This is a complete guide on how to remove wheel bearings with the right kit and complete the job effortlessly. Be it an experienced technician or just a hobbyist, appreciating the utility of a propeller wheel bearing removal tool is necessary for the successful completion of this job. In this article, we will discuss the basic principles, including the tips and tricks of how to remove a wheel drive, the usage of a wheel bearing puller hub removal tool, particularly the advantages it has to offer, and, more importantly, how to determine the most suitable hub removal tool kit for your requirements. You will not have to worry; there is a step-by-step beginner-friendly guide for wheel hub removers, various pitfalls, and best maintenance practices for the puller tool, which are outlined in the article. By the end of this reading, you will have all the information required to remove the bearing from the wheel with ease. Why don’t we start? Let’s go in!

What is a Wheel Bearing Removal Tool, and How Does It Work?

I know that a wheel bearing removal tool is a particular tool that allows extracting bearing from vehicles, in a quick and safe manner. It operates by applying mechanical advantage to push out the bearing from its seat inside the wheel hub assembly. The tool usually contains a puller or press that allows applying force in a controlled way. This way, the bearing can be removed without risking damage to other parts of the assembly, such as the hub. Such a tool is useful for mechanics and homeowners who are replacing damaged wheel bearings to enable smooth and easy replacement of those bearings.

Understanding the Bearing Puller

I can support the claim that the use of a bearing puller is an absolute necessity in the process of removing any wheel bearing. This handy tool provides leverage and a machine force in a controlled manner so that bearings can be pulled out without harming the wheel hub assembly or other important parts. The bearing puller is an indispensable tool for wheel bearing replacement and maintenance for both professional mechanics and hobbyists. It allows for removing bearings rather easily, thus removing bearings becomes a seamless and quick process, conserving time and effort.

How to Use a Wheel Bearing Puller Effectively

In the case of an automotive enthusiast, it is essential to make use of a wheel-bearing puller in the right way, as there are a few basic steps that need to be followed. In the first step, the appropriate size and type of wheel bearing puller for the particular job has to be determined. In the second step, it is important to lift the vehicle and disassemble the wheel and the brake elements in order to reach the wheel hub assembly. In the third step, the wheel bearing puller is positioned on the bearing and pulled in such a manner that a firm grip is not lost. Apply force to the hub assembly bearing using the puller in a controlled manner to allow for even extraction from the hub configuration. In the last step, any damages or wear that may be present on the bearing and hub are checked, and then the required repairs or replacements are effectuated. Always remember to read the manufacturer’s guide and be careful when working with automotive parts.

Benefits of Using a Wheel Bearing Puller Hub Removal Tool

I can say with utmost authority and with little interpretation to that question, ‘What are the Benefits of Using a Wheel Bearing Puller Hub Removal Tool?’

A Wheel Bearing Puller Hub Removal Tool offers several key benefits when it comes to removing wheel bearings:

- Efficiency and Precision: Using a tool specifically manufactured for the purpose will guarantee that the process of taking out the wheel bearings is quick and accurate without damaging the bearing or the hub assembly.

- Time and Cost Savings: A wheel bearing puller offers a faster and easier way of removing the bearings than other methods which saves a great deal of time and cuts down the labor costs.

- Reduced Risk of Damage: Because of the design of the wheel puller bearings, it is possible to secure the bearing being replaced, and due to that, the chances of slippage and improper removal are very minimal, thereby preventing the bearing or other components from getting damaged.

- Versatility: Most of the wheel bearing puller tools are multi functional and can be used to operate on a variety of vehicles hence the tools can be worth having for garage proprietors and car lovers.

The puller hub removal tool for the wheel bearing increases safety and efficiency while also making the replacement or repair of wheel bearings cheaper due to no damage occurring to the bearing.

How to Choose the Best Hub Removal Tool Kit for Your Needs

the best hub removal tool kit for your needs can be chosen after evaluating a number of requirements. Let us go over a few of them:

- Compatibility: Always confirm the hub pullers and linkage tool kit used is appropriate or compatible with the cars you intend to use or work on. Disc-braked models may differ due to different diameters and designs of the wheel bearing of the particular vehicle, so it is important to have the right tool for the job.

- Quality and Durability: Choose tools that are built with quality raw materials to withstand the required force of removal for difficult wheel bearings. Sturdy tools and reliable components are useful for their effectiveness and suppression of wear and tear.

