Wheel bearings are a vital component of cars or any type of vehicle and they do need frequent replacement. The process of replacing them can be challenging, but with the correct methods and equipment, such as a wheel bearing extractor, you can safely and efficiently undergo this task. This tutorial aims to educate people about the workings and functionality of a wheel-bearing extractor while also providing tips about how to use it. Armed with the knowledge that this article offers, you will be able to take on tasks like hub removal, which will increase your level of confidence when it comes to car maintenance. This is especially important if you are a hobbyist who is looking to do repairs around the house. If you are a mechanic, this will make hub removals much easier.

What is a wheel-bearing extractor tool, and why do I need one?

The wheel bearing extractor tool is designed especially for fixtures in a way that incorporates ease of putting on wheel bearings and removing them without causing damage to the hub or adjacent parts. It is quite important since it aids in making the operation easier, saves time, and reduces any possible risks that might develop through the use of inadequate tools or methods, thus rendering it a useful tool for both professionals and other handymen.

Understanding wheel bearings and their importance

A vehicle’s wheel assembly incorporates wheel bearings which allow the wheels to spin while at the same time bearing the load of the vehicle. Wheel bearings minimize the friction that occurs between the axle and the wheel, thus allowing smooth and unstressed driving. Wheel bearings, if functioning properly, assure the handling of the vehicle, fuel economy, and safety of the vehicle while all the set bearings are intact or undamaged. Otherwise, if bearings are damaged or worn out, they will cause uneven wear of the tire pattern, vibration, and possible failure of the wheel assembly system, too.

The role of a wheel bearing extractor in maintenance

a bearing puller is a wonderful tool in maintenance because it greatly facilitates the wearing or damage bearing removal practice I should mention the tool enables us to remove the bearing without any threat to any nearby parts like the hub grille axle It precision cuts time, reduces the level of the labor intensity, and makes sure the percentage of the replaced bearing matches the areas of the assembly it is meant to encourage an increase on the durability and dependability of the wheel assembly installed in the vehicle Using a well-designed extractor is not only an economic consideration but also a measure of professional decency in the automobile sector.

When to use a wheel-bearing puller

A wheel bearing puller is crucial in any instance where a wheel bearing needs to be pulled out of the hub or axle while ensuring that the surrounding components are not damaged. In the industry, I’ve come to find that a wheel bearing puller is the best tool for certain situations, and I’ll explain these to you in due course:

- When the bearing is seized or stuck – After several years, a wheel bearing may be corroded or stuck because of wear and tear, corrosion, or weather elements. A puller provides the controlled force necessary to drive out the bearing without excessive hammering or leverage, which might damage the hub or axle.

- During routine maintenance or complete replacement – Bearings cannot last forever as they are subjected to constant turning and loading. If a bearing is clearly damaged, for example, it shows grinding noise or wheel play, the process of removing and replacing them has to be precise in order to achieve perfect performance.

- To avoid collateral damage – Ripping a bearing out without any caution might cause deformation to the hub assembly, flanges, or axle shaft. Indeed, a puller works like a charm as it applies uniform pressure, thereby ensuring only the bearing gets taken out.

- Time is of the essence in automotive work for accuracy and time efficiency. A wheel bearing puller helps to complete the task quickly and allows easy and precise work, thereby reducing the amount of labor and saving time in case of a faulty job.

Someone looking for a puller should never say, “I am just seeking a tool for my job.” Instead, they should be looking for ways to preserve the integrity of the vehicle that they are working on and, more so, for the repairs in the long term. This in turn would create a safer vehicle for the whole world to use. Whenever you are using a puller, be sure that the puller is in alignment with the wheel bearing size and type; otherwise, it will be a nightmare down the road.

How do I choose the right wheel bearing puller for my vehicle?

Concerning the Vehicle In functional terms, the wheel bearing puller that you opt for has to be based on the make and model of the vehicle in question. It is absolutely imperative that the Puller of this tool is made for the size and kind of wheel bearings that are fitted in your car. Be sure to check the specs of the tool and confirm the size of the bearing it can work on. Same goes with the bearing puller, I also check the material from which the puller is made as it has to be robust enough otherwise the tool will get damaged before it completes a job. Finally, I will suggest using a puller that is equipped with various features, such as adjustable arms or extension poles, to work with multiple bearing configurations. Purchasing the right tool makes sure that the whole procedure is done faster, more accurately, and in a risk-free manner.

