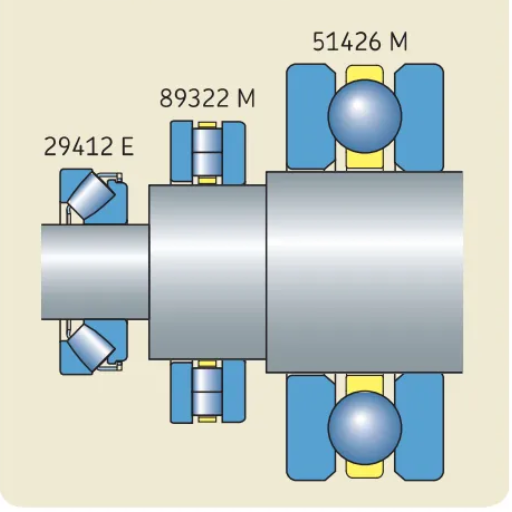

Thrust ball bearings have a wide application in mechanical engineering and are known for transferring high axial loads quite efficiently. They are highly specialized devices that operate in systems that are required to operate under axial loading, that is, loading parallel to the shaft’s axis. With widespread applications across machinery, automotive designs, and aerospace even, these thrust ball bearings are essential for smooth functioning. These thrust ball bearings have multiple uses and advantages as well as unique structural characteristics, and this article aims to explain their working principles in diverse engineering and mechanical systems. If you want to know more about how these mechanical components work, be it as an industry professional or out of sheer curiosity about modern machines, this guide will serve you clearly.

What are thrust ball bearings, and how do they work?

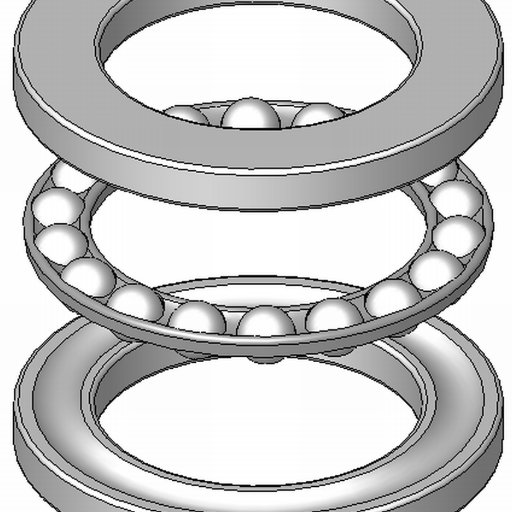

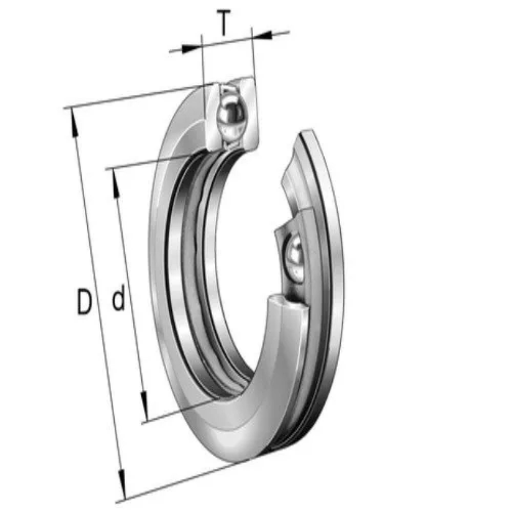

Thrust ball bearings are unique mechanical parts that are meant to carry axial loads with the ease of rotating motion. They are made up of two bearing discs, sometimes called washers, and a set of steel balls placed between them. These steel balls minimize friction by serving as an interface between the discs which allows smoother motion. These bearings are widely used in processes that experience linear direction forces in special beam directions, such as steering mechanisms for vehicles, industrial machines, and marine apparatus. Their specially designed structure guarantees stability, robustness, and precise working conditions within high-pressure constraints.

Understanding the basic structure of thrust ball bearings

Thrust ball bearings are effective in managing axial loads; the two washer-like discs, steel balls, and steel ball cages used in its construction are rather uncomplicated in their design and principle of operation. However, even under high levels of stress, the rotary bearing works smoothly owing to the fact that there is limited friction… Also, thrust ball bearings are strong and reliable, and because they can be used in complicated systems, their modular construction makes it easy to replace and maintain them.

How thrust ball bearings handle axial loads

In order to explain the way in which thrust ball bearings are capable of dealing with axial loads, I will take you through this in a really straightforward and comprehensible manner, step by step. Axial loads are referred to as forces that apply along the shaft’s axis – thrust ball bearings were specifically designed to be able to bear such forces.

