Wheel bearings function to support the weight of the vehicle as the wheel rotates; they ensure smooth and efficient movement of the wheels and the entire vehicle. However, like any other mechanical component, they eventually wear out. In this article, we will be discussing various aspects of wheel bearing replacement, including the most appropriate time to change them, reasons for change, and the right person qualified to undertake such a task. Whether you are just an everyday driver or an experienced motorhead, this comprehensive guide will prepare you to make the right decisions about the maintenance of your vehicle comfortably. However, the question that needs to be addressed before grasping this concept is, why is it important to maintain the wheel bearings?

What are the signs of a bad wheel bearing?

One of the early signs of a bad wheel bear is the unusual noise when driving. Other signs include the feeling of vibration in the steering wheel, uneven tire wear, and a loose feeling in the vehicle as it retains handling. Grinding, humming, or whining noises from the wheel area are also another sign of an impending wheel bearing failure. It is also possible that the wheel bearing might fail and trigger the ABS warning light. The best course of action is to consider getting the vehicle serviced at the first signs of the damage. Otherwise, your vehicle safety might be compromised.

Unusual noises from the wheel area

the unusual sounds that come from the wheels are the most frequent signs that there are some deeper problems with the wheel bearing along with other important parts. I’ve witnessed situations where drivers would overlook the grinding or growling of their car engine, and it would later develop into a bigger problem that could cost quite a lot. My recommendation? Don’t waste time – look for any signs of unequal tire wear, evaluate how the car behaves on the road, and let the specialists check the wheel bearings instantly. Troubles of this sort, if caught early, can save your life as well as the car’s functionality for an extended period.

Steering wheel vibrations and wobbling

Vibrations in a steering wheel can essentially be felt in the palms due to the back-and-forth effect created when there is an imbalance in the suspension, tie rod, or wheel alignment. Before addressing additional components, check and make sure that your tires are not damaged and have a proper wear pattern. If the problem continues, it is likely the issue lies with the suspension, specifically, the tie rods or the ball joints. It is then important for the motorist to rectify these challenges as that would ensure an increase in the vehicle’s durability while also ensuring safe mobility.

Uneven tire wear patterns

a couple of things are a recurrent theme whenever I come across uneven tire wear, and knowing them in advance is beneficial to the user. So here’s what you have to keep in mind:

- Wheel Alignment

Most of the time, cars will experience either one or the other of the issues, i.e., there will either be a suspension problem or a wheel alignment issue. Most of them end up discovering it too late because they don’t have the knowledge or don’t take their alignment too seriously, which ultimately leads to frustration because of the wear on the tires as well as steering issues. The steering issues are caused by additional friction forces being placed onto one side of the tire, which causes wear and tear and pulls the sides. This is a major reason as to why the vehicle’s tire alignment must be checked at the very least once a year, while more regular checks are recommended.

- Tire Pressure

As mentioned above, wearing out or over-inflating tires wear out the tire unevenly, and that creates problems. Overinflation of tires results in wearing out primarily the center of the tire, whereas if a tire is underinflated, then the edge takes the brunt of wear and tear. To tackle this problem at hand, it would be a good idea to check the pressure of the tire at the beginning of every month and ensure it is equal to the threshold that has been set by the car manufacturer, which is typically written in the manual.

- Suspension Components

Such parts would include suspension parts such as shocks or struts that assist the car’s tires to make more or less contact with the ground, which in turn leads to various results in terms of performance. This then leads to the car experiencing a bumpy ride or a jumpy one, which consumes a lot of energy. If not, it is better advised to get the suspension checked up, as that could also be a factor for uneven wear on tires.

- Tire Rotation

If you drive around with the same tires on the same side, then eventually, wear and Tear unevenly occur, which is why it is advised to rotate tires. On average, it is best to do tire rotation at intervals of 5000- 7500 miles as this allows the front tires to lessen the rate with which they are worn out.

- Driving Habits

Making quick turns, accelerating quickly, or pressing the gas pedal hard all fall under aggressive driving styles. Such driving habits can make your tires wear down unevenly. While putting on some smoother driving styles will take care of your tires, it can also save you on fuel.

When these parameters are looked at it becomes easier to understand the reason why tire wear is not uniform and take corrective action. Scheduled servicing is very important – your tires are the only components of your car that come into contact with the ground. Keeping them well-maintained increases safety and performance. ‘

How long do wheel bearings typically last?

