Welcome to “The Master Handbook on bearing types and their applications”! This dynamic and comprehensive guide intends to enable you to comprehend all bearing types and significantly appreciate their various uses across industries. It does not matter if you are an engineering lover, a mechanical professional, or just have some interest in bearings; this guide has been set up to give you sufficient information, knowledge, and perspective to understand the general concept and operations of the bearings. We will begin with the basic mechanism of the bearings and then discuss the various designs and, of course, how they are used. So, are you ready? Let’s go and discover the mysteries of bearings.

What Are Bearing Types and How Do They Function?

you may be wondering, “What are bearing types, and how do they function?” Be ready, as we are here to review the fascinating world of bearings and understand the answers! Bearings are important parts of any mechanical assembly as they allow relative motion between the majority of the components to be as easy as possible. They serve the purpose of allowing two parts or multiple parts that are in physical contact with each other with relative motion to either rotate or move linearly with as little force as required to move in such a way. There are many types of bearings based on the application and conditions. For example, ball bearings, which employ the use of balls to spacers between moving parts, roller bearings in which cylindrical rollers are used and many others with their respective designs and functions. The principle works by supporting the weight of the machines and reducing any materials that cause friction of movement, thus making it easier for the machine to work and ensuring that it serves its purpose for a longer period of time. Whether you are an engineering aficionado, a mechanical working professional, or you have a simple inquisitiveness for bearings, this guide presents an elaborate narration in-depth with all the underlying details, enabling you to grasp all the fundamentals and working aspects of these crucial components. Therefore, we shall embark on this fascinating journey of understanding bearings!

Understanding the Basic Bearing Mechanism

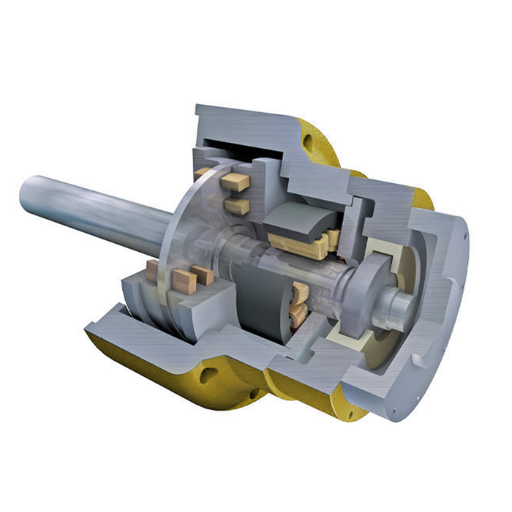

you may ask yourself– what does a bearing do, and what is it? In the simplest of terms, a bearing is a specially made, integral part, which, in the case of connecting two parts that are capable of relative motion, minimizes friction and helps to perform rotary or sliding motions. It comprises two major parts, the inner ring, and the outer ring, and interposed in these two rings are the rolling elements, such as balls or rollers. These rolling elements allow smooth movement by applying the load in a way that reduces the effort needed to rotate these elements, thus minimizing friction and contributing to better functionality and life of the equipment. Hence, as we analyze the basic bearing design, we lay the groundwork for examining the numerous types of bearings and their uses in various fields. Let us join together this fascinating world of bearings and visit a great deal together!

Exploring the Various Types of Bearing

I will take you through the wonderful journey of bearings and learn about the different types of bearings that are vital in machines. Bearings are mechanical components which facilitate movement and reduce friction forces through uniform load distribution. They consist of an outer ring and inner ring, separated by rolling elements (balls or rollers). Now, we can shift our focus to the various groups of bearings and the purposes for which they are used in different industries.

- Deep Groove Ball Bearings: These general-purpose bearings are utilized in household, electric motor, and vehicle parts. They can bear axial and radial loads, have low friction and are high-speed.

- Tapered Roller Bearings: These bearings allow radial and axial loads. They are used in a variety of vehicle wheel hubs, construction apparatus and conveyor transport mechanisms. They are good in resistance to impact load and allow some degree of misalignment.

- Cylindrical Roller Bearings: These bearings are best used in high radial loads and high speed applications. They are fitted in gearboxes, machine tools and power industry apparatus. They are stiff and can take force on one axe.

- Thrust Ball Bearings: These types of bearings can take a load in one direction and find applications in cars, machines, and farm equipment. It has two washers and a ball bearing in its construction.

