hand bearings

To procure affordable bearings and explore online bearing marketplaces, it is imperative to utilize sites such as Alibaba or even eBay. These sites market heavily in second-hand industrial components while always allowing for customer reviews and ratings to influence what users purchase. BearingNet allows buyers and sellers to connect directly through their user-friendly interface. Make sure to always go through detailed product descriptions, check seller reputations, and reach out for information regarding specifications so that you don’t buy something that is entirely different. Fortunately for me, these platforms have made it significantly easier to meet my meetings.

What types of second-hand bearings are commonly available?

Second-hand bearings come in a variety of sizes and styles tailored to meet the requirements of any given industry. Certainly, I have had an opportunity to deal with many; the most popular ones are:

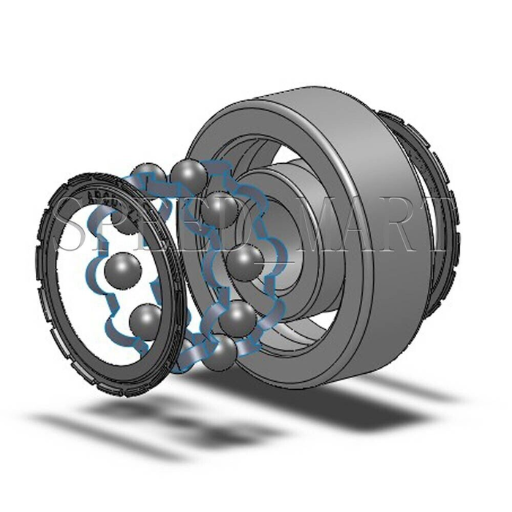

- Ball Bearings – Ball bearings usually have a reduction of friction in their applications and are capable of accepting both radial and axial loads, making them rather versatile. Due to their popularity in different industries, such as manufacturing and automotive, they tend to be customer structures, too.

- Roller Bearings -Another bearing type that is commonly used is roller bearings, as they are able to withstand heavy load conditions with ease. They come in numerous styles, such as cylindrical, tapered, and spherical bearings, which depend on the kind of load and alignment needed.

- Thrust Bearings -When needing axial load handling, thrust bearings are often the go-to type, and automotive and power transmission activities use them. When dealing with less crucial tasks, alternatively, use secondhand thrust bearings as an inexpensive option.

- Deep Groove Bearings – One of the most frequently seen pairs in the second-hand market is deep groove ball bearings. This can be attributed to the sheer simplicity of design paired with widespread use. The robustness proves helpful when purchasing them as a used item.

- Mounted Bearings – This structure is frequently sold with the housing already attached, and since these units are fitted with precision machines, they are relatively prevalent in the second-hand market, especially for agricultural and heavy machinery devices.

In the case of second-hand bearings, one needs to take into account the material, wear and tear, load capacity, operating speed, and lubrication conditions. Making sure that each of these parameters is suited for the application of the bearing will help enhance the machine’s performance and safety. Second-hand options are great if you are on a budget, however, thorough inspection and validation is of utmost importance!

Used ball bearings: Types and applications

In relation to the bearing balls, I believe it is important to understand the types and their respective application in order to make the right selection. For instance, there are deep grooves, angular contact, thrust, and self-aligning bearings, among others. Space in such a setting serves some purpose, and deep groove bearings are an excellent example, as they are adaptable and widely used in electric motors and household appliances. Angular contact bearings why perform extraordinarily well when combined loads are present; hence, these would suit pumps or gearboxes well, while thrust bearings are limited in use to axial loads and are mainly utilized in the automotive and aerospace industries. At the same time, self-aligning bearings find applications in such cases when the problem of misalignment is posed since these bearings automatically adapt to deflections of the shaft. Following this approach to the selection of bearings by their intended application, I have successfully maintained reliability and accuracy even with used parts.

Second-hand roller bearings: What you need to know

Bearings that have already been used should regularly be checked for wear, rust, and/or damage, as they can influence performance by a great margin, components should also be sourced from trusted businesses in order to prevent the risk of obtaining counterfit items. Maintaining lubricated, clean, and appropriately stored bearings is vital to ensure durability, and when sourced appropriately, used bearings can perform reliably and provide significant value. Always remember to assess the condition, maintenance history, and appeal of the bearing—the assembly of your second-hand roller bearing will always include these three aspects.