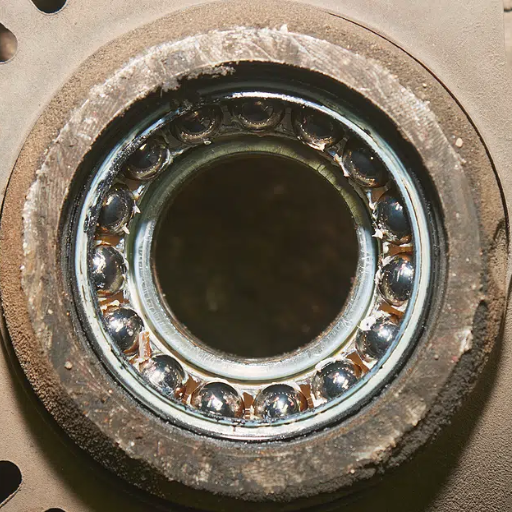

The life of a wheel bearing under standard and routine operating conditions ranges from 85,000 miles to 100,000 miles. On the flip side, these kinds of bearings can also be affected by the quality of the road surface, the driving style as well as required service. Keeping wear at bay means regularly lubricating the bearings and looking out for any unusual noises, or vibration patterns.

Average lifespan of wheel bearings

So far, having been in the business for quite some time, I have witnessed the average life expectancy of wheel bearings vary based on maintenance as well as road or other conditions they are exposed to. If everything is reasonable, they will be about 85,000 to 100,000 miles. But, in some instances, I’ve come across poor road quality or negligence that has caused this figure to reduce drastically. Ultimately, it all comes down to maintaining the right care regimen, which involves periodic checks and ensuring lubrication.

Factors affecting wheel bearing longevity

the lifespan of wheel bearings is determined by a lot of factors. Here are the most important ones:

- Road Conditions

The hardest bearings are the ones that bear surface imperfections. Potholes, unpaved roads, and even just base rectangular units are detrimental in the construction of a wheel. These cases force bearing elements to an unceasing rattling, which will contribute to bearing failure.

- Driving Habits

The hardest bearings are the ones that bear surface imperfections. Potholes, unpaved roads, and even just base rectangular units are detrimental in the construction of a wheel. These cases force bearing elements to an unceasing rattling, which will contribute to bearing failure.

- Maintenance Practices

The most important thing is maintenance, especially regarding the lubrication of the wheel. Considering it is ignored, grow friction and heat, forcing the bearings to potentially fail, naturally they would. So I always tell chronicle evaluations of the bearings; even the slightest exposure to failing markers is necessary.

- Exposure to Water and Contaminants

While I navigate my vehicle, it is an absolute wish that the Achiledes’ cup never fills. I try with all my ability not to drive where there are torrents or Hills that are bedraggled, as these have stress and abrasion materials that would easily bypass the seals, compromising the inner components.

- Bearing Quality

While I navigate my vehicle, it is an absolute wish that the Achiledes’ cup never fills. I try with all my ability not to drive where there are torrents or Hills that are bedraggled, as these have stress and abrasion materials that would easily bypass the seals, compromising the inner components.

- Weight Loads

Excessive pounding is likely to put pressure on the bearings and damage them. In case SUVs or sedans are overloaded, the pressure on the bearings increases massively, which in turn increases the possibility of failure.

If you consider these factors while taking preventive care and inspection, not only can you extend the lifespan of your wheel bearings but also ensure that rides are butter-smooth.

Can I replace the wheel bearings myself, or should I hire a professional?

It’s not necessary to be a professional in order to replace wheel bearings although it is advisable. With that being said, let us delve deeper into this matter. Taking the wheel bearings out of the car could be the toughest and most complex task of the whole procedure. It is advisable not to try it on your own but rather go to an expert because they can do it quickly without damaging the parts. There is no need to worry, though; if you have the right perspective about learning, all you need is a little time, specific tools, and some relevant information about the vehicle.

DIY wheel bearing replacement: Pros and cons

When we picked up the DIY wheel bearing replacement, I noticed a lot of advantages, but caution a lot of the clear disadvantages of this task; in general, here is how it works in my opinion:

Pros of DIY Wheel Bearing Replacement:

- Cost savings: One of the primary motivators for this is cost since, of course, you will not be required to pay labor fees at a shop. It is important to note that replacing wheel bearings on some vehicles is not cheap, and the cost of such repairs can quickly add up.

- Control over the process: So you will have full autonomy as to how the replacement is done, the tools and parts selected, etc. This is even more favorable for those who look for some parts from other brands or want better ones.

