Modern machinery is incomplete without bearings since they allow smooth movement to take place while ensuring minimal friction; however, even with its importance, it is often overlooked. For instance, industrial machines or even car wheels would not function without bearings. Starting from ancient times and up until now, the world has seen immense evolution and advancement in bearings. In this blog, we will explore the history of bearings and how Leonardo da Vinci’s innovative designs have drastically changed the current technological sphere. Furthermore, we will dive deep into the realms of how these intricate devices have led to the transportation and mechanical industries’ advancement so much so within centuries.

Who is credited with inventing the first bearing?

Historical accounts suggest that one of the most influential Renaissance figures, Leonardo da Vinci, was the first to design a bearing sometime around the late 1400s. This charismatic inventor was known to have designed a device, which would reduce friction and would serve to hold a rotating element within another device. Indeed, Leonardo set the stage for future endorsements. Philip Vaughan’s 1794 patent, which is widely regarded as the first functional ball bearing, was designed by the Welsh inventor Philip Vaughan and shaped modern engineering practices.

Ancient Egyptian contributions to bearing technology

It is remarkable to note that Ancient Egyptians significantly contributed to the early stages of bearing technology development. They also appear to have effectively utilized lubrication and rolling mechanisms, with particular regard being given to the movement of large stones required for monumental structures utilizing large cylindrical rollers. This primitive idea contains the seeds of the concepts of friction reduction and load transfer, which are core to modern bearing technologies. Their creativity provided a vital basis for construction and transportation methods that we still seek to improve.

Leonardo da Vinci’s revolutionary bearing designs

Leonardo da Vinci is regarded as an incredible thinker, having created rotary support bearing which had a noteworthy design. His invention was built to have the purpose of adapting the force of friction in rotating objects; its configuration is in parallel with modern designs. His sketches, which featured ball bearings and cages to keep them in place for spacing purposes, were an advanced engineering idea for that particular period. The work this created allowed for the streamlined development of effective machinery, which had numerous applications in the industries of the modern day.

Galileo’s impact on bearing development

I find it evident that Galileo has served as the starting point for the development of bearings. He designed new types of mechanisms that served as a key principle in engineering development, specifically, a means to reduce friction in the rotation of systems. He was indeed a visionary since he not only imagined but also sketched mechanisms such as ball bearings with cages. Such drafts had an impact on the machinery and technologies of his time and also directed the development of the current bearings used today in the automotive, aerospace,e and other industries.

How did bearings evolve during the Industrial Revolution?

The epoch of the Industrial Revolution was a significant point in the advancement of bearings. If you like, I can elucidate it step by step. During this period, the emergence of the textile, transport, and manufacturing industries raised the need for machines that would work more efficiently and carry heavier loads. This was the time when the use of bearings became crucial.

- Material Advancements: The use of steel on the hardware found in industrial machines and equipment is one of the major advances made in the bearing development process. It replaced the earlier used wooden or bronze bearings, which could only function up to a certain load and velocity.

- Improved Lubrication: The invention of specialized lubricants made it possible to significantly eliminate friction and wear, which made the life span of bearings longer and even allowed machines to operate for longer periods without repetitive service, which was of utmost importance for industrialization.

- Design Standardization: The standardization process extended to engineers who started designing components in fixed sizes and shapes. This standardization not only simplified manufacturers in producing the same parts but also allowed the bearings to be mass-manufactured at low costs, making them available for widespread use.

- Surface Finish Enhancements: Parameters such as precision machining and surface finishing techniques, among other factors, emerged as yet another important enhancement to bearings. These made the components of the bearings smooth, reducing the frictional effect and enabling the bearings to perform better at higher speeds.

- Integration with New Systems: The other application was in novel mechanical systems such as steam engines, spinning frames, and locomotives. Their success in those systems relied on their ability to enable rotating parts to move more smoothly and efficiently.

The Industrial Revolution brought about new advancements concerning machine parts such as bearings. Throughout history, bearings have been evolving, and an important moment in the history of bearings was the Industrial Revolution. These improvements in bearings supplied Revolutionary change in machines, Due to such such advancements, Several parameters governing machines like their efficiency, durability, and their scale significantly improved and enabled machines and engines to work with a higher level of reliability. Enormous enhancements were made to bearings that gave birth to the machines that defined the Second Industrial Revolution. It is amazing to see how factors of that time helped in developing modern bearing technologies.

