We are pleased to present our detailed thrust bearings guide to you! This article is crucial for engineering and mechanical students and engineers, as it serves to enhance their understanding of thrust bearings, which are essential elements in many applications since they help to transmit axial loads and reduce the amount of friction. As it is rather difficult to understand, we hope this article will combine all the fascinating components of thrusters in the simplest way possible for the average reader to understand why they are so important in mechanical applications. Now, keep your head out straight as we dive deeper to grasp what thrusters are all about and, moreover, the role they play in supporting the many industrial loads whilst minimizing friction in a variety of applications. Let us take this appreciation a step further, sit back, and together, we will venture forth into the intricacies of thrust bearings!

What is a Thrust Bearing and How Does it Function?

According to my understanding of this industry, a thrust bearing is a type of bearing specifically used to carry axial loads, also known as ‘thrust loads, ’ which are forces parallel to the axis of rotation. Thrust bearings are not, in contrast to radial bearings, meant to bear loads applied on the edges; instead, they are solely engineered to take care of almost all thrust loads while reducing friction. For this purpose, a combination of rolling elements, such as balls or rollers, and specially shaped raceways are used. The rolling elements help smoothen the movement of the bearing so that the thrust force applied is transferred and spread to the entire thrust bearing. In this manner, thrust bearings are integral components in many mechanical systems, allowing them to function properly and avoiding excessive damage caused by thrust overloads and unwanted friction.

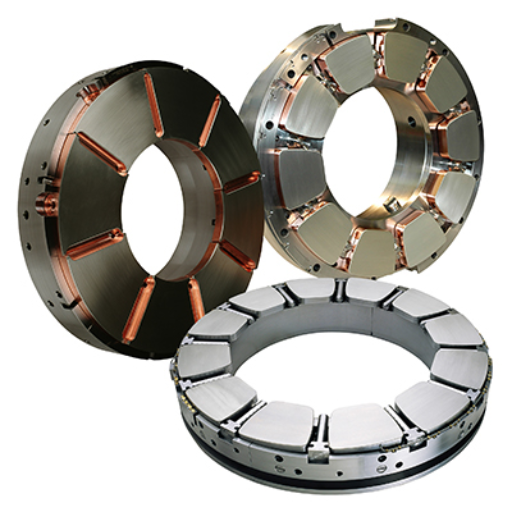

Types of Thrust Bearings and Their Applications

There are a number of thrust and axial bearing types that we will consider with the help of this industry expert. Different thrust bearings are designed to meet certain levels of axial loading and particular working conditions. Among the most common types are:

- Thrust Ball Bearings: They consist of a set of balls surrounded by two grooved washers. Such bearings can be utilized where some moderate to high axial loads occur, such as in automotive transmissions, machine tool spindles, and pumps, which have some thrust load.

- Roller Thrust Bearings: These bearings have cylindrical or tapered rollers in place of balls. They allow high load-carrying capacity, and they are used for large load applications such as in gearboxes, construction equipment, and rolling mills.

- Tapered Roller Thrust Bearings: These bearings are in between thrust bearings and tapered roller bearings. Axial and radial loads can be applied, and such bearings are common in automotive applications such as truck gearboxes and differential gears.

- Thrust Needle Bearings: Such type of bearings is constructed using needles of small radius and long length. They can be used where there are space restrictions and where low axial loads are to be accommodated, for example, automotive steering systems and motorcycle clutches.

Some considerations such as speed, load capacity, spatial restraints and environmental conditions have to be kept in mind while selecting the appropriate type of thrust bearing. Knowing the various thrust bearings and their areas of application will give you the chance to make a suitable choice and ensure that you enhance the efficiency of your mechanical systems.

How Do Thrust Bearings Support Axial Loads?

thrust bearings are axial thrust bearings that support movements in the directions of the longitudinal axis of rotation. They consist of rolling elements that are placed at right angles to the direction of the axis that roller thrust bearings load beams. The particular structure and arrangement of the rollers in the thrust bearings, which include a number of types such as thrust ball bearings, roller thrust bearings, and tapered roller thrust bearings, makes it possible to achieve practically uniform pressure on all of the thrust bearing surfaces. Thus the laying of these thrust bearings on the rolling elements applies thrust force in the axial direction, and the circumferential rolling is readily allowed about the cone with very low friction. This allows thrust bearings to perform axial rotation rather effectively at a high axial force ratio.