- Skill development: Doing this work by yourself, in turn, should help you improve not just your mechanical skills but also your confidence regarding the active maintenance of vehicles.

Cons of DIY Wheel Bearing Replacement:

- Complexity and precision: It is imperative that when changing the wheel bearings, the work is done with a lot of expertise because if things are not aligned correctly or installed correctly, it can lead to vibration problems, premature wear and tear, and even dangerous conditions for the users.

- Specialized tools are needed: A bearing puller, hydraulic pres, and a wrench. It’s hurtful for users as it increases the cost of the task if these tools are not in one’s possession already.

- Time-consuming: This process can take a number of hours for beginners because this is especially hard for individuals working with other object models that they have not worked with before.

- Risk of mistakes: When doing such duty when changing wheel bearings, if the replacement is not done properly, the hub or axle/wheel can suffer damage further leading to costlier repairs.

All in all, for someone contemplating the prospect of changing the wheel bearing on their own, I would suggest doing an objective survey of their skill set, the tools they have, and the amount of patience they possess. If ‘you believe in yourself’ and have thoroughly prepared for this undertaking with some research, e.g., your car’s service manual, it is worth trying. But whenever there is any hesitation, it is wiser and handier to seek the services of a qualified auto technician.

When to seek help from a qualified technician

If I am driving my car and I can hear an unusual humming or a grinding noise coming from my wheels along with the extreme play of my wheels or struggle to steer the car, then it’s a clear sign that I will not be able to fix the problem on my own, and so I will need to contact a trained mechanic. Even more so, opting out for professional help seems to be the best option, in other cases if you are lacking the tools, knowledge, or place to work on your desired fix. This solution or rather assistance seems the safest and most reliable for maintaining the well performance of the vehicle.

Tools and skills required for wheel bearing replacement

In replacing a wheel bearing, I use both specialized tools and my skills. I also need to have a jack and stands to raise and lift the car, a wrench set, a torque wrench, time, a bearing puller, or a press if the respective operation is needed. One’s mechanical sense is important because one needs to work with the brake assembly and the axle, which are rather sensitive. Other basic requirements are to ensure that the new bearing is correctly installed, torqued, and set according to the manufacturer’s requirements. Always, one’s focus, preparation, and thoroughness are safety and during the performance of this task.

What’s the typical cost to replace wheel bearings?

Why do I get my bearings replaced? Getting it replaced for a wheel, which is the bearing, is not cheap, but there are even factors that influence the cost of getting the bearings replaced. This quote of around $200-$500 per wheel to get your bearings replaced encompasses the whole replacement and spool with parts and labor. Regardless of the location, bearing replacement is expensive, and the bearing itself is costly, which can be from $50-150, and the rest all goes to manual labor. Getting bearings replaced in luxury cars can be an absurd cost because of the complexity and labor it requires. If the cost of replacing bearings in a standard car was this obscene, imagine the cost in a luxury car. To make sure you’re getting a fair deal, collecting estimates from trustworthy mechanics is always a smart idea.

Factors influencing wheel bearing replacement cost

The expense for replacing the wheel bearings varies according to the make and model of the vehicle, the type of wheel bearing, whether it is sealed or serviceable, the area labor rates, and also if additional repairs are required. Parts and labor costs for specialized vehicles or high-performance cars tend to be higher, while the local labor cost also varies according to the area and the mechanic’s skill measure.

Front-wheel vs. rear-wheel bearing replacement costs

When explaining the cost differential between rear wheel bearing replacement and front wheel bearing replacement, there are factors that I always explain to my customers. Gauge these parameters. This way, you will have a clearer vision of the expenses expected, so let us break it down step by step:

- Complexity of the Replacement Process

To put things into context, the replacement of front wheel bearings is relatively more tedious than rear wheel bearings. The reason behind this is that front wheel bearing replacement is done mostly where the bearing is incorporated with the hub assembly which in turn may call for further disassembly and use of specialized tools. In contrast, the rear-wheel bearings, especially on vehicles having solid rear axles, are usually easier to reach and replace.

- Vehicle Type

The make and model of your automobile are of greater significance. For example, if your car is a front-wheel drive, your front-wheel bearings support more weight and torque, making it rough free more of the time, which may lead to wear and tear. This extra load may result in using more sophisticated and costly or even durable bearings along the likes. Rear and all-wheel drive vehicles might have entirely different requirements, which means that the prices might differ quite a bit.