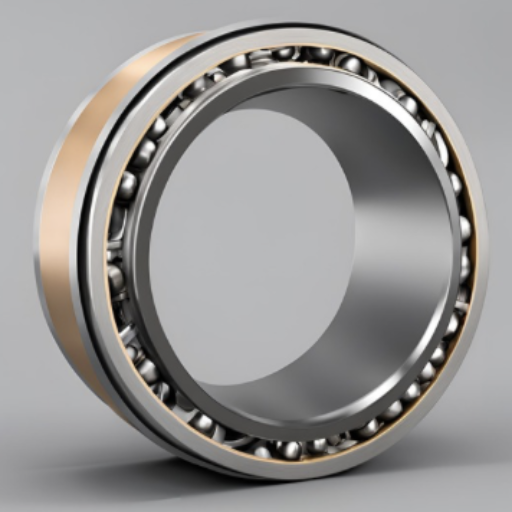

The importance of bearings in machinery advancements

it is impossible to downplay the importance of bearings in the progress of machines. Almost all bearings serve the purpose of reducing friction, and these are used in innumerable applications to increase efficiency and allow for motion. Their ability to bear considerable pressures while reducing wear and losses of energy has been very important in the development of machines for industries. In subsequent years, improvements to bearings’ geometry, materials used in their production and lubrication techniques have assisted machines to work successfully in more vigorous environments. I must say that because of these changes, a great number of modern engineering achievements would be unthinkable. Bearings are, without a doubt, the quiet catalysts of engineering developments.

Philip Vaughan’s 1794 patent for ball bearings

The ball bearing was invented by Philip Vaughan in 1794, and it was a remarkable invention that greatly enhanced the field of mechanical engineering. A good way to think of this device is to first look at what its purpose is. The main aim of these devices is to eliminate the friction between the moving parts, and according to Vaughan’s invention, it is the first time when a ball in a housing has grooves to run in. That gave a great improvement over the older method of moving parts, as it enabled to work with smooth motion rather than sliding surfaces which quickly went out of working to be efficient.

From a technical standpoint, a few parameters indicate the importance of Vaughan’s invention:

- Friction Reduction -With Vaughan’s innovation of ball bearings, there was the enablement of rolling motion instead of sliding, which greatly reduced the friction experienced by the components; this helped the machinery run more efficiently, with the risk of overheating or excessive wear almost negligible.

- Load Distribution – Thanks to the spherical structure of the balls, the loads I have been evenly distributed across the contact surfaces enabling greater durability and performance of the machinery.

- Longevity -The developed groove design greatly enhanced the lifespan of the components as placing the balls properly inhibited excessive wear on them or the housing.

- Versatility – The design developed by Vaughan could be fitted on numerous machines, these range from simple carts and wagons to advanced industrial systems, this resulted in the design spread rapidly.

The inventors of this patent pioneered contemporary bearing technology along with the advancement needed to construct modern high-speed and highly accurate equipment. it’s crazy to think how the invention from the 1700s has managed to still aid in engineering advancements even after 200 years.

The rise of bearing manufacturers during this era

This period witnessed bearers manufacturers surging, which was a critical point for the industrial evolution. Drawing from my extensive business analysis of the industry, I believe that this was the period during which the manufacturers diversified their production capabilities and perfected their production processes. Companies began to focus on the production of complex and highly specialized engineered bearings in response to the growing demands from the railways, machinery sectors, and the nascent automotive industry. This specialization didn’t just enhance competition but also led to huge strides in engineering and manufacturing, augmenting material sciences and manufacturing techniques. It is at this time that bearings developed from simplistic components to largely required features in engineering as we know it.

What are the key milestones in the history of bearings?

Key Milestones in the History of Bearings

- Ancient Origins – The history of the reduction of movement resistance can be traced back to the ancient world, where wooden rollers and lubricated grooves were utilized in the transportation of heavy stones in Egypt.

- 16th Century Innovation -One of the first concepts of modern bearing was drawn by Leonardo da Vinci for the purpose of reducing the wear of a part mechanism and improving its efficiency.

- Industrial Revolution – The introduction of modern machinery in the eighteen and nineteen hundreds accelerated the production of metal bearings, which became indispensable components for the machines of that time.

- Early 20th Century Advancements – The mass production of ball and roller bearings, which improved the performance of cars and aircraft, brought about tremendous growth in this industry.

- Post-War Material Science Breakthroughs – The new materials, such as chromium steel and ceramics developed after World War II, have greatly improved durability, accuracy, and load-bearing capacity.