Exploring other types of used bearings in the market

As I mentioned previously, ball bearings have certain applications which limit usage and are sensitive to pitting. These used ball bearings are very often found in high-speed applications since they offer low friction, however, the surfaces need to be worn out otherwise we have a problem on our hands. Looking for viscosity and alignment in tapered roller bearings allows better tumbler control for the industrial mosaic. I have noticed that spherical bearings are also used for dirty environments provided the seals and housing don’t allow contaminants to penetrate and because self-aligning capability avoids tweaking to achieve alignment. Ultimately, working with reputable suppliers and conducting thorough evaluations ensure these used bearings serve as viable, cost-saving alternatives without sacrificing performance or safety.

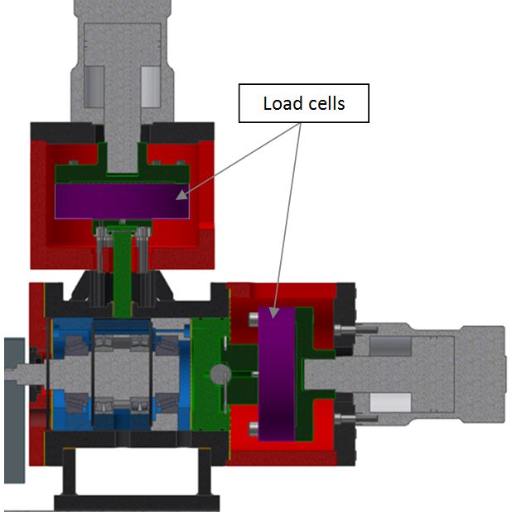

How can the quality and condition of second-hand bearings be assessed?

Inspect visually any scratches, corrosion, or damage to assess second-hand bearings’ quality. Assess rotation for abnormal movements such as grinding or rattling. More advanced measuring tools can be used to evaluate the bearings’ crucial characteristics according to manufacturer specifications. Non-damaging Tests such as ultrasonic or magnetic particle inspections can be utilized to identify defects within the bearing’s interior. Finally, if maintenance and operation documentation exists, review its content to ascertain whether the bearings installed in the machinery meet the required safety standards and performance specifications.

Visual inspection techniques for used bearings

While carrying out visual inspection of the used bearings I use a methodical and well-defined procedure in order to ensure that no aspect is neglected. To start off, I check the outer surfaces for signs or traces of wear, rust, and pitting, which may be symptomatic of other factors. Thereafter, I move on to the rolling elements and raceways while looking for scratches, indentations, or other indicators of spalling. Good lighting and sufficient optical power are valuable assets in this category, as they aid in spotting defects that are not so easy to see. I also check for tarnishing which may be an indication of overheating or contamination. As a result of continuous attention and reliability of the tools used, I avoid any imperfections before commencing any detailed examination or undertaking repairs.

Understanding bearing grading systems

An industrialist gets adequately qualified experts bearing the answers to frequently asked questions. A profound one I have noticed is the influence of bearing grading systems on performance and reliability. To put things simply, bearing grading is the group classification of bearings, categorizing them based on their precision and dimensional tolerances. To make sense of things, here’s a more straightforward view of how I approach these systems:

- Dimensional Accuracy – The manufacturing accuracy of a bearing is measured according to how closely its dimensions correspond to the specified values. Small numbers of differences are going to affect their fit and function, which is why this limits the dimensional deviations of the bearing with respect to the assembly parts.

- Rotational Accuracy – This is the degree to which the bearing is able to turn around its axis under load and the accuracy with which the bearing rotates. Bearings of a higher grade are more suited for rotational speeds; this is critical for high-speed devices.

- Load Capacity – With reference to the requirements, the ability of the bearing to support certain loads is usually indicated by its grade, including radial loads or axial loads. This is decisive information when employing bearings in heavy-duty operations or in high-duty applications.

- Surface Finish – The standard of the surface finish is also an aspect that gets graded which affects friction and wear and thus is an evaluative factor. Most of the time, padded surfaces are found on high-grade bearings to reduce energy loss and increase service life.

- Noise and Vibration – There has been a set of tests within which Super Precision Bearings have been assessed and graded with reference to noise and vibration. For ultra-precision devices, bearings are designed with high care so that they operate with lower noise and low vibration; such devices are suitable for sensitive equipment.

Chinese ISO and ABEC standards set bearing performance parameters that aim to maintain consistency and understanding, which is why grading systems are so important. Each parameter is vital and helps in selecting the best bearing for the job. Such considerations, in my opinion, are essential in increasing the efficiency and lifespan of a machine.