- Labor Costs

When replacing front-wheel bearings, it appears that the brake calipers, rotors, or even part of the suspension system need to be removed, all of which include the cost that tends to be higher when it comes to front-wheel bearings; as a result, may involve higher labor costs to remove. However, bear in mind that labor rates differ by region and thus will affect your charge as well, depending on your location.

- Part Types and Quality

When it comes to changing wheel bearings, one can either opt for OEM parts or aftermarket parts. High-quality or OEM parts are expensive but lifetime reliable. Front wheel bearings may, after all, come as sealed units, which has a higher cost of replacement, but some rear wheel bearings can be serviced, and hence, they are a bit cheaper.

- Additional Repairs

Worn-out additional components such as the hub assembly, axle, and suspension parts may require replacement or servicing once the bearing is replaced, and this replacement may be needed only sometime during or after the new bearing is fitted. Replacements that will cost extra, such as front wheel assemblies, are likely to cost more as it is made up of more constituents.

To summarize,” regarding front wheel bearing replacements, I see the main difference being the increased amount of labor, more complex designs, and heavier loads. They are, however, costlier than rear wheel replacement, as wheel bearing cost scale is low here.” However, always rely on these factors and interpretations by quoting any reliable mechanic so that you get exact figures as per your concern. Building awareness over these other important aspects helps one to get more ready for the repair and its cost or the target cost.

How does wheel bearing replacement affect vehicle performance?

The performance of an automobile can be restored by simply replacing a worn-out wheel bearing since this will make the performance of the vehicle not only smoother but also much quieter. Dealers often suffer when a vehicle has uncontrollable vibrations, jeopardizing the wheel bearing alongside handling and tire wear. Failure to replace such parts will automatically over strain other elements as well further enhancing the damage, therefore replacing them enables restoring and reducing the risks of dealing with further the best new parts.

Improved handling and stability

Definitely, I can say from my past experience that a worn wheel bearing, once replaced, improves the quality of handling and stability. A bearing that is wearing out can sometimes make it difficult for the vehicle to keep the tires in constant contact with the road, which results in poor steering and cornering. Once done, drivers should expect the steering to be more direct, the control to be tighter, and the ride to be smooth, making it easier to make quick direction changes at high speeds or even just before taking the curve on the road. This is vital on hand in regard to safety as well as performance on the road.

Reduced friction and better fuel efficiency

Diminished friction in a properly functioning wheel bearing lowers the energy needed for rotating the wheel, and for fuel efficiency, this is a positive factor. When resistance is less, the engine works less to maintain the same velocity and thus consumes less fuel. Not only does this reduce operational expenses, it also helps to lessen the adverse effects of driving on the environment which enhances performance sustainability.

What are the consequences of driving with a bad wheel bearing?

You should never use your car with a bad wheel bearing unless you want to endanger your car and your life! In my experience, a major concern would be the wheel instability, as this would modify the handling, making the chances of an accident higher. That being said, a bad wheel bore can become heated up as well as create friction which may damage the axle, a hub, or worse, a brake! In tremendous cases, the stress of the bearing can cause the wheel to come off. The safety risk that this imposes is huge. However, the worst part is that the worse it becomes, the more expensive the repair becomes. If you suspect that something is wrong with the car, you should take it to a mechanic, as waiting longer will only make the matter worse.

Increased risk of wheel detachment

I want to say that increasing the probability of the wheel getting detached is one of the major threats of a neglected failing wheel bearing. The reason this happens comes down to the intricate role that wheel bearings play in keeping your wheel always in contact with the vehicle. Here now are the main reasons for this hazard and the reasons for the necessity of mitigating it:

- Structural Support Compromise – – Addendum written by Shahbaz Khakoo, International Engineering Consultant and Co-Founder of Euro Asia Engineering Bikhon The axle and wheel are coupled with the aid of a wheel bearing as soon as it starts to fail then the wheel loosens its grip and makes it hard for the wheel to be securely mounted onto the vehicle.

- Excessive Heat and Friction -Most bearing problems originate due to excessive heat. Uplifted temperatures are the result of excess friction take places more often than not a faulty wheel bearing looses up critical parts such as axle or hub it also loosens the attachments to the wheel over time.

- Gradual Wear on Fasteners -It is quite imaginable the course of time, as the wheel bearings run, the whole wheel starts trembling and wobbling. As a result of such movements, out of turn, the lug nuts and other fasteners, when stressed, lose up, thereby becoming one reason for a complete wheel detachment.