- Computer-Aided Designs (CAD) and Modern Manufacturing – The synergy between CAD and industrial development in the 1980s marked a central tangent in bearing production, whereby speed and accuracy were greatly improved.

- Sustainability and Smart Bearings – Newer smart bearings focus on connectivity and energy efficiency by utilizing sensors that allow for predictive maintenance and real-time monitoring.

A right-meld of technological evolution and demands of society is depicted by every milestone.

The discovery of the Lake Nemi wooden ball bearing (40 BC)

The wedge-shaped wooden bearing from Lake Nemi, dated back to 40 BC, heralds the history of engineering. The softly tapered wooden bearings discovered in Caligula’s ceremonial ships underscore early attempts to reduce rotational friction on machinery. Their development highlights the innovative creativity of Roman engineering, where the principles of mechanical devices were understood and which would eventually lead to modern bearing devices.

17th-century innovations in bearing design

The 17th century bore witness to meaningful improvement in the design of bearings, which enabled machinery to be more efficient. Starting materials like brass, along with much more advanced manufacturing, were important innovations. Important figures like Galileo aided in the understanding of the principles of friction, which allowed the production of bearings that utilized rolling elements, which enhanced the functionality and durability of clocks and equipment made during the early industrial age. Such innovation set the groundwork for further improvement with clean technologies made during the Industrial Age.

The first modern ball-bearing design and its impact

Marking an important development in engineering, the modern ball-bearing was first patented in 1794 by Philip Vaughan. Speaking as a practitioner, I have witnessed in what way this invention created foundations for nearly all modern rotating equipment. Vaughan’s design introduced a grooved axle into which the balls were to be fitted, which in turn provided a more efficient means of reduction of friction. It not only made appliances used in factories more efficient but also made transport and manufacturing processes work more smoothly. Its impact is still evident today, as modern bearings can be said to originate from this important invention.

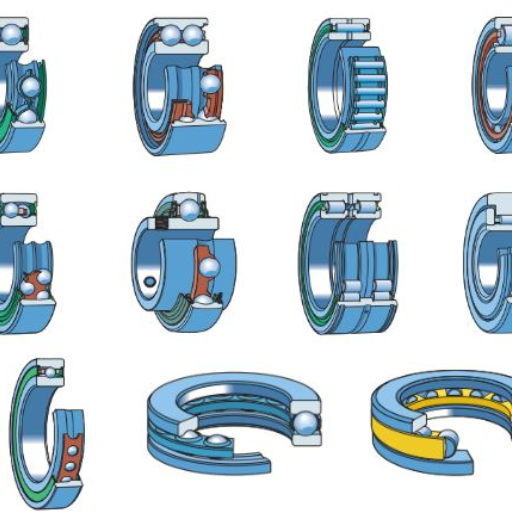

How have different types of bearings emerged over time?

The basic need for bearing has evolved over the years due to its more advanced applications and performance requirements in businesses. The first rolling element, which was a plain bearing, developed into a rolling element, such as the ball and roller bearing, to facilitate higher efficiency and load capacity. The emergence of advanced materials, technologies, and designs gave way to thrust bearings, magnetic bearings, and fluid-film bearings that meet demands, which include but are not limited to high speed, low friction, and high loads. This evolution is a consequence of the increasingly intricate and complex nature of industrial and technological elements and the need to function accurately in various systems’ machinery.

The evolution from plain bearings to rolling element bearings

The development from simple bearings to rolling element bearings is quite a cut above the rest in the field of mechanical engineering. The simple bearings, though rudimentary, were tough but used to require lubrication, which meant higher friction. However, rolling element bearings are an entirely different story because of their new construction, which uses balls or rollers, friction has been cut down considerably, the effectiveness has improved, and greater loads can be borne at much higher speeds. This change made various industries more efficient and technologically advanced due to the introduction of more reliable and diverse applications.

The development of roller bearings and tapered roller bearings

the adoption of roller and then tapered roller bearings is presumed to have revolutionized the design of mechanical components, tools, and devices. Thanks to their cylindrical rolling elements, roller bearings are more evenly loaded over a bigger surface area, making wear less intense and making the machine more durable. Such innovation was important for cases where high radial loading was needed. Tapered roller bearings increased this development in that they could handle both axial and radial loads at the same time. In their conical shape, they provided excellent stability and accuracy in challenging situations such as automotive axles and heavy-duty industrial machinery. Such advances facilitated and increased possibilities for modern engineering design.