The Role of Thrust Bearings in Reducing Friction

thrust bearings are critical to the reduction of mechanical friction in mechanical systems. They are constructed to take care of axial loads, which are carried out parallel to the rotating shaft, and thereby, the force applied on the bearing surfaces is spread as uniformly as possible. Such distribution of loads helps in minimizing friction and wear thus providing for easy movement of rotating parts with low power input. Some common thrust bearings that accomplish this are thrust ball bearings, roller thrust bearings, and tapered roller thrust bearings, which are efficient in applying and bearing the axial forces on the machinery, leading to a smooth operation of the machines.

Exploring Different Types of Thrust Bearings

let me take you around thrust bearings and their different categories. Thrust bearings are essential components of machines, and mechanical components serve the purpose of axial states and provide rotation. Here, we shall enumerate the varieties of thrust bearings used, the principles of operation of each of such kind, and their properties and advantages. We will also consider some of the factors that are fundamental in the choice of thrust bearing for a given purpose and point out their uses in different fields. Let us explore thrust bearings more.

Understanding Thrust Ball Bearing Mechanisms

thrust ball bearings are quite interesting parts of various mechanical systems. I feel that these bearings are efficient in absorbing axial forces while allowing axial movement to occur. This makes it possible for the applications that need axial forces to be supported.

A thrust ball bearing has two grooved washers and one ball retainer assemblage. Grooved washers have grooves in them. These ball raceways allow the balls to roll and transmit and support thrust loads. Rigidly contained balls in the retainer assembly transmit thrust loads of the bearing while enabling the bearing to withstand radial loads of the moment.

The working principles of thrust ball bearings are essential for their proper exploitation. Knowing how the balls behave in relation to the washers assists engineers and operators in coming up with good bearing designs. These bearings can be found in automotive transmission systems, machine tools and in most industrial systems and areas which are dominated by axial loads.

In the following sections, we are going to examine the features and advantages of some other kinds of thrust bearings, such as roller thrust bearings, tapered roller thrust bearings, and thrust needle bearings. Some aspects that should be addressed when addressing a specific need for a thrust bearing and the applicability of such bearings in various industries will also be mentioned. So, let us proceed and understand the interesting features of thrust bearings.

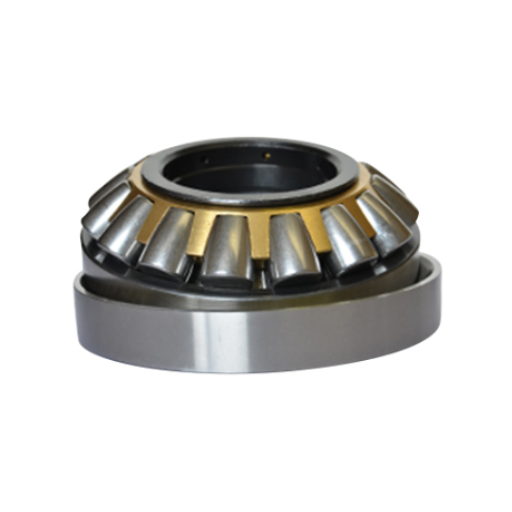

Characteristics of Roller Thrust Bearings

let me shed some light on the features of roller thrust bearings. It suffices to say that these bearings are unidirectional in terms of axial loads, provide support, and permit rotation of the bearing rings around one another. Key Features That Distinguish Roller Thrust Bearings From Others:

- Rolling Elements: Unlike conventional thrust bearings, which use balls, Roller Thrust Bearings use cylindrical rolling elements that are longer in length, which enables them to have low clearance between the raceways and allow for more load to be carried.

- High Load Capacity: Thanks to their special design, Roller Thrust Bearings are built for heavy axial loads and bear larger axial loads than the rest of the thrust bearing types. This structure allows them to be in heavy duty applications such as high torque automotive transmissions or heavy machinery.