- Spherical Roller Bearings: Bearings whose axis of rotation is free to revolve around a point in space. Heavy and misaligned applications such as those used in mining equipment, paper mills, and steel mills. Radial and axial loads are also within their means.

These different types of bearings have specific characteristics and applications that we should understand in order to select the most appropriate one for particular machinery and industries. The use of bearings is essential as they aid in the proper functionality and performance of mechanical systems in terms of friction management and longevity. We will further appreciate and look at the working principles, applications, and benefits of various types of bearings in the remaining sections.

How Do Different Bearings Work in Machinery?

so let us now examine the operating principles of various types of bearings used in machines. Bearings are vital parts that carry out the movements of machines effectively and efficiently, minimizing friction and increasing the durability of the mechanical systems. Let us now look briefly at the operation of different types of bearings:

- Ball Bearings: Ball bearings are composed of small metal balls that act as a separator between the moving parts so as to minimize friction. The balls are constrained within the two rings referred to as the inner and outer races and hence rotate smoothly.

- Roller Bearings: A roller bearing uses either cylindrical or tapered rollers rather than balls in order to distribute the load over a greater area. This design enables them to withstand larger radial and axial loads relative to other designs.

- Fluid Bearings: Fluid bearings are those that utilize a thin film of liquid, which can either be oil or air, to separate the two working surfaces. This film lowers the coefficient of friction and increases the degree of freedom thereby allowing smooth rotation while minimizing abrasion.

- Magnetic Bearings: Magnetic bearings can operate by means of revolving components whilst eliminating contact and is achieved by employing magnetic fields. Due to the absence of this contact friction it makes it possible to rotate at higher rates.

Comprehending the operational mechanisms behind the various kinds of bearings allows us to make a proper selection for specific types of machinery together with various industries. We will take our next step in the application, benefits and amazing usage of motors’ parts such as bearings.

What Are the Different Applications of Bearing?

it’s important to appreciate the wide range of bearings used across different industries. The contribution of bearings to functioning mechanical systems is rather fundamental, as bearings allow for relative motion between moving parts to be performed more easily and in more varieties. Among different types of bearings, the other applications of bearings include:

- Automotive Industry: Every car has a wide variety of systems like engines, transmissions, wheels, and suspensions. All these systems use bearings as key components that allow for smooth rotation movement while reducing friction thus making the performance more powerful.

- Industrial Machinery: Some industrial best-performing motors, pumps, compressors, turbines, conveyors, and manufacturing plants are built with integrated systems that make these bears the most important components in this industrial machinery. This makes the tasks easier, achieving the goals perfectly in such a complex system.

- Aerospace and Aviation: Bearings in the aerospace industry are extensively used, especially for aircraft engines, landing gear, control surfaces, and other flight controls. They allow the structures to behave with stability, precision and strength in extreme conditions which would otherwise be unacceptable.

- Power Generation: Moreover, turbines on wind generators and channels on hydroelectric plants utilize bearings. The function to rotate generator shafts or other components seamlessly to produce electricity of the essential mechanical energy needed, is done through these bearings.

- Medical Equipment: By using bearings, medical devices and equipment such as prosthetics, surgical and robotic systems are made efficient and reliable which improves medical procedures’ quality and the best possible accuracy. Further, imaging machines have integrated bearings too.

- Renewable Energy: In addition, there are solar trackers and tidal systems that are used with bearings. Thus, optimally capturing solar energy and generating power is done through the rotation of the solar panels and turbines, all thanks to it.

The scope of usage of bearings in various industries as depicted by the foregoing examples is quite immense. Considering the selection of the most appropriate type of bearing for a given type of machine, load bearing capacity, speed, and working environment, engineers and industry workers ensure that all mechanical devices work efficiently and serve a long time.

Why Bearings Are Used in Mechanical Systems

Bearings have been at the forefront of contemporary mechanized systems and their operations. In simple terms, bearings assist in minimizing the frictional resistance caused by the movement of different parts. They ensure that rotating or linear parts of the machine move smoothly, minimize the chances of mechanical abrasion, and increase the lifetime of machines. For efficient working, a series of loads have to be mechanically applied. Bearings assist in transmitting such loads, and hence, even stress is applied on components without applying undue pressure on any specific one. Therefore, the use of bearings in mechanical systems enables more efficient designs, helping reduce energy demands and enhancing functionality and dependability for more operations and industries.

