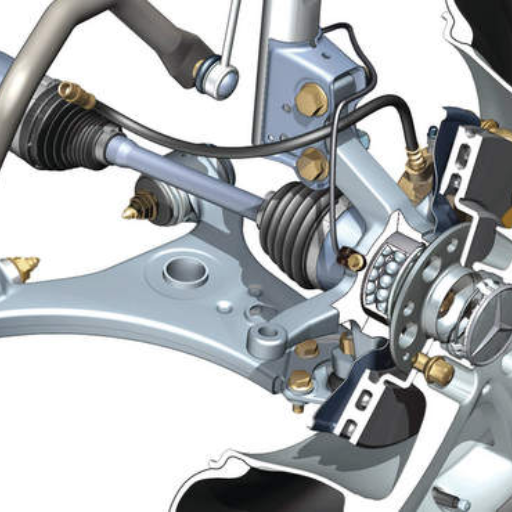

Wheel bearings are probably one of the most important components of your vehicle. A vehicle wheel bearing enables the wheel to make a full rotation with minimum friction while also supporting the entire weight of the car. Like any component in a machine, they do wear out with time. However, it is important to note that failing wheel bearings can create a serious safety hazard; for example, the car may not handle properly, or the wheel may even come off the car in extreme situations. This blog post aims to detail 10 signs that indicate wheel bearing potential failure in a bid to multiply the odds of detecting the problem early so that you can save yourself from expensive repairs and dangerous situations. It does not matter whether you have been driving for decades or are completely new to working with your vehicle; these signs are vital for the safe and hassle-free operation of your car.

What are the most common symptoms of a bad wheel bearing?

Most times, you will be able to notice a bad wheel bearing by the unpleasant sounds that emerge from grinding, humming, and growling, particularly when a turn is made. A loose feeling in your steering, or shaky steering while driving, is also a sign, along with increased wearing of the tires. In some cases, the wheel will wobble in a fashion movement that is not smooth. ABS warning lights would likely appear in this case because of the bearing interference with wheel speed sensors. Never ignore all of these signs, as they are important for extensive damage as well as safety purposes.

Unusual noises: grinding, humming, and whirring

If your car makes unusual noises when driving, such as grinding, humming, or whirring, it suggests that there is a problem with the wheel bearings of your car. These sounds are due to some damage to the bearings, which are very important parts for the smooth rotation of the wheels. In order to help your better understanding of this issue, let us dissect it on the relevant parameters one at a time:

- Grinding Noise

The presence of grinding noise might indicate that the bearing has broken down due to heavy internal wear, such as metal parts scraping against one another because of overheating. This is a very serious concern that can affect the functioning and safety of your automobile greatly.

- Humming Noise

Humming sounds are more likely to happen because of an imbalanced order of load or unscrewed wheel bearings. It is common for this sound to be more pronounced during acceleration and when maintaining certain velocity ranges. If they overlap with other related components, such as tires or brakes, it may require deeper investigation.

- Whirring Noise

A whirring sound could be caused by dirt or lack of proper bearing installation, which could account for why the bearing is starting to wear out. A whirring noise is still a good diagnostic clue for mechanics as it frequently varies based on vehicle speed.

Ignoring these signs can spell disaster in the future, as it could cause irreparable damage to your vehicle’s overall functionality. Each one of these sounds is a clear red flag, and if you hear any of them, then it’s time to have your wheel bearing inspected and replaced.

Steering wheel vibrations and looseness

it has been evident that steering wheel shake and looseness are normally associated with a wheel bearing problem. Loosening of the steering wheel as well can result when the bearing is either worn out or damaged. This, in return, has an effect on the steering accuracy and control since steering is designed to be very precise. Also, when a wheel bearing gets worn or breaks, the loss of stability in a wheel hub causes shaking that is felt through the steering wheel. Addressing these signs promptly is critical to ensuring safety and avoiding excessive wear on the steering or suspension components.

Uneven tire wear patterns

Worn tires may have uneven wear patterns because of misalignment among the wheels, inappropriate inflation levels, mouse suspension load, and the like. In order to resolve this issue, regular inspection of the tires, proper tire pressure, and correct alignment of the wheels are required. If the main cause of the problem is solved in time, it not only helps in increasing the estimated life of the tires but also the safety and performance of driving are improved.

How can I tell which wheel bearing is failing?

In order to identify which wheel bearing is faulty, it is wise to observe specific symptoms while operating the vehicle. An evident sign is the presence of loud humming or grinding sounds which get louder as speed is increased. Similarly, try and slowly wiggle the steering wheel left and right and try to assess which side’s wheel bearing is damaged. Other indicators might be uneven tire wear and juggling steering wheel vibrations, to name a few. For protection from extra loss and harm, I recommend examining the part in detail as soon as possible if it is malfunctioning.

