In this in-depth piece, we aim to look into the world of ball bearings and explain how they are helpful in various industries and applications. Learning their use together with their design can give us an understanding of the significance of these small components and their strength in reducing friction, providing support, and enabling motion. We define the construct of a ball bearing set, analyze the particular varieties of ball bearings, identify the minerals of each featured model, and look for their extended uses in the automotive and aerospace industries. So, let’s start on this journey, which is sure to explain the workings of ball bearings, which are present in innumerable mechanical systems and even more.

What Are Ball Bearings and How Do They Operate?

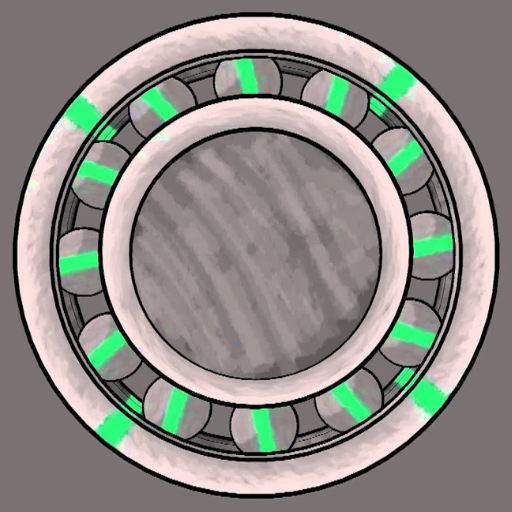

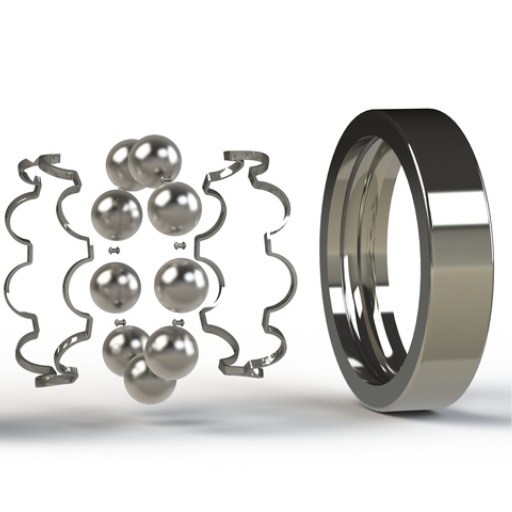

In ball bearings, the components are known in mechanical engineering as elements that reduce friction and weight support and facilitate applications. Components include an outer ring, an inner ring, and a ball set placed between them. The balls roll and allow for a smaller area of surface contact and friction against the rings. Rotation increases the efficiency of the tasks performed and the lifetime of the mechanical systems. Bearing balls enable a rotational or linear motion whilst reducing the amount of friction, these devices are very important in the functioning of machines and equipment to achieve the best performance.

Understanding the Basics: Ball Bearing Functionality

I’m going to be providing you with some information about the use of ball bearings in machines as I am well-positioned to talk about their functioning, being an industry expert myself. In precise words, ball bearings assist in motion in machines within a range of 90–95 degrees, which means they reduce friction between different parts, which makes their work more efficient. To explain it in an easier way, a ball bearing is made up of two rings and balls attached in between, and those balls roll and reduce the contact area that exists between the two metal rings, which improves the performance of the working system and makes it last longer. By transferring forces rotationally or linearly but with a little friction, they were able to make many pieces of equipment more efficient and reliable, which is their main purpose. This level of physical understanding of the basic working principles of ball bearings is of utmost necessity for engineers, manufacturers, and, most importantly, those operating and designing mechanical systems.

How Ball Bearings Reduce Friction in Mechanical Systems

ball bearings are devices used for reducing friction in machinery, within its design and workings. It comprises two rings, one fitted within the other, with several small balls located in between the two rings. The roles of these balls are known as rolling elements, which allow for a motion in a rotational or linear direction effortlessly and effectively. Since a ball bearing limits the number of contact surfaces between two moving components, friction is decreased and consequently prevents wear of the components, thus improving the efficiency and life span of machines and mechanical systems. This reduction in friction will also improve efficiency and energy wastage, allowing machines to function properly with less maintenance required. Since ball bearings can take up both radial and axial loadings, they come in useful in many applications from automotive and aerospace to industrial machines and even household items.