Red flags to watch out for when buying second-hand bearings

While purchasing used bearings, physical indicators like pitting, scratches, or color changes indicate abuse or improper lubrication, and would be regarded as key ‘warning bells’. Further examine that there are no signs of rust and corrosion, as they could potentially compromise the overall integrity of the bearing. Do ensure that the bearing is not too loose or wobbly, as this would indicate internal damage. Also, be sure to check that the bearing moves without any abnormal sounds, such as grinding, meaning debris or defects are present. Finally, check the specifications and markings that the manufacturer has put in place to ensure correct machinery compatibility.

What are the price considerations for second-hand bearings?

I try to find a balance between price selection and condition, considering the purchase price of used bearings. The more a bearing is worn out, the shorter its lifespan is—but in this case, if the bearing has been used quite little, it tends to be charged more for it. In addition, I take into account the brand and its model as well, for example spare parts for popular brands can still be expensive even if home appliances are entirely second-hand because they are well known. Another consideration is supply and demand, where sometimes the high cost of bearings is justified by the inability to purchase them from shops. Consulting tuning or remodeling services is the last aspect that will increase the price. However, I consider these modifications necessary. Ostensibly, these factors are sufficient to ensure that I get a good deal and simultaneously achieve the desired outcome within a set time frame.

Factors affecting the cost of used bearings

it can be concluded that there are several factors that determine used bearings price. Knowing these factors is useful for making appropriate purchases as well as assuring that performance alongside value is not sacrificed. These are the factors that I usually take into account:

- Brand Reputation

Renowned manufacturers generally produce high-quality bearings that are reliable and durable. This value also exists in the used market as buyers will highly value the brands for their quality. A brand name has a huge impact on the price, but it is sure to be a good investment if the quality of performance lasts long.

- Bearing Type and Specifications

Various types of bearings, be it ball bearings or cylindrical bearings, come with different casting work depending on their type and use. Equipped bearings specialized for heavy loads, high speeds, and other specific uses will probably be sold at a higher price since they are tailored for that specific purpose with a lower supply of them.

- Condition and Wear

The physical condition of the bearing matters a lot. If a bearing is in working condition with a low amount of wear and tear or has been properly maintained, it usually comes at a higher price. Always check used bearings for signs of damage or excessive use since it shortens life span and may increase prices.

- Availability and Rarity

Of course bearings that are out of stock of the manufacturer or are hard to find are likely to be sold at a higher price point due to the limited stock and availability. If those fulfill a need and supply substitutes to the specific need are limited, then they would become more sought after, and that would likely increase the price.

- Reconditioning or Repair Needs

At first glance, reconditioning work such as cleaning, deeper painting, and greasing seem less expensive, but in reality, they do add to the costs. Before making a decision, I always take into consideration the possible reconditioning expenses.

- Market Demand

The industrial sector includes energy, automotive, and manufacturing. Due to the high exigency of these industries, prices for the required bearings can go upwards. Staying aligned with market trends would assist in comprehending flexible pricing strategies.

In this way, every used bearing I purchase can meet pre-set operational criteria and remain competitively priced.

Comparing prices: New vs. second-hand bearings

The differences between new and replacement bearings can mostly be summarized under the heading of cost versus quality. In most cases, new ones come with some sort of guarantee from the bearing manufacturer. Replacements are definitely cheaper but need to be thoroughly examined so they do not introduce maintenance costs down the line. In the end, it all depends on the specific application, the quality-user’s budget, and the acceptable level of risk.

Tips for negotiating prices with suppliers

We all know the supplier can’t go on the spree of offering us discounts, so we will ensure we research the market rates thoroughly. But how do we negotiate with the suppliers for the best rates? Well, my friends, everything lies within ‘preparation.’ All you have to do is amend the way in which you communicate with the suppliers, treat them with respect, and build a relationship with them. It is also important to keep in mind the fact that loyal customers are more likely to be offered splashes of discounts and bargains. Inform your suppliers that you have future long term ‘businesswork’ to make them incentivized. Moreover, think about utilizing volume buying or bundling multiple goods to do the same thing. Always look for a solution to the business that is satisfactory for everyone involved and has the scope for more partnerships in the future.

How can the proper installation and maintenance of second-hand bearings be ensured?

Inspection and maintenance of second-hand bearings is crucial, so start by looking over the bearings for damage. Old lubricants can remain on the piece, so use minimal solvents to clean the debris left on the surface carefully. Attach the bearings and avoid using excessive force during the process. Follow the instructions provided by the manufacturers as they help prevent misalignment. It is important to ensure timely maintenance; use the desired grade and sufficient amount of lubricants to reduce friction with wear. Additionally, look out for vibrations, loud noises or a change in temperature, they can display the condition of the bearings. Ensure close provision of care and meticulous work to guarantee prolonged reliability along with functionality.