- Flat or Angular Contact Surface: Thrust ball bearings have flat components with slight angles with regard to their contact surfaces. This aids in ensuring that the thrust bearing distributes the axial load evenly, which minimizes undue force exerted on any particular component, thus increasing stability.

- High-Quality Steel Balls: The steel balls that are placed inside the bearing are made with the help of precision machining, and therefore, these balls are of high quality. These balls are smoothly rolling elements that are encased within grooves for reduced friction and enhanced load transfer.

- Rigid Washer Design: The washers on either side of the bearings are engineered to resist the effects of axial forces. These washers, when encapsulated, retain their shape and construction, which ensures that their application is not impacted by pressure.

- Cage for Component Alignment: A cage is used to hold each steel ball in its place but ensures that the balls are not touching one another, so there is even spacing between the balls, and no specific orientation should be maintained for those balls. Since these cages fit perfectly, wear is reduced, and the amount of load that can be put on the bearing is increased.

- Low Friction Performance: Thrust ball bearings are specifically made from materials with a variety of surface finishes that prevent acceleration. This helps substantially in dealing with axial forces but also reduces power consumption within the system.

The High Thrust Ball Bearing is particularly ideal for applications where axial loads are present. This bearing supports thrust and can hold axial loads only in one direction. These components are precision-engineered to high-performance requirements, ensuring a good fit while correcting for misalignment.

Comparing thrust ball bearings to other types of thrust bearings

With every thrust bearing, as I observe the thrust ball bearing, there’s something unique that keeps it slightly distinct. For example, thrust ball bearings are able to function at high rotation speeds. However, in situations where lower torque is required, precision designs and incorporated smooth rolling elements will give the thrust ball bearing a competitive edge over other bearings. For wider-range operations where both axial and radial loads need to be performed, thrust bearings are suggested. Assemblies that have space constraints will help in compact designs, allowing for the use of needle thrust bearings in a wider set of factors, capping load varieties, unlike ball or roller varieties. Finally, the availability of extensive assemblies such as spindle bearings, c basis, housing, and head with shafts makes it extremely easy to select which specific bearing to use from the extensive set.

What are the main applications of thrust ball bearings?

thrust ball bearings are primarily applied when axial force loadings are high; in stark contrast, their rotational speeds are supremely low. They can be found in automotive parts such as gearboxes and steering to provide smooth rotary motions under constant axial load. In addition, they are used in civil engineering equipment such as cranes and pumps since they can transfer axial thrust with high reliability. In all these applications, their design and performance requirements show that they are essential in most cases where there is a rotation of the component with high accuracy and endurance under axial load.

Common industrial uses for thrust ball bearings

I have learned that thrust ball bearings are key components in various industrial machines since they support heavy loads without distortion, in tremendous detail. I have noticed that they have a wide application in mechanical systems, such as conveyor applications where moving and transferring are required to be smooth. Besides, they are used in turbine assemblies that facilitate rotation of a shaft while being subjected to high axial loads. Their suitability and highly built quality make them ideal for engineers developing superminis that typically operate with axial loads in reliable and steady conditions.

Automotive applications of thrust ball bearings

Thrust ball bearings are important in the automobile sector, especially in elements that rotate with axial loads. In my view, they are most frequently used in various components of transmission systems to enable smooth gear change and support axial force during rotation. Also, they are widely used in clutch assemblies to provide effective engagement and disengagement of power supply with less rotational resistance. Their ability to perform reliably under high-speed and high-load conditions makes them essential in modern automotive engineering design elements.

Thrust ball bearings in marine and aerospace industries.

Thrust ball bearings are quite useful in marine engineering and aerospace. As regards marine applications more particularly, they are used in a number of propulsion mechanisms, shaft supports, and most importantly, in lubricant and grease seals under severe and elevated pressure conditions. Likewise, in the aerospace industry, these bearings are useful in securing loads in end machinery, components, and devices like turbojet engines and control surfaces where immense loads and energy dissipation in the form of low temperatures are needed. These make them very effective in these demanding industries, for durability is one of their greatest assets.

How do thrust ball bearings compare to other bearing types?