Types of wheel bearing extractors available

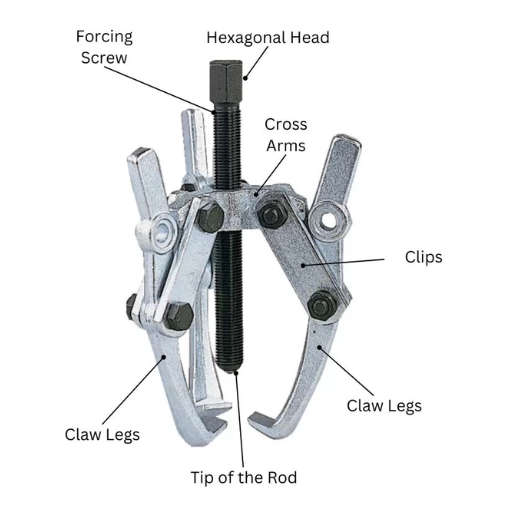

Each type of wheel-bearing extractor serves a specific purpose. Popular for ease of use and effectiveness, slide hammer pullers are often used to pull off stubborn bearings. However, Hydraulic bearing pullers do provide a lot of force with little effort and are better suited for heavy work. Then, three-jaw pullers are good for gripping and pulling bearings, combining the effectiveness of having no free arms and the ability to cover a large range of bore sizes and shapes. Also, custom bearing press sets can be purchased to allow for mounting and demounting of bearings, allowing low damage to the other parts. The choice of the extractor varies according to the requirements of the job, the type of bearing, and the amount of control needed during the removal process.

Compatibility with different makes and models

What I learned working in the sector is that the selection of the tools must be made with attention to the fact that the tool will be compatible with a range of makes and models. An example of this is universal bearing pullers and press kits, as these extremes can be catered for numerous vehicles and machinery with different specifications. However, I always advise checking the dimensions and parameters of the tool against the manufacturer’s recommendations to avoid mismatches. If you buy tools that are high quality and adjustable, you will have to sacrifice some quality and efficiency when it comes to time because these tools are reliable, especially for those who work in the industry with many types and brands of equipment.

Considering universal vs. specific wheel bearing removal tools

In regard to the question of whether you should go for a universal tool or a specific one made for particular wheel bearing removal, I always suggest you take into consideration the requirements and the nature of work you do frequently, and here is how I make the decision:

- Compatibility: There are many professional tools available in the market that offer compatibility with multiple makes and models of cars and machinery. If you often change equipment brands or types, you should consider using a universal tool. However, if you work primarily with a certain model or make, a set of specific tools designed for that equipment will yield a better fit and provide better performance.

- Ease of Use: Using specific tools is easy because they are made with a singular purpose in mind. They can be time savers as well as effort savers while removing the piece. On the other hand, universal tools can be adjusted but also add to the complexity, but do make things easier.

- Cost Effectiveness: Universal tools are most effective for professionals who have to work with any number of vehicle models and do not want the hassle of buying new tools for specific jobs. On the other hand, if you service certain particular models only, then buying individual tools makes more sense.

- Durability and Performance: In both cases, the potential for durability is great, but tool durability is quality-oriented. Universal tools have to withstand greater stress because of their adjustable nature; thus, it is important to buy good ones. The performance, on the other hand, is robust, and usually, the performance is great for designated use cases.

In the end, it is all up to the type of work you do. For my part, I also have a universal tool – or it is universal for its occasions – and several precise tools to be used in situations where speed and precision are vital. So, gauge your work content and other parameters like use case, performance, and expense, and decide what is right for you.

What are the steps to remove a wheel bearing using an extractor tool?

- Prepare Your Workspace: Before starting, make sure to chock the wheels as well as the vehicle to avoid unnecessary movement. Place a hydraulic bottle jack to raise the vehicle and then use a jack stand for support.

- Remove the Wheel: In order to get access to the wheel bearing assembly, start by removing the lug nuts and subsequently taking off the wheel.

- Detach the Brake Components: Take off the brake, which includes the brake caliper, brake pads, and rotor, while making sure to fasten the caliper to avoid putting stress on the brake lines.

- Access the Wheel Bearing: The wheel Bearing is situated by removing all the dust caps, cotter pins, and lock nuts.