Identifying the source of noise while driving

To determine the origin of a noise while driving, begin by recording the time and location. Also, note any alteration to the noise, whether it is affected by the vehicle’s motion or any specific action like turning or applying brakes. A whirring sound may occur as a result of problems in the transmission or differential, whereas the odds are that a clattering noise stems from the suspension or the driveshaft. When in doubt during turns, inspection for a possible faulty wheel bearing should be conducted as whining or growling noise emanating is a good indicator. Always check the condition of tires and brakes since they account for abnormal sound effects at most times. Early recognition of such matters is helpful in maintaining safety and also in warding off further mechanical damage.

Checking for play in the wheel

In diagnosing slack in the wheels, I first make sure that the vehicle stands in a properly elevated and supported position. I firmly grab the wheel at the 12 and 6 O’clock positions, In this instance like the above panning, it helps to feel any looseness there might be by pushing and pulling. Whatever movement could be observed here would tend to suggest a defect in the wheel bearing or in the suspension parts. To follow, I do a similar action at the side opposite, 9 and 3’ O o’clock, which might also indicate defects in the steering linkage. I further seek to locate the source of slack in this instance If I observe slack in this movement. This method is as basic as it gets, but it is indispensable in the intended goal, which is a proper approximation of the condition of the drivetrain and the suspension and its parts.

Professional diagnosis with specialized tools

Specialized tools greatly aid in diagnosing a problem with a vehicle’s drivetrain and suspension system. One tool that I often use when assessing the amount of play in a wheel bearing or a suspension part is a dial indicator. Here’s how I approach it:

- Dial Indicator for Measuring Play – Measures movement in either the wheel or suspension component with a high level of accuracy. When too much play is detected by the dial indicator, for instance, this usually tends to indicate a faulty wheel bearing or loose suspension parts that need to be replaced.

- Torque Wrench for Proper Tightening – A proper amount of force must be exercised when the lug nuts and other fasteners are put into place, for instance. A torque wrench makes this other lovingly use the manufacturer’s specified torque force, which ensures the safety and all-around performance of the component.

- Ball Joint Separator for Component Inspection – In most cases, when doing inspections of ball joints, if I have to change the ball joints in place, I use a ball joint separator, which makes the task easier to dismantle the parts without having to cause any damage.

- Steering and Suspension Tester – Occasionally, I use a suspension tester to replace the steering and suspension of a vehicle when the car is stationary as I use it to test other effects on the vehicle, from its weight to rough driving on the steering components and the suspension system. This tool is useful for diagnosis, which manual inspection can skip, such as faults in the steering linkage, which are harder to detect.

- OBD-II Scanner for Drivetrain Diagnostics – Particularly for drivetrain defects, this scanner can be advantageous in identifying them, especially for missing or lit lights on the dashboard. It gives me error codes that help me to understand where the problem is hidden.

Employing these tools, I am able to make a much more precise evaluation and offer a thorough solution. These accurate measurements and assessments are the difference between an educated guess and rapid estimating of the right problem.

What causes wheel bearings to fail prematurely?

a variety of factors can lead to premature failure of wheel bearings. One such element is the installation itself, where excessive stress might be applied to the bearing. Also, improper sealing often leads to penetration through contamination of dirt, water, or other debris, which results in wear and tear. Moreover, counterfeit components are commonly witnessed as they are below average and lack durability. Then, there’s always the possibility of inadequate lubrication or overheating because of excessive friction, which would certainly reduce the lifespan of a wheel bearing. Recognizing these reasons during maintenance may assist in averting such failures and making sure vehicles are within safe and decent operating limits.

Poor road conditions and impact damage

Such stresses can also lead to vibrations, misalignments, and increased wear and tear of components, such as wheel bearings, to fail prematurely. Such stresses also include substandard roads as well as curb impacts and collisions. Regular vehicle inspections coupled with careful driving aid in the mitigation of these risks and increase the lifespan of vehicle components.

Contamination from water or debris

the most frequent reason why wheel bearings fail is due to contamination of water or debris. Such foreign elements can degrade the lub grease and damage the internal components of the bearing. This is the case because foreign elements create friction, which causes overheating, corrosion, and wear and tear.

To prevent this, there are a few key parameters to consider:

- Sealing Integrity – A high-standard wheel bearing is incorporated with quality embedded seals, which exclude moisture and debris from the internal components. As time progresses, natural wear and tear can be attributed to these seals, so they need to be monitored on a regular basis.