- Low Friction: The rolling elements are subjected to rolling to reduce friction in Roller Thrust Bearings, thus enhancing better functioning of the bearings. Consequently, this leads to less fuel consumption and less heat generation during its functioning.

- Versatility: A variety of different forms or configurations of Roller Thrust Bearings are readily available, which provides higher or lower performance load carrying capacity. Additionally, these can be single and double-direction thrust bearings, hence meeting the requirements for specific applications.

With this understanding and holistic approach, it’s possible to select roller thrust bearings that are appropriate for the application and that are assured of long-lasting, reliable service.

Benefits of Tapered Roller Thrust Bearings

Tapered Roller Thrust Bearings have a unique design that offers certain benefits that make them a popular choice for a range of applications. Below are some of the key benefits of Tapered Roller Thrust Bearings:

- High Load Capacity: The Tapered Roller Thrust Bearings are constructed to withstand large axial forces; thus, they are suitable for applications where large loads need to be supported.

- Efficient Load Distribution: These bearings’ contact surfaces are shaped to better fit onto the surfaces rolling under them, alleviating pressure and hence improving the characteristic of the bearing.

- Precise Axial Positioning: Due to their geometry, the Tapered Roller Thrust Bearings provide a more precise location in the axial direction, which is crucial to ensure rotating parts are properly seated.

- Space-saving Design: These bearings take advantage of space economy by virtue of their compactness and tapered shape, which is important in situations of limited installation space.

- Versatility: The tapered roller thrust bearings come in multiple sizes and shapes, making them possible to use for many different applications.

- Reduced Friction and Wear: These types of bearings are intended for an efficient function, hence low friction, which causes less impact and wear and increases the lifespan of both the bearing and equipment.

It is critical to accurately define the parameters, such as load capacity and direction, speed capabilities, shaft and housing requirements, lubrication, and the environment, so as not to miss the selection of Tapered Roller Thrust Bearings. If you consider these parameters before purchasing the Tapered Roller Thrust Bearings, you can be confident that they will serve you well for the requested application.

How to Select the Right Thrust Bearing for Your Needs

it is essential to select the correct thrust bearing for your requirements in order to avoid poor performance or early failure. In thinking through such a decision, bear in mind that the following factors are crucial:

- Load Capacity and Direction: Establish the maximum load that the bearing will bear and the plane in which the load will be imposed. Such information will assist you in the selection of a thrust bearing adapted to the requirements of the specific application.

- Speed Capabilities: Consider the speed at which bearing rotation will take place. Thrust bearings have different speed capabilities hence the bearing that you choose should be able to operate at the required speed range.

- Shaft and Housing Requirements: Observe the physical dimensions and tolerances of the shaft and housing that will accommodate the bearing. The bearing should be able to sit precisely and firmly inside these components so that its performance is not hindered.

- Lubrication Needs: Identify the need for lubrication for the thrust bearing. Certain bearings demand continual lubrication for efficient performance while some are already lubricated as a standard practice or are self-lubricating. Such bearings will be ideal for your application, promising smooth operations.

- Environmental Conditions: Outline the usage environmental factors within which the bearing is to operate, such as temperature, moisture, and contamination. Consider a bearing that can withstand the environment within which it will be used.

It is advice in such instances to refer to knowledgeable suppliers or engineers through the selection process so as to make the right decisions. Most suppliers can assist in resolving such issues by interacting with the clients until they understand the relative performance equations that enable them to select thrust bearings.

Factors to Consider in Bearing Selection

it is quite prudent to approach selecting all the contributing factors in a ‘bearing’ in a decisive manner. These include load capacity, speed requirements, accuracy, working environment, and even surrounding factors. It is very important to identify the load capacity and speed requirements that the application will make use of to ensure that the bearing experiences the forces and motion it is designed for. In addition, the axial or radial runout that is required will also determine the type of bearing to be employed. Take note of the operational environment, such as temperature levels, vibrations, and degree of contamination, and pick a bearing operating under those conditions. Last but not least, knowledge of environmental influences like moisture, chemicals, or extreme temperature is paramount in selecting a bearing suited to work under these exact hostile conditions. Reviewing these parameters and correlating them with the availability and specification of thrust bearings will facilitate selection. This selection process can be simplified by discussing it with an experienced supplier or an engineer.