The Role of Ball Bearings in Motion and Load Support

When it comes to moving parts and bearing loads, ball bearings are commonly utilized in most industries. These are mechanical devices that minimize the relative motion of two parts of a machine, increasing their operational effectiveness. Because they reduce energy waste and improve efficiency, ball bearings ensure dependable machine operation with minimal upkeep. They are used in almost every machine – automotive, aerospace, industrial, and household – which provides radial and axial loads. As a result of their wide range of applications and their reliability, ball bearings enhance the performance of many mechanical units, which is extremely important in today’s engineering.

What Are the Different Types of Ball Bearings?

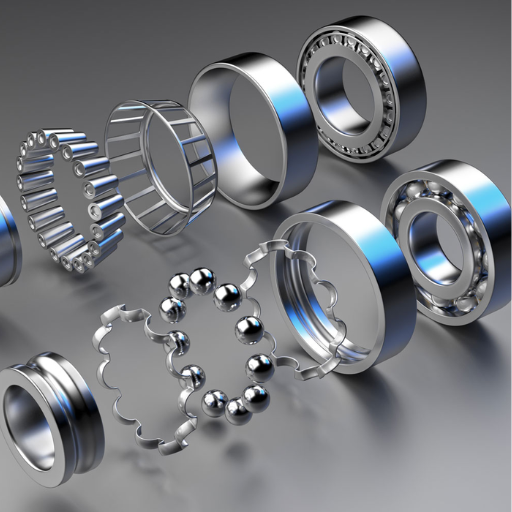

Let’s now turn our attention to ball bearings and the main types that can be identified. There are three basic ball-bearing types:

- Deep Groove Ball Bearings: These bearings are known for their deep raceways, which allows them to support radial and axial loads. They are most widely used in high speed and low friction applications such as electric motors, automotive parts and household devices.

- Thrust Ball Bearings: As thrust bearings engaged thrust loads, they themselves are especially suited for such devices, which require heavy-duty thrust ball bearings, i.e., automotive transmission, agricultural machinery, and heavy construction equipment. It consists of two washers with a number of balls in a cage, bearing assembly that permits transmittal of force in one direction only.

- Self-Aligning Ball Bearings: Out of these bearings, this self-aligning type is designed to compensate for the misalignment between shaft and housing. These types of bearings can be used in applications where shaft deflection and misalignment is liable to happen i.e. in conveyor systems, agricultural equipment and industrial gearbox systems.

There is a ball bearing available for each of the applications ensuring the smooth functioning of a variety of mechanical systems across different industries.

Exploring Deep Groove Ball Bearings and Their Uses

With a comprehensive understanding of the industry, Deep Groove Ball Bearings are ball bearings which are commonly used with a vast scope of applications in many industries. These bearings employ raceways that are deep and uninterrupted, both of which can handle radial and axial loads. Since their design is deep, the ball bearings are capable of working smoothly and efficiently, reaping the benefits of reduced friction. Due to their performance, deep groove ball bearings are located within a variety of machinery and equipment, such as electrical motors, pumps, automobile units, and home appliances. Their field of application includes high-speed units as well as strong parts; hence, in a lot of mechanical systems, these components are vital.

How Thrust Ball Bearings Handle Axial Loads

thrust ball bearings are used when necessary to support axial loads, which are forces that are in line with the shaft of the bearing. They withstand high thrust forces as the rotations of the axles are smooth and expansive; strength is achieved with the extended preferential design of the bearing containing a series of the spheres held in a recess between two washers when the contact angle of the spheres supports axial loads which are able to be transmitted in the direction of the shaft of the bearing. This design permits a great deal of friction land ess abuse of the bearing when axial forces of a high order are present. They are, however, extensively used in automotive transmissions and other places where there is an axial load in machine tools and even heavy machinery.