Best practices for installing used bearings

It is very important that all Worn or used bearings are carefully prepared in order to be installed correctly. As a first step, I always make sure that all surfaces are thoroughly degreased/bathed, as even the slightest trace of dirt or unwanted materials can impair performance. Besides, the tools needed must never be improvised to avoid causing unnecessary overcuts or damages; while this might seem trivial but in fact, doing so ensures wear and tear during the installation process is kept to a minimum amount. Bearing installations are to be done with caution to ensure that no unnecessary force is applied in a manner where the focus on precision is compromised. Further to my work, I find routine lubrication of components with the right type of lubricant in terms of reducing friction. I also do constant checks for any signs of issues like strange noises or unusual heat, which can sometimes be treated before they become a larger and more expensive problem.

Maintenance tips to extend the life of second-hand bearings

I have learned some handy tips that can go a long way in increasing the durability of second-hand bearings. To start off, I always ensure that I protect my bearings from the dangers of moisture and particles. A clean, dry space at the start of the process should be adequate. The next step in the process is cleaning the bearings with the utmost quality. A minor debris is all it takes to ruin an entire fitting, doing the opposite of what is intended. Now that the bearings are fitted, I make it a point to use precision tools. This way, I ensure that the torsional strength of the part is not put at risk. Routine maintenance is an absolute must. One part may malfunction, for example, misalignment, but more parts shouldn’t have to, and doing regular maintenance does just that. Once everything is in place, I turn my focus to lubricating the bearings. During this stage, I ensure that the torque is kept to a minimum and supported by the proper grease or oil. In short, remove any signs of wear and keep the bearings lubricated and in check for warranty reasons.

When to replace your second-hand bearings

the ideal moment to install a new second-hand bearing is when it starts to show significant signs of wear that can no longer be looked after with any repairs. Continuous noise, overheating, or vibration, which, even when properly aligned and lubricated, begins to show, is, in most cases, an indicator of the decline of the bearing. Moreover, cracks or excessive pits, or any kind of visible deformation are clearly what I considered red flags. For me, the key is balancing cost-efficiency with reliability—any equipment or safety risk posed by a failing bearing is well worth the cost of a replacement. Helping and being attentive to spotting such problems in case they occur will be helpful to the functioning of the equipment and even to its upkeep.

What are the potential risks and challenges of using second-hand bearings?

Buying used bearings has its pitfalls and challenges, which I have personally experienced. The biggest of the worries is their history—wear and tear, overloading, or even neglect in maintenance of even the last owners can degrade their working conditions over the years in ways that might be hard to sense at first. Furthermore, second-hand bearings rarely have the appropriate documentation, so verifying their specifications or the conditions of usage in the past can be a challenge. I have also noticed that these can contain hitherto latent defects such as micro in the cracks or fatigue, which may result in failures at an earlier date. There is good reason to believe that while they are cheap, they create a delay in supply. The time taken in the repair and the time lost in the downtime pushes back the savings, and I find this practice quite futile. For me, used bearings are a last resort and in using them i thoroughly check and test them before making the decision.

Common issues associated with used bearings

one of the noteworthy concerns with used bearings is how uneven wear happens, and this goes back to how the bearing had been installed or the conditions within which it had been used to operate previously. This tends to cause irregular motion, which increases vibration and leads to high damage to the machine. Contaminations especially are quite a recurring issue, used bearings are usually coated in dirt and debris or greater degrees of degraded lubrication which leads to a greater degree of fast wear. In addition to this, it is almost impossible to determine through maintenance records whether or not the pace and loads at which the bearing was responsive were intended. All these tend to accumulate to one large uncertainty, where even the well-functioning parts can easily malfunction, and quite abruptly too. For these reasons, I always advocate for control testing and more detailed inspections when it comes to used bearings.

How to mitigate risks when using second-hand bearings

My first measure in dealing with risks related to second-hand bearings is a detailed visual inspection. I check for scratches, excessive wear, corrosion, and other imperfections that may hinder the operation. Then, I make sure the bearing is cleaned first, re-lubed with grease or oil, and cleaned again, followed by appropriate cleaning to remove contaminants. There is a need to test the equipment to assess its performance under controlled conditions and hear for any noise, excessive vibration, or unevenness in rotation that may indicate a problem. I also check the rotational and operational specs of the bearing against those of the required application model, primarily in respect of speed and load. Best practices in maintenance, in conjunction with these steps, make it possible for second-hand bearings to be safely operated to the extent possible.