- Position the Extractor Tool: The bearing assembly needs to be properly mounted to the extractor tool, which can be done with the help of the manufacturer’s guidelines.

- Extract the Bearing: Using the hydraulic indeed press function and gently rotating the handle of the extractor tool will pull the wheel bearing off its housing.

- Inspect and Replace: After removing the bearing, make sure to clean all the furniture while checking it for wear and tear. Once the inspection is complete, the new bearing needs to be secured in a proper fashion.

- Reassemble the Components: In the right order, begin flush seating the bolts while securing them according to the specifications provided by the manufacturer.

- Test the Vehicle: Lower the car, attach the wheel, and then perform a comprehensive check-up to make sure everything is working perfectly and the repair is successful.

Preparing your vehicle for wheel bearing removal

preparing your vehicle for wheel bearing removal is of paramount importance in order to make the process smooth and efficient. Here are the key steps I always recommend following:

- Secure the Vehicle Properly: Whenever I am about to start working on a car, one of the first steps that I take is to make sure that the car is parked on a firm surface. I then put in some wheel chocks to ensure that there was no movement. It is all about safety first, and this basic step can save you a lot of headaches later.

- Gather the Right Tools: Another step that I always make sure to take is to have all the right tools with me, as not having them around will make some processes really tough. For example, if I am about to do a wheel bearing removal, then all i need to have with me is a jack, jack stands, a socket set, a breaker bar, a torque wrench, a bearing puller or a press depending on how complicated everything will be. So, in order to avoid wasting time, I always make sure to check the toolbox before moving out.

- Lift the Vehicle Safely: All I need to do when raising the vehicle is use strong jack stands and a jack to raise the vehicle off the ground, which the manual clearly explains. This is very useful as not only does it allow me to lift the vehicle at all the necessary jacking points, but it also does not damage any part of the vehicle and provides the necessary stability when I am working underneath it.

- Remove the Wheel Carefully: When taking out the wheels, I begin by loosening the lug nuts while the wheel is still on the ground, and once I have slightly loosened them, I completely take the wheel off when the car is lifted. This is a great trick as it reduces strain during the process.

- Inspect Surrounding Components: Before removing a bearing, I check other parts like the brake caliper, rotor, and suspension components. If these elements appear to be worn or damaged, this is a good time to work on them since everything is exposed.

That is all these guidelines boast, and in my personal opinion, I think they are simply a form of self-trust that can only be beneficial. Take care of small things, and the big ones take care of themselves. If you do these things, you will make your repair quite easy.

Using the wheel bearing puller: A step-by-step guide

- Prepare the Workspace

Make sure that the vehicle’s lifting and positioning has been done properly. Jack stands should be placed along with wheel chocks to avoid vehicle roll while working on it.

- Attach the Wheel Bearing Puller

Now, take out the puller tool and place it on top of the hub assembly. Make sure it goes center and connects firmly with the wheel bearing, then apply bolts, ensuring fastening completely.

- Apply Controlled Force

Pull the central bolt of the puller tool or enhance the invocation of the hydraulic system. This will allow the puller to slowly draw the bearing from the casing without harming the fixtures near to it.

- Inspect Components

The next step is to take out the removed bearing and check for rust, dirt, or scratches on the housing near the bearing. Make sure to properly clean the area in order to properly place the new bearing.

- Install the Replacement

When fitting the new wheel bearing, ensure it is not fitted wrong and push it in place with the puller’s reversing or applying pressure from the bearing itself. After pushing in the new one, make sure it is secure and all components are assembled.

Following this set of organized steps quiets the process, minimizes probable mistakes, and guarantees the lifetime service of the new wheel bearing.

Troubleshooting stubborn wheel bearing hubs

In order to work with a tight wheel bearing hub, for starters, hammer around the hub assembly with a penetrating lubricant so as to loosen some of the rust or debris that is stuck. Wait for about 10-15 minutes to allow the lubricant to fully soak in. After the time has elapsed, apply heat using a rubber mallet together with a hub puller tool, ensuring that the force applied on the hub is evenly distributed. The metal inside might expand if necessary so a heat gun can be helpful due to its capability of heating the metal to relatively low temperatures, however one must take care that not to blow components off. Always ensure proper safety precautions and consult the manufacturer’s instructions for your specific vehicle.