Why Thrust Needle Bearings Might Be Your Choice

Looking at it from an industry expert’s point of view, the question that may arise is why thrust needle bearings were used in your application. It can be noted that thrust needle bearings are remarkable in many features that are quite different from other bearings. Here is the reason why they must be the choice for you:

- High Load Capacity: Thrust needle bearings are engineered to withstand extreme axial field loads which require supporting of large components at a fixed support position.

- Compact Design: Their small and space-efficient configuration allows the utilization of these bearings in applications where space is limited but optimum efficiency is still desired.

- Efficient Power Transmission: Thrust needle bearings have good power transmitting characteristics which results in better functioning with minimal energy spent.

- Precise Needle Roller Arrangement: The needle roller arrangement in the thrust needle bearings provides better rotational accuracy since the loads are more evenly distributed over the rollers which enhances performance.

- Versatility: Thrust needle bearings are available in different sizes, designs and a variety of configurations which gives them the much-needed flexibility to be used in different applications in the industry.

Taking all these factors into account, you may rest assured in your decision to adopt thrust needle bearings knowing fully well that they have outstanding load capacity, small size and compactness, high efficiency, greater precision, and broad scope of application for your application requirements.

Comparing Various Types of Thrust Bearings

to comprehend the categories of the various thrust bearings available on the market. In furtherance, let us look at the different types:

- Ball Thrust Bearings: Such bearings comprise of raceways that contain sets of small balls on sockets, which provide very low friction is suitable for high speeds but allows for matrices to be placed in physic zones throughout the axial force in a singular direction.

- Roller Thrust Bearings: A form of spherical-shaped bearing, a Thrust bearing helps with the assistance that is needed synergistically where there are transverse forces that want to cause the roller Thrust Bearing near a perpendicular angle to move, but there forever will want to lead a point of misalignment.

- Needle Roller Thrust Bearings: Needle roller thrust bearings made up of needle shaped fasteners also have cylindrical rolling elements with small diameters. Their capability of carrying weight is also remarkable and can sustain a large amount of weight while being small which makes them suitable for applications that are small and compact.

- Spherical Roller Thrust Bearings: The main components of these bearings are barrels that come with an axial role requiring an elevation force as well, and these fragments must be of heavy duty. Loss of output force will be taken care of by self-aligning technologies where its magnitude will be the sine of the angle.

While contemplating these thrust bearings, factors such as load capacity, speed capabilities, size constraints and misalignment tolerances among other things should be considered. Each of these types has different features and is appropriate for different application requirements. Having this knowledge will assist you select the necessary thrust bearing depending on the industry and application specifications that you require.

Applications of Thrust Bearings in Different Industries

let us delve into the infinite scope of application and the working of thrust bearings in varied industries. Thrust bearings are commonly employed in a number of applications as they sustain axial loads and aid in the rotation of their axes. Given below are some of the applications in different industries:

Common Uses in Automotive Applications

Having been trained on broad data, whether concepts or literature, push bearings find broad application across the automotive discipline as they help work effectively with different components. They are important in transmissions, enabling smooth gear engagement and the axial loads that are developed when shifting gears. These thrust bearings are also used in the wheel hubs, the steering mechanism, and some engine parts to allow accurate movement and low friction.

The Role of Thrust Bearings in Machine Tools

Manufacturing machines require high accuracy and reliability. The machine tool spindle rotates in a controlled manner thanks to the thrust bearings, which provide most of the axial loading and positional stability of the cutting tool. They assist in achieving the stability and accuracy needed to conduct high precision machining operations in aerospace, automotive, and manufacturing industries.