Warranty and return policies for used bearings

On the topic of used bearings, I have realized that warranty, return policies, and return of these bearings are highly determined by the supplier. There are few suppliers who provide a credible line of defense against product defects and still go ahead and provide warranty coverage. It is critical, however, to keep in mind that such a warranty does not amount to the one provided with the new bearings, so always urge each individual to read the terms and conditions keenly before signing buying agreements. The return policies with respect to second-hand bearings are also crucial to consider; in some cases, suppliers will only accept the product back under certain circumstances, such as the product being deemed defective at the time of delivery. In all cases of sourcing used bearings, I liaise with the supplier directly and ask as many questions as possible,e especially those related to the warranties and return procedures. Doing this cuts down on the chances of being confused regarding their requirements or policy and allows me to make better choices in relation to sourcing used bearings.

Reference

- Practical Machinist Forum – A community discussion about various bearing sources, including user experiences with purchasing bearings.

- Sawmill Creek Forum – Another forum where users share their preferred sources for bearings, including hard-to-find ones.

- GlobeNewswire Report – A report on the bearings market, providing insights into market trends and demands.

Frequently Asked Questions (FAQs)

Q: What are second-hand bearings, and why should I consider them?

A: Second-hand bearings are pre-owned bearings that have been used in various industrial applications. They offer a cost-effective alternative to new bearings, making them an attractive option for budget-conscious buyers. These bearings are often refurbished and can provide reliable performance for mechanical use in machinery, construction equipment, and automotive applications.

Q: Are used bearings for sale safe to use in industrial machinery?

A: Yes, used bearings can be safe for industrial machinery when properly inspected and refurbished. Reputable sellers often clean, inspect, and test second hand bearings to ensure they meet quality standards. However, it’s essential to purchase from trusted sources and verify the condition and specifications of the bearings before use.

Q: What types of second-hand bearings are commonly available?

A: Various types of used bearings are available, including deep groove ball bearings, needle bearings, and roller bearings. You can find popular series like 6304 and 2RS bearings. These bearings cater to different applications in industries such as automotive, construction, and manufacturing.

Q: How can I find wholesale deep groove ball bearings for my business?

A: To find wholesale deep groove ball bearings, you can explore online marketplaces like Alibaba.com. These platforms offer a wide variety of bearings from different manufacturers and suppliers. Look for sellers who specialize in second-hand bearings and offer competitive prices for bulk purchases.

Q: What should I consider when buying used bearings for tractors or farm equipment?

A: When purchasing used bearings for tractors or farm equipment, consider factors such as the bearing’s dimensions, load capacity, and sealing type. Look for durable options that can withstand harsh agricultural environments. It’s also important to verify the condition of the bearing cage and ensure that the bearing housing is compatible with your specific equipment.

Q: Are there any advantages to buying second-hand bearing housings?

A: Yes, second-hand bearing housings can offer several advantages. They are often more affordable than new housings while still providing adequate protection for bearings. Used housings may also be available for older or discontinued machinery models, making them valuable for maintenance and repairs of legacy equipment.

Q: How do I ensure the quality of used bearings when purchasing online?

A: To ensure the quality of used bearings purchased online, look for sellers who provide detailed product descriptions, high-quality pictures, and information about the bearings’ condition. Check if the seller offers any guarantees or return policies. It’s also helpful to read customer reviews and ask for additional details or certifications if needed.

Q: Can I find used precision bearings for high-performance applications?

A: Yes, it’s possible to find precision bearings that are used for high-performance applications. Some suppliers specialize in refurbished high-quality bearings suitable for precision machinery. When looking for such bearings, pay close attention to tolerance specifications, material quality, and any available performance data to ensure they meet your requirements.

Q: What are the benefits of buying from a wholesale factory that deals in used bearings?

A: Purchasing from a wholesale factory specializing in used bearings can offer several benefits. These may include access to a wide range of bearing types and sizes, competitive pricing for bulk orders, and expertise in bearing refurbishment. Many wholesale factories also provide fast shipping and may offer customization options for specific industrial needs.

Q: How do I maintain second-hand bearings to ensure their longevity?

A: To maintain second-hand bearings and extend their lifespan, regular inspection and proper lubrication are crucial. Clean the bearings periodically, check for signs of wear or damage, and replace seals or shields if necessary. Ensure proper alignment during installation and avoid overloading. Following these practices can help you get the most value out of your used bearings in various applications, from motorcycles to industrial machinery.