Advancements in bearing materials and technology

I’ve witnessed remarkable growth in materials and technologies over this period. These developments have changed the characteristics of bearings in performance parameters, durability, and application mechanisms in different sectors. To help further, I will break it down step by step:

- Material Improvements

There are new materials created, such as hybrid materials, ceramic composites, and even high-strength alloy steels, that allow for greater bearing resilience and efficiency. Strengthened steel is a prime example of extending bearings’ functional life even in harsh operating environments, as it is incredibly resistant to wear and fatigue. Furthermore, the use of ceramic materials is perfect for high-speed technology as well as aerospace due to their lightweight and high thermal resistance.

- Surface Treatments and Coatings

Currently, bearing surfaces can gain enhanced toughness thanks to the Ai-based services that include but are not limited to carburizing and nitriding. Moreover, other technologies that include molybdenum disulfide and Diamond-Like Carbon (DLC) alleviating friction while withstanding moisture or chemical erosion become ideal, considering they also enhance coating. Lastly, all of these improvements enhance equipment reliability and lessen maintenance needs.

- Precision Manufacturing and Inspection

It’s true that industries are quite demanding of the bearings, and it has become possible to make such components meet those demands thanks to advances in computer-controlled grinding and laser tracking. The reduction in bearing vibration and noise has aided the use in the fields of robotics and electronics. Making sure that everything is up to par quality-wise is no longer an issue, thanks to automated inspection systems that can detect even the smallest imperfections.

- Innovative Sealing Technologies

Mechanisms such as labyrinth and contact seals have been designed to protect the bearings from dust, dirt, and other pollutants; these seals also help retain the lubricant within the bearing to eliminate wear and ensure longer and smoother running time.

- Smart Bearings and IoT Integration

One of the most recent and interesting developments has been the smart bearings with installed sensors. These cover all parameter monitoring for temperature, vibration, and loads, among others. More importantly, being part of the IoT systems, they not only promise to increase efficiency through reducing maintenance but predictive and anticipative maintenance as well.

The surge in the performance of applications in many industries is responsible for such advancements. This makes us more capable of responding to modern-day engineering problems and ensuring efficiency, reliability, and sustainability anywhere in the globe with each innovation. I would willingly entertain the idea if there is anything to discuss further.

What role did bearings play in the world’s first bicycle road race?

Bearings greatly assisted in enhancing the performance and efficiency of bicycles, which in turn greatly contributed to ensuring the successful completion of the very first road bicycle race in the world. Through my lens as an industry insider, I can surely state that in the absence of bearings, due to which the friction was decreased, cyclists would have unfortunately sustained a tremendous amount of resistance, making the race exceedingly challenging. The bicycles made in the early times heavily relied on basic designs, while the introduction of bearings permitted smooth movement and enabled better transfer of power, giving cyclists an edge. Such advancement not only contributed to that historical race but also made modern-day innovations in cycling possible.

The Parisian bicycle mechanic’s contribution to bearing design

Now, while reading the above, let me ask you this: How does a Parisian bicycle mechanic manage to change the design of bearings? By introducing a new system that focuses more on precision and durability, the mechanic has managed to reduce friction significantly. Thus, cycling mechanics have drastically changed with the introduction of this innovative idea of doing things. The bike rides became so much more enjoyable after this.

How Bearings Improved Bicycle Performance

Bearings started making a significant difference in bicycle design owing to the fact that they allowed the wheels, pedals, and other components to rotate with minimal friction. This, in turn, reduced the amount of work the cyclist had to put in, enabling him to go faster while using less energy and the cycle itself becoming more robust. On top of that, the new designs of the bearings improved their reliability as well as energy transfer which completely changed the way bike was ridden.

How have modern-day bearings revolutionized various industries?

Neck and Neck With the Rest of the World, Bearing Technologies Provided By Omega Bearing are Working to Help the Industry Negotiate The Rapid Expansion of Global Competition. Even in the Aerospace sector, the bearing technology, which has been recognized as the backbone of any industry, has been transformative in the way it is used. More research into their internal structure can result in better development and consequently better engagement with their applications. Changes in the mode of operation of bearings have been revolutionary and outpaced the competition considerably in their thermodynamics, stresses, and pressure modes, as well as oscillatory mechanisms. Are bearings truly compatible with modern technologies? It is in the best interests of the aerospace industry to see if it’s possible.

The impact of better bearings on mechanical engineering

These developments have enabled us to make machines with greater characteristics and accuracy. Higher-quality materials and lubrication technology enable bearings to carry more weight and operate in harsher conditions, which lets us explore new horizons. From manufacturing more fuel-efficient motors to designing ultra-precise robots, mechanical engineering has been redefined with modern bearings.