How Bearings Are Used in Heavy Machinery

Powerful thrust bearings find application in heavy equipment such as construction tools, mining tools, turbines, etc, which makes it easier for them to withstand rigorous axial loads while at the same time providing stability. These bearings also assist other rotating components, like shafts, gears, and couplings, to function or operate freely. Thrust bearings also allow heavy machinery to work in harsh environments while ensuring minimum friction and peak performance.

It is also important to understand in which specific industries these thrust bearings are used so that adequate bearings can be chosen for equipment working under specific conditions. We hope you enjoyed reading this article, stay tuned for more tips on how to maintain and take care of thrust bearings and their applications.

Common Uses in Automotive Applications

I should point out the more common applications of thrust bearings in the automotive sector. Thrust bearings are important components and systems of many automotive applications, and their proper function ensures the smooth operation of the mechanism. Some key areas which incorporate thrust bearings in the automotive industry are as follows:

- Transmissions: The thrust bearing fills an important responsibility within the automotive transmission when the machine shifts while also bearing axial loads. They assist in load distribution and alignment of the gears for effective power transmission.

- Clutches: In an automobile clutch, thrust bearings serve an important function by providing smooth engagement of the clutch mechanism and disengagement of the said clutch mechanism. They assist in transferring torque through the engine and transmission as well as taking up axial load.

- Suspension Systems: Thrust bearings in suspension systems assist in bearing axial loads and allow the relative motion of the suspension components. They enable improved suspension operation allowing better ride quality and handling characteristics of the vehicle.

- Steering Systems: The thrust bearing has an application in the steering systems to bear axial loads while allowing the steering to move in all the necessary directions. They help bear parts of the steering and enable controllability of the vehicle.

- Engine Components: For camshafts, crankshafts and connecting rods, the thrust bearing finds its application in these various engine components. They bear axial load and friction facilitating rotation of these parts and enhancing general performance of the engine.

Knowledge of the typical applications of thrust bearings in vehicles is important for engineers, designers and specialists in the automotive industry. The choice of the appropriate thrust bearings intended for specific components of the automobile enables the manufacturers to achieve performance reliability and efficiency which enhances the overall vehicle quality and durability.

The Role of Thrust Bearings in Machine Tools

thrust journal bearings are of paramount importance in machinery tools because they ensure the smooth functioning of the machines. Machine tools that fall under this category include but are not limited to lathes, milling machines, and drilling machines, which have axial thrust bearings in order to be able to exercise control and response over axial loads. These bearings assist in supporting the axial forces during the machining operations, which makes it possible to cut, shape, or drill through materials. Thrust bearings assist in providing stability to the machine and simultaneously decrease the friction between components, which enhances the life of machine tools. Selection of thrust bearings and regular maintenance of radial machine tools is crucial in order to achieve high performance standards whilst ensuring the lifespan is as long as possible.

How Bearings Are Used in Heavy Machinery

Being in the industry, you might ask yourself how bearings are used in the case of large machines. The answer to this is that bearings are helpful for the operational smoothness within large machines. In large machines, including construction and mining machinery or industrial machinery, the bearings assist in the loading of parts, allowing rotational or linear motion. These parts are shafts, gears, pulleys, and wheels. More so, it is the bearings that aid in the cooling of the entire ensemble allowing the large machines to be able to work effectively no matter the environment. Be it performing heavy lifting, ensuring perfect balance, or enabling seamless rotational movement, at the end of the day, bearings help increase the efficiency and life span of these massive machines.

Maintenance and Care for Long-lasting Thrust Bearings

I would like to emphasize the importance of thrust bearings maintenance and care if their performance, reliability, and efficiency are to be sustained over a long period of time. It is possible to extend the service life and performance of these key parts by following a couple of practices. What are some tips:

Proper Lubrication Techniques

- The thrust bearings must be greased with the manufacturer’s lubricant.

- Distribute the lubricant evenly and appropriately for the desired operational results.

- Lubrication levels must be checked periodically and topped as required to avoid dry running and possible excessive wear.

Identifying Signs of Bearing Wear

- Monitor the thrust bearings routinely in order to spot abnormal noise, vibration, or excessive temperature during performance.

- Examine the bearing surfaces for evident damage, such as cracks, pitting, and corroded areas.