In regard to comparing thrust ball bearings to any other type of bearing, I would tout them as best suited to particular applications as they can support axial loads very effectively. Unlike cylindrical or spherical bearings, thrust ball bearings are designed to accommodate only pure axial loads and not radial ones, which makes them suitable for use on vertical shafts or rotating tables. They provide the accuracy of the low friction performance,e which distinguishes them, while their ability to withstand only moderate speed and constant axial pressure loads is a drawback. Axial load applications that require stiffness is the main goal, emphasis should focus primarily on thrust ball bearings as others may sacrifice that for versatility or greater radial load requirements.

Thrust ball bearings vs. deep groove ball bearings.

Thrust ball bearings can take loads that are axial in nature, and these bearings can be used for any application that requires great precision parameters when rotated, including rotating tables or vertical shafts. Furthermore, there are deep groove ball bearings that also have axial overlaps, and these bearings can spin at relatively high speeds due to their radial design. The most suitable of the two options always tends to rely on which type is the primary load in that application, whereby thrust ball bearings predominately work on axial load applications, and deep groove ball bearings are used where loads are much broader.

Differences between thrust ball bearings and tapered roller thrust bearings

A thrust ball bearing is a bearing type that is only capable of carrying axial loads and is suitable for low-speed applications that need precision and smooth operation. The devices that work at low speeds, such as low-speed machines and turntables, employ these types of bearings. However, tapered roller thrust bearings are able to support axial and radial loads because of their cone-shaped rolling elements. Thrust bearings are more favorable in robot arms as they can support heavy weight and a high-speed rotation, forming an essential part of automotive gearboxes or heavy machinery. The differences are mostly in the loads they can bear, the speed at which they can rotate, and how the design was able to adapt to the operational requirements.

Comparing thrust ball bearings to cylindrical thrust roller bearings

it is always up to the application and the load conditions when the bearing choice comes down between thrust ball bearings and cylindrical thrust roller bearings. Thrust ball bearings are more appropriate for applications that require lightweight axial loads and high precision, including sensitive instruments or light machines. On the other hand, cylindrical thrust roller bearings work better for applications with higher axial and moderate radial loads. They are also more suitable for applications like heavy industrial machinery or equipment that requires smooth running and high-speed performance because of their robust construction. The appropriate bearing should always be determined after careful consideration of the operation conditions and load requirements.

What are the advantages of using thrust ball bearings?

Thrust ball bearings are an ideal solution for applications where accuracy and capacity to withstand axial forces are essential aspects. In my view, their most important benefit stems from the configuration, which allows low-friction operation even when high axial force is being applied. Also, they can be successfully used in low-speed rotating applications where stable performance is required. Most of the time, I’ve found them applied in automotive systems and automotive machinery, where precision and efficacy are the winning factors. Their ease of installation and maintenance further adds to their appeal, making them a fitting choice for multiple sectors.

High efficiency in handling axial loads

Axial bearings are able to handle high axial loads relatively easily as a result of their design geometry, which reduces friction and enhances load distribution. Also, using modern materials and reasonable shapes results in the bearing remaining stiff and strong even when large forces are applied to it. These sets of attributes enable them to perform well in the most challenging environments, which is why they are particularly used in industries that require accurate and controlled siding loads.

Low friction and smooth operation

The combination of advanced lubricants, precision manufacturing, and innovative design, such as enhanced contact surfaces and materials, helps achieve low friction and smooth functioning in bearings. Quite remarkably, these attributes are optimally balanced to minimize energy waste, heat production, and aging of the bearing, thus providing a dependable performance throughout its range of applications.

Compact design and space-saving benefits

compact designs are very important, especially in modern machinery and equipment in which space is a limiting factor. Space constraints allow for optimal use of resources where performance and reliability are still guaranteed. This is done through detailed design and material selection.

In order to underscore the benefits, below are the relevant parameters that, in compact design, substantiate the importance of its conception:

- Dimensional Efficiency: The elements shall be miniaturized to enable the machine to be more compact. This is advantageous for robotics, automobile systems and aerospace technologies.

- Weight Reduction: One of the benefits of compact bearings is their lightness which then results in reducing the weight of the entire system. This is very important in transportation or mobile application,s whereby a weight reduction leads to better fuel and environmental performance.

- Performance Optimization: Smaller designs do not impede the efficiency and operational reliability of the bearings so long as the tolerances remain stringent. Advanced materials and design structures permit high loads and high rotations in a smaller configuration.

- System Integration: Compact bearings usually provide easy access for the incorporation of additional system parts around them, thus allowing multi-enabled occupation of the limited space and minimizing the complexity of the assembly.