The Unique Features of Self-Aligning Ball Bearings

Self aligning ball bearings are a method of choice in many applications due to several distinguishing features possessed by this particular bearing type. They include an inherent design feature that allows the bearing to compensate for angular misalignment between the shaft and the housing it is fitted into. This self-aligning capability is possible because of its design, which has two rows of balls and a spherical outer ring. The construction of the bearing permits it to compensate for misalignment induced by shaft deflections, assembly inaccuracies, thermal expansion of the shaft, etc. High-speed self-aligning ball bearings have the properties of high speed, excellent shock absorption, and low frictional losses, making them ideally suited for any application that is characterized by the presence of shaft misalignments and where high rotation speeds are needed, such as mechanical and automobile systems.

How Are Ball Bearings Made and What Materials Are Used?

Making ball bearings comprises several processes that are interconnected. To start any such process, it is necessary to focus on the correct material – steel or ceramic – which is well recognized for its strength and low friction. The blank is configured into a more specific shape by forging or casting. The next step involves the fabrication of the inner and outer rings, which are later subjected to machining processes aimed at achieving the desired size and finishing. The ball bearings are put together by inserting the balls between the inner and outer rings and then locking them into position. Last in line for the bearings is a series of tests that validate their capabilities and reliability under working conditions.

The Manufacturing Process: From Material Used to Finished Product

As we have seen from the preceding discussion, there is an expert quality control program in place. Bear in mind that the elimination of cross-contamination from other metalworking processes, such as the machining of steel end caps or laces, requires careful attention to detail. Still, plating solutions can be quite expensive in quantity and often complex mixtures of nickel and silver coatings in intricate layers. In such conditions, their almost complete absence in overlap technology guarantees economic efficiency. The mechanical strength and toughness of the inner LOC of the ball bearing are optimal within specific dosage ranges that are dependent on the size of the ball, the method of application, and the material of the base or device.

Why Ceramic Ball Bearings Are Gaining Popularity

The rise of ceramic ball bearings into prominence is well warranted and as one who has monitored the developments in the bearings segment. Indeed, ceramic ball bearings provide specific benefits that cannot be easily afforded by steel ball bearings and, hence, are gaining increasing traction in a number of sectors. Their outstanding attributes, which include high hardness, low density, and corrosion resistance, deliver a myriad of advantages such as:

- Improved Performance: Ceramic Ball bearings have lower friction and generation of heat which results to more efficiency and effectiveness in high speed applications.

- Extended Lifespan: Due to the remarkable hardness and wear resistance of ceramic materials, ceramic ball bearings have a longer service life. This leads to a longer service life, lesser maintenance, and reduced replacement expenses.

- Enhanced Durability: Ceramic ball bearings are impervious to corrosion, which enables them to work under extreme working conditions and environments in which steel ball bearings fail to.

- Lightweight Design: Because of the low density of the ceramic materials, ceramic ball bearings are relatively lighter and more efficient than steel ball bearings. This weight reduction also aids in the overall performance of the system since it is very critical in industries such as aerospace where every gram is crucial.

- High Temperature Capabilities: One of the distinguishing features of ceramic ball bearings is their excellent thermal stability which allows them to bear high temperatures without affecting performance; thus, they can be employed in extreme conditions.

As a result of these unquestionable advantages, the automotive, aerospace, medical equipment, and several other industries are widely introducing the use of ceramic ball bearings into their systems. In the same way, as technology and manufacturing capability improve, the ceramic ball bearing demand will also grow, continuously challenging the level of performance in a range of segments, thus inspiring innovation.

The Importance of Inner and Outer Ring Design

I cannot overemphasize the significance of inner and outer ring design when it comes to the making of ball bearings. The other two aspects of the ball bearings are the essence of how the bearings behave and how long they remain intact. The inner and outer rings act as the skeleton of the ball bearings, so they ease the alignment, the load transfer, and the rotation of the ball bearings. The inner and outer ring design is done in such a way that the efficiency and lifetime of the bearings are considerably improved by reducing friction and wear and tear. There is a need for great emphasis on the design and production of these rings for them to be optimal in performance and reliable for the different uses in the market.