Common Applications of Bearing in Industry

I believe it is worth grasping the fundamental uses of bearings across so many industries. Without most bearings, mechanical systems would not provide support, stability, or satisfactory function. The following are some of the prevalent uses of bearings in the industry:

- Automotive Industry: Automotive Bearings, which are employed within automotive designs for wheel hubs, transmissions, engines, and suspensions, allow the components to rotate smoothly and reduce friction between them.

- Aerospace Industry: In the Aerospace arena, bearings are utilized in aircraft engines, landing gears, control surfaces, and any other subsystems where high precision, high reliability, and durability are required.

- Industrial Machinery: In addition, bearings are used in various industrial machinery, for instance, in pumps, conveyors, machine tools, turbines, and gearboxes, as components that provide support, reduce friction and enhance overall productivity.

- Power Generation: Bearings are known to be as parts of power generation devices, owing to turbines, generators, wind-turbines and Hydro-Electric systems for maintaining desired rotation while reducing energy losses.

- Construction and Mining: In the construction and mining industry specifically, bearings are employed in large traction machines, heavy machinery, and vehicles, enabling smooth movements and bearing a heavy amount of load.

- Medical Equipment: For instance, precision bearings are required in a medical device employed to provide CT scan, X-ray surgery, or MRI guidance to ensure consistent accuracy, reliability, and smooth performance.

Including bearings in these applications and considerably more allows the industry to enhance performance, minimize maintenance, and increase the operational level. Bearings are active structural elements which have brought about change in many sectors and helped with the advancement of technology and industry.

Innovative Uses for Bearings in Modern Technology

I have insights to share on the modern use of bearings which is an innovative concept. Various applications are made possible due to the bearing and its effective utilization, as it reduces maintenance and optimizes performance while being efficient in operations. Here are some key points to consider:

- Bearings in Medical Equipment: Various bearings are crucial elements in multiple pieces of Within medical equipment. For instance, CT and X-ray scanners, MRI systems as well as other sensors, and surgical instruments and other devices, all of which are utilized by medical personnel to deliver accurate and reliable services while enhancing smooth operations in clinics and hospitals as well as providing high quality services.

- Advancements in Technology and Industry: Though they were not as widely known in the past, these days, bearings play a critical role in the advancement of technology and industry. Bearings enhance the of all kinds of machines by allowing for the movement of rotation in cars interfaces, for instance, parts of a car, transport systems, and various industrial machinery.

- Different Types of Bearings: The two main types of bearings are ball and roller bearings. Both have their fair shares of benefits and usages. Ball bearings would perfectly suffice in situations or environments where speed is important, but loads are low, while roller bearings would perform receptively better where heavy loads are present.

- Advanced Bearing Technologies: There are two types of advancements, namely fluid earth and levitated magnets, which can also be categorized as bearings, which have some unique capabilities. Instead of using the maglev motor control, we used rotational magnetic encoders. Fluid bearings are also worth mentioning, who have shafts submerged in motor oil to limit friction.

- Benefits of Plain Bearings: Yes, they do, more commonly known as bushings, offer low friction, self-lubrication, and excellent load-carrying capabilities, as well as many applications in a wide variety of automotive, aerospace, and industrial machinery.

In conclusion, the applications of bearings in contemporary technology are simply remarkable. The impact of their use on elevating performance, decreasing maintenance, and increasing efficiency is essential in medical devices, transportation systems, etc. Understanding the various types of bearings and their uses would enable industries to choose wisely, enhancing their activities and fostering technology advancement.

How Are Ball Bearings and Roller Bearings Different?

let’s explore the details that differentiate ball bearings from roller bearings. Both types of bearings are relevant in plenty of operations, however, they vary in terms of design and the performance features.

Ball Bearings: Ball bearings have a very specific characteristic in the sense that they have balls in their construction, which makes them roll and rotate with very little friction. Perhaps the most easily defined characteristic of these bearings is their ability to operate at high speeds and with very little friction, which makes them ideal for applications that require fast rotation with high accuracy. As a result, they are widely incorporated in machinery, cars, and home appliances.