- Environment – The geographical location from where you drive your vehicle has an important impact on the wheel bearing. If you reside in an area that is muddy, wet and does not have paved roads, you will have increased contamination of your wheel bearings due to these conditions. Avoiding such conditions whenever possible can ameliorate the health of your bearings.

- Proper Installation –Gaps left between improperly fitted wheel gun bearings can be exposed to debris and dirt, which can adversely impact them. Always use the right kind of equipment and expertise for the installation of these bearings so that the fitted seals are bolstered.

- Regular Maintenance – When you are getting your vehicles adjoined with new wheels, look to see if there are any traces of grease escaping from seals and if there are ANY signs of dirt filling into the rim encasing. Having dry grease allows your bearings to be lubricated and protected.

Taking these parameters into consideration will assist in avoiding contamination concerns and, at the same time, guarantee the longevity of the wheel bearings. Focusing on the bearings and the environment is key!

Improper installation or maintenance

insufficient assembling or servicing comes in the regular wheel bearing malfunction list. Incorrect bearing installation, irrespective of minor issues, can make the wheel assembly work harder. Some instances of failure have also been caused by over or under-torquing. Furthermore, the lack of proper care, such as greasing or adjusting for wear, can make small problems turn catastrophic. To avert such occurrences, making sure that appropriate protocols for installation are performed and intervals for maintenance are observed are important steps.

How does a bad wheel bearing affect vehicle performance?

Degraded wheel bearings raise the heat on the other components of the vehicle, which brings instability in efficiency and cost-engaging fuel burnouts. If they serve their purpose poorly, it is also disappointing as they tend to make a lot of noise, vibrate a lot, and make the tires uneven where even handling is compromised of the vehicle. Living amiss or neglecting a bad wire hub diameter wear bearing can cause detachable wheel bearings or a broader limit state of damage to surrounding parts.

Reduced handling and stability

I can reliably state that wheel bearing failures do negatively affect a vehicle’s handling and stability. A loose condition in the wheel assembly arises once the bearing starts to deteriorate, making it difficult to carry out steering and control over the vehicle. This instability is felt the most at times when cornering or on bumpy roads, which creates a threat for both passengers and the driver. In order to ensure optimal performance with wheel bearing problems, it is highly important to fix the issues as soon as possible.

Increased fuel consumption

Increased fuel consumption due to vehicle problems is likely to involve, among others, problems related to wheel bearings:

- Friction

Friction is high as there is increased wear and tear on the wheel assembly, which occurs because of a damaged wheel bearing. There is additional friction and, hence, resistance, which makes the engine work harder to maintain speed, which means it consumes more fuel. Time-to-time service may also reduce this friction.

- Rolling Resistance

With a bad bearing, the wheels are difficult to roll smoothly, leading to an increase in rolling resistance, which makes moving the vehicle start requiring more energy than it would have with no resistance. The amount of fuel used increases with the amount of resistance that is faced.

- Alignment Issues

A bearing that requires attention tends to change the wheel’s alignment. In such an event, an engine is forced to work harder in order to even out the opposing forces through the wheels, which leads to more fuel being consumed.

- Excessive Heat

Extra friction will come from a deteriorated bearing, and excessive heat for the wheel assembly will be created. This heat can then be efficiently used to worsen the functionality of the vehicle, thus setting the stage for a lower fuel economy.

In order to guarantee the greatest fuel efficiency for their transport vehicles, the wheel bearings should always be checked in terms of their wear and damage at regular intervals and changed during maintenance if found worn. Fixing such problems early saves costs on fuel and stops larger mechanical issues around the corner.

Potential ABS system malfunctions

I am aware of the fact that bearing problems can severely compromise the work of the anti-lock diametric system. The deterioration of the rim’s bearing wears it out, and such degradation sends incorrect messages or signals to the ABS (Anti-lock Braking System) sensors. Consequently, this may result in such malfunctions as irregular or noisy braking or even the illumination of the ABS indicator on the furnace panel board. Regularly servicing and monitoring for the early stages of the rim’s bearing wear is vital to keep the ABS in good working condition.

What is the typical lifespan of wheel bearings?

The lifespan of wheel bearings can be influenced by many variables, but they are usually intended to have a normal operational range of between 85,000 and 100,000 and, in many instances, are able to withstand such mileage. But this expectation is contingent upon some parameters that can affect their lifespan directly:

- Driving Conditions – In an ideal world, we recommend you don’t take your vehicles off-road, but it can vastly increase the life cycle of your wheel bearings as potholes and uneven terrain can place unwarranted stress on the bearings, reducing their lifespan.