Steel bearings and their role in industrial machinery

Steel bearings have a crucial function in industrial processes as they facilitate rotational or linear movements and decrease friction and wear between the interacting parts. Steel bearings are virtually required in any operation, starting from rough machines and sophisticated devices, due to their long life, large load-bearing capacity, and ability to withstand harsh environmental conditions. Thus, steel bearings enhance operational efficiency and help make industrial systems more robust and longer-lasting.

The importance of choosing the right bearing for specific applications

Choosing the most suitable bearing for a specific task helps in maximizing performance, efficiency, and wear. A description of the task usually includes factors such as load and its application, operating speed, working environment, and the expected endurance of machinery. Any bearing’s misuse, such as wrong application or installation, can increase wear, friction, or even system failure, which results in downtimes and heavy maintenance costs. Industries help in improving reliability and performance through a systematic evaluation of application needs and consultation with bearing engineers.

Reference

- History of ball bearings – This source discusses the historical development of ball, cylindrical, and taper roller bearings.

- History of rolling bearings – This article covers the evolution of rolling bearings from ancient times to modern applications.

- Leonardo da Vinci’s studies of rolling-element, disc, and sector bearings – This paper focuses on Leonardo da Vinci’s contributions to the design and understanding of bearings.

Frequently Asked Questions (FAQs)

Q: How did Leonardo da Vinci contribute to the history of bearings?

A: Leonardo da Vinci made significant contributions to the history of bearings. He is credited with creating detailed sketches of ball bearings in the late 15th century. These drawings showcased a rotating table supported by what appears to be a primitive form of ball bearings. While he didn’t invent the concept, his designs were far ahead of their time and laid the groundwork for future developments in bearing technology.

Q: What role did ancient civilizations play in the invention of the rolling bearing?

A: The invention of the rolling bearing can be traced back to ancient civilizations. For instance, in ancient Egypt, roller bearings were used to move large stone blocks for building pyramids. The Egyptians used roller bearings in the form of tree trunks under sleds to transport heavy loads. This early application of the principle of reducing friction through rolling motion was a crucial step in the evolution of bearings.

Q: How did Galileo contribute to the development of bearings?

A: Galileo Galilei, the famous Italian scientist, made important contributions to bearing technology in the early 17th century. He described the use of brass cages to separate the balls in a bearing assembly. This innovation was crucial as it prevented the balls from rubbing against each other, reducing friction and wear. Galileo’s work on cages significantly improved the efficiency and lifespan of bearings.

Q: Who is credited with the creation of an independent bearing industry?

A: The creation of an independent bearing industry is largely attributed to Philip Vaughan. In 1794, Vaughan patented the first design for a ball bearing with a ball running along a groove in an axle assembly. This patent marked a significant step in the commercialization of bearing technology and laid the foundation for the modern bearing industry.

Q: What was the significance of Henry Timken’s invention in the evolution of bearings?

A: Henry Timken played a crucial role in the evolution of bearings when he patented the tapered roller bearing in 1898. This design was particularly important for handling both radial and thrust loads simultaneously. Timken’s invention found widespread use in wheel bearings for wagons and later automobiles, significantly improving their performance and durability.

Q: How did Sven Wingquist contribute to the development of ball bearings?

A: Sven Wingquist made a significant contribution to bearing technology with his self-aligning design of ball bearings in 1907. This innovation allowed the bearing to adapt to misalignment of the shaft, reducing wear and extending the bearing’s lifespan. Wingquist’s design was particularly useful in applications where precise alignment was difficult to maintain, such as in heavy machinery and vehicles.

Q: What are some modern applications where bearings are used extensively?

A: In modern times, bearings have become ubiquitous in various applications. They are used in automotive engines, wheels, and transmissions; in industrial machinery like conveyor systems and turbines; in aerospace for aircraft engines and control surfaces; in household appliances like washing machines and fans; and in computer hard drives. The versatility of bearings has made them essential components in virtually all rotating machinery.

Q: How have bearing designs evolved to meet modern engineering challenges?

A: Bearing designs have evolved significantly to meet modern engineering challenges. Today, we have various bearing types, such as ball bearings, roller bearings, thrust bearings, and magnetic bearings. Advanced materials like ceramics and exotic alloys are used for high-temperature or corrosive environments. Bearings may also incorporate smart features like sensors for condition monitoring. The design of bearings continues to evolve, focusing on reducing friction, increasing load capacity, and improving durability in extreme conditions.