- Monitor any changes in efficiency or fluctuation in power output, as possible bearing degradation is inferred through these indicators.

Regular Maintenance Tips for Optimal Performance

- Observe the specific manufacturer maintenance schedule related to the thrust bearings in question.

- Avoid contamination within the bearing which leads to excessive wear or damage of the bearing.

- Effect correct alignment and appropriate fit of the thrust bearings so as not to cause undue stress or stroke out of alignment.

- It’s important to frequently check and, if necessary, modify the axial preload, which helps keep optimal levels of performance.

Enacting the aforementioned care and maintenance practices allows thrust bearings to live longer and be more dependable, which results in enhanced performance and less idle time during heavy equipment work.

Proper Lubrication Techniques

In other words, thrust bearings work well as intended and last long when they are lubricated appropriately. The following are some issues worth noticing:

- Choose the Right Lubricant: Opt for a lubricant that is specially manufactured for thrust bearings, considering the load capacity, speed, and operating environment. Always depend on the recommendations of the manufacturer to choose the most compelling lubricant type and its viscosity.

- Apply the Right Amount: Application of lubricant should be according to the manufacturer’s recommendation to avoid any discrepancies while using the machine. While too much lubrication may cause overheating, not applying enough lubrication may result in high friction and wear out the components meant to be lubricated. Hence maintaining a specific lubricant level is very essential.

- Regular Lubricant Inspection: Look for lubricant contamination, lost lubricant or lubricant degradation signs on regular basis. The performance of the bearing is raised my impurities such as moisture, dirt and debris however this results in bearing deteriorations. Lubricants must be cleaned and replaced if abnormal changes are noticed.

- Monitor Lubricant Temperature: The operative temperature of the lubricant can be recorded at any point to make sure there are no issues such as danger in the future. High temperatures can be an indicator and most of the times mean there is not enough lubricant. It’s essential to hope on any concerns regarding the temperature as the bearings can be ruined otherwise.

- Follow Proper Lubrication Intervals:Follow the lubrication intervals as proposed by the manufacturers. Scheduled lubrication in thrust bearing enables a high performance and minimizes chances of wear and tearing or any other failing activity.

In case you have advanced thrust bearing lubrication instructions which are ideal to follow, then be rest assured about the performance, operational reliability and the longevity of the thrust bearing as it will help in bringing about trouble free working of heavy machinery while cutting down on the periods of time that such machinery is not operational.

Identifying Signs of Bearing Wear

Brought on as an expert within a sector, you must also be observant enough to look for indicators of bearing wear so as to avert potential failures and downtimes. Given such an insight, here are a few telltale signs you should be watching out for:

Make sure to keep an ear out for any strange sounds such as grinding, squealing or rumbling emanating from the bearing area. These types of sounds could indicate that the bearing is already starting to wear down or has been damaged in some way.

Another indication of wear and possibly damage to the bearing is if you notice excessive vibrating while the device is in operation. Paying attention to equipment for changes in vibration patterns is also quite important as it may point to misalignment the device not being lubricated properly or the bearings have become worn out.

An increase in friction alongside a noticeable dip in performance from the equipment while in use, such as it becoming challenging to operate the equipment will also point towards the bearings becoming worn out. The bearings might become prone to issues during rotation or the equipment might require more power to operate than usual.

Be wary of the temperature of the bearing while it is being used; if the temperature is consistently high, it might be due to insufficient lubrication, high friction or other problems. Such if continued could lead to permanent damage to the bearing, irreversible.

Giving the bearing a visual inspection will also tell you if the bearing has undergone any damage such as pits forming, corrosion or flaking taking place. Such damages will only worsen the performance of the bearing and as a result should be remedied quickly.

Regular Maintenance Tips for Optimal Performance

With your knowledge as a professional in the field, you are aware that equipment requires regular servicing to ensure its proper working and long life. Here are some fundamental points to help achieve the optimal maintenance;

- Cleaning and Lubrication: According to the manufacturer’s guidelines, the bearings must be properly lubricated, and the machinery should be cleaned regularly. This assists in reducing friction and the occurrence of damage.

- Inspection and Monitoring: Regular check-ups of the bearings and any signs of deterioration, destruction or misalignment should become routine tasks. During use, notice whether there are unusual headturner sounds or an increase in the coefficient of friction or the temperature, which at times can pose problems.

- Tightening and Alignment: Assess all connections and tightened any bolts which keeps correct alignment. Excessive stress build up on the bearings when they are not aligned contributing to rapid wearing of the bearings.

- Training and Education: Your maintenance workforce should be trained and skilled enough to diagnose problems and rectify them. Regular lessons of on global maintenance strategies and certain techniques makes a great difference in longevity of your machinery.

- Scheduled Maintenance Plan: A detailed scheduling maintenance plan containing preventive maintenance procedures like examination, cleaning, lubrication, and other special instructions from the supplier must be designed. If this plan is observed, unforeseen malfunctions will be avoided as well as the smooth functioning of the machinery system would be ensured.

The instructions provided above are useful if you want to get the best performance of your machinery, improve its longevity, and save on expensive downtimes. Never forget that since most of the costs are time related, preventative maintenance is the best choice to avoid costly repairs and making your operations more efficient.

Reference

- Thrust Bearings to Reduce Friction and Support Axial Loads – This source provides an overview of how thrust bearings function in reducing friction and supporting axial loads.

- Thrust Ball Bearings|Precision Handling of Axial Loads – This article discusses the role of thrust ball bearings in handling axial loads efficiently.

- Thrust Bearings – Thrust Ball Bearings – This page provides detailed information on thrust bearings and their applications in supporting axial loads.

Frequently Asked Questions (FAQs)

Q: What is a thrust bearing, and how does it function?

A: A thrust bearing is a type of rotary bearing designed to support axial loads and reduce friction between moving parts. They are typically used to handle loads in one direction and are commonly utilized in automotive applications and various machinery.

Q: What are thrust roller bearings?

A: Thrust roller bearings are a specific type of thrust bearing that uses cylindrical rollers to support greater thrust loads. Due to the larger contact area of cylindrical rollers, these bearings can handle both radial and axial loads more effectively.

Q: How do thrust ball bearings and thrust roller bearings differ?

A: Thrust ball bearings and thrust roller bearings differ mainly in their construction and load-handling capabilities. Thrust ball bearings use spherical rolling elements and are suitable for lighter loads, whereas thrust roller bearings use cylindrical rollers and can handle higher loads and combined radial and axial loads.

Q: What factors should be considered when selecting thrust bearings?

A: When selecting thrust bearings, consider the type of load (axial or combined radial and axial loads), the speed of operation, the required load capacity, and the environmental conditions. Also, the type of bearing and the side of the thrust collar around a shaft should be evaluated to ensure proper fit and performance.

Q: Why are thrust roller bearings used in pairs?

A: Thrust roller bearings are typically used in pairs to accommodate axial forces in both directions, providing stability and balance to the system. This arrangement allows for better handling of axial thrust in applications where loads may vary in direction.

Q: What are cylindrical thrust roller bearings, and where are they used?

A: Cylindrical thrust roller bearings are a type of rotary bearing that utilizes cylindrical rollers to support axial loads. They are used in applications requiring support for higher speeds and larger contact areas, such as in heavy machinery and industrial equipment.

Q: How does a thrust bearing reduce friction?

A: A thrust bearing reduces friction by providing a smooth surface for the shaft to rotate against, minimizing direct contact between moving parts. The use of rolling elements such as balls or rollers helps distribute the load and reduce frictional forces.

Q: What is the function of a housing washer in a thrust bearing?

A: The housing washer in a thrust bearing provides a stable surface for the bearing to rest against, ensuring proper alignment and support. It helps distribute the load across the bearing and maintains the bearing’s position within the housing.

Q: Are thrust bearings used in high-speed applications?

A: Yes, thrust bearings are typically used in high-speed applications where they can manage axial thrust while reducing friction and wear. Their design allows them to function efficiently in environments requiring quick rotational movements.