Are there different techniques for front and rear wheel bearing removal?

different procedures are necessary when removing front and rear wheel bearings due to differences in design and function. Front-wheel bearings are normally found in the hub assembly, which means that there is often a need to replace the whole assembly or use a special press to extract the bearing. However, rear-wheel bearings may be incorporated within a drum or rotor assembly, which can either be pressed out or pulled out. The particular technique used is determined by the vehicle manufacturer; always check the manufacturer’s specifications for the correct procedure.

Front-wheel bearing extraction methods

everyone I know who has extracted front-wheel bearings agrees that the methods they are using are not very accurate and require the right tools. Manual procedures exhibit the greatest risk of damage, which is why they are replaced with automatic means of extraction, such as a hydraulic press gun. In the case of bearings being completely sealed inside the hub assembly, it is more rational and easier to replace the whole assembly rather than trying to target one part. Furthermore, portable pullers are bearing extractors or special tools designed for the hub and wheel bearing, and different types of portable hubs can sometimes be carried on the job site for quicker fixes. Just be sure safety measures are employed, since improper use can endanger not only the vehicle, but the mechanic too.

Rear axle bearing removal process

To start, I make sure the rear axle bearing removal area is safe, and there is no risk to myself or the vehicle. Next, I’ll take off the wheel and the brake assembly so that I have access to the axle shaft. Depending on the type of vehicle, I remove any retainer clips with a bolt that may be locking the axle bearing into position before coaxing the axle out. Next, mounted to a bearing puller, I apply relatively low suction pressure on the bearing to be pulled so that it comes out without damaging the housing. In case the bearing is of a press-fit type, I use a hydraulic press or even some specialized tools. Lastly, I check the region for possible wear and tear for the area to be fitted with the new bearing, an adequate amount of lubricant is put on the bearing to prevent aligning issues upon fastening of the new bearing. After going through these steps, my bearing replacement process has always been fast and reliable.

Dealing with eight lug hubs and other variations

It ensures that with every 8-lug hub and other types of vehicle, one uses the right tools for the task at hand and meets the requirements set by the automobile specifications of the vehicle they’re working on. First, establish the hub type in question and check if there is a need for a custom bolt circle, bolt patterns, or any other requirements. Make sure to apply a torque screw when fastening the bolts and nuts, paying attention to the recommended torque to prevent concentrates of excessive force in one object, which can result in premature wear or structural failure. When dealing with other hub variants looking into the company’s guide as well as having precision instruments can aid in the accuracy and level of trust when assembling the unit. When dealing with such a requirement, never forget to do ‘fine tuning’ regarding safety and alignment measures to ensure good working conditions.

What features should I look for in a quality wheel-bearing removal kit?

When I am looking to buy a durable and reliable wheel bearing removal kit, I almost always prioritize strength and compatibility over the first two positions. In tough job operations, only tough kits made from high-strength steel would be able to withstand the forces being applied without bending or breaking. Another key factor is compatibility—opt for a kit that is tailored for several types of vehicles and bearing sizes to improve usability. Besides, I also prefer kits where the components are separated and organized properly in the set, with cables, adapters, and any other item clearly marked, which streamlines the working process significantly. Another plus is the existence of precise guidelines and ergonomic devices in the kit, as this can facilitate the task and cut down on possible mistakes. Finally, in order to achieve a professional quality of work, it will be prudent to choose a kit that can also be provided with a case to store and protect the items.

Essential components of a comprehensive toolset

It is important for a comprehensive toolset to contain features like standard and non-standard adapters, robust extractors, and a host of threading tools for a wide range of applications. Comprehensive diagrams depicting all the tools and equipment’s intended uses are of particular importance. Also, specialized features like ergonomic handles for comfort, suitable materials for strength, and an efficient carrying case for order and safety are crucial features for an advanced tool set.

The importance of a robust puller set

Now, let me tell you about a robust puller. It is a removing tool that professionals employ to remove gears, bearings, and other fitted parts without injuring other components of the machinery. There are many varieties of pullers available comprising 2 or 3 angles, curved hook, center bolt type, and internally threaded pullers. Downtime is minimized by the strength and utility of a high-quality puller set. With all suck functionalities, a puller set is worth having by engineers.