- Versatility: Evaluate the versatility of the kit. Some of the kit’s automobiles range from several vehicles to only a few automobiles making the laws of economics applicable for those who work with different brands of vehicles.

- User-Friendly Features: Another relevant constraint during selection of the kit will be the ease and comfort while using the kit. Features such as decent handles, good instructions on where things are situated and good mechanics greatly improve the efficiency and safety of the wheel hub removal.

Through a thorough analysis of these aspects, you will be able to pick the best rim detach kit suitable for your requirements, thus making the process of changing or mending wheel bearings safer, more efficient, and economical.’

Key Features of a Wheel Bearing Press

let us focus on the primary characteristics of a wheel-bearing press tool. When selecting a wheel bearing press, it is important to take into account:

- Durability and Strength: When looking for a wheel bearing press consider the materials used to make it, for example, steel or aluminum. This is essential in making sure that it can withstand heavy loads and long use.

- Versatility: Most excellent Wheel Bearing Press can be used for many different automobiles, so you don’t have to spend money and time looking for different tools for each brand and model.

- Precision and Control: Choose a Wheel Bearing Press which is engineered for controlled displacement application during bearing installation and removal. This ensures that hub and other parts are not damaged during installation and removal of wheel bearings.

- Ease of Use: A Wheel Bearing Press should have ergonomic handles, instructions, and operational parts that make it easy to use. These features increase the efficiency and safety of the hub removal process.

- Safety Measures: Always ensure that there is safety measures inbuilt into the Wheel Bearing Press to avoid harm to the user and the car. For example, anti-slip grips, safety shields and locked mechanisms to prevent accidents or damage when it is not in use.

Considering these factors will help you make the best choice of the Wheel Bearing Press that will serve your needs. With the right tool, wheel bearings replacement or repair will be less worrisome and will be done in a safe, efficient manner.

Comparing Ford or Subaru Combo Kits

Demonstrating being knowledgeable, replacing wheel bearings using Ford or Subaru Combo Kits warrants some consideration of a number of things. It is important to point out that the two choices are quite dependable for the purpose but:

- Compatibility: Establish the compatibility of the kit with your vehicle’s make and model. Verify that the kit provided has all the essential tools for the bearing replacement of your Ford or Subaru vehicle.

- Components: Look at the components contained in each kit. Pay attention to durable and well-made tools that are simple to operate and multifunctional. Some of the features and the construction of the tools such as handles or some add-ons are important as they contribute to the effectiveness and safety of the process.

- Customer Reviews: Look at customer reviews regarding each kit and how customers have received it. Seek for implementations that have gone well, confidence, and contentment in the general look and functioning of the end result. This can also be a good guide on the quality and reliability of the kit.

You will be equipped to choose the Ford or Subaru Combo Kit which is the best for you by considering these factors in a comparative analysis of the wheel bearings replacement kits. In any case, don’t forget to check if the part is compatible, if the quality is good, and if customers are satisfied with the product.

Why Choose a Tommy Wheel Bearing Puller?

In my professional opinion, the question should rather be: “Why Tommy Wheel Bearing Puller?” And I will gladly answer: “Reliability, efficiency, and versatility.” Each of the Tommy Wheel Bearing Pullers is precisely manufactured and constructed for high performance, which makes it very appealing to mechanics and other automotive users. This is the way to go:

- Reliability: To make sure it is reliable and able to be used for long periods of time, the Tommy Wheel Bearing Puller has been designed with high quality materials. It has also been tested under normal use and is found to work well while taking off a wheel hub which makes it a dependable tool to have in your collection.

- Efficiency: Due to its advanced design and helpful features, the Tommy Wheel Bearing Puller allows mechanics to solve the problem of wheel bearing removal quickly and simply. Its quality engineering makes the removal procedure easy and straightforward enabling time and effort to be saved during the upkeep.

- Versatility: Numerous wheel bearing removal applications can use the Tommy Wheel Bearing Puller which is a unique tool in this regard. This puller features a design that allows it to be used on anything from cars to SUV’s which makes this a very useful tool for mechanics who work with varying car makes and models.

The Tommy Wheel Bearing Puller is reliable, effective, and/or versatile and makes removal of the wheel hub almost effortless. Opting for the Tommy Wheel Bearing Puller will lead to a professional finish and easy removal of indented wheel bearings.