Roller Bearings: On the other hand roller bearings employ the use of cylindrical or conical shape of rollers instead of balls. These kinds of roller bearigns can transmit greater forces since they have more surface area touching and have greater radial and axial support. This type of bearings are more commonly used in construction machinery, ones used in factories and transmission of vehicles and many more heavy duty applications.

In conclusion, ball bearings are best suited for high-speed use and usage in low-friction environments, whereas roller bearings have the best applications in heavy-weight circumstances that need resilience and strong load-bearing performance. So, while opting for ball bearings or roller bearings it is always prudent to understand the application requirements so that one does get optimal output towards operational effectiveness.

When to Use Ball Bearings

In my opinion, the use of ball bearings should depend on the demands of the application. Ball bearings have the capability of functioning at high speeds with low resistance and smooth operations. They are especially useful in situations where fast rotation and accurate location are required. The balls are spherical in shape which allows for point contact and thus less friction to operate efficiently at high speeds. Also, ball bearings are suitable for those designs that contain little space and volume restrictions. Their properties, along with their ability to withstand radial and thrust forces, have made them widely used in the fields of automotive, aerospace, robotics, and many other applications.

Advantages of Roller Bearings in Heavy Load Situations

In my professional opinion, roller bearings have a number of important advantages when it comes to heavy load situations. These sturdy bearings are able to withstand a multitude of radial and axial forces, which makes them ideal for use in numerous industries where operating on heavy machinery, large equipment, or high force is a requirement. The following are the key benefits of using roller bearings in heavy-load situations:

- Increased Load Capacity: The area of contact of roller bearings is more than that of ball bearings. That’s why the load which would normally be concentrated on a small area gets more spread around. This allows them to carry greater loads and have better load carrying capacity.

- Greater Durability: The shape of the roller bearing is either cylindrical or it is tapered. Such geometries do help the roller bearings to bear more stress and resist deformation. Such traits increase the reliability of the performance and the life of the bearing.

- Improved Stability and Rigidity: The size and the area of contact of roller bearings are greater than their ball counterparts, resulting in increased stability and rigidity. This characteristic enables the bearings to have great accuracy of alignment, enabling them to bear heavy loads with a low risk of misalignment and wear due to contact.

- Reduced Friction and Heat Generation: The rolling elements in roller bearings have a larger diameter than those in ball bearings, resulting in lower contact pressure in roller bearings which equates to lower frictional forces. This not only cuts down on energy loses but also lessens heat which in turn increases efficiency and dependability.

Exploiting such benefits, roller bearings are well suited for use in applications that require heavy loads, high speeds, and durability. They are extensively used in the mining, construction, heavy machinery, and wind energy industries, ensuring that optimal performance is delivered even in strenuous conditions.

Choosing Between Ball or Roller Types

As far as I am concerned as an industry specialist with all things considered, it all boils down to the details of the application in question when asked to choose between ball bearings and roller bearings. There are both advantages and disadvantages to both types.

- Ball Bearings: Due to their low friction and a relatively small area of contact, ball bearings are useful in high speed with moderate load applications. They are useful in applications where low torque and smooth functioning is required such as electric motors, automotive and small size machine tools. Moreover, ball bearings are also small in size, adaptable, and are easy to fit.

- Roller Bearings: However, roller bearings are made to bear the brunt of great loads as well as extreme conditions. They have a larger surface area in contact with the bearing, which elopes loading over a greater area, which gives them the ability to carry heavy loads. This suggests the fact that roller bearings would be most effective in industries like mining, construction, heavy machinery, and wind energy, where high demands of speed and heavy loads are the norm.

In order to assist you in making the best choice, please take into consideration the load requirements, speed, the environment as well as application aspects. For better guidance on the most applicable bearing for the particular situation, a talk with the bearing specialist or an engineer may be quite beneficial.

How Do Fluid Bearings and Magnetic Bearings Work?

let’s take a look at fluid bearings and magnetic bearings. Fluid bearings, as the name implies, contain a thin film of a liquid, such as oil or air, separating the rotating shaft from the material surfaces of the bearing. This is a fluid layer that acts something to reduce friction and, therefore, ease up the rotation. The fundamental concept of fluid bearing is the hydrodynamic effect; the rotating member causes a pressure differential to form in the fluid, and the differential enables the formation of an upward force that supports the working load.