Additional tools for complete hub removal

Completely removing a hub often requires one or two other tools depending on the size of the hub fitted; these tools include a hub puller or a hydraulic press. Other important tools would be the appropriate torque wrench or a socket set for fastening the bolts or nuts, a mallet or hammer for slightly moving the components, or some lubricant for easier disassembly of parts or components. With these tools, complete accuracy of the procedure is achieved without the risk of damaging the components.

How do I maintain my wheel bearing extractor tool for longevity?

Preserving the long life of your wheel bearing extractor tool is very easy to do as long as you take some basic precautions. First of all, I always clean the tool after using it in order to clear any grease, dirt, or other particles that could be corrosive in the future. I use a mild solvent or degreaser to get the job done and ensure to wipe it off properly. Then, rub some oil onto all moving parts to keep them rust-free. I use the tool to check for any worn signs, such as cracks or bent parts, and fix them. Lastly, put it in a safe dry place to avoid moisture and abuse. This way, my extractor tools have been in working condition for years.

Proper cleaning and storage techniques

After each use, ensure to always clean your tools using a light solvent or degreaser then clean them with a cloth. Ensure that the moving parts are lubricated to guard against rust and make it easier to use. Regularly check for damage and act early if there are any problems while also putting your tools away in a safe, dry place to keep them away from moisture and other accidental damage. With these techniques, durability, and efficiency will be optimal over the course of the tool’s lifetime.

Lubricating moving parts of the extractor

extractor tools work smoothly and efficiently if proper lubrication is done. I would recommend using high-quality light viscosity oil, which is manufactured for precision tools. A small amount of lubricant is best administered on all moving joints, hinges, and mechanisms of the tool after it has been cleaned and dried. It is important to dispense it evenly without layering too much, which attracts dirt. Regular lubrication allows for friction and wear to be avoided and, at the same time, gives a guarantee that the tool performs its function when it’s required. Adding this step into routine maintenance has made the performance and service life of my equipment to always improve constantly.

When to replace worn components in your tool kit

Any worn parts in your toolbox should be replaced right away whenever they do not work effectively or exhibit any form of visible or mechanical damage. Dull cutting edges or a cracked or loose mechanism can render your tools unsafe to use and unsupported in their performance. Regular inspections are critical – it’s good to take a look at your tools before and after using them. This way, problems can be traced early on. The early substitution will restore functionality and even disallow possible deterioration in other parts of the working process.

Can I use a wheel-bearing puller for other automotive tasks?

The tool can also accomplish other auto tasks, but that depends on the design features of the wheel bearing puller. Its design clearly states that it is mainly meant to function as a tool for removing and putting wheel bearings; however, some pullers can help to remove other press-fitted pieces as well, such as bushings, pulleys, or gears. Still, it is worth stressing that the overhead can only be used if it fits with the specific component, as in some cases, such overlap may end up damaging the tool and the part. Always refer to the guidelines provided by the manufacturer for proper and safe use in other operations.

Versatility of bearing pullers in car maintenance

Bearing pullers have proven to be excellent tools with many applications during the maintenance of a car. With them, one can easily remove a wide variety of interference-fitted parts like gears, pulley wheels, and bushings, thus speeding up repair work and reducing the chances of breakage. This indeed calls for their inclusion in the toolkit of a mechanic, especially if glued as per the safety and functional requirements supplied by the manufacturer.

Using the extractor for brake and suspension work

It’s quite a good idea to use an extractor when working with parts such as brake calipers, bushings, or suspension bearings. It simplifies the extraction of press-fitted components without causing any damage to other parts. Any mechanic will be able to use the correct size and type of puller, replace components in a less tedious way, and achieve good main repair quality.

Adapting the tool for non-automotive applications

Modifying an extractor for functions other than automobiles means employing its versatility for jobs in the manufacturing, construction, and even house repair industries. For instance, extractors can be useful in removing bearings of industrial machinery, detaching stuck parts during metalworks or even removing furniture dovetail joints. The trick is choosing the right size and right type of extractor that corresponds to the specific utilization of the tool while careful orientation and limited pressure are exerted so that the workpiece is not ruined. Following these directives allows the use of extractors way beyond the automotive sector, providing a trustworthy and flexible means of solving problems in different domains.

Reference

- A Comprehensive Guide to Car Wheel Bearing Removal Tools for DIYers

- Car Wheel Bearing Removal Tools: A Comprehensive Guide

- How To Use A Wheel-Bearing Tool The Right Way

Frequently Asked Questions (FAQs)

Q: What is a wheel hub puller, and why is it essential for wheel bearing removal?

A: A wheel hub puller is an essential tool designed to remove wheel hubs and bearings from vehicles. It’s crucial for safely and efficiently extracting stubborn wheel bearings without damaging surrounding components. This tool is particularly useful when dealing with rust or corrosion, making it an indispensable part of any mechanic’s toolkit.

Q: How does a Tommy wheel bearing puller work?

A: A Tommy wheel bearing puller, also known as a Tommy wheel bearing hub puller, works by applying controlled force to the wheel hub to separate it from the axle or steering knuckle. It typically consists of a central bolt or hydraulic cylinder that pushes against the axle while arms or jaws grip the hub. This design allows for even pressure distribution, reducing the risk of damage to the hub or bearing during removal.

Q: What are the advantages of using a universal wheel bearing hub removal tool?

A: A universal wheel-bearing hub removal tool offers versatility and convenience. It can be adjusted to fit various hub sizes and configurations, making it suitable for a wide range of vehicle makes and models. This adaptability eliminates the need for multiple specialized tools, saving both time and money for mechanics and DIY enthusiasts.

Q: How do I choose the right wheel-bearing puller kit for my needs?

A: When selecting a wheel bearing puller kit, consider factors such as the types of vehicles you’ll be working on, the size range of wheel hubs you’ll encounter, and the kit’s compatibility with specific makes and models. Look for kits that include various adapters, a sturdy construction, and a comprehensive set of components. Some kits are designed for select Ford and Subaru models, while others offer more universal applications.

Q: What is a bearing separator, and how is it used for wheel bearing removal?

A: A bearing separator is a specialized tool used to separate the inner bearing race from the hub or shaft. It’s often used in conjunction with a gear puller or hydraulic press to remove bearings that are press-fit onto a shaft. The separator fits behind the bearing and provides a surface for the puller to grip, allowing for controlled and even force application during the removal process.

Q: How does a Tommy rail system enhance wheel bearing removal?

A: A Tommy rail system is an advanced feature found in some wheel-bearing removal tools. It provides a stable guide for the central pushing bolt, ensuring straight and centered force application to the wheel hub. This system helps prevent misalignment during the removal process, reducing the risk of damage to the hub, bearing, or surrounding components. It’s particularly useful when dealing with stubborn wheel bearings that require significant force for removal.

Q: What safety precautions should I take when using a wheel bearing hub removal tool?

A: When using a wheel-bearing hub removal tool, always wear appropriate personal protective equipment, including safety glasses and gloves. Ensure the vehicle is properly supported and stable before beginning work. Follow the manufacturer’s instructions for your specific tool, and avoid applying excessive force that could damage components. It’s also important to clean and lubricate the tool regularly to maintain its performance and longevity.

Q: How do I maintain my wheel bearing puller kit for optimal performance?

A: To maintain your wheel bearing puller kit, clean all components after each use to remove dirt, grease, and metal particles. Lubricate moving parts with a light oil or as recommended by the manufacturer. Inspect the tool regularly for signs of wear or damage, particularly on the jaws, bolts, and hydraulic components if applicable. Store the kit in a dry, clean environment to prevent rust and corrosion. Proper maintenance ensures reliable performance and extends the life of your wheel bearing tool.

Q: Can a wheel bearing puller be used for other automotive repair tasks?

A: Yes, many wheel-bearing pullers are versatile tools that can be used for various automotive repair tasks. They can often be adapted to remove gears, pulleys, and other press-fit components. Some puller kits include additional attachments or adapters that expand their functionality. However, always ensure that the tool is appropriate for the specific task at hand to avoid damage to the tool or vehicle components.

Q: How do I know when it’s time to replace my wheel bearings?

A: Signs that it’s time to replace your wheel bearings include unusual noises (such as grinding, humming, or rumbling), steering wheel vibrations, uneven tire wear, and loose or wobbly wheel movement. If you notice any of these symptoms, it’s important to inspect and potentially replace the wheel bearings promptly. Regular maintenance, including proper wheel bearing grease application, can help extend the life of your bearings and improve overall vehicle performance.