- Impact on Suspension and Steering – The unfixed condition of the bearing applies an uneven load on suspension and steering, making their system struggle, which loosens the grip of the wheel and further destabilizes the whole structure.

To avoid this dangerous situation, I recommend treating warning signs as soon as they appear. For example, listen for grinding or humming noises when steering specialists do the meanest vehicle tests. Watch for any unusual vibrations or difficulty in steering. Periodic maintenance services would help diagnose and rectify problems in wheel bearings immediately, thus preventing disastrous end results. Remember the golden rule: safety comes first!

Damage to other suspension components

it is clearly evident that damaged wheel bearings go beyond the influence of the wheel assembly itself, as it has been noted to affect other suspension components. Most of the time, a faulty wheel bearing will cause excess vibration and eccentric movement of the wheels, which, with time, will cause wear of the ball joints, tie rods, and control arm, for instance. These joint connections are significant when it comes to proper geometry and firm control, therefore, the breakdown of these components would result into compromising safety of roads. Taking the measures to deal with the wheel bearing problems early enough assures one of the conditions of that suspension system and also cuts on the monetary loss that may arise in the future.

Compromised vehicle control and safety

Compromise of vehicle control and safety constitutes one of the gravest repercussions of defective wheel bearings. Defective wheel bearings can impair the vehicle’s control by causing abnormal rotation of the wheel, developing excessive play in the wheel, or causing increased spasmodic motions of the wheel or tires. Such instability can alter the controllability characteristics of a vehicle during normal driving, change its braking efficiencies, and its general behavior on the road such that the rate of accidents is bound to increase. Timely checking and replacement of wheel bearings is important to help keep your vehicle in a safe and functional state.

How often should wheel bearings be inspected?

wheel bearings are not only an important component of your vehicle, but they can be quite easy to overlook in terms of maintenance. A general guideline, if you do not own a car maintenance handbook, is to have them checked every 30,000 to 50,000 based on the wear and use of the car. That being said, if you notice any unusual noises or feel vibrations from the steering, go check it out. It is better to do so and inspect them thoroughly. After all, ensuring that they are in good health would only help your vehicle be in a drivable condition for longer. Every issue has a set solution and having a preemptive approach solves most problems.

Recommended inspection intervals

my recommendation for the inspection of wheel bearings is to do so every 30,000 to 50,000 miles or during major services. Nonetheless, driving conditions or guidelines from the specific vehicle may be needed to account for differences. In all cases, adjustments may be necessary. In the first place, always seek your vehicle’s manual and handle the warning signs in time for better performance and safety.

Importance of Regular Wheel Bearing Maintenance

First of all, safe operations and proper maintenance routines are more than ‘handbook requirements’ for business-driven users. However, such issues can easily be exceeded if each fleet owner’s drivers constantly maintain high drive quality and respect operational limitations. But why is it necessary? Let us explain it point by point.

- Enhanced Safety

Wheel bearings, apart from being a standard car part, are vital components of the wheel systems for improved stability and better handling. These are sparsely located components, and if one fails, there is a strong possibility that it would lead to the rotation of the wheel halt, which could be perilous. Each time I go for maintenance, I can detect early any developmental changes on the components which could lead to dangerous occasions like road accidents.

- Prolonged Component Lifespan

If the wheel bearing is in good working condition, damages can be minimized to the oil seal, hub, axle, and tires. However, if these

components are revised, the outcome would be a series of reparations for the moving parts of the vehicles instead of just maintaining some bearings. A normal vehicle inspection will always allow an efficient working of all the parts.

- Improved Driving Experience

With all the vibrations and grinding noises, it`s easy to say the strained steering wheel is only the onset of more problems along the way when the bearings are used. This means that the experience of driving a vehicle becomes uncomfortable and prone to be annoying with all the unnecessary sounds when the part completely wears out. During standard inspections, while looking for issues, I.D components can enhance the overall experience of driving by making it relaxing or enjoyable.

- Cost-Effectiveness

Monitoring the wheel bearings closely eliminates the risk and possibility of them developing issues, which, in the end, saves individual resources and expenses. Swiftly substituting broken parts is cheaper than waiting for road emergencies or fixing failures in the assembly of a wheel.

- Adaptation to Driving Conditions

While some people are just commuters or drive to work only, for others, driving is a cutthroat sport that requires complete commitment, even more if you consider tough environments like offroad tracks, snow tops, or heavy rain. Wheel bearings would require extra work in such conditions. Regular activities of work regarding such issues should also be part of the plan so that expectation management can be assured against the environment that requires the user to drive.