At the other extreme, magnetic bearings create an electromagnetic field that supports the rotating shaft and allows it to be positioned accurately. They include electromagnets which produce letracting or repulsive force which enables accurate positioning of the shaft. The savings in materials, assembly time and weight along with the inherent advantages of low friction, no mechanical contact and reduction or complete removal of lubricants makes magnetic bearings very attractive.

Magnetic bearings and fluid bearings have their special qualities and work in different fields. It would be beneficial for engineers and others working in the power shift to know the working, mechanisms and application of these bearings so as to make a right choice wherever they are required.

Understanding Fluid Bearings and Their Applications

In this article, we would like to provide some insights into fluid bearings and their application in the bearings industry. Fluid bearings are those that allow relative motion between two surfaces separated by a thin layer of fluid (oil or air) and also rotate a shaft. The rotating shaft gets a rotational motion with very little resistance owing to the fluid film, which lessens friction. This distinct construction has many benefits, thus making it applicable in specific cases. In the present article, we discuss briefly some fundamental features of fluid bearings and their use in different industries.

The Role of Magnetic Bearings in Reducing Friction

Now, let us look into the importance of magnetic bearings in friction reduction. A shaft can be rotated and suspended in midair thanks to magnetic bearings; they engage in the attractive and repulsive forces of magnets, and therefore, lubricant is not employed. This is a radical departure from traditional design, and it has several advantages in terms of friction reduction and performance enhancement. These bearings employ magnetic levitation, which implies lesser energy loss and, hence, greater efficiency and lesser wear and tear. Furthermore, the utilization of magnetic bearings facilitates greater efficient performance, which provides smooth motion, enhanced accuracy, and precision with reduced vibrations and increased reliability. Due to the low friction and controllability they provide, magnetic bearings are used in many fields, such as aerospace, power generation, and high-velocity machines.

Comparing Traditional and Advanced Bearing Types

it would be interesting to start off with an exciting comparison between the old and the new bearing types.

So, for many years, a ball bearing and roller bearing, also known as traditional bearing have been in many applications. They have moving parts that make contact and hence need lubrication in an effort to reduce friction. Nevertheless, these types of bearing have served the purpose well but there is a new type which is like an improvement on them, such as magnetic bearings which seem to be more effective and proactive.

- Friction Reduction: Conventional bearings engage in physical contact which leads to a generation of friction and energy losses. On the other hand, more advanced types of bearings, such as a magnetic bearing employs the use of magnets to suspend and rotate a shaft without contact, thus minimizing energy and friction losses. Furthermore, such a configuration reduces the overall wear and tear and increases efficiency.

- Higher Efficiency: Advanced bearing types, because of the reduction in friction and energy losses, possess greater energy efficiency than conventional bearings. Such minimal amount of friction lost when energy is exerted also promotes energy efficiency thus making it preferred in fields where efficient use of energy is paramount of importance.

- Precision and Control:Magnetic bearings, for instance, are able to control precision and stability at a fine angle. Accurate control of the levitation and the rate of the shaft rotation creates an effective control, low vibration and increases the reliability of the device. Such accuracy is most beneficial in the aerospace, electricity and high-speed engineering machinery industries.

However, when traditional and advanced bearing types are compared, it is clear that with regards to friction, efficiency, and precision, advanced bearing technologies, such as magnetic bearings, have remarkable advantages, which are ideal characteristics and advantages for many companies and industries looking for better performance and robustness on their applications.

What Are the Benefits of Using Plain Bearings?

I find it evident that there are a variety of advantages to the use of plain bearings. A selection of these advantages that make plain bearings a preferred option in many cases are:

- Low Friction and High Efficiency: The construction of plain bearings is such that the amount of friction between synchronously rotating surfaces is as low as possible. In this way, less energy is lost or wasted, energy consumption improves, and productivity increases in the end.

- Reliability and Durability: Due to their basic construction, plain bearings are reliable and long lasting devices. The device has the capacity to bear substantial pressures, shocks, and vibrations hence is used in rough conditions.

- Cost-Effective Solution: When compared with other kinds of bearings, the plain ones tend to be cheaper in both the acquisition and maintenance costs. Their construction and the long working time they possess makes their overall costs lower.