Compact designs indeed provide effective operational efficiencies as well as a competitive advantage in space-constrained applications, which is critical for many industries. Thus, by optimizing the processes involved in designing the bearing, it becomes possible to cater to the increasing requirement of compact, space, and weight-optimized products while ensuring their quality standards and operational reliability.

Are there different types of thrust ball bearings?

Yes, thrust ball bearings do come in different profiles.I may say that they are generally classified into single-direction and double-direction thrust ball bearings. A single thrust ball bearing is intended to accommodate axial loads in one direction only, making it suitable for situations where the load is in one direction only. On the other hand, double-direction thrust ball bearings are used mainly for those applications where they have to bear axial loads in two directions, which is beneficial for systems requiring support in both directions. Each type has its functionality and is chosen appropriately depending on the direction of the load and the performance level required for the application.

Single-direction vs. double-direction thrust ball bearings.

Whether to use single-direction or double-direction thrust ball bearings will depend on the load characteristics of your application. Should your system only have an axial load acting in one direction, then single-direction thrust ball bearings would be quite satisfactory. But if your application endures axial load in opposing directions, double-direction thrust ball bearings are generally required. It is, therefore, critical to select the appropriate bearing type for the proper performance, durability, and reliability of your equipment.

Exploring thrust ball bearings with various ball sizes and arrangements

My experience with thrust ball bearings has been all but straightforward, as I’ve noticed that the size and arrangement of the ball bearing can pretty much spell the difference between success and failure. For instance, as a rule of thumb, the smaller the balls used, the lesser the friction level, which then translates to higher speeds, which is highly desirable in this case. However, having larger balls compensates for the fact that they have a high load and wear and tear threshold, so they are better suited to heavy industry equipment. Just how the balls are arranged also matters, single rows are great when the load is on the lighter side but when the forces become more substantial a double row configuration works wonders. So, adjusting these parameters to the application makes it possible to get an ideal level of efficiency, durability, and reliability all at once.

What factors should be considered when selecting thrust ball bearings?

When starting to choose thrust ball bearings, I always first assess the particulars of the application in view. Here are the key factors I recommend taking into consideration so as to get the optimal performance out of the bearing:

- Load Capacity

First and foremost, it’s crucial to comprehend the sort of load and its magnitude requirements. Since axial loads are within the scope of thrust ball bearings, they need to be ascertained whether it is a case of light, medium, or heavy application. In such cases of higher loads, bearings with greater ball diameter or double rows of bearings are more effective.

- Speed Requirements

Another critical factor in your application is how fast the application rotates. Generally, the bearings with small balls work well at high speeds because of a reduced friction component. Always check the rating of the bearing in terms of the specified speed and if it falls within the operating range of the machine to eliminate undesired heating effects or wear out quickly.

- Material and Durability

Depending on the surrounding conditions, you could require bearings of different materials. For example, stainless steel bearings are very good in resistance to corrosion in cases of humid or chemical contact while best performance ceramic-coated make logical sense in high-temperature applications.

- Space and Design Constraints

The area in which the bearing will be installed has specific dimensions that the bearing can’t exceed. In certain cases, only slim or thin bearings may fit easily, for example, when the device is compact, while much more robust options will fit when a larger system is in place.

- Lubrication Compatibility

Smooth functioning and enhanced and lesser wear and tear are dependent on proper lubrication. So, no matter which device is being used, it is imperative to make sure that the selected bearing has the right compatibility with the lubrication, be it grease, oil, or solid film.

- Application-Specific Conditions

Bearings can be highly influenced in their operation by the application of extreme environmental conditions such as humidity, dust, moisture, vibration, or temperature. In such demanding cases, it would be reasonable to suggest that sealed or shielded bearings are better suited.

Taking these parameters into careful consideration and cross-referencing them to the specifications of the bearing that corresponds with the requirement you have will result in optimum efficiency of work and maximum life of service for the piece of equipment. When in doubt, always consult with the bearings expert or supplier in order to make the correct decision.

Load capacity and speed requirements

it is of great importance to take into consideration the load capacity and speed requirements, as well as the operational demands of your application. To begin with, estimating the types and quantities of loads in terms of radial and/or axial forces helps ensure the designed bearing is not going to be structurally over-torqued at any point in time. In the same manner, operational speed should also be assessed; there is an upper threshold of revolutions per bearing that can be achieved, and engaging that excessive rotation speed can lead to overheating. I have found that picking out an over-torqued bearing or a more robust one could be a good rule of thumb with respect to both reliability and efficiency goals. Consult manufacturer specifications in order to ensure proper application.