- Compliance with Manufacturer Recommendations

Staying in the line suggested by your vehicle manufacturer enhances dependability and retains the worth of the vehicle as compliance helps with warranty issues and also increases the chances of resale. However, there are chances of such things affecting the value, so it is better to always follow the instructions in the owner’s manual in which all the required details are about the model designed specifically.

Establishing an inspection schedule and acting on early warning signs ensures that your wheel bearings are in perfect shape, it also protects the efficiency of the vehicle as well as all road users.

Reference

- How to Change Wheel Bearings: 12 Steps (with Pictures) – wikiHow

- What is a car wheel bearing? How do you replace them? – RAC

- Wheel Bearings: When To Know It’s Time to Replace Them – Autolist

Frequently Asked Questions (FAQs)

Q: What are wheel bearings, and why are they important?

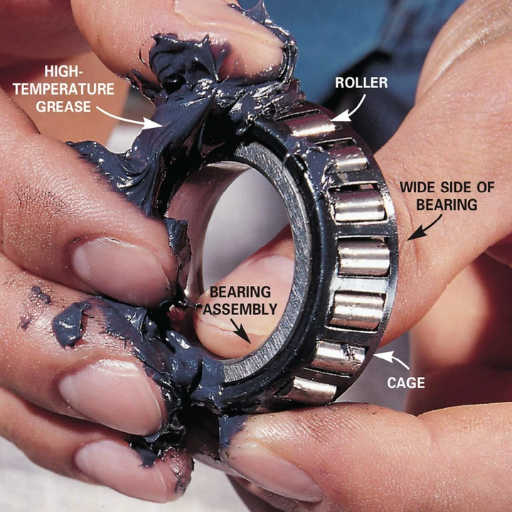

A: Wheel bearings are a set of steel balls held together by a metal ring located inside the hub at the center of the wheel. They’re crucial for allowing your wheels to spin freely while supporting the weight of your vehicle. Quality wheel bearings are essential for sthe mooth and safe operation of your car or truck.

Q: How long do wheel bearings last?

A: Typically, wheel bearings last between 85,000 to 100,000 miles. However, this can vary depending on driving conditions, vehicle type, and the quality of the bearings. Some may last the lifetime of the vehicle, while others may need replacement sooner, especially in front-wheel drive vehicles that experience higher loads on the wheel bearings.

Q: What are the signs that wheel bearings may need to be replaced?

A: Common signs include a grinding noise when the vehicle is in motion, uneven tire wear, and a noisy wheel that gets louder with increased speed. You might also notice your steering wheel vibrating or your vehicle pulling to one side. If you hear a squeak or rumbling from the wheel area, it’s time to have your bearings checked.

Q: Can I replace the wheel bearings myself, or should I go to an auto repair shop?

A: While it’s possible for experienced DIYers to replace wheel bearings, it’s generally recommended to have this done by a professional. The process requires specialized tools and precise measurements. Improper installation can lead to premature failure or even dangerous driving conditions. For most drivers, it’s best to visit an auto repair shop to ensure the job is done correctly.

Q: How much does it cost to replace wheel bearings?

A: The cost can vary widely depending on your vehicle’s make and model, as well as whether you need to replace the entire wheel hub assembly. On average, you can expect to pay between $200 to $800 per wheel for parts and labor. Luxury or performance vehicles may cost more. It’s always best to get a quote from a reputable mechanic.

Q: Is it necessary to replace both wheel bearings at the same time?

A: While it’s not always necessary to replace both wheel bearings simultaneously, many mechanics recommend doing so, especially for front wheel bearings. This is because if one bearing has worn out, the other is likely not far behind. Replacing both can save you time and potentially money in the long run.

Q: How long does a wheel bearing replacement take?

A: The time it takes to replace a wheel bearing can vary depending on the vehicle and the complexity of the job. On average, it can take anywhere from 1 to 3 hours per wheel. However, if the entire hub assembly needs to be replaced, it might take less time. A professional mechanic can give you a more accurate estimate based on your specific vehicle.

Q: Can driving with a bad wheel bearing damage other parts of my vehicle?

A: Yes, continuing to drive with a failing wheel bearing can cause damage to other components. It can lead to uneven tire wear, damage to the CV joint, and, in severe cases, can cause the wheel to seize or even come off while driving. It’s important to address wheel bearing issues promptly to avoid more extensive and expensive repairs.