- Versatility and Adaptability: Plain bearings can be produced using various composition bearing materials. They can, therefore, be suited for specific requirements in terms of use and working conditions. This makes plain bearings widely used in many more industries.

- Self-Lubrication: Some plain bearings are designed to be self-lubricating, so there is less need for external lubrication which cuts down the need for maintenance. This feature allows for a reduction in the operational costs as well as offering ease of use.

In conclusion, the most important advantages provided by plain bearings are their low friction, high efficiency, cost-effectiveness, and reliability. The range of applications due to their versatility, as well as their self-lubricating characteristics, makes them as suitable for many industries. Reducing friction, increasing efficiency, or providing dependable functioning – plain bearings excel in meeting these requirements.

Exploring the Design of Plain Bearings

Irrespective of your skills, let’s look into the construction of plain bearings and discuss how they manage to perform efficiently in certain regions. Also referred to as sleeve bearings or bushings, plain bearings are quite simple in construction yet very effective in use as they help in load bearing and friction reduction in a number of mechanisms. It comprises a cylindrical sleeve made of bronze, steel, or plastic such that a shaft rotates within it. Now, let us examine the best features of the plain bearing design from the perspective of its principles of operation:

- Low Friction and High Efficiency: The main purpose of plain bearings is to ease the friction surfaces with the freedom of rotational stroke. The sleeve of the bearing can be considered as a low friction surface that connects the shaft and the surrounding structure resulting in less energy dissipation and better efficiency.

- Load Capacity and Reliability: Plain bearings are designed and constructed to have the ability to fulfill significant radial and axial loads. The capacity of a plain bearing depends on the material, bearing dimensions, and lubrication. With the right plans and material chosen, it becomes possible to design one that performs reliably even with heavy loads.

- Cost-Effectiveness: A number of applications can efficiently use plain bearings. Due to their simple structure as well as relative ease of applying them, they are less costly than other types of bearings, particularly in applications which experience low medium loads and medium speeds.

- Versatility and Adaptability: A number of materials can be used in manufacturing plain bearings therefore expansion for particular application or operating conditions could be done. Owing to this property this bearings can find application in a number of industries.

- Self-Lubrication: A self lubricating feature enhances many plain bearings preventing a need for external lubrication and maintenance. This trait helps lower so many operating costs and provides a greater level of convenience.

To conclude, the construction of plain bearings guarantees low friction, high efficiency, reliability, and low cost. Their broad application and self-lubricating features enable them to be very beneficial in numerous industries. Be it reduction of friction, improvement of efficiency, or performance that can be relied upon, plain bearings provide all of these and even more.

Why Plain Bearings Excel in Specific Environments

plain bearings’ capability of performing successfully in selected environments is primarily a result of their specific characteristics and advantages. Here are some key reasons why plain bearings excel in specific environments:

- Low Friction and High Efficiency: Plain bearings function by preventing slip between surfaces, stressing on reducing energy expenditure while allowing for standard motion in harsh conditions. This results in reduction of energy loss, improvement in effectiveness and providence of extensive service to the bearing.

- Durability and Reliability: Heavy load bearing, shock, and vibration are common applications where pure friction bearings seek use due to their ability to combat wear and tear. Their ability to withstand extreme conditions and aging makes the bearing consecutively perfect for applications where service time and reliability are essential factors.

- Cost-Effectiveness: Compared to several other types of bearings, pure friction bearings are cost-cut, simple, require minimal installation, and are quick and do not take much time assembling, do not require high maintenance, so they are faster. As a consequence, it does not take much time to operate.

- Versatility and Adaptability: Plain bearings come in a wide variety of shapes and sizes, and materials can be adjusted to suit requirements, strengthening the bonding force used. Making them highly advantageous in multinational firms that operate in numerous fields.

- Self-Lubrication: Most Plain bearings can lubricate themselves, requiring little maintenance and time to be spent, as a result the rates fell and numerous users were attracted.

To conclude the design of plain bearings allows for low friction while maintaining maximum efficiency and reliability at a low cost. Their wide application potential and self lubrication capabilities make them a great fit for a number of industries and uses. Be it reducing friction or augmenting efficiency or ensuring reliability, plain bearings do the job superbly.