- Quality of the Wheel Bearings – Superior quality wheel bearings manufactured by top-tier brands tend to be more robust and can endure added stress compared to non-branded or unpracticed alternatives.

- Vehicle Load -Barring any Arizona summers, heavy towing on a regular basis or carrying larger loads can apply too much stress onto the wheel bearings, reducing its life expectancy.

- Maintenance and Installation – Correct installation of wheel bearings with the help of appropriate tools and methods will help these parts last longer. Also, maintaining these parts properly, such as lubricating them regularly, will help extend their life cycle.

- Environmental Factors – Vehicles in coastal and snowy regions are at higher risk of damaging corrosion as harsh environmental factors coupled with a damaged seal can lead to moisture contamination, spinning the wheel bearings ‘out of tune.’

If wheel bearings remain intact for an extended period around your hub, some of them sustain the scarring that causes extreme damage. To ensure you cut costs in the long run and avoid making expensive repairs, managing these factors and comprehending them is essential. It is particularly important that you follow your vehicle manual because of the manufacturer’s guidance regarding when the wheel bearings need replacement.

Factors influencing wheel bearing longevity

it can be said without doubt that wheel bearing units can last long if maintained and used properly. Regular freeze-out checks are a must, as they may relieve you from greater complications in the future. Also, keeping the bearings clean and well quit is a must, especially for those who drive under severe conditions like wet and salty. I have witnessed firsthand how poor seal coverage could lead to rust and subsequent bearing failure, hence attention to fine details may go a long way. It can simply be stated that bearing the manufacturer’s instructions and being proactive with maintenance procedures is the key to having trusty wheel bearings for the year to come.

Signs of natural wear vs. premature failure

In most cases, natural attrition of wheel bearings occurs over a period of time as part of normal use. Such a condition may be evidenced through the sensation of a very faint humming or growling noise, which becomes more perceptible during the progress of usage. However, certain external factors such as contamination, incorrect fitting, or insufficient lubrication may result in a wheel bearing failure at an early stage. Early upper-end signs may include louder and more irregular noises, irregularities in wheel rotation, and abrupt differential wear patterns on tires. Spotting these distinguishing features in good time will facilitate rectification at the most prevalent area and hence prevent escalation of the issue.

How much does it cost to replace a wheel bearing?

The rate of replacing a wheel bearing is highly contingent on the model and make of your vehicle, as well as the amount charged for labor in your region. Speaking from my perspective, the rate is normally between 150 and 500 dollars for each wheel, which includes both labor and parts. If a wheel bearing has to be replaced by you personally, the cost for the part usually varies between $50 and $150. However, proper installation of the bearing is very important; otherwise, it may fail sooner than expected. For many car owners, the advice of family members or friends, who in most cases tend to a mechanic, has proven to be the best course of action in regard to car repair.

Factors affecting wheel bearing replacement costs

You should be aware that there are many factors that can influence the cost of DIY wheel bearing replacement, and I will detail them for you:

- Vehicle Make and Model: The make of an automobile can affect the cost of the car part, for instance, the car wheel bearings. Luxury cars tend to have costlier wheel bearings compared to economy sedan cars due to their complex design. Moreover, some car designs just require more work, which also affects costs.

- Type of Wheel Bearing: There are different types of wheel bearings available, such as ball bearings, roller bearings, and hub assemblies. For example, hub assemblies are usually sold as complete units which increases their costs when compared to a bearing as a separate part.

- Labor Rates in Your Area: People are paid differently depending on where they are located. Certain places have higher than normal living, which subsequently increases the repair shop’s labor rates, which translates to more money if you need a repair in a metropolitan area as opposed to a small town.

- Front vs. Rear Bearings: In comparison to rear bearings, front wheel bearings are costlier to replace since most hub assemblies include front bearings and other components. The extra parts mean more elaborate work, which leads to higher costs.

- Condition of Related Parts: At times, associated components such as the spindle, hub, or axle can also be worn out or damaged. Replacement of such parts will add up to the cost of the exercise on the whole.

- DIY vs. Professional Service: In the case of replacing the wheel bearing yourself, you will incur no labor expenses, though a proper follow-up is made to ensure you have the right tools and procedures. Improper fitting may lead to failure at an earlier stage, which can be more expensive in the end.

Through these considerations you will be able to have a better understanding of what may change the amount spent in replacing a wheel bearing in your vehicle. Do take a reliable mechanic’s advice for a professional diagnosis and repair!

Can I drive with a failing wheel bearing, and for how long?