What Are the Applications of Ball Bearings?

ball bearings have their place in many activities enabling the performance of smooth and efficient operation. Some of the commonplace uses of ball bearings are given below:

- Automotive Industry: The strong use of ball bearings in the automotive sphere is reflected in the extension of such applications as wheel hub assemblies, transmissions’ movements, and critical engine rotations, where they provide smooth rotation and minimize the effects of friction.

- Aerospace Industry: Critical for the aeronautical ball bearings can be found in the following elements of the aircraft such as an engine, landing gear box, and control surfaces which machinery is willingly exposed to outright hostility of the aerospace environment.

- Industrial Machinery: Even in an industry where these machinery parts can be classified as auxiliary parts, they are widely deployed and are indispensable in manufacturing machinery, conveyors, and construction or mining machinery. They promote ease of movement, serve to prevent friction and wear components of manufactured machinery, and increase their operating life.

- Electric Motors: Motors, which fall into a category of electric devices, consume a lot of wattage to overcome the frictional loss that is intensified with ball bearings, thus improving rotation efficiency for a long service life. It is useful for numerous devices including appliances, construction devices, and industrial devices.

- Medical Equipment: Spherical types can also be found in certain medical equipment, especially surgical and image machines and for any diagnostic machine. Such devices contain high precision due to their capability of accurate positioning and reliability when medical operations are being carried out.

Industrial and technological facets can also include other application examples, among which are the most important, of course the ball bearings.

Common Industries Where Ball Bearings Are Used

I know that all rotating objects like engines, wheels, and others with circular profiles use ball bearings to increase the efficiency of their operations or their performance. Common industries where ball bearings are used are:

- Automotive Industry: Ball bearings are present in the engine, transmission, wheels, and other automotive systems, where they improve rotation and decrease friction and are integral in the overall operation.

- Aerospace Industry: Ball bearings exhibit a great deal of importance in aircraft engines, landing gears, control systems, and some other applications in the aerospace. They give consistent performance, they endure harsh conditions, and are able to enhance the safety and the effectiveness of the aerospace technology.

- Industrial Manufacturing: Also such devices are ball bearings, which are applied in heavy machinery, conveyors, robotics, manufacturing equipment, etc. They augment the exact movement, increase physical processes efficiency due minimization of friction in industrial processes.

- Medical and Healthcare:Ball bearings are an important element of medical devices such as surgical instruments, imaging devices, and diagnostic devices in healthcare. They are used in providing movements and confirming reliability that will enhance performance for medical practices.

- Energy and Power Generation: Ball bearings can be found in machinery such as turbines, generators, wind wheels, and other forms of power generation. They act to reduce losses in friction, assist in energy conversion, and increase effective energy in general terms.

It further demonstrates their versatility and the range of applications they can have across different industries or sectors: traffic sciences, engineering, and medical industries.

How Ball Bearings Improve Efficiency in Automotive Applications

you will never forget that a ball bearing is an essential element in the automotive application in terms of efficiency improvements. It helps in achieving smooth and low-friction motion which leads to decreased energy losses and an increased performance. Applying ball bearings in automotive elements such as engines, gears, or wheel bearing hubs helps reduce friction and ensures less wear and tear, better fuel consumption, and enhanced control of the car vehicle. Ball bearings allow friction forces to be reduced and increase the efficiency of energy transfer, which improves the functioning of individual automotive systems and contributes to a more durable and economically sound driving process.