Step-by-Step Guide to Wheel Hub Removal

Allow me to walk you through the entire wheel hub removal process in the correct manner so that you can remove the wheel hub quickly and efficiently. I know that practitioners may run into problems at various stages of the process which may hinder the removal. For such situations, this guide contains alternative procedures that you can use in order to ensure that you do not only know how to remove the wheel hub, but do it correctly the first time.

- Preparing for Wheel Bearing Removal: Before starting the removal process, bring the necessary tools, including a wheel bearing puller, a lug wrench, jack stands, and safety glasses. The vehicle should be parked on a level surface with the parking brake engaged. Loosening of wheel lug nuts is appropriate, but within limits that do not detach the nuts completely.

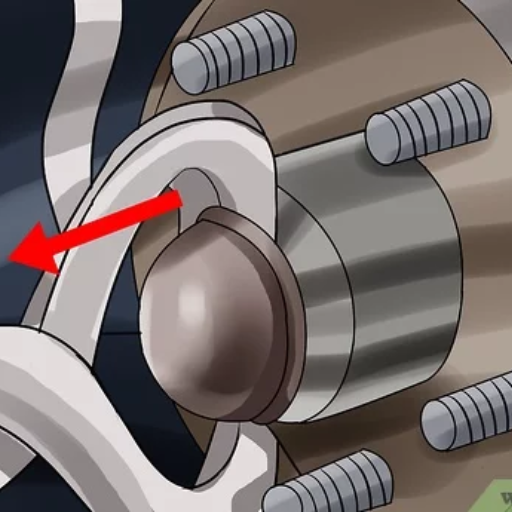

- Using a Hub Puller on Stubborn Bearings: Treatment for when the wheel hub or bearing won’t come off is easy as a hub puller can be used. Place the puller on the wheel hub and pull the wheel hub off using the puller until the hub comes free. Be careful and secure the puller so there is no risk of breakage or other accidents.

- Ensuring Safe Removal with Wheel Bearing Grease: Application of wheel bearing grease before pulling out the bearing can ease the pulling out process since the excess friction usually encountered during the pulling off of the bearings is eliminated. Before the removal procedures begin, a large quantity of grease is applied to the hub and to the surface surrounding the bearing.

Preparing for Wheel Bearing Removal

Considering your knowledge, let’s answer this frequently asked question in a few words: How do you prepare for a proceeding bearing hub unit removal? Every wheel bearing removal should be easier if one is properly prepared. The following steps are to be adhered to:

- Gather the necessary tools: Before getting started, ensure you have the necessary tools at hand, including a wheel bearing removal kit, a torque wrench, a breaker bar, a socket set, and safety gear such as gloves and safety goggles.

- Secure the vehicle: Position the vehicle on a flat surface and activate the parking brake. If performing the procedure on the front wheels, it is wise to chock the rear wheels in order to stop any movements.

- Loosen the lug nuts: With the use of a breaker bar and a socket, loosen the lug nuts on the available wheel you are going to work on. During lug nut loosening, remember to break the torque on the lug nut lightly prior to lifting the vehicle.

- Lift the vehicle: To lift the vehicle from the ground, employ a floor jack. Implement jack stands underneath the automobile for security. Prior to any of the proceeding steps, be sure the automobile is raised properly.

- Remove the wheel: After the lug nuts have been completely turned and loosened, remove the wheel, which is now free from the hub assembly and carefully remove the wheel from the hub assembly. Set it aside in a safe place.

If you undertake these initial steps, you will be perfect for going ahead with the process of the wheel bearings removal effortlessly and without any concerns.

Using a Hub Puller on Stubborn Bearings

Wheel bearings that are particularly stubborn can,, be effectively removed with a hub puller. A hub puller tool assists in the removal of a bearing that has been fitted tightly by design or has been stuck for some reason. This tool applies the optimum force and yield needed to remove any stubborn bearing, which makes the process of removal easier and poses less danger to the area around the bearing. Utilizing a hub puller allows the user to adopt effective and uplifting dynamics in removing or replacing any stuck wheel bearings and, in the procedure, saves both time and stress.