Challenges and Solutions for Plain Bearing Applications

Your plain bearings are not the true bearing of highly complicated applications or systems that absolutely require any unique factors. There is a solution to these issues obviously. Some solutions have already been worked out. Let us analyze some of the common challenges faced in plain bearing applications and their corresponding solutions:

- High Loads and Stress: It is a known fact that plain bearings are subject to wear and sometimes violent destruction even during normal operation, given that they experience heavy loads and extensive stress. To combat this issue, a proper bearing selection is necessary. Select for materials that are suitable for high load conditions and consider the use of reinforced or composite bearings for harsh environments.

- Contamination and Corrosion: Out in the open environment, plain bearings are exposed to dirt, dust, moisture, chemicals, and other harmful substances which diminish both their function and their lifespan. To relieve this problem, proper sealing systems and bearings made of corrosion resistant materials can be ordered. Further, proper cleaning and maintenance schedules must also be instituted to avoid contaminant accumulation.

- Temperature and Heat Management: Operating at extreme temperatures can undeniably affect the plain bearing’s efficiency and structural organization. There exist some bearing materials that are ideal for use in bearing high temperatures. Effective lubrication is also very important in controlling the amount of heat generated and increasing its dissipation.

- Vibration and Noise: The performance of plain bearing and its related systems can undergo critical functionality failures or reduce their efficiencies when subjected to vibrations or excessive noise. The effective absorption of excessive vibrations or noise is key to the flat use of a plain bearing. Shock absorber mounts and vibration-dampening bearings can be used for this application.

Such challenges, once understood and tackled properly, can help you to enhance the performance, and reliability and extend the life of any plain bearing application so long as it works efficiently in different kinds of industries.

Reference

- Emerson Bearing: The Best Type of Bearing for Your Application – This guide covers various types of bearings and their specific applications.

- ISK Bearing: Different Types of Bearings and Their Applications – This resource provides insights into different types of bearings and their uses.

- Lily Bearing: Types of Bearings – A Comprehensive Guide – Offers a detailed overview of different bearing types, including their pros and cons.

Frequently Asked Questions (FAQs)

Q: What is a rolling element bearing?

A: A rolling element bearing is a machine element that uses rolling elements, such as balls or rollers, to maintain the separation between moving parts and reduce friction. They are widely used in various types of machinery.

Q: How do thrust bearings work?

A: Thrust bearings are designed to handle axial loads along the bearing axis. They are often used in applications where the bearing may need to support a load from only one direction or in both directions, known as single-direction or double-direction bearings.

Q: What are the differences between ball and roller bearings?

A: Ball bearings provide low friction and are used to support radial and axial loads with high-speed capabilities. Roller bearings are used for heavier loads and can handle both radial and thrust loads more effectively due to the line contact between the rolling elements and the raceways.

Q: In which applications are angular contact bearings widely used?

A: Angular contact bearings are widely used in applications that require high precision and high-speed performance, such as in aerospace and automotive industries. They can support combined radial and axial loads due to their angled contact points.

Q: What are needle roller bearings?

A: Needle roller bearings are a type of rolling element bearing with long, thin cylindrical rollers. They are used in applications where space is limited and the load capacity needs to be high, providing excellent load-bearing capabilities in a compact design.

Q: How are bearings classified?

A: Bearings are classified based on their design and application, including categories such as radial bearings, thrust bearings, angular contact bearings, and needle roller bearings. Each type is used to support specific load conditions and machinery requirements.

Q: Why are ceramic bearings used?

A: Ceramic bearings are used due to their high resistance to wear and corrosion, making them suitable for extreme environments. They also exhibit low friction and can operate at higher speeds compared to traditional steel bearings.

Q: What role do thrust roller bearings play in machinery?

A: Thrust roller bearings are used to support large axial loads in machinery. They are particularly effective in applications where high load capacity is needed along the bearing axis, such as in heavy machinery and automotive gearboxes.

Q: What are the advantages of using rolling bearings in machinery?

A: Rolling bearings are typically used in machinery due to their ability to reduce friction, support radial and axial loads, and provide long service life with minimal maintenance. They are widely used in various applications for their efficiency and reliability.

Q: What are passive magnetic bearings, and where are they used?

A: Passive magnetic bearings use magnetic fields to support moving parts without physical contact. They are often used in applications requiring low maintenance and high speed, such as in turbomachinery and flywheels.