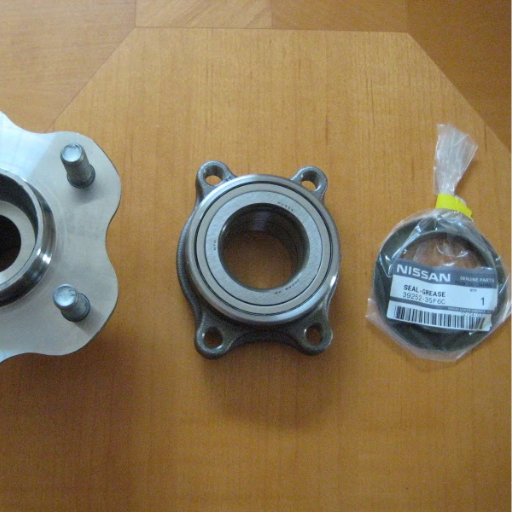

A car owner needs to take care of various feels, just like any other machinery. A common complaint that they experience, which in many cases remains unattended, is the wheel bearing problem. Due to consistent use and time-lapse, this problem appears due to wear and tear, which in turn causes the wheel bearing to not rotate efficiently and may produce sound, or in some cases, may put a person’s safety at risk. People who perform repairs on front wheel drive cars will find a wheel bearing press kit a necessary tool in removing and replacing defective bearings, this guide will provide the broad insight into wheel bearing press kit, such as it’s key function, it’s components, and how it should be used, by the end of this guide, you will be able to perform bearing removal for the front wheel drive in a professional manner.

What is a wheel bearing press tool, and why do I need one?

Wheel bearing press tool is a specialized apparatus that makes the task of fitting or un-fitting wheel bearings without damaging them or other mating parts easier. As such, the effort required is less than that of manual methods and accuracy is quite acceptable. The tool is critical for effective and proper operation of wheel rotation, prevention of excessive wear, and protection of the vehicle’s front-wheel-drive system from failure.

Understanding wheel bearings and their importance

wheel bearings assist in the proper working of the vehicle. These components revolutionize the functioning of wheels by allowing the axle and wheel to rotate with minimal friction. Poor functioning causes issues such as the nagging sound of the bearing grinding or poor handling, along with the tendency of tires to wear out easily over a period of time. Eventually, if they are not taken care of, it will lead to either safety issues or extremely expensive repairs. That’s the reason tools such as the wheel bearing press come in handy, as they enable you to prevent damaging the components and help service them perfectly, allowing for trouble- and safety-free drives.

Benefits of using a wheel bearing press tool

I have no doubts that a wheel bearing press tool is probably the most crucial tool for all practitioners looking onto wheel bearings. The reasons are the following:

- Precision and Accuracy

When you utilize a wheel bearing press tool, you significantly mitigate the risk of inflicting damage to your wheel bearings or related components during installation or extraction. Most importantly, it guarantees the correct alignment of the bearings with the axle, which is necessary to ensure the correct functioning and bearing life.

- Time Efficiency

If you decide to extract or replace the wheel bearings without utilizing the press tool, it may appear to be long and tedious, especially when components are locked in place, requiring ample force to loosen them. A wheel-bearing press tool makes the procedure less of a painstaking task, allowing its user to channel efforts into other vehicle repair activities.

- Improved Safety

Loosening or re-fitting of the wheel bearings improperly is also done at risk as it poses the risk of steering or the whole car being compromised. The chances of mistakes, in this case, are negligible as a press tool has too little tolerance, applying only the required force and alignment.

- Versatility

Most quality wheel bearing press tools are made to fit a number of vehicle makers and models, decreasing the limit virtuous the vehicle operated on. Starting from sedan cars, moving on to SUVs and light trucks, wheel-bearing press tools stand into play for uniformity in results.

- Cost-Effectiveness

The cost of the tool can be seen as a cost with a payback period, but over the long term, it can assist you in saving money on costly repairs owing to an incompetent bearing installation. Furthermore, you will not have to depend on outside mechanics for even the simplest of jobs.

It seems to me that every job is specific and therefore needs to have suitable implements such as a wheel bearing press tool which is absolutely great in enhancing professional service in car servicing.

Different types of wheel-bearing press tools

In the market, many types of wheel-bearing press tools are available, which differ according to the required expertise as well as needs. In my practice, manual press tools, hydraulic press tools, and slide hammer kits are the most prominent in this category. The manual press tools are cheaper and are good for small tasks but they need a lot of physical time for the work. For more heavy tasks, a hydraulic press tool is more appropriate as it is efficient in doing the work by saving a lot of manual work. Slide hammer kits, on the other hand, do a good job of removing the most stubborn bearings from a tight area. It all comes down to which vehicle is preferred, how complicated the task is, and what a professional’s or personal preference is. For me, I have found hydraulic press tools to be helpful and practical the most when time-saving and accuracy are required during difficult tasks.

How do I choose the right wheel bearing puller tool set?

Would you tell me what procedure I should follow to pick the appropriate wheel bearing puller tool set so that I can use it efficiently and effectively on my project? The first step that must be completed is to determine the size of the wheel bearings that the automobile fits, as the type of automobile to be serviced is important to know at this stage. The next step is to find out how complicated the work is going to be: A hydraulic press tool is best suited for heavy-duty applications, while a slide hammer kit works better in confined spaces. Lastly, evaluate your skill and finances; such high-end sets are expensive, but it’s worth the money once you see how long it lasts and how accurate it is. If these factors are given due consideration, you will be able to make the right decision.

Key features to look for in a wheel-bearing press kit

I have realized that when acquiring a wheel-bearing press kit, one needs to consider a few factors and features depending on the type of tasks one intends to carry out. To begin with, a degree of adaptability is a must – a decent kit should have many nipples and multiple fitting adapters for a variety of vehicles and bearing sizes. This is also an important issue; various kits that suit the models being worked on better should be made from alloy steel that is tempered for extensive use. In fact, it is equally significant – for example, kits with fine-printed instructions and neat ergonomic forms would greatly facilitate the task for those unused to their application. On the final note, I always recommend looking at the set of tools included in the kit, the complexity of tasks that such tools will cope with in relation to confined spaces, and the working order they provide.

Comparing various wheel bearing puller tool sets

The most important factors to consider when comparing several wheels bearing puller tool sets are how strong the tools are once in use and how easily any user can operate them. Check for sets manufactured from strong materials such as forged steel and those that come with tools that facilitate fitting different car sizes and types. The multifunctional kits ought to be able to make both the many easier and more involved applications, most importantly with tools suitable for around corners. Furthermore, categories such as ergonomics and clear guides are critical, especially for less knowledgeable users. Finally, take home a toolset that is of good quality, fits its purpose, and is comfortable to handle, and will be reliable.

Considerations for front wheel drive bearing removal

Removing front-wheel-drive bearings requires careful selection of tools and adequate planning, and this is always my message to the workers. Start by preparing yourself with a full set of pullers that are built for front-wheel drive systems since the latter are usually smaller and are built to tighter tolerances. As with any activity cut of a new region, once again, proper safety should be observed: always place the car in a lift or on jack stands to avoid it caving in on itself. Before commencing work, I typically suggest looking over the local parts, which would be the spindle and maybe even the hub, for any wear and tear. Therefore, if one takes the time to do so, the process is made easier as well,l and the risks of unnecessary turbulence are also reduced significantly.

What’s included in a typical 24-pc wheel bearing puller tool set?

The set of 24 pieces of wheel bearing pullers is remarkable, as it enables easy installation and removal of bearings. In my opinion, the above sets come with several sizes of bearing drifts which range from small diameters that are required for passenger cars to larger ones for trucks and SUVs. There are many more in the kit, including several robust steel adapters made for different hub configurations.” The kit consists of a main spindle or push shaft, heavy washers, and bolts, which are specially designed to withstand high pressures. Further, many kits include a solid carrying case. Thus, tools are neatly organized and can be conveniently transported. This range of variety provides these tools with the much-needed compatibility with a wide range of automobiles, so it makes them the best choice for many professionals and hobbyists like me.

Essential components of a comprehensive wheel bearing press kit

A comprehensive wheel bearing press kit should include a puller or spindle shaft, a variety of heavy-duty washers and adapters, as well as a variety of press plates for various bearing diameters. It should also include high-strength bolts, hydraulic or mechanized pressing tools, and a robust case for better handling and transport. These components ensure the requisite versatility, precision, and reliability across a variety of applications.

Understanding sliding screws, universal bushings, and sleeves

It seems that there’s a lack of clarity in understanding sliding screws and universal bushings, as well as sleeves. So, it might help to point out their respective functions in mechanical construction. In threaded constructions, sliding screws assist in the management of non-symmetrical and complicated structure movement, ensuring desired position and amount of deflection for external disturbances. Universal bushings are intermediate parts that allow a certain degree of rotation and sliding between two parts that move relative to each other while they also perform an anti-friction role. Sleeves, by integration, act to provide enhancement and safeguard the portion from excessive strain or injury. To conclude, these parts are all important for the operation of a machine.

Storage options for your wheel bearing puller tool set

In terms of keeping your wheel-bearing puller tool set in good shape, proper storage is essential. Try using storage cases with compartments that will hold the tools in place. Hard plastic and metal cases would also be ideal to ensure no external damage is inflicted upon them. Also, pick a case that has designated places for the tools in the form of label slots or foam inserts so loss of the tools is avoided. Proper storage enables your toolset to always be in perfect shape and ready to be used whenever need to be.

How do I use a wheel bearing press tool for front wheel bearing removal?

It is essential that all steps are followed when using the wheel bearing press tool in order to ensure the front wheel bearing removal is basic. My first step is to raise the vehicle while the wheel is taken off in order to have access to the hub assembly. After that, I removed the brake caliper along with the rotor, which means that I now have access to the wheel hub. Exposing the hub allows me to put the press tool so that when the old bearing gets pushed out, it does not damage other parts. For removal of the bearing, I place the bearing inside the press and apply pressure. Everything has to be lined up properly and the movements should be done in the right way so the problems can be avoided. Bearing is taken off as soon as it is bearing removed I want to check that area for any broken particles or dust before I move onto the installation stage.

Step-by-step guide to removing front wheel bearings

- Prepare the Vehicle: Raise the vehicle tightly in such a way that the indicating stick coincides in position with its friction surface. Once done, allow the level to drop vertically so that the indicated upper side and the jack’s horizontal bar coincide. Start by removing the wheel in order to expose the brake assembly in addition to the wheel hub.

- Remove the Brake Components: Untie the brake caliper and rotor “BBQ,” always exercising care not to twist or harm the brake hose. This action makes it easy to remove the wheel hub.

- Access the Wheel Hub: Prepare some bearings, washers, or housings and rotate them while installing or unfastening the threads. What has to be done will expose the bearing after stepping the required segments.

- Use a Bearing Press Tool: This brings a pressure tool in order to press the bearing as intended. Bearing the proper surrounding components, the old bearing is removed by bearing a steady and careful pressure and pushing it out.

- Inspect and Clean the Area: Take appropriate measures to ensure that debris or damage in the bearing housing is within limits, then thoroughly clean the area before moving to the installation stage for any new factors.

- Install the New Bearing (Optional): In case of a bearing replacement, ensure the new component is positioned correctly by using the press tool, allow it to secure into place, and return all removed parts in the reverse sequence.

Tips for using a puller tool set with sliding screws

using a puller tool set with sliding screws seem to rely on accuracy and well-laid-out tactical approaches. First, take a moment to focus on the dimension of the puller you are going to utilize so that you avoid damage or slippage. It is also important to make sure that arms are evenly secured around the component because this helps to secure balance and the opposite however is true, if there is imbalance excess pressure may cause wear and tear or in the worst cause failure of the part. Before you start, check that the sliding screws have been adequately oiled; this will reduce any chance of friction and allow it to operate freely. In conclusion, applying gradual pressure and ensuring a steady hand is key — in any situation, forcing things too quickly interferes with focus and comprehension. Always ensure that the right speed and nerves are held, which helps deliver good results.

Common mistakes to avoid during wheel bearing removal

One of the most frequent blunders I have witnessed while people are trying to remove wheel bearings is trying to press out the bearing whilst applying non-uniform force. This not only causes misalignment of the bearing but can also lead to damage to other vital parts. To prevent such a situation from arising, it is important to make sure that the load applied remains consistent throughout the process. Here is how you can do it step by step:

- Inspect Tools and Setup: Avoid using an ill-suited press tool for a bearing type and size. This is integral as an ill-fitted tool can cause a source of vulnerability centering on ease of use or an uneven force distribution.

- Lubricate Moving Parts: Lastly, always double-check to see that the moving parts on the press system and the sliding screws, if any, have been serviced well. This is because friction prevents a smooth movement.

- Align Components Correctly: One should refrain from applying force in the middle of the process. Rather, as a better measure, it is favorable to shift the bearing and other components to achieve proper alignment, which will displace more than one part.

- Avoid Rushing the Process: Slowly turn the pressure up and follow what is going on; never force a bearing out of its place. If too much effort is exerted onto the bearing, it risks the chance of many parts shattering or becoming torn to shreds, and this factor is more disconcerting than beginning the process, taking things slowly.

- Check for Residual Fasteners: One enters the batch expecting to always get in the last popsicle when sometimes, once retaining clips or more remain on the batch. Unfastened hardware can slow down work and damage bearings further on.

By adhering to these benchmarks, you will minimize the chances of difficulties arising during the extraction of wheel bearings. Ensure, as always, that planning and meticulousness are what allowed you to do this job as a last resort.

Can I use the same tool for both front and rear wheel bearing removal?

For the most part, the wheel bearing design will dictate whether or not the same tool can be used on both front and rear wheel bearing removal, although from my experience, most bearing press kits are fairly interchangeable for both front and rear applications. A word of caution, as I advise taking a look at the tool specifications and cross-checking them to the requirements of your vehicle before commencing the job. It is the best practice and will save you from undue hassles. Proper preparation and the right equipment are keys to success.

Differences between front and rear wheel bearing removal techniques

One of the major differences in the methods of removing the front and rear wheel bearings is the configuration of the driveline and the design of the assembly. In particular, when dealing with front wheel-driven vehicles, front wheel bearings could be a part of the hub assembly, which might need additional efforts like supporting the axle disc or the brake assemblies. On the contrary, most rear wheel designs tend to be more dissimilar depending on whether the vehicle has or does not have a rear solid axle. Solid axle configurations entail pressing the bearings directly onto the axle shaft, while without it would mean rear suspension components with hub assemblies paneled to the front. Knowing these distinctions and using the appropriate vehicle service manual can enable simplicity in removal.

Adapting your wheel bearing press kit for various vehicle types

In fact, adapting your wheel bearing press kit to various vehicle types is about preparation and flexibility. During my career, I have dealt with compact cars and heavy trucks and had to work around them. The essence of it is that every time you are creating your press kit, consider using multiple adapters, sleeves, and plates for this press to help accommodate different sized and configuration bearings. For example, many front-wheel-drive vehicles may require tools oriented toward hub assembly, while solid axles may require external or precision press plates. I always stress the importance of referring to the service manual for the specific vehicle in case of doubt – this is to check for suitability and to avoid premature damage to your tools. Presumably, this speaks to having an adequate number of kits as well as their versatility which ultimately saves time and allows one to take on different kinds of tasks confidently and quickly.

How do I maintain and care for my wheel-bearing puller tool set?

In this way, regular care of the wheel bearing puller tool set guarantees endurance and performance. Begin the maintenance process by thoroughly cleaning germ, grease, and grime from all parts after every use. Identify damage in the tools and replace them so both the durability and functionality remain safe. Always keep the tool set in a well ventilated and dry place in order to prevent rust formation or corrosivity, applying a light coat of lubricant would also help. Lastly, ensure that you follow the manufacturer’s instructions properly, as tools can easily be damaged if mistreated, and that would reduce their efficacy.

Cleaning and storing your wheel bearing press kit

Just like how a snap-on tire changer is important, how you clean and store a wheel bearing press kit is important too, and I don’t encourage it to be complicated. I focus on the dirt covering a component – grease, and debris, then wipe clean every component after they are finished being in use. Also a gentle solvent is good to work with if the grime gets tougher, it does not ruin the components of presses. Then, I place everything within a strong, dry case to prevent all rust and rot. The cleaning that occurs here will also go on to mean that the tools have a long durability as well as being ready for the next cycle of work.

Extending the lifespan of your wheel bearing removal tools

It is fair to say that proper application, timely maintenance, and correct storage of a wheel bearing removal tool could enhance its life span and longevity. Always remember to follow the set of instructions, as the purpose of the tools is to avoid considerable force being applied to them. After every job, it is necessary to wash them with grease, dirt, and other cleaning agents, as well as grease the moving parts to lessen friction. Organized packing, which is ventilated, saves the tools from rust and corrosion. If adhered to, these practices will make sure that your tools serve you adeptly for several years down the line.

Are there any alternatives to using a wheel-bearing press tool?

Definitely, I do concede that there are other methods to avoid using a wheel bearing press tool however, they might not be as effective or accurate all the time. One common practice is the hammering and use of sockets or bearing drivers which are of appropriate size to force the bearing in or out. Although this method may function in a hurry, it requires a considerable amount of attention to avert injuring the bearing and neighboring parts. Using a hydraulic press is another approach that enables you to control the amount of force used, although access to certain tools is essential. In my opinion, these alternatives would appear to make a saving initially, but more often than not, they tend to cost in terms of time and effort or even the risk of an imperfect installation, which is why I would advise you still get a dedicated wheel bearing press tool if you want to achieve reliable results.

Comparing professional services vs. DIY wheel bearing removal

when choosing between hiring a professional and doing it yourself when removing the wheel bearings, it all comes down to tools, skill, and enough time. The advantage that lies within professional services is specialized equipment and trained technicians who will ensure that the task takes the least time and is accurate as there is less chance of damaging the vehicle. Alternatively, if you already have the right amount of tools and the skills needed, it is cheaper to remove it yourself. Still, it may take time and also demands accuracy because, without the right technique, it could create the need for further repair in the future. I understand everybody’s desire to do any work themselves, but my recommendation is that one must always consider the difficulty of the task and how comfortable they are to do it themselves. On most occasions, the amount of money an individual has to pay to the professionals could feel like a lot, but the satisfaction and peace of mind they provide are much more worth it.

Exploring other methods for wheel bearing replacement

Another way of substituting the bearing is using what is called the “hammer and socket” technique. All this requires is a socket of the appropriate diameter and a hammer which will be used to push out the old bearing and install the new one. Although operative, this method is risky since not reaching certain precision during the process may risk damaging the bearing, which in turn may also damage the hub or perhaps put surrounding components in danger. In the same spirit, the bearing may be removed, and the new one may be installed onto the hub using heat. It is however better not to heat increments because overheating it is also not good due to the risk of warping. The methods indicated above are for people with experience as they are less reliable and time-consuming in comparison to proper tooling techniques.

Reference

- Instructions for RRP Bearing Press & Extraction Tool – This document provides detailed instructions on using a bearing press tool.

- Master Wheel Hub and Bearing Remover and Installer Kit – An owner’s manual that includes safety information and usage instructions for a wheel hub and bearing remover kit.

- 23 Piece FWD Bearing Removal And Installer Kit – A product page that describes a kit designed for removing and installing front wheel drive wheel bearings.

Frequently Asked Questions (FAQs)

Q: What is a wheel bearing press kit for front wheel drive bearing removal?

A: A wheel bearing press kit for front wheel drive bearing removal is a specialized tool kit designed to assist in the removal and installation of wheel bearings on front wheel drive cars. It typically includes a set of sliding screws, universal bushings, sleeves, and a storage case. This tool kit is essential for mechanics and DIY enthusiasts working on wheel bearings, as it provides the necessary components to safely and efficiently remove and install bearings without damaging the wheel hub or surrounding parts.

Q: What components are typically included in a wheel bearing tool kit?

A: A comprehensive wheel bearing tool kit usually includes: 1. A main puller body 2. Various sizes of sliding screws 3. Universal bushings and sleeves 4. A bearing race and seal driver set 5. Adapter plates 6. A storage case for organizing and protecting the tools Some kits, like the VEVOR wheel bearing press kit or the 23pcs FWD front wheel drive bearing puller set, may include additional specialized components for specific vehicle makes and models.

Q: How does a bearing press kit for front wheel drive cars work?

A: A bearing press kit for front wheel drive cars works by applying controlled pressure to remove or install wheel bearings. The process typically involves: 1. Selecting the appropriate sized bushings and sleeves 2. Positioning the puller body on the wheel hub 3. Using sliding screws to secure the tool in place 4. Applying pressure using the central screw to push out the old bearing or press in a new one The universal design of these kits allows them to work on a wide range of front wheel drive vehicles, making them versatile tools for automotive repair.

Q: What are the advantages of using a front wheel drive bearing puller set?

A: Using a front wheel drive bearing puller set offers several advantages: 1. Precision: It allows for accurate removal and installation of bearings 2. Versatility: Can be used on various makes and models of front wheel drive cars 3. Cost-effective: Saves money on professional service fees 4. Time-saving: Speeds up the bearing replacement process 5. Safety: Reduces the risk of damaging other components during bearing removal 6. Convenience: The storage case keeps all components organized and easily accessible

Q: How do I choose the right wheel bearing press kit for my needs?

A: When selecting a wheel bearing press kit, consider the following factors: 1. Compatibility with your vehicle’s make and model 2. The range of bearing sizes it can accommodate 3. The quality and durability of the tools (e.g., Orion Motor Tech wheel bearing press kit) 4. The number of components included (e.g., 23pcs FWD front wheel drive set) 5. The presence of a storage case for organization 6. User reviews and ratings 7. Your budget and frequency of use: Choose a kit that offers a good balance between versatility, quality, and value for your specific needs.

Q: Can I use a wheel bearing press kit for other automotive tasks?

A: Yes, many wheel-bearing press kits are versatile tools that can be used for other automotive tasks. In addition to wheel bearing removal and installation, these kits can often be used for: 1. Removing and installing bushings 2. Pressing in wheel studs 3. Installing and removing silent bloc bushings 4. Working on some suspension components However, always ensure that the kit is suitable for the specific task at hand and follow manufacturer guidelines to avoid damaging the tools or vehicle components.

Q: How do I maintain my wheel bearing press kit?

A: To maintain your wheel bearing press kit and ensure its longevity: 1. Clean the tools after each use to remove dirt and grease 2. Apply a light coat of oil to metal components to prevent rust 3. Store the kit in its provided case to protect it from damage and moisture 4. Regularly inspect the tools for signs of wear or damage 5. Replace any worn or damaged components promptly 6. Keep the sliding screws, universal bushings, and sleeves organized in the storage case 7. Follow the manufacturer’s maintenance recommendations for your specific kit

Q: Is it necessary to have a professional-grade wheel-bearing press kit for DIY repairs?

A: While professional-grade kits like the VEVOR wheel bearing press kit or Orion Motor Tech wheel bearing press kit offer high quality and durability, they may not be necessary for occasional DIY repairs. For infrequent use, a mid-range kit with good reviews can suffice. However, if you plan to work on multiple vehicles or perform frequent bearing replacements, investing in a professional-grade kit can be beneficial. It’s important to choose a kit that matches your skill level, frequency of use, and the types of vehicles you’ll be working on.