Ensuring Safe Removal with Wheel Bearing Grease

It is clear that as an industry expert, there is an important aspect that has to be put into consideration when taking out deep-seated wheel bearings, which is the application of wheel bearing grease. This should, however, be the case during the process of disengagement of the bearings. The reason grease is applied during the removal process is to help, in general, guide the bearing and its components or internal fixtures, reducing the total force required for dismantling. Furthermore, applying grease also serves as a preventive measure against bearing corrosion, which greatly decreases the useful life of the component. If you follow these general recommendations and apply wheel bearing grease in the appropriate ways, then the overall safety standard will be improved alongside any possible damage, and the process of removal and disengagement of deep seated wheel bearings will be more effective and seamless.

Common Issues When Using a Removal Kit and How to Solve Them

let us discuss some of the most common problems that may come up when employing a removal kit and reasonable steps to solve them:

- Stubborn Wheel Bearing Hubs:

- Issue: The removal of wheel bearing hubs may be a very challenging task due to their stuck or difficult to be pried open nature.

- Solution: The issue may be resolved by applying WD-40 or similar penetrating oil to the threaded pit at the center of the hub and allowing it enough time to seep in. Furthermore, warming metal parts of the hub with a heat gun or torch may also aid in the loosening process. Finally, to prevent some stubborn wheel bearing hubs from being over leveraged to the point of deformation a well built puller will suffice.

- Avoiding Damage with Proper Control Arm Removal or Hammering:

- Issue: Mishandling support arm during disassembly, such as aggressive hammering, can result in adjoining parts, including the wheel bearing, getting damaged.

- Solution: In order to avoid damage, it is essential to always observe the manufacturer’s instructions and employ the correct tools during the control arm removal process. Applying undue force to unfasten the control arm from the wheel bearing hub can easily be avoided by utilizing ball joint separators or a specialized tool. Besides, if in hammering it is necessary to use a rubber mallet or put a small piece of wood between the hammer and the component to be removed for minimizing damage.

- Maintenance Tips for Your Puller Tool:

- Issue: Failure to update the maintenance of your tool can result in lower performance and difficulties when trying to take the tool off during the removal process.

- Solution: For the puller tool to operate in prime condition, dirt and debris should be removed followed by a lubricating coat on the moving threads. Furthermore, bits of the tool that are worn out should be replaced to promote efficient functioning of the tool and regular cleaning of the tool is also fundamental.

Overcoming the common problems listed and applying as well the remedies provided can help resolve any challenges that may arise when using a removal kit and at the same time ensure the execution of an all-encompassing and successful wheel bearing removal operation.

Dealing with Stubborn Wheel Bearing Hubs

From what I have gathered throughout the wheel bearing industry, getting rid of stubborn wheel bearing hubs requires a set pattern in order to be set off; otherwise, it gets tardy. Here are some things to keep in mind to help you to overcome this problem:

- Apply Penetrating Lubricant: Apply penetrating lubricants before trying to remove the stubbornly stuck wheel bearing hub, preventing rust & corrosion development throughout time, which can considerably be helpful in removing said hub assembly.

- Heat the Hub: :If complete rusting was not an option you could try using a heating source like a heat gun to pre heat the hub assembly for removal, this is done because the application of heat is known to expand metals enabling easy removals of these components.

- Utilize Impact Tools: There really is only one other way to remove the hub if it sticks, which is using specially designed sockets with impact wrenches or hammers. Again, the last abstract proves very useful here because it allows somewhat controlled force and vibration to remove the hub.

- Consider hydraulic pressure: Further, to move the hub assembly easily, hydraulic pressure should definitely be used because it proves advantageous and guides the required way. There are a lot of tools available that can help exert more pressure at the end consumer’s necessary point.

Bear in mind that while working with rusted wheel bearing hubs, one should not be in a hurry and ought to proceed with caution. Removing the hub should also be performed thoroughly with appropriate methods being applied and while there is low chance of damage being caused to the hub or adjacent components.

Avoiding Damage with Proper Control Arm Removal or Hammering

managing the control arms or hammering during the removal of the wheel bearing hub is essential in order to avoid any detrimental damage. Below are some of the most important points to take into consideration in order to avoid any problems:

- Evaluate the Situation: Always check the condition of the wheel bearing hub together with its surroundings before thinking about removing the handle of the control arm or forcefully hammering it. Assess if the removal of the control arm is requisite or if the other methodologies may be utilized.