The Role of Ball Bearings in Aerospace Technology

The professional and practical activities of the author allow us to view in a more critical and practiced way the significance of elements in aviation mechanisms such as ball bearings. Depending on the construction and materials used, ball bearings are employed in numerous aircraft parts to operate efficiently, reliably, and with minimum friction energy losses. They are used primarily for the improvement of energy transmission efficiency and are incorporated in turbines, control mechanisms, undercarriages, and many other aircraft systems and functions. Through the use of energy-transferring ball bearings, friction is addressed, thus preventing wear and tear and enhancing the fuel economy of aerospace apparatus while helping to prolong the working life of aerospace equipment. The result is the efficient and dependable functioning of other aerospace systems, which ensures aerial security and reliability.

What Are the Benefits of Ball Bearings?

Throughout my career in the industry, I have come to appreciate the many advantages of ball bearings. They serve to extend the life of machines by minimizing wear-and-tear as they reduce the friction that occurs between moving parts, thereby increasing equipment life. Making use of ball bearings increases the cost-effectiveness of a product by increasing energy transfer, increasing efficiency, and decreasing maintenance costs. Equally, they have been cited as helping in conserving the environment by reducing friction and energy losses. Innovative designs, such as hybrid ball bearings, which create new and exciting opportunities, can make use of such advances. Advances in roller-bearing technology have also revolutionized a number of industries. To summarize, ball bearings have a very important function when used in aerospace applications for the optimal operation, safety, and reliability of aircraft systems.

How Ball Bearings Enhance Machinery Longevity

I can say that there are multiple benefits to using ball bearings, and these ultimately are factors that help prolong aging. These benefits ensure that there is low friction between moving components, which effectively translates to less wear and tear. This also means increased energy transfer and efficiency and lower maintenance costs. As a result, the machinery performs satisfactorily and has a longer service life, which means that disruptions caused by repairs or replacements are infrequent, and their costs would be reduced. Furthermore, Firm and controlled rotational motion provided by ball bearings is an important aspect that also addresses the safety and dependability of machines. As a whole, the incorporation of ball bearings in machines facilitates the latter’s normal operation and enhances its performance characteristics. This equates to durability and cost-effectiveness in the longer term.

The Economic Advantages of Using Ball Bearings

Having been in the industry for some time now, the economic aspects of the use of ball bearings are worth noting. The introduction of ball bearings into any piece of machinery enables the company to accrue so many benefits that translate into reduced costs and enhanced efficiency. Following are a few of the key benefits:

- Reduced Maintenance Costs: Circulating the load to the moving parts is achieved using ball bearings which are able to minimize the friction and in effect the wear and tear of the machine parts. As the reduction of friction will imply less maintenance the frequency of repair or of parts replacement will be decreased.

- Increased Energy Efficiency: Providing the machinery with ball bearings would allow for a much more energy efficient machinery due to less exertion of force within the moving parts of the machinery. With this increased energy efficiency comes from the fact that less power demand is needed to run the utility, leading to lower costs associated with electricity supply.

- Extended Machinery Lifespan: High levels of durability and longevity attributes ball bearings into being able to increase the lifecycle of the machine. Due to the low friction and wear, the machine parts can work for extended durations without needing to be replaced. This leads to the reduction of costs associated with early replacement of machine parts.

- Enhanced Performance and Productivity: The other possible application of ball bearings includes their production as the moving parts of machinery hence impacting the performance of the machines. Therefore, production impact increases, meaning that the company will be able to achieve its production targets quickly and in a more cost effective

- Cost-Effective Solution: Overall, the benefits that come from incorporating ball bearings within a machine can outweigh the economic costs of doing so. This is a result of low costs of maintenance, high-performance energy efficiency, long life spans, and productivity of the ball bearings of the company making it a viable economic solution.

Owning ball bearings has its economic advantages and, industries can control their production expenses and boost the profitability of their machines with such components, to put it simply.

Environmental Benefits: Reducing Friction Between Moving Parts

I can state with full conviction that the technological advancement of ball bearings has the ability to greatly reduce environmental degradation in a specific way. The wear and tear of machine parts is significantly minimized when ball bearings are used since they greatly reduce friction, which in turn has the following positive environmental impacts:

- Energy Efficiency: The application of frictionless bearings leads to improved energy efficiency of machinery and equipment since less energy is wasted as heat. This not only leads to less energy use as well as lower greenhouse gas emissions thus making operations greener and more sustainable.