Environmental conditions and lubrication needs

I have come to the understanding that environmental conditions are crucial for the long-term survival of the bearings. Working at extremely high or low temperatures and dealing with moisture, dust, and corrosive materials puts bearings at risk, and hence it is imperative to use well-designed materials and seals that can withstand such challenges. To illustrate, it is commonly known that ceramic and stainless steel bearings are ideal for high moisture to corrosive conditions.

Equally important to seal and material selection is the correct application of lubricant. I cannot stress enough how lubrication acts as the lifeblood of bearing functionality—it not only reduces friction but also protects against contaminants and minimizes wear. To start with, correct lubricant selection, whether grease or oil and lubrication intervals will help. For this reason, I advise adjusting the conditions of lubricants based on their working conditions, but neglecting this direction is usually one of the most common causes of bearing failures.

Space constraints and mounting considerations

Throughout these years, I’ve had opportunities where security and space considerations required out-of-the-box thinking to deliver improved performance while retaining product lifetime in good shape. Miniaturized equipment or space-restricted areas require that the bearings be suitably configured to such compact areas whilst still being able to support the loads. Such restrictions can be successfully removed through the use of either low-level bearings or specified bespoke ones. Installing the bearing in a proper manner is just if not equally, essential— poor installation not only decreases efficiency but can also result in the outright disintegration of the bearing. From my experience, aligning everything accurately and using the correct working tools during the fitting is an “I have to” sort of thing. I tend to focus on the need to obey the manufacturer’s instructions letters in terms of clearance and to check their compliance during the system’s operations so as not to damage the assembled units or disrupt their working conditions. These steps might seem basic, but they go a long way in extending the bearing’s lifecycle and maintaining overall system reliability.

How do we maintain and extend the lifespan of thrust ball bearings?

In order to properly maintain and increase the lifespan of thrust ball bearings, I always begin by conducting routine checks and preventive care. First and foremost is cleanliness: lubricated ball bearings should not be tarnished by dirt, debris, or water, which would lead to extensive deterioration of the bearing. I make a conscious effort to use the correct type and quantity of lubricant because, without a doubt, hair dry systems failure due to overheating or excessive friction is attributable to inadequate lubrication. Another important measure is to monitor operating parameters such as loads, speeds, and temperatures; otherwise, applying excessive stress to the bearings will shorten their operational lifetime or lead to failure as a result of fatigue. Finally, I suggest that worn-out components be replaced at the right time so that more damage does not occur in the system. By doing so and staying observant, operational reliability and, consequently, costs, in the long run, are enhanced significantly.

Proper lubrication techniques for thrust ball bearings

I am always able to highlight a few principles that need to be followed when it comes to thrust ball-bearing lubrication. Here’s what I prepare:

- Choose the Right Lubricant

Grease or oil is chosen based on the working condition of the bearing. Refer to the lubricants recommended by the bearing manufacturer. For instance, grease is ideal for medium speeds and for moderate loads, and is preferred with bearings that turn at lower RPMs, while oil is most effective in high RPM scenarios. A good choice has to be made so that there are no discrepancies between the lubricant and the bearing material.

- Apply the Right Amount

While quality lubricant is a requirement, proper application is pivotal too: too much is as bad as too little, over-lubricating a bearing creates excessive heat and more drag, while under-lubricating increases friction and wear. Therefore, acceptable limits for bearing size and application are recommended and, as a rule, I stick to those.

- Reapply at Regular Intervals

One of the most important parts of lubrication is maintenance and too much of it is never enough. Load speed and ambient conditions all have to be factored in while setting intervals for reapplication; higher load means more lubrication and vice versa. In addition to these factors, it is critical to always monitor if the lubricant is contaminated or has broken down over the course of time.

- Consider Environmental Factors

Bearings lubricated in harsh conditions or extreme temperatures, water, or dust will need special lubricants, such as synthetic grease for high temperature grade applications and waterproof or corrosion resistant for high moisture environments.

- Ensure Clean Application

Before applying the lubricants, Bearing regions are greeted with the appropriate washing to prevent contamination. Contamination is one of the key tins that affects the bearing health, particularly in early use, and therefore, hygiene is upheld when lubricants are being used.

Through the implementation of the following and customizing lubrication methods according to the parameters of operation, I have witnessed how substantially this practice can improve the operation of thrust ball bearings. Properly lubricated bearings not only reduce friction but also increase the efficiency of the operational process thereby minimizing the wear and tear of the system and reducing the overall costs.