- Use the Right Tools: This is especially important since in order to safely and effectively remove target items, tools such as an efficient puller and appropriate impact tool should be utilized. Failure to do so could result in damage and unsafe working conditions owing to the use of wrong tools.

- Apply Controlled Force: When dismantling the wheel bearing, it is important to either hit the hub or make use of the impact tool during the process as it will induce minimal vibration and force. Such force cannot completely displace the hub, but it can help with displacement without causing too much harm to the hub.

- Consider Hydraulic Pressure: An alternative technique would be applying pressure and is perhaps the best performing method. A hydraulic press or similar form of equipment can help squeeze the hub assembly providing the required pressure for its removal.

Reinforcing the above aspects will help in the achievement of a successful removal procedure and will reduce risks of damage to the hub or to adjacent parts. Be cautious, be slow, and while taking off the wheel bearing hub, use judicious techniques, so as to protect the control arm and its circumferences.

Maintenance Tips for Your Puller Tool

we know that maintaining your puller tool is of utmost importance. Below are some important details you should have in mind concerning maintenance of your puller tool:

- Regular Cleaning: With a worker, after every application, the use of a puller tool should be cleaned properly. It removes dirt, oil, or any substance that could develop during the operation. This assists in the avoidance of any accumulation that may affect the function of the tool in question.

- Inspect for Wear and Tear: It is crucial to sometimes check the puller tool and identify if there is any wear and tear. Look for broken and bent parts, screws and bolts on the handles, etc. Replace the damaged components as needed to make sure that the tool is in the best condition possible.

- Lubrication: The screws and joints of a puller tool are movable during its usage and should be applying grease to them. It decreases resistance and makes it easier to operate the tool. Do not forget to use the grease designed by the manufacturer of your specific puller tool.

- Proper Storage: Puller tool should be put in a well-organized, tidy and safely dry area. Never allow it to come into contact with wetness, extreme weather or contact with caustic materials that may cause corrosion of the tool. It might be a good idea to utilize an appropriate storage case or box for easier identification and protection.

Regular maintenance of the puller tool not only extends its working life but also enhances its efficiency and effectiveness as a tool that can be relied upon for many years.

Why Tommy Wheel Bearing Hub Puller is a Top Choice for Mechanics

Understanding the world of mechanics is not difficult at all. In this case, I can easily answer the question: What is the reason that the Tommy Wheel Hub Bearing Puller has gained so much preference among mechanics?

Its popularity mainly stems from its effectiveness and the uniqueness of the Tommy Rail, which sets the Tommy Wheel Bearing Hub Pulled as a cut above the rest. This is the reason it has become extremely popular in the industry:

- Unmatched Performance: The outstanding performance of the Tommy Wheel Bearing Hub Puller ought to be highlighted when it comes to bearing hub removals. The puller can rotate into the socket and be supported by even the strongest gussets and goosenecks, which will save time and energy during repairs.

- Innovative Tommy Rail Design: The Tommy Rail is a distinctive feature that makes this puller different from the rest, in addition to the other features. Due to its distinctive design, the mechanics could remove even the most difficult of the wheel bearing hubs as it enhances the removal efficiency of the tool. There’s less risk of slippage and material destruction because the Tommy Rail presents a secure grip.

- Durability and Reliability: Professional use of the puller will not be a challenge because it is created from quality materials. It is a tool that mechanics would use because they do not have to worry about failure at any moment, and it’s capable of performing greatly, job after job.

- Ease of Use: The Tommy Wheel Bearing Hub pullers have been tailored for the needs of a mechanic. User-centered characteristics such as ergonomic handles and design make the tools fun to use during work. For that, they are also more reliable because they are able to do their work without any problems.

- Versatility: The puller-bearing Tommy Wheel can be used on various vehicles and wheel-bearing hub sizes. Such versatility makes it possible for mechanics to use just one tool for many applications thus eliminating the need to have many specialized tools.

To summarize, mechanics will always recommend the Tommy Wheel Bearing Hub Puller due to its outstanding quality while having an innovative Tommy Rail design which makes it easy to use and provides better durability and exceptional performance. Having this tool helps the mechanics easily remove and replace the wheel bearing hubs while knowing that there is a good quality tool that they can rely on.