The bearing on its last las, it confident advisable but I suggest you don recommend đg. As this is compromised safety and steering of your car, it should not show the beast of problem condition. Wheel bearings with a bad vet might fail to some extent, so someone might need to replace them. Such a problem may lead to the degradation of more important structures like fordingsom Things. Another thing might happen, and that would be the extreme case: the wheel could be completely locked up, or the wheels could be detached completely. Having a doubt about bearing, better come to find the reason as soon as possible. Safety is a priority for the head professional, and getting the proper check-up and recuring done at the earliest possible time.

Risks associated with driving on a bad wheel bearing

Inadequate control of the motor vehicle due to driving on a bad wheel bearing, overheating of surrounding components, or even slippage and failure of the axle are phenomena that must be avoided at all costs. In fact, the safety of the motorist, as well as those driving around them, can be placed in jeopardy if the wheel bearing were to overheat, seize up, or even worse, detach from the axle suspension. It is extremely important to fix the issue as quickly as possible to avoid more expensive repairs and to keep the vehicle operational.

Emergency measures for temporary driving

In case you happen to be in a situation where you have to drive with a worn wheel bearing temporarily, there are a few measures you can take in order to reduce the risk factors. To begin with, reduce your speed considerably, as the high-speed rotation will put more strain on the failing component, leading to a higher chance of failure. Any kind of maneuver such as hard braking, sharp turns, or quick acceleration, which are only likely to increase the damage, should be avoided. Keep the accelerations to a minimum. Change direction only if necessary, and take the shortest and least populated roads, then head to the nearest repair shop. Estimate how far you can go because underestimating can ensure this is just a temporary solution. Returning back to safety is the prior point, followed by dealing with the problem you have encountered with a professional.

Reference

- Kelley Blue Book: How Do I Know if I Need a Replacement?

- JustAnswer: How do I tell if a wheel bearing is going bad in my vehicle

- Meineke: 6 Signs of a Bad Wheel Bearing

Frequently Asked Questions (FAQs)

Q: What are the most common bad wheel-bearing symptoms?

A: The most common symptoms of bad wheel bearings include unusual noises like grinding, humming, or whirring, especially when turning or at higher speeds. Other signs include vibrations in the steering wheel, uneven tire wear, and the vehicle pulling to one side while driving. These symptoms can vary depending on whether it’s a front or rear wheel bearing that’s failing.

Q: How can I tell if my wheel bearing is bad?

A: To check for a bad wheel bearing, listen for unusual noises while driving, particularly when turning. Pay attention to any vibrations in the steering wheel or floor. You may also notice your vehicle pulling to one side or uneven tire wear. If you suspect a problem, have a professional mechanic inspect your vehicle’s wheel bearings as soon as possible.

Q: What are the consequences of wheel bearing failure?

A: Wheel bearing failure can lead to serious safety issues. It can cause the wheel to seize or even detach from the vehicle while you’re driving. This can result in loss of control, accidents, and expensive damage to other components. Additionally, a failing wheel bearing can trigger the ABS warning light and affect your vehicle’s handling and stability.

Q: What causes wheel bearing failure?

A: Common causes of wheel bearing failure include normal wear and tear, poor quality bearings, improper installation, contamination from water or dirt, and excessive load or stress on the bearing. Hitting potholes or curbs can also damage wheel bearings, as can driving through deep water. Regular maintenance and careful driving can help prevent premature bearing failure.

Q: How can I distinguish wheel bearing noise from tire noise?

A: Wheel bearing noise is typically a humming, grinding, or growling sound that changes with vehicle speed and is often more noticeable when turning. Tire noise, on the other hand, is usually a constant hum or roar that doesn’t change significantly with steering input. If you’re unsure, have a professional mechanic diagnose the source of the noise.

Q: Can a bad wheel bearing cause a loose steering wheel?

A: Yes, a bad wheel bearing can cause the steering wheel to feel loose or unstable. As the bearing wears, it can create play in the wheel assembly, which may be felt through the steering wheel. This can make the steering feel less responsive or cause the wheel to wobble. If you experience loose steering, it’s important to have your vehicle inspected promptly.

Q: How often should wheel bearings be replaced?

A: There’s no set interval for wheel bearing replacement, as their lifespan depends on various factors such as driving conditions, vehicle type, and bearing quality. Many wheel bearings can last 100,000 miles or more under normal conditions. However, it’s important to be aware of the symptoms of bad wheel bearings and have them checked regularly during routine maintenance to catch any issues early.

Q: Can I drive with a bad wheel bearing?

A: While you may be able to drive short distances with a bad wheel bearing, it’s not recommended. A failing wheel bearing can cause the wheel to seize or detach, leading to a loss of control and potential accidents. It’s best to have the bearing replaced as soon as possible after noticing symptoms of failure to ensure your safety and prevent further damage to your vehicle.