- Longer Lifespan: The use of ball bearings decreases the average friction of machines, which in turn increases the lifespan of certain machine parts. This translates to less replacement and, hence, less material waste generation and preservation of resources.

- Reduced Lubrication Requirements: It can also be noted that ball bearings allow to significantly cut down on lubricants which in effect result in a lower negative impact on the environment.

- Minimized Noise Pollution: The performance of ball bearing eliminates internal circumferential motion due to its smooth rotation and, in turn, motion, which leads to quieter machinery, therefore leading to a reduction in industrial noise pollution. Not only does this enhance the workers’ well-being, but it also reduces the impact on nearby residents and the environment.

Now, as noted above, the energetic contributions of the ball bearing technology to the environment do not end there. It is the ball bearings that reduce the friction and increase the performance of machinery which’s effect is felt in energy savings, equipment longevity, lubrication, and quietness. The ball bearing designs in particular, if appreciated and developed, would allow for more eco-friendly practices in the different sectors.

How Does Ball Bearing Technology Continue to Evolve?

The trend that started decades ago has now permeated life in every sector imaginable, including agricultural machinery, and the credit for such advancements goes to constant innovation in ball-bearing technology. It is needless to say that innovation fuels such constant advancements, which include new ideas, new materials, and new manufacturing methods, allowing ball bearings to be more efficient, more functional, and more robust. Active load research and development are being done to seek an increase in the load capacity of bearings, the components that are so critical in supplying reduction in friction while improving dynamic rigidity. In addition, advances in CAD and simulation technology have changed the way ball bearing designs are optimized, allowing engineers to develop products that are not only made to fit but also perform well in all anticipated uses. The demands of the market clearly indicate that such technologies have an appealing future within the domains of increased precision, increased power efficiency, and greater versatility with new technologies like IoT and automation.

Recent Innovations in Ball Bearing Designs

I have observed some interesting recent evolutions in the designs of ball bearings, which are changing the world. Producers have never downplayed their creativity and are always focusing on new design concepts, materials, and different ways of manufacturing to improve the performance, efficiency, and longevity of ball bearings. There is a lot of emphasis on R&D work for these innovations that attempt to increase load capacity, reduce friction, and ultimately increase the life curtains of these components.

New methodologies are emerging in a number of fields, including computer-aided design (CAD) tools for better integration into industries. This enables engineers to manufacture bearing ball designs as required and function,n considering the optimal level throughout the given range of intended use. This also serves to encourage other manufacturers to produce better simulation of ball bearings meeting the standards of expected energy efficiency.

In addition, developments of ball bearings should not stop now as there is potential for even more advanced designs. Attention will continue to be placed on aiming for higher precision, advanced materials and coatings, and reaching out for new applications, for example, in IoT and automation. The adoption of IoT and automation, together with ball bearings, creates numerous opportunities for better performance standards, reliability, and functionality for use in various industries.

To sum up, the last few years have seen new designs for ball bearing constructions that pushed bearings further than approaching new levels of performance and efficiency. Accompanied by continuous development and an emphasis on technology, accuracy, and life, ball-bearing applications are surely going to achieve more excellent innovations in the future.

The Future of Hybrid Ball Bearings and Their Applications

Considering my professional knowledge and within the industry, my vision toward the prospect of hybrid ball bearings seems quite bright. These innovative bearings are great in performance because they combine the best of the ceramic and steel materials into a single structure. The incorporation of ceramic balls reduces friction and enhances the speed capabilities of the component while making it resistant to corrosion and even wear and tear. All this renders them suitable for use in harsh industries like automotive, aerospace, or even renewable energy. What is more, the future expansion of hybrid ball bearings in electric vehicles and robotics opens space for more efficient and environmentally friendly technologies. They will also foster the proliferation of hybrid technologies in various sectors as they will be critical in enhancing performance.

The Impact of Roller Bearing Advancements on the Industry

I have seen the benefits of advancements made in roller bearings by different sectors over time. Transforming the processes and machinery of industry, roller bearings have a proved ability of heavy load support and high radial and axial load capacities. Such trends as roller bearing development certainly positively affected performance, efficiency and reliability of multiple sectors.

In manufacturing, roller bearings became a good tool in maximizing production activities through minimum resistance, minimum idle time and quick and accurate operations of giant machines. That led to enhanced output, cost reduction, and general operational efficiency.

In the auto industry, features of roller bearing technology have led to increased safety and reliability of automobiles. Roller bearings are installed in key parts of automobiles as wheel hubs, transmissions, engines etc. Where, great strength, low friction, and high performance is expected. This improves the automobile very ease in handling, fuel consumption efficiency and durability.

Moreover, the capacity of roller bearings have extensively benefited the energy industry in wind turbines and other renewable energy systems. Looking at reasons why roller bearings are perfect for wind turbine applications, the ability to withstand horizontal load together with the shaft rotation speed numerous times makes them a sure way of power generation.

As a conclusion, the roller bearing developments have significantly contributed to the development of different sectors as they have enabled smoother activities, enhanced product functionality, and improved reliability. With further developments in technology, it can be expected that roller bearings will still be at the forefront of transformation and enhancement of industrial processes.

Reference

- An expert system for the design and selection of ball bearing parameters – This article discusses the design and selection of ball and roller bearings.

- Design optimization of an angular contact ball bearing for the main shaft of a grinder – This paper covers the design optimization of angular contact ball bearings under various loads.

- Ball bearing skidding and over-skidding in large-scale angular contact ball bearings – This study explores the skidding and over-skidding behavior in industrial angular contact ball bearings.

Frequently Asked Questions (FAQs)

Q: How are ball bearings made?

A: Ball bearings are made through a multi-step process that includes forging, heat treating, grinding, and polishing. The balls are made from stainless steel or other durable materials to ensure longevity and performance. Precision manufacturing processes are used to maintain the quality and accuracy of the bearings.

Q: What are ball bearings used for?

A: Ball bearings use balls to reduce friction between moving parts and are used in various applications, including automotive, aerospace, and industrial machinery. They help in supporting radial and axial loads and enable smooth, high-speed rotation.

Q: What is a rolling-element bearing?

A: A rolling-element bearing is a type of bearing that uses rolling elements, such as balls or rollers, to maintain the separation between moving parts. This allows for reduced friction and wear, enhancing the efficiency and lifespan of machinery.

Q: What are the different types of bearings?

A: There are several types of bearings, including ball bearings, cylindrical roller bearings, thrust bearings, and angular contact bearings. Each type is designed to handle specific loads and applications, providing flexibility and efficiency in mechanical designs.

Q: How are ball bearings featured in mechanical applications?

A: Ball bearings feature prominently in mechanical applications by reducing friction and supporting radial and axial loads. They are designed to allow for smooth and efficient rotation, which is critical for the performance of various machines and equipment.

Q: Why are ball bearings typically made from stainless steel?

A: Ball bearings are typically made from stainless steel due to their durability, resistance to corrosion, and ability to withstand high temperatures and loads. This ensures that the bearings can perform reliably in demanding environments.

Q: What role do precision ball bearings play in high-speed applications?

A: Precision ball bearings are designed to support high-speed applications by providing low friction and consistent performance. They are critical in environments where speed and accuracy are essential, such as in aerospace and high-performance machinery.

Q: How do thrust bearings differ from other bearings?

A: Thrust bearings are designed to handle axial loads, which are forces parallel to the axis of rotation. Unlike other bearings that primarily handle radial loads, thrust bearings are key in applications where axial load support is crucial.

Q: Are ball bearings available in different sizes and configurations?

A: Yes, ball bearings are available in a wide range of sizes and configurations to suit different applications and requirements. This versatility allows them to be used in everything from small electronic devices to large industrial machinery.