Regular inspection and cleaning procedures

Any application relies heavily on clean thrust ball bugs and maintenance for a long life. For myself, I always make visual inspections a goal in order to catch any indicators of wear, corrosion or debris. Every time a bearing is taken apart for cleaning purposes, special tools and solvents are used to remove dirt and old grease from all parts. This practice is not only a safeguard but negates the chances of damaging parts during the cleaning process, ensuring that a fresh lubricant is able to be spread in a clean environment. From my experience, I have noticed that sufficient regular checks along with cleaning maintenance prevent abrupt malfunctions and enhance performance.

Recognizing signs of wear and when to replace thrust ball bearings

To avert system breakdowns and maintain baller efficiency, it is pertinent to identify the indications of wear in thrust ball bearings. Unlocked girls, spikes in vibration, gales while operating the equipment, flakes, and color distortion on the surfaces of bearings, as well as excessive movement, all indicate wearing out. All of the above should be replaced together to avoid more severe damage when one of these signs is observed during operation. By routinely replacing these ball bearings and adhering to mechanisms for signals, it is also possible to reduce the likelihood of unanticipated breakdowns.

Reference

- EZO USA – Thrust Bearings | Applications & Benefits: This source provides insights into the applications and benefits of thrust ball bearings in various industries, including automotive and heavy-duty machinery.

- BMC Bearing – Thrust Bearings to Reduce Friction and Support Axial Loads: This blog discusses the use of thrust ball bearings in industries such as aerospace and the chemical industry.

- Tameson – Thrust Bearings – An Overview: This overview explains the different types of thrust bearings and their applications in supporting axial loads.

Frequently Asked Questions (FAQs)

Q: What is a thrust ball bearing, and how does it differ from other types of bearings?

A: A thrust ball bearing is a type of rotary bearing specifically designed to support axial loads (thrust loads) in one direction. Unlike radial bearings that handle forces perpendicular to the shaft, thrust bearings are used to manage forces parallel to the shaft. They consist of ball bearings arranged between two flat washers or races, allowing for smooth rotation while supporting axial loads.

Q: What are the common applications for thrust ball bearings?

A: Thrust ball bearings are used in various applications where axial loads need to be supported. Common applications include automotive transmissions, gearboxes, machine tools, pumps, and aerospace equipment. They are particularly useful in situations where rotational speeds are moderate and thrust loads are significant.

Q: How do thrust ball bearings compare to thrust needle bearings?

A: While both are types of thrust bearings, thrust ball bearings use spherical balls as rolling elements, whereas thrust needle bearings use cylindrical rollers (needles). Thrust ball bearings generally handle higher speeds and moderate loads, while thrust needle bearings are better suited for heavy loads at lower speeds. Thrust ball bearings also tend to have a larger overall diameter compared to thrust needle bearings.

Q: Can thrust ball bearings support loads in both directions?

A: Typically, thrust ball bearings are designed to support loads in one direction. However, they are often used in pairs to handle thrust loads in both directions. When bi-directional support is required, two thrust ball bearings are installed back-to-back or a double-acting thrust bearing is used.

Q: What are the advantages of using thrust ball bearings?

A: Thrust ball bearings offer several advantages, including low friction, high efficiency, and the ability to support significant axial loads. They are compact, easy to install, and provide precise axial positioning of rotating shafts. These bearings are also capable of operating at higher speeds compared to some other types of thrust bearings.

Q: Are there any limitations to using thrust ball bearings?

A: While thrust ball bearings are versatile, they do have some limitations. They cannot support radial loads effectively, so they are often used in conjunction with radial bearings. Additionally, thrust ball bearings have a lower load capacity compared to spherical roller thrust bearings, especially at lower speeds. They may also require more frequent maintenance in high-load or high-speed applications.

Q: How are thrust ball bearings typically installed?

A: Thrust ball bearings are typically installed between a rotating component (such as a shaft) and a stationary component (like a housing). The bearing is placed perpendicular to the shaft axis, with one race (usually the shaft washer) rotating with the shaft and the other race remaining stationary. Proper alignment and lubrication are crucial for optimal performance and longevity of the bearing.

Q: What factors should be considered when selecting a thrust ball bearing for a specific application?

A: When selecting a thrust ball bearing, consider factors such as the magnitude and direction of the thrust load, rotational speed, operating temperature, environmental conditions, and space constraints. It’s also important to evaluate the required lifespan of the bearing, lubrication methods, and any specific industry standards or regulations that may apply to the application.