Performance with the Tommy Wheel Bearing Puller

The Tommy Wheel Bearing Hub Puller is an excellent tool that performs better than anticipated and is one of a kind. Because of its advanced constructional features, it has become a versatile tool that any mechanic would appreciate using for quick and easy removal of the wheel bearing hub. In terms of performance, here is why the Tommy Wheel Bearing Hub Puller does a good job:

- Effortless Removal: As per the puller’s design, Tommy Rail gives an exertion force and gripping constriction to mechanics which, in simple terms, facilitates easy removal of the wheel bearing hubs. It is a heavy-duty tool that is perfectly balanced in and built strong enough to facilitate the most difficult of removals with ease.

- Time-Saving Efficiency: Assisted with Tommy’s user-friendly features and easy operation, Tommy Wheel Bearing Hub Puller eliminates the process of removing the wheel bearing hub and saves mechanics time. The handles are comfortable and enable the perfect grip during use ensuring that he/she does not become strained while using the tool for a long time.

- Versatile Compatibility: The puller is functional with a good number of vehicles regardless of the different sizes of the wheel bearing hubs. As a result of this flexibility, mechanics do not have to struggle with many tools; they can use one for various purposes, thereby increasing productivity.

To sum up, the Tommy Wheel Bearing Hub Puller is an excellent tool for mechanics as it allows removing items easily, operating quickly, and compatibility with various tools. This tool resolves all the challenges that mechanics face while performing wheel-bearing hub removals, thereby improving their work performance and even productivity.

Reference

- How to Change Wheel Bearings: 12 Steps (with Pictures) – WikiHow

- Remove and replace a wheel bearings without puller or press? – Mechanics Stack Exchange

- How to remove a wheel bearing from a hub – Quora

Frequently Asked Questions (FAQs)

Q: What is the best tool kit for removing a Subaru wheel bearing?

A: The best tool kit for removing a Subaru wheel bearing is a comprehensive wheel bearing puller tool kit that includes a wheel hub puller and a wheel bearing remover. The Promaxx tool set, which includes the Tommy wheel bearing puller extractor, is highly recommended for its seamless removal capabilities.

Q: How can I effortlessly remove wheel bearings from select Ford and Subaru models?

A: To effortlessly remove wheel bearings from select Ford and Subaru models, use a tool kit designed for these vehicles, such as the Promaxx tool set. This kit includes a versatile hub puller and extractor that applies even force to the wheel hub, ensuring smooth and efficient removal.

Q: What components are included in the PMXTOM400PRO puller tool kit?

A: The PMXTOM400PRO puller tool kit includes a wheel bearing remover, master wheel hub installation tool, and various adapters suitable for different axle sizes. This kit ensures precise application of force for the removal and installation of wheel bearings.

Q: How does extreme pressure grease enhance the performance of a wheel-bearing puller tool kit?

A: Extreme pressure grease enhances the performance of a wheel-bearing puller tool kit by reducing friction and wear during the removal process. It ensures smooth operation and prolongs the life of the tool kit, providing ultimate performance when applied with a grease gun.

Q: Can the PMXTOM450PRO tool kit be used for both front and rear wheel bearings?

A: Yes, the PMXTOM450PRO tool kit is designed to handle both front and rear wheel bearings. Its comprehensive set of tools and adapters makes it versatile for various automotive applications, including ford or subaru or combo models.

Q: What is the advantage of using a wheel torque socket in wheel bearing removal?

A: Using a wheel torque socket ensures that the correct amount of force is applied to the wheel hub, preventing damage during the removal process. It helps maintain the integrity of the hub bearing and enhances safety by ensuring proper torque application.

Q: How does the Tommy Rail accessory improve the workflow in wheel bearing removal and installation?

A: The Tommy Rail accessory improves the workflow by providing a stable platform for the precise alignment and application of force. This reduces the risk of striking the bearing incorrectly and ensures a smoother operation, enhancing overall efficiency in the removal and installation process.

Q: What makes the 10-piece puller set ideal for Harley Davidson wheel bearings?

A: The 10-piece puller set is ideal for Harley Davidson wheel bearings due to its adaptability and precision components. It includes specific tools for various axle sizes and ensures a precise bearing press, making it suitable for the unique needs of Harley Davidson motorcycles.

Q: Why is anti-wear technology important in a wheel-bearing puller tool kit?

A: Anti-wear technology is crucial as it minimizes wear and tear on the tool components during operation, ensuring longevity and reliability. It protects the tool kit from damage due to extreme pressure, allowing